The mining process starts with the breaking up of the rock face and continues through the processing of the minerals, utilizing such technology as cutting equipment, screening machinery, stockpiling equipment and conveying equipment.

Loyal business is committed to preserving and enhancing your bearing's dependability, make the most of uptime, lower upkeep and replacement expenses along with enhance performance. Our client assistance services are developed so that you can pick the level of proficiency and resources you require to keep your procedures and facilities at peak functional efficiency, throughout the wold, at any time you require us.

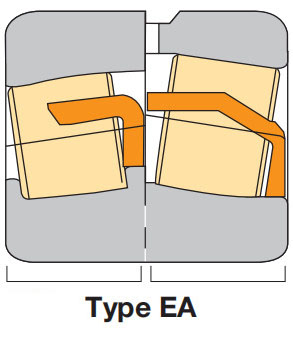

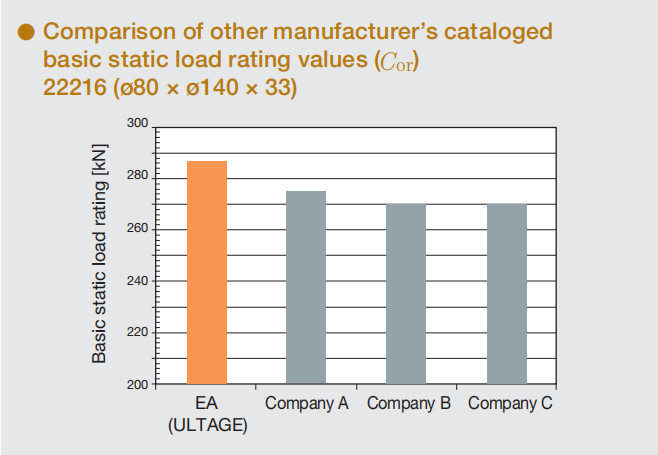

By maximizing the roller diameter, the number of rollers and roller design, longer operating life and higher load ratings have been achieved. With this improvement maintenance cycles can be extended

Higher operating speeds have been achieved by using an optimized design pressed steel cage.

The results of comparative testing of bearing temperature rise under circulating oiling conditions show that this bearing suppresses temperature rise at a lower torque compared to other manufacturers' bearings.

Loyal in mining and mineral processing market

We begin with the very best bearings, bearing engineering know-how and over a century of understanding and knowledge of equipment parts and procedure control in mines. Our group then offers high quality bearings items, services and options to assist mining and mineral processing consumers enhance their power and performance leading to increased accessibility and greater life time equipment expenses.

Loyal Bearing operating in severe ecological conditions

Big open-pit mining operations throughout the world utilize our roller Bearings to increase the efficiency of your devices, enhanced bearing qualities: load, speed, torque and sound with the Loyal round roller bearings item range.When a bearing service is required in the mining or building and construction markets. contact with Loyal

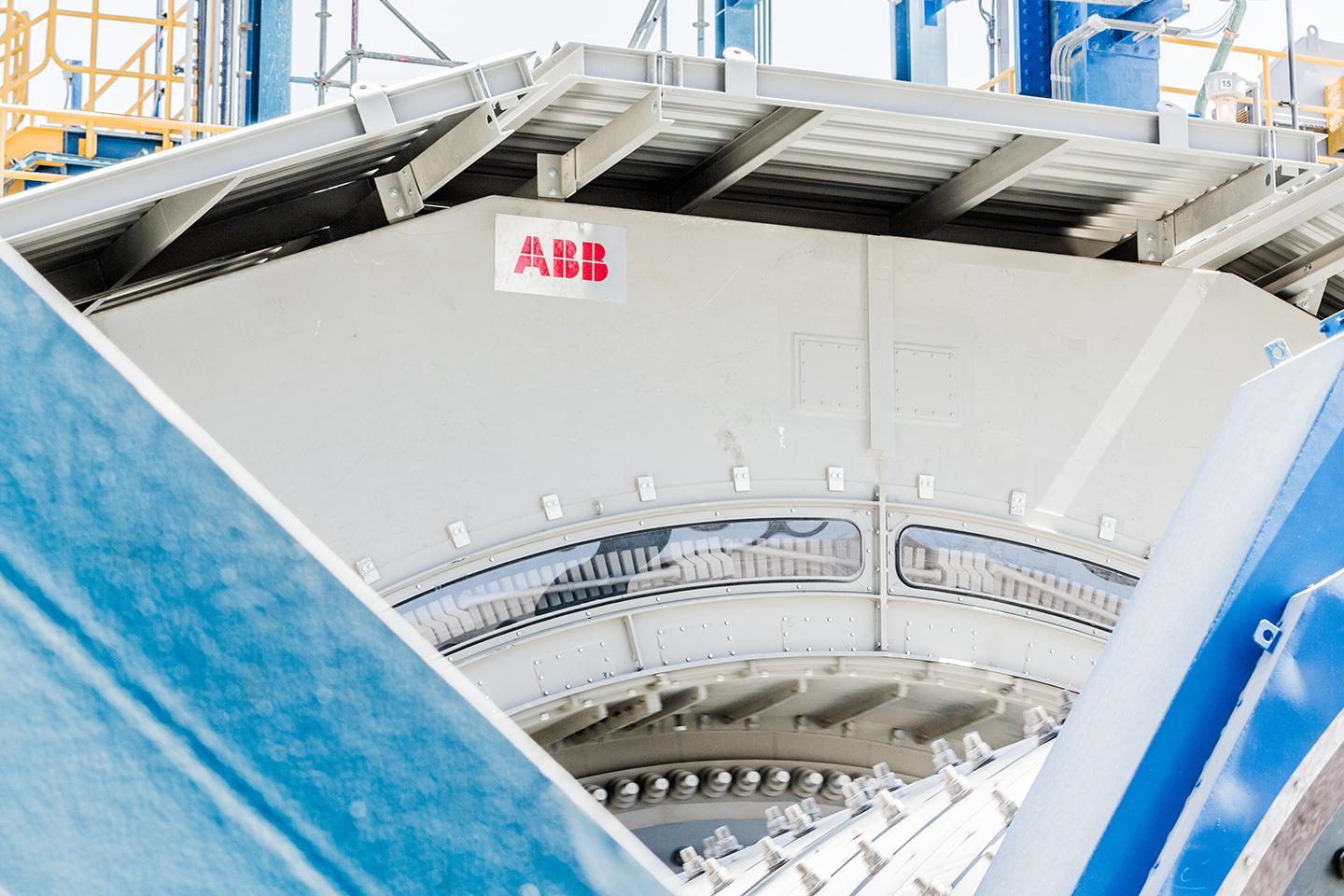

We are a prominent provider of Tapered Roller Bearing for Construction Machinery Travel Reduction Gears for a complete series of mining devices, consisting of; bucket-wheel and bucket-chain excavators, spreaders, stackers, reclaimers, crushers, shovels, draglines, belt conveyor systems, and stockpiles. With more than 1,000 big mining makers running all over the world, our bearings has actually shown to hold up against the severe conditions of open-pit mining, from dirty and filthy environments, to serious vibrations, to temperature levels varying from -40 ° C to +60 ° C. Standard thrust ball bearings and round bearing have actually been mechanically enhanced to make them ideal for the small sector.

Furthermore, our professionals established present a series of brand-new generation, high-load capability round roller bearings with extraordinary attributes in the locations of capability and long life. for all mining devices that permits you to handle load-sharing of multi-drive applications, making sure safe operation in all modes.

Loyal continues with its advancement efforts day-in and day-out in order to preserve its position as the provider of OEM bearings. Our experience in international mining and building applications, competence in bearings and bearing elements, and ingenious innovation permit Loyal to supply clients with constant service and the correct options.

State-of-the-art control and drive systems for large open-pit mining operations?

Absolutely.

Top productivity with complete hoist systems, transportation solutions, mine electrification and automation?

Certainly.

Reliable solutions for material handing and open-pit mining?

Absolutely.

Robust grinding technology for highest availability, reliability and maximum productivity?

Definitely.

Optimized technology for your processing and refining facilities?

Certainly.

Integrated material handling solutions for efficient transport of your product to market?

Absolutely.

State-of-the-art systems and solutions covering the complete value chain from mine to market?

Absolutely.

A complete service portfolio to cover your needs?

Definitely.

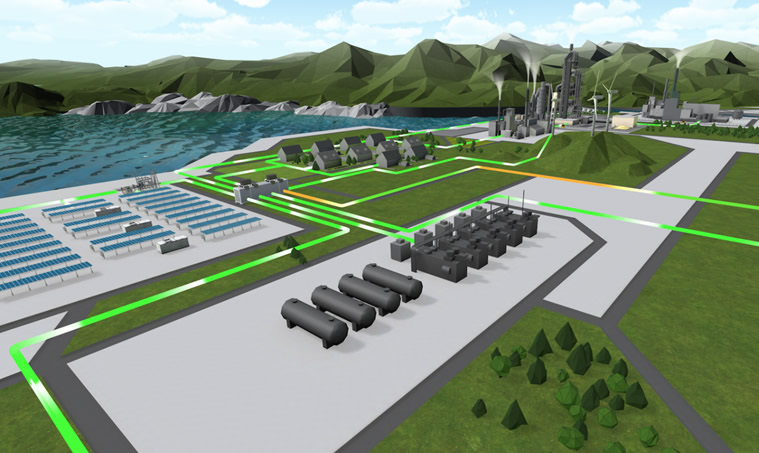

Affordable energy solutions using renewables

The future of mining – Bringing equipment, systems and people together

Loyal Experience & Technologyhave led to greater operational safety and an ever longer operating life of Loyal bearings.

We have the bearings you require for each phase of your mining or quarrying operation: extraction, squashing and grinding, screening and communicating.

Boost performance and success

In a market where uptime is crucial, Loyal'll assist provide you the self-confidence you require in the performance and security of your operation.

enhanced bearing attributes: load, speed, torque and sound with the Loyal round roller bearings item variety.

Loyal Spherical Roller Bearings with brass cages supply additional strength and toughness in the most relentless conditions, consisting of severe shock and vibration, high velocity forces and very little lubrication.

Enhance employee security.

Mining is a hard company and it gets harder every day. Decreasing ore grades put pressure on all elements of your mining operation, whether your establishing a greenfield website or working an existing mine.

Heavy loads. Abrasive dust and dirt. Severe temperature levels and more. These conditions make it tough, even hazardous for mines and cement plants to keep their equipment. Employee injuries and unintended downtime are a continuous danger.

Loyal Bearings developed for extreme environments (dust, wetness, heat).

lubrication services for heavy loads and vibration.

Decrease unexpected downtime.

At the core of every mining operation is an intricate range of mining devices, Loyal has bearings for each of these procedures. Loyal Spherical Roller Bearings with solidified steel cages provide higher tiredness strength, increased wear-resistance and harder defense versus shock and acceleration.With our experience in the mining, building and construction, farming, Loyal tapered roller bearings are readily available in a range of setups for durable truck markets, we have the items efficient in carrying out in the filthy, severe environments of mines and going beyond dependability and life requirements.

Assisting you increase uptime securely and effectively.

Your crusher represent the greatest energy intake of your operation and the conveyor is among the best sources of devices failure onsite. The needs put on crushers are severe. They're anticipated to run non-stop while standing up to extreme vibration, dust and severe temperature levels.

Advanced bearings for various Mining and Processing

The challenging operating and environmental conditions in the Mining and Processing require extremely robust bearings. Our customers build and operate ore conveyor systems, mines, cement plants, oil platforms, crushing machines.

Whether original equipment or spare parts, increase the performance of your bearings for mining and quarrying.

We have the bearings you need for every stage of your mining or quarrying operation: extraction, crushing and grinding, screening and conveying.

Crushing and grinding:

Ranges of High-Capacity Cylindrical Roller bearings EW and EM Series, tapered roller bearings and Industrial Machinery Full-Complement Cylindrical Roller Bearings for Crane Sheaves

primary applications: jaw, impact and gyratory crushers , Drilling rig units, drilling turbines, pipe-laying drums

secondary applications: hammer and cone crushers , Bucket wheel excavators, transport systems

vibrating applications: shaker screens , vertical mills, tube mills, vibrating screens

Conveying:ranges of Sealed Deep Groove Ball Bearings, spherical roller bearings (standard and narrow series), houksed bearing units and plummer block housings