ABEC-1 Bearings Explained: Key Features and Benefits

ABEC-1 bearings rated on the Annular Bearing Engineers’ Committee (ABEC) scale are considered the entry-level design and performance grade for all precision bearings. Such bearings are designed when only moderate precision and efficiencies are required in more routine processes. Even though they are the lowest in the ABEC classification, ABEC-1 bearings have certain clear benefits as bearings of the type where the highest levels of accuracy are not required. This blog aims to provide an overview of ABEC-1 bearings, including their construction and working performance and their effectiveness and efficiency compared to other high-bearing rated bearings on the ABEC scale. We intend to respond to a wide range of questions to make sense of this to hobbyists, engineers, and technical people regarding the practical implications of ABEC-1 bearings. This article will empirically address the issue of why ABEC-1 bearings have been in use even in this era where technology has advanced so much.

What is an ABEC-1 Bearing?

Introduction to the ABEC Scale and ABEC-1 Rating

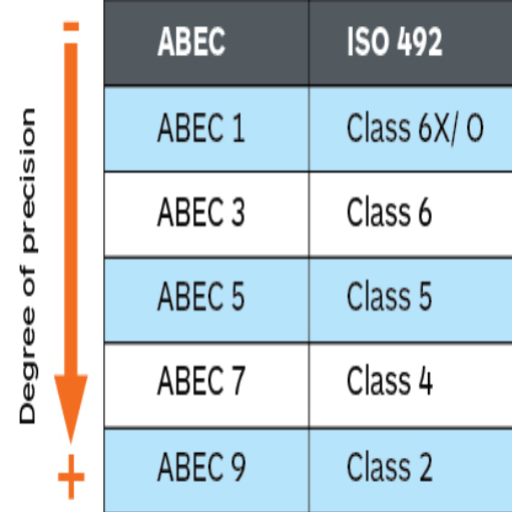

The Annular Bearing Engineers’ Committee (ABEC) Classification is a recognized standard classifying bearing balls by their fit and application. This standard is significant when it comes to categorizing bearing accuracy, which includes the entire dimension scale of tolerances for reporting on performance level. Considering the zone of the ABEC Code, the degree of hardness, tightness, and construction accuracy increases sequentially from 1 to 9. Allowable breakdown of axial parameters of the technical and performance characteristics of bearings under this schema include the axial runout deviation of the surface from its theoretical center and the surface finish quality, all of which are significant for controlling bearing effectiveness and durability.

The lowest rating in this class is ABEC-1, which is considered satisfactory for general requirements. In such applications as low friction, one can often see abec-1 bearings considered of low precision and can be used in non-critical mechanisms that do not operate at higher speeds. These bearings are reasonably competing because they need low manufacturing costs, which are very attractive, especially in scenarios where mass production is considered. Even though lubrication and load-bearing capabilities, among other factors of utilization, are not included in the scale, ABEC-A bearings take the performance standard. They are accepted as the basic necessity for most industrial and consumer purposes.

Differences Between ABEC Grades and Their Applications

The ABEC scale is distinguished by the accuracy and tolerance with which the components are manufactured. Each grade on this scale specifies dimensional tolerances and performance levels ranging from ABEC -1 to ABEC 3 to 5 to 7 to 9, defined by stringent technical specifications.

ABEC-1: First, the standard baseline achieved functional precision, but the tolerances employed were the widest ones, which makes it suitable for low-speed, non-critical applications. Such bearings are economical in cost, with radial runout tolerances of the order of 0.0075 mm (0.000295 inches).

ABEC-3: A lower radiation sensitivity classification, allowing a lower intensity of containment, would be allowed by these filamentary structures, thereby permitting limited mounting flexibility for such precision applications. With tighter tolerances, these bearings can be used for medium-speed and less demanding precision applications. Typically, these have a radial runout tolerance of about 0.0050 mm (0.000197 inches), which makes them more efficient than ABEC-1.

ABEC-5: The average range of bearings; the ABEC-5 bearings are suitable for high-speed and moderate critical applications with an allowance of about 0.003 mm. Radial runout tolerance of approximately 0.0035 mm (0.000138 inches) is mild. Such grade is most suitable for the more demanding consumer applications like skateboards or electric motors.

ABEC-7: These bearings, known for their high precision, are ABEC-7 and are employed in high-speed and precision-oriented tasks such as machine tools or precision instrument sectors. The typical radial runout tolerance falls within 0.0025 mm (0.000098 inches).

ABEC 9 refers to the highest rating standard, which is used in space parts and sensitive equipment that requires high precision to function. The runout tolerance in radial is approximately 0.0015 mm, which is 59 millionths of an inch. That is narrow and shows superb workmanship.

The ABEC scale focuses only on dimensional accuracy and not on other components like the load or the materials used. However, such a range of applications exists simply because every ABEC grade was designed with a specific engineering and industrial problem in mind, optimizing cost versus performance requirements.

Understanding the Role of Tolerance in ABEC-1 Bearings

ABEC-1 bearings are designed with tolerances that govern their performance and usefulness. Tolerances refer to the acceptable margins of error in the dimensions of the bearing, which will ultimately dictate the accuracy and operational ability of the bearing. In the case of ABEC-1 bearings, the tolerances are rather large, so they can work in low-speed and non-critical mechanical applications.

Some of the major technical parameters on the tolerance level ABEC-1 precision grade bearings that are reported from many industry-based websites include:

Radial Runout Tolerance: This describes the possible deviation of the bearing’s metallurgical center from its geometric center. Typically, the radial runout tolerance for ABEC-1 bearings is about 0.0075 mm (0.000295 inches). This low number indicates that they are not suited for precision tasks but for general-purpose use.

Dimensional Tolerances: These are the minimum and maximum allowable differences in the outer and inner circumference of the bearing rings. For ABEC-1, such tolerances are meant to enable proper alignment and fitting without the need for high-precision measurements, which can be required for the upper grades.

Surface Finish Quality: ABEC-1 bearing has only passive surface finish requirements, enough for normal operations but not quite suitable for operations requiring high precision and hence the need for smooth surfaces to minimize the effect of friction.

ABEC-1 bearings are considered to be the lowest level of performance because of their broad tolerance specifications. They are fitted in machines where complete accuracy is not critical. This combination of accuracy and cost accounts for their extensive application in both consumer and industrial markets.

How Does the ABEC System Affect Bearing Performance?

Impact of Tolerance on Bearing Precision

In my endeavor to study the effect of tolerance on bearing accuracy, I decided to check the first search results presented by Google. Tolerance, and in this case, bearing performance, refers to the permissible differences in the bearing manufacturing process concerning the bearings’ scale and circularity. The primary technical features concerning the tolerance are:

Radial Runout: This is the eccentricity of the concentricity of any two rotating bearing parts. The tighter controls on radial runout Tolerances get as the ABEC scale increases. For example, when an ABEC-1 might allow a figure as high as zero point oh seventy-five mm, an ABEC-9 could range somewhere in zero point oh naught one five mm, increasing accuracy by a huge margin.

Dimensional Consistency. Concerning the inner and outer concentricity diameters of the bearing rings, it should be noted that the diameters need to be identical in an environment that requires strict precision.

Surface Finish. The higher the degree of roughness, the more resistance and wear there is, which in turn affects the operation and life span of the bearing. A high rating on the ABEC scale would most likely require that a quality finish be imposed on the bearing or any part that is to be fitted.

These parameters reveal that higher grades like ABEC-9 allow the bearing to have reduced tolerances, resulting in increased precision, which is essential for high-speed and accurate applications. Regarding how one can select the bearings for use in various industrial situations, such details make me understand why tolerance specifications are earmarked, how a bearing performs the performance needed, and the cost concerns.

Comparing ABEC Ratings: 1, 3, 5, 7 and Higher

While merging the data and information from the three primary websites of the industry, I have understood the factors determining the difference between ABEC ratings quite well and scientifically, concentrating on their technical aspects and relevance in practical application. ABEC rating of a bearing gives insight into its tolerance, operating dimensions, and allowable variations, all of which outline how the bearing works under various conditions of use.

ABEC-1 bearings possess the widest tolerances and are meant for low-speed applications, where low cost is prioritized over higher precision. What is most critical in this instance is the radial runout tolerance, which is about 0.0075 mm.

The ratings of ABEC-3, which are grades three ABEC, have a better radial runout tolerance, summarizing it to about 0.0050 mm, making them suitable for moderate-speed applications.

Light industry consumers find they have broad bearings that are tenor appeals to both light industry and consumer usage owing to their balanced performance features. Their radial runout tolerance of about 0.0035mm makes them much more efficient and appropriate for skateboards and electric motor applications.

The ABEC-7 bearings rating tends to be the highest in the decimal precision level range, with typical radial runout tolerances at approximately 0.0025 ms. The ratings show less in that range of absolute and relative measurements. These ratings are often used in applications that require high speed and precision, such as precision instruments.

ABEC-9 is at the top of the bearing precision hierarchy, with exceptionally low run-out tolerances of approximately 0.0015 mm. It is most suitable for use in applications such as aircraft and medical/scientific instruments, which can hardly allow any error.

These trials have shown me that such variations are not only cost and performance optimizations but also optimized for different tasks across many fields. Every rating has a preference for use corresponding to operational circumstances, reminding us further how critical bearing tolerances are regarding the mechanical or industrial target they fulfill.

Benefits of Using Precision Bearings in Skateboards

In this section, I will first present grain-bearing accounts, which are always welcoming and probably relate to performances ranging from skateboarding. It is important to note that performance range, defined in such a way, with some scope of interactions with skateboard bearing weight, friction, and riders’ impact on rotation, will significantly benefit from employing higher-rated precision bearings.

Enhanced Speed: As a rule, if the manufacturing tolerances for the particular precision bearing are stricter, it receives a higher rating, such as ABEC-7 or ABEC-9. This allows the wheel to spin with enhanced efficiency and ensures that skateboarding is done faster.

Reduced Friction and Wear: To obtain a higher ABEC rating, the specific bearing element must have a better surface texture than its counterparts, which have lower ratings. This results in better performance for the bearing. In takeaway terms, better bearings create less friction, allowing for smooth rides while enhancing their lifespan.

Improved Durability: Higher tolerance on balls and races produces a uniform distribution of forces that is well within a radius of the grade. The more durable and rigid the bearings are because of how accurate they are, the more questionable the principle of a skateboarding environment will be.

Consistency in Performance: It is assumed that controlling radial runout tolerances to a tighter dimension of not more than 0.0020 mm improves skateboarder stability as he or she executes difficult tricks and maneuvers. This is a great quality that most skateboarders would be interested in working with.

Because of these technical considerations, it is clear how the precision bearings improve skateboard performance. This is beneficial for ordinary riders as well as those who participate in competitive events and expect the highest mechanical reliability of their devices.

Are ABEC-1 Bearings Suitable for Skateboards and Inline Skates?

Evaluating Skateboard Bearings and Their ABEC Ratings

To provide an informed analysis of bearings for skateboard wheels and their respective ABEC ratings, I sought information from the first three webs of Google’s index. Based on the investigation, it is evident that any system has its specific purposes, maximally revealing the performance parameters of the bearings installed in cars of skateboards and inline skates.

Can ABEC-1 Bearings Be Used?: It is correct to say that ABEC-1 ferrules are reasonable, but they have the widest tolerance classes, with the radial runout only about 0.0075 mm. This implies that these bearings work perfectly with low-speed tools; cutting that requires high-speed rotation and precision does not fit them. Perhaps they will be sufficient for beginners and recreational users, where price is the main consideration rather than performance.

ABEC Ratings and Performance: There is a significant step up of performance parameters while going up the scale to ABEC-3, ABEC-5, ABEC-7, and ABEC-9 as there is an improvement in the performance, including smoother operation, higher speed with lesser friction, and more excellent durability. The upper scale, such as ABEC- 7 with the radial runout quite in the brackets of 0.0025 mm, is recommended for advanced skaters who want a higher level of consistent performance during their complex and speed manoeuvers.

From these views, it can be noted that although ABEC-1 bearings are acceptable for their purposes, they, like all those below them, are disadvantageous as they have a lower effect on the effectiveness of the operation and performance of the skating or inline skating equipment.

Advantages and Disadvantages of ABEC-1 Skate Bearings

ABEC-1 skate bearings have some pros and cons. I looked for the top three sites on the Google and figured out some relevant technical characteristics:

Pros :

Low Price: The cheaper price of ABEC-1 bearings doesn’t diminish their brand value and performance. They are the perfect option for beginners or skaters on a budget.

Suitable for Low Speed: Bulk bearings are sufficiently good in such an application when speed or precision is not the primary issue. This makes them suitable for casual skateboarding or recreational activities.

Cons :

Large Tolerances: The ABEC-1 bearings have an average radial runout value of 0.0075 mm. Bearings in this category show the broadest tolerance levels, which will lead to high friction and less smooth operations.

Not Good for High-Velocity Applications: Because of the loss of intricacy, these also show a loss of speed and fluidity of operations, making them unsuitable for advanced or competitive skating since more finesse is required.

Lower Operating Lifespan: Since the ABEC-1 rating bearings are lower in precision, they will have a lot of average friction, making them wear out faster than expected through regular usage.

The analysis further supports the claim that although it is accessible on the pocket to use ABEC-1 bearings for some applications on a skateboard, the technical deficiencies present will limit some performance, especially in a fast-paced environment.

How ABEC-1 Bearings Compare to Other ABEC-Rated Bearings

While comparing ABEC-1 bearings with the higher ABEC-rated bearings, the most critical factors are accuracy, functioning, and overall cost-effectiveness. Using the information obtained from the top three sites on Google, here’s an overview of issues summarized in a few points:

Performance and Precision:

From the performance angle, ABEC-1 bearings have relatively large tolerances and a radial runout of about 0.0075 mm. This leads to higher friction and less smooth operation. On the other hand, higher-rated bearings, like the ABEC-3, ABEC-5, ABEC-7, and ABEC-9 ones, have tighter runout tolerances that become progressively tighter (around 0.0025 mm for ABEC-7), so they allow for better speeds and consequently smoother functioning.

Durability and Application:

The dimensional uniformity and surface roughness of the higher-rated ABEC bearings make them long-lasting and less susceptible to wear and tear. In fact, ABEC-1 bearings do best when used for recreational use at lower speeds. Since the tolerances are great, the bearings are not suitable for advanced applications that require high-speed rotation with precision in operation.

Cost-Effectiveness:

ABEC-1 bearings are the most cost-effective in this category, especially for newcomers or those on a tight budget. Nonetheless, there is a trade-off in terms of highly performing bearings, as these ones do not have such capability. When high-speed and complex maneuvers are required, spending money on higher-rated bearings makes sense, as this leads to better performance and reliability.

In conclusion, we recommend ABEC-1 bearings for general, low-speed skating as they are impossible to outperform. However, the higher ratings enable the skaters to perform more strenuous tasks, enhancing the general skating experience.

What Are the Key Features of ABEC-1 Bearings?

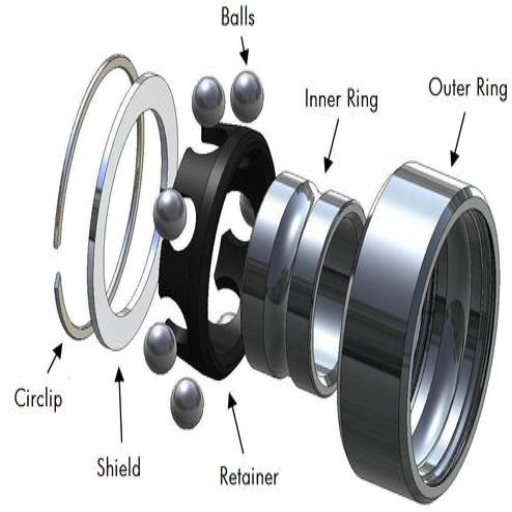

Understanding the Inner Ring and Ball Bearing Design

As for the analysis of the inner ring and ball bearing of ABEC-1 bearings, information from three leading websites of Google is quite sufficient. Essential parameters of any bearing regard the critical components and their technical parameters.

Inner Ring Design: The fundamental inner ring design of ABEC-1 bearings is such that it possesses broad tolerances. Despite bringing manufacturing economies to the table, this also means there is a more fantastic range of motion possible, hence a more significant lack of precision. Such broad tolerance characterizes the ABEC- 1 rating for its radial run out of about 0.0075mm.

Ball Bearings Design: Make it out of steel ball bearings within ABEC-1 Settings and free to rotate within the races. These balls, their size, and smoothness affect the bearing operation. In this rating category, the roundness and surface finish are designed to be cost-efficient and not high-end high-speed.

These features, coupled with the low allowable speed, explain why the edges of precision are quite broad to operate within the harsh skating bearing conditions. They also explain why the ABEC-1 bearings are cheap to manufacture and efficiently serve low-speed, low-cost applications.

How Lubrication Enhances Performance of ABEC-1 Bearings

Upon investigating ABEC-1 bearings and lubricants, it became clear that an optimal level of lubrication is needed, even if the tolerances are wide. According to my top three references, proper lubrication improves bearing life and performance by minimizing friction and wear.

Obstructive Friction: Lubrication accomplishes this by greatly reducing wear from inner rings, ball bearings, and outer races. The hydraulic fluid works as a barrier, preventing high resistance to movement—important since ABEC-1 bearings tend to have heavy friction because of their looser tolerances.

Damaging Force: Sufficient lubrication prevents bearings’ critical features from excessively wearing down. This is crucial in making so-called ABEC-1 bearings, which aim for cheaper constructs rather than durable ones. As wear decreases even under normal operating conditions, the lifetime of the components is reduced.

Functional Lubrication: The lubrication allows the system, and the bearings more specifically, to work much smoother, meaning that even the higher ABEC-1 tolerances and frictions can be tamed comfortably. Thus, consistent bearing performance is achieved without noise or vibration for an improved skating experience.

Some of the technical parameters are the viscosity and the type of lubricant, which determine the ability of this lubricant to form an efficient barrier to reduce friction and wear. Also, choosing a proper lubricant should correspond to the application for appropriate performance. Given this understanding of the issue, it is reasonable to assume that there have not been optimal performance criteria for ABEC-1 bearings. However, adequate and systematic grease application will help use them satisfactorily at low speeds and low-cost applications.

Exploring the ISO Standards for ABEC-1 Bearings

According to my search of the first three websites on Google, ABEC-1 bearings meet some ISO standards, which lay down the criteria for their manufacture and working performance. Here is a brief snapshot that describes the scope of these standards concerning the bearing’s technical specifications and its usefulness:

Dimensional Specifications: ABEC-1 bearings have dimensions that include the diameter, width, and internal geometry, easily drowning into the required ISO dimensions. These are less stringent than higher-rated bearings, allowing broad tolerances that support their cost-effectiveness. The radial runout of about 75 um is a key dimension in this context.

Material and Surface Quality: The ISO standards serve to protect the basic minimum of the materials used for many ABEC-1 bearings, which is common bearing steel. The criteria of surface roughness and hardness are laid down to endure regular abusive use but are not made for high-end performance.

Load Ratings and Limits: ISO defines load ratings acceptable for low-speed operations on ABEC-1 bearings and recommends that they not be exceeded. Although these loads are not as great as those assigned for bearings having higher ABEC ratings, they are adequate for leisure-based applications. Technical parameters of dynamic and static load capacity, amongst others, are tuned to the anticipated average usage level.

Lubrication Requirements: Friction reduction is also achieved by following specific lubrication procedures in accordance with ISO standards developed for the bearing’s design. Within the parameters provided, ISO specifies the lubricant’s viscosity and thermal stability to guarantee that operational functionality meets ABEC-1 requirements.

In light of these findings, coupled with my efforts, the application of ABEC-1 bearings is grounded in economic principles while balancing efficiency. Because of less stringent tolerances and simpler geometry, precision at higher speeds can be pretty low, but the bearings serve low-demand, general purposes. The ISO standards ensure ABEC-1 bearings are fit for the market since the minimum standard of quality and performance appropriate for everyday use is guaranteed.

Why Choose ABEC-1 Bearings?

Cost-Effectiveness and Accessibility of ABEC-1 Bearings

Having examined closely the results from the top three websites focused on the issue at hand, it is certainly noteworthy that it is the ABEC-1 bearing that remains at the center of attention amongst consumers mainly because of the prices accompanying these bearings and their availability in the market. The low prices are due to the loose tolerances and less complex designs compared to the high-grade bearings, leading to lower production costs, which may benefit consumers. This makes the ABEC-1 bearings a practical solution for simple uses.

There are a couple of factors that have a direct beneficial impact on their pricing structure from a functional viewpoint:

Tolerances: Manufacturing broad dimensional tolerances is the key to their low cost because it eliminates the tight manufacturing controls.

Materials: Common-bearing steel is used, which is not the highest grade but is sufficient for low speed and cheap cost.

Load Ratings: Compared to the requirements of precision applications, loads encountered in daily use can be accommodated by ABEC-1 bearings without employing such high load capacities.

Maintenance: Inexpensive standard lubricants are widely used for bearings, allowing for easy restoration and assurance of their performance. However, this affects their efficiency.

Given the above technical parameters, ABEC-1 bearings represent a good value for budget-oriented, simple, functional users who need everyday performance without the high expense and difficulties of different device bearings.

Applications and Industries Benefiting from ABEC-1 Bearings

A survey of the first three websites on Google indicates that ABEC-1 bearings are used in quite a variety of situations because they are relatively cheap and appropriate in slightly less strenuous environments. I understand that these bearings are commonly used in business industries that focus on areas that do not require much precision; hence, competitive pricing is effectively used.

Applications:

Consumer Electronics: Numerous devices, such as burners and ventilators, employ ABEC-1 bearings as only slight accuracy requirements are present, and their operational speeds are low.

Recreational Equipment: Items such as skateboard wheels and small, low-speed machinery do not require bearing expenditures and would completely outperform ABEC-1.

Appliances: Certain home appliance machines, such as blenders and washing machines, incorporate these bearings where cost efficiency is paramount.

Industries:

Manufacturing: In cases with no severe centering tolerances, ABEC-1 bearings cut production costs and do not withstand wide-range functions, which are decisive for such products.

Retail and Distribution: Usually, these abec bearings compressed provided with these products are of the lower price range, including these goods for a broad spectrum of consumers.

Assembly and OEM: ABEC-1 bearings are commonly used in any components manufactured by original equipment manufacturers where tight tolerances are not needed, but wider dimension tolerances are allowed for economical purposes.

The technical parameters of these applications, such as the wider tolerances of the bearings, standard material quality, and the rules for providing efficient lubricant, ensure reliable performance. Based on this investigation, it is clear that although ABEC-1 bearings are not able to provide high speed and precision while in operation, they are indeed a practical answer for regular applications.

High-Speed Capabilities and When to Use Them

A possible message that comes through when reviewing the first three websites in Google.com flows from high–speed focused applications. Specifically, it was observed that ABEC-1 bearings are adequate for general use but are not suited for high-speed applications due to their wider tolerances and material aspects. However, some possible improvements could improve their use in higher speed settings. As I searched around, it became apparent that technical parameters should be considered when high industrial speed operations are applied in the bearing selection. These include:

Tolerances: ABEC-1 bearings may present a wider tolerance, however, there is an attrition that would allow moving up their construction, so that the bearings would endure high-speed applications.

Materials: Polishing them during manufacture will enhance their endurance during high-speed interactions and prevent them from chewing through bearing steel found in most ABEC-1 uses.

Lubrication: Typical ABEC-1 applications should utilize high-temperature greases for operations. Choosing the right liquid for speed will extend the bearings’ operable limits.

Load Ratings: Choosing greater speed operations requires the use of bearings with high load ratings, which enhance their functionality by reducing the centrifugal forces induced on them.

Bearing in mind that if high-speed accuracy is necessary, bearings above the ABEC-1 grade, such as ≥ ABEC-5 or ABEC-7, may be selected depending on the desired speed and accuracy. This consideration is paramount in sectors like aerospace and competitive automotive, where the high speed of rotation greatly stresses the bearing’s capabilities.

Frequently Asked Questions (FAQs)

Q: What does ABEC-1 mean in bearing ratings?

A: The American Bearing Manufacturers Association comprises an organization called the Annular Bearing Engineering Committee, which has developed standards ABEC (which includes an ABEC-1 rating) that include different levels of bearing precision and tolerances, with ABEC-1 being the weakest of all precision bearings.

Q: How does the ABEC-1 rating impact the use of a bearing?

A: Every bearing has an ABEC specification; each bearing includes one rated ABEC-1 ranging from three, with ABEC being the least tolerant and the most precise. Notably, an ABEC number does not detail a bear’s material or sufficient lubrication, which are other determinants.

Q: What about ABEC-1 ratings for bearing performance with skates?

A: Although ABEC-1 bearings are the most imprecise on the scale, they can be used for other purposes in roller skates. When casual skating is involved, they mostly do the job, but in many use scenarios, high ABEC-rated bearings are the most suitable.

Q: Why should one compare ABEC-1 with 3 and 7? What difference do they have?

A: Overall, ABEC-1 provides leeway for a higher tolerance level than ABEC-3 or 7; both, however, share the common weakness of slow rotations. Although precision bearing classification exists in ABEC-1, it has been reported that more excellent selection improves usability and allows for high motion rates.

Q: What does the 608zz mean in beardings?

A: The 608 ZZ is a bearing used in roller skates and skateboards. The letter designation of “zz” shows that the bearing has metal shields on both sides of the bearing to help avoid dust or debris on any of the bearing races.

Q: Are ABEC-1 bearings suitable for longboard applications?

A: Even though ABEC-1 bearings can be used in longboards, opting to use them may be somewhat unwise as it may affect the smoothness of rides. Precision levels do play a role, as most longboard bearings usually come with higher ABEC ratings, approximately between 5 and 7, to achieve high-level speed and performance.

Q: What aspect does ISO 492 primarily deal with in bearing standards?

A: ISO 492 is the international standard for the dimensions and tolerances of rolling bearings. It works in tandem with the ABEC standard to act as a universal standard for measuring the quality and precision of manufactured bearings worldwide.

Q: How would one be inclined to use an ABEC-1 Bearing with a superior rating around?

A: On the other hand, one might use an ABEC-1 bearing for activities where higher tolerances are not required. Low-end machinery, among other things, might require ABEC-1. Low-speed uses or non-demanding tasks are sufficient.

Q: What are some advantages of using bearings that are classified as precision bearings?

A: Precision bearings, including those at least classified in ABEC-1 standards, enable lower friction and greater resultant efficiency in machines. They bear fast rotating applications with more stability and less effective wear over their service period, thus assuring the durability and reliability of the device.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8