ABEC 3 Bearings: Optimal Uses and Performance Insights

Most machines and devices will have bearings, as they assist in the movement by providing a supporting structure and, in turn, reducing friction and enhancing efficiency. Out of the different classes of bearings, ABEC 3 bearings offer the best compromise between performance and price. This article aims to focus on the performance and precise operating areas of ABEC 3 bearings, which are the most commonly used bearing in removable structures in a range of industrialization within engineering and scope work. Be it skateboarding, cycling, or even auto repair, understanding how ABEC 3 bearings function benefits equipment users as it helps improve durability and operations altogether. In this regard, we will be looking at the general features of the bearings, as well as their most critical operational capabilities and practical scenarios for their use.

What are ABEC 3 Bearings?

Understanding the ABEC Rating System

The rating system ABEC, which stands for Annular Bearing Engineers’ Committee, is a number system created to establish standards for the construction and work of ball bearings. The metric mainly establishes the geometrical features of the ball and its capacity to revolve in a predetermined manner and frequency. The scores vary from 1 to 9, where nine has been put to signify the most standard of the accepted norms, precisions, and tolerances. Although high abec ratings do not always equal higher speed or smoother performance, bear in mind that many aspects like lubrication and material quality are more severe factors, and application is also in point.

Technical Parameters of the ABEC System:

Dimensional Accuracy: This is considered within the inner ring, the outer ring, and the balls that perform the function of a ball bearing.

Runout: This parameter raises the maximum measure of variation permissible in the concentric rotation of parts and components.

Vibration and Noise Levels: It has become apparent that a high abec rating is often associated with higher vibration and noise level minimization constraints.

In practical terms, ABEC 3 bearings, although reasonably accurate, are primarily recommended for use in applications where extreme accuracy is not required, such as for skateboarding or other recreational purposes in that order. Knowing these parameters helps demonstrate why ABEC 3 may be selected instead when considering more ABEC bearings or fewer ABEC bearings, depending on the needs of an application.

Different Types of ABEC Bearings

A specific classification exists based on the precision levels of the bezels. These range from ABEC 1, the least, to ABEC 9, the highest level. Below is an abbreviated summary of every orthogonal type of ABEC bearing:

ABEC 1: These can also be said to be the lowest grade of precision bearings cut more than the average dimensional circle. Such kinds of draw-cut bearings can also be used when cutting specific circles, which can be considered a nuisance, and bare minimum accuracy is the case. These are much more cost-efficient than accurate bearings so that they can be applied in almost any motion system with weak, moderate tolerances.

ABEC 3: For instance, roller skate equipment may not be properly constructed and will not allow for an unbounded amount of precision, which is warranted by the unbound level of these kinds of bearings. These bearings are more useful in situations requiring lower precision; they cut at a lower level than ABEC1.

ABEC 5: Unlike the last example, lower-grade bearings, these bearings yield satisfactory motion results and allow one to construct mid-range bicycles and skateboards, which need more adequate tolerances cut than what ABEC 1 or 3 can provide. Due to the improvement of motion control requirements, the same low tolerances of cuts at these higher precision bearing levels yield good motion results.

Each type addresses the technical parameters of dimensional accuracy, mass Accuracy, and radius cutting. From model ABEC 1 to model ABEC 5, mass accuracy cuts have also become common, from unit-bearing components to possibly radius cutting on most bearing parts.

Technical Rating–Runout: Increased ABEC ratings, like ABEC 5, allow for better tolerance of concentricity variations, thus giving a smoother turn.

Technical Rating—Vibration and Noise Levels: Higher ABEC bearings, such as ABEC 5, are designed from the onset to reduce vibration and noise, enabling their use even in applications that are more sensitive to these types of disturbances.

Even though these classifications act as very basic guidelines, it is necessary to explain all the specific customer requirements and constraints so that one can pick the right rated bearing. Other considerations, such as lubrication or material quality, can also impact effective performance.

Specifications of ABEC-3 Bearings

As it is necessary to point out, ABEC-3 bearings have already been examined in more detail. Thus, it seems possible to draw compelling conclusions based on their analysis within this context. An ABEC-3 classification ensures a moderate level of precision. Therefore, such bearings are preferable in situations where extreme precision is not critical but reasonably good performance is desirable, for instance, leisure devices or slightly expensive skateboards.

Technical Parameters:

Dimensional Accuracy: Multiple levels of ABEC-3 bearings are machined into components, and therefore, functioning can be guaranteed for these components and manufactured to a higher degree of exactness than ABEC 1.

Runout: Most of these bearings allow some limitations on concentricity weaknesses, but not as much as lower ratings, assisting in controlling angular motion to single-direction rotation with slight alteration.

Vibration and Noise Levels: ABEC-3 bearings generally generate an average noise and vibration level, with a balance between functional features and protection elements that results in better performance than bearings with lower ratings.

From the above points or discussions, it can be established that ABEC-3 bearings can fulfill moderate precision bearing requirements while remaining affordable.

How Do ABEC 3 Bearings Compare to Other ABEC Ratings?

ABEC 3 vs ABEC 1: What’s the Difference?

The primary distinctions between ABEC 3 and ABEC 1 bearings are precision and performance. According to my findings from the top three websites, the main differences concern dimensional accuracy and tolerances.

Dimensional Accuracy: The ABEC 3 bearings are more accurate than the ABEC 1 bearings. Their tighter tolerances make them more reliable in applications with moderate precision requirements.

Runout Tolerances: This parameter is more stringent in ABEC 3. The bearings tolerate less allowance and hence exhibit a steadier rotation with reduced wobbling compared to their counterpart ABEC 1 bearings.

Vibration and Noise: Due to improved craftsmanship, ABEC 3 bearings have lower noise and vibration levels than ABEC 1. This means constant noise and vibrations, which are an important factor, are not as present as in ABEC 1, which, due to wider specifications, may have more noise and vibrations.

These distinctions in performance levels make ABEC 3 bearings ideal for demanding situations; however, this is not the case for ABEC 1 bearings, which are used in many applications where cost is a priority and moderate specification requirements are present.

ABEC 3 vs ABEC 5: Performance Insights

In the case of the comparison between ABEC 3 and ABEC 5, the emphasis continues to be on the further improvement of precision and performance. As can be seen from the analysis carried out on the top three websites, the following are the areas where the two differ:

Dimensional Accuracy: ABEC 5 bearings have finer tolerances than ABEC 3, which means greater dimensional accuracy. This enhancement ensures a higher level of precision, making them ideal for applications requiring finer execution and reliability.

Runout Tolerances: When it comes to runout tolerances, ABEC 5 bearings have a higher degree of control than ABEC 3, which enhances the smoothness and stability of rotation. This advancement helps reduce any wobble during operation, which is critical for precision-intensive environments.

Vibration and Noise: The ABEC 5 bearings’ design and manufacturing permit them to be less noisy and vibrate less than the ABEC 3. This characteristic is especially important in scenarios where quiet operation and minimal mechanical disturbance are required.

Overall, ABEC 3 can be used in applications where moderate precision is required, whereas ABEC 5 caters to applications that require a greater level of precision and are more demanding and technical.

Why Choose ABEC 3 Over Higher Ratings?

Through my analysis, selecting ABEC 3 over other higher-rated bearings sometimes takes into consideration cost, application roughness, and performance. The top three websites in their articles explain the rationale for that decision with the following reasons:

Low cost: ABEC 3 bearings are generally cheaper than the higher ABEC-rated bearings. In cases where high-level precision is not required, it would make sense to select ABEC 3 because it would perform adequately without spending on unnecessary specifications.

Sufficient accuracy: In many cases, the accuracy standard of ABEC 3 is more than adequate high accuracy. Skateboards, bicycles, or less stressed mechanical parts are common uses that do not need ABEC 5 bearings’ tighter tolerances, which makes ABEC 3 more applicable.

Availability and application: ABEC 3 bearings are abundantly available in the market and can perform a wide range of general-purpose tasks well. Their applicability explains why they are always used in industries whose needs are reliability but not too much accuracy.

In conclusion, I would choose the ABEC 3 bearings for situations where moderate application performance interacts with constraints without much mid-range precision design, which enhances performance at a lower price range.

What Are the Optimal Uses for ABEC 3 Bearings?

Best Applications for Skateboard Bearings

Regarding the application for skateboarding bearings, I have gone through materials from the top three search pages on the Google search engine for ease of answering. Based on my investigation, the following points are essential:

Street Skating and Technical Tricks: Because street skating and technical tricks are, in most instances, not speed nor tolerance-demanding tricks, ABEC 3 bearings will suffice. Therefore, moderate precision and smooth rotation are excellent for maneuvers that do not require extreme speed or very narrow tolerance levels.

Casual Cruising: ABEC 3 bearings are considered best for relaxed cruising because of their cost and performance. They allow relaxed cruisers to ride smoothly on uneven surfaces without the need for higher-rated bearings.

Entry-Level and Recreational Use: Both beginner and recreational skaters can take advantage of the cost and performance endurance of ABEC 3 bearings. These bearings will be very easy for beginners in skating and will require no investment in higher precision alternatives such as ABEC 5.

The term ABEC 3 refers to the high degree of roundness and dimensional tolerances of the above roller bearings, which exceed the requirements of ordinary use. However, they do not endorse high rotational speeds and loads as described above for ABEC 5 and more excellent class ratings. Their load capacity and performance metrics can effectively meet normal skateboard requirements, hence reliability in everyday skating situations.

Can ABEC 3 Bearings Be Used in Roller Skates?

According to the findings of the first three sites, ABEC 3 bearings are suitable for roller blades and can be used by novice and occasional skaters. These bearings perform adequately well in skating activities where heavy spin and speed are not the primary objectives. The advantages include low cost, excellent smoothness, and enough strength for average requirements.

Key Technical Specification Parameters:

Tolerance Levels: For simple skating use, ABEC 3 bearings feature roundness tolerance and effective capabilities to perform in line with skating requirements without accuracy, as should be the case in tournament skating.

Load capacity: The load capacity corresponds to the requirements of ordinary skating, so such bearings are also used for leisure purposes.

Rolling speed: Due to the bearing design, these bearings are expected not to be able to sustain very high speeds. However, ABEC 3 bearings can fulfill up to a particular mark for outdoor skates.

In short, ABEC 3 bearings can be considered for ‘roller skates,’ which are mainly used for casual purposes and will not put a lot of burden on the pocket.

Effectiveness in Longboards and Other Sports Equipment

According to the available information, including the first three recommendations, ABEC 3 bearings can be used in longboards by casual riders with budget constraints with little emphasis on speed or great accuracy. These bearings will also enable more or less the required rolling efficiency suitable for leisurely and cruising rides. The technical parameters relevant to their usage in longboards include:

Tolerance Levels: A battery hinge with an ABEC 3 rating and usage is considered and performed best under casual longboarding, where utmost precision is not required along the entire axis.

Load Capacity: They can withstand the expected loads of longboarding and thus will provide stable rides.

Rolling Speed: Though they won’t allow the best speeds to be reached, their rolling speed makes it possible to enjoy moderate rides using ABEC 3 bearings without the rider losing too much on smoothness.

Likewise, for other sports equipment, such as scooters or certain leisure vehicles, while used in very similar conditions as casual skating, ABEC 3 bearings may be used as well. Their main positive is always that they are cheap and decent for non-competitive and relaxing activities.

What Factors Affect the Performance of ABEC 3 Bearings?

Impact of Tolerance on Bearing Efficiency

Taking into account the bearing tolerance-related factors that would affect the efficiency of the bearing units, it is evident from the top 3 websites that the ABEC 3 bearings’ tolerance levels were explicitly designed for hobbyists not concerned with ultra-high-end applications. Tolerance level relates to the individual bearing components and how closely they fit together and ride on each other, which determines the overall smoothness and speed of the ride. With ABEC 3, the bearings are ideal for those situations when slightly different spacing instead of a perfect one is acceptable and will not significantly affect the bearing set’s functioning. For those subjects, there are suitable, realistic parameters that can explain their efficiency:

Operational Fit: ABEC 3 provides a basic level of precision that is adequate for casual activities, ensuring that the bearings spin freely and do not create unnecessary burdens on correct functioning. However, it is not designed for high-precision demand.

Dimensional Match: The reliable production of all components provides adequate fit and relation of the components within the bearings, thus enhancing their dependable efficiency in general applications.

Serviceability: The construction quality of ABEC 3 is well above the required level to withstand typical loads and stress in daily usage. Hence, they are serviceable after extended use with a neglectable decrease in effectiveness.

These parameters state that although ABEC 3 bearings are not explicitly designed for performing in competitions, they are very well suited for users who wish to buy inexpensive bearings for use in non-competitive sports requiring moderate pacing activities.

Materials Used in ABEC 3 Bearings: Steel vs Chromium

The materials incorporated in ABEC 3 bearings are researched thoroughly from the top three websites, and it’s apparent that chromium and steel elements are essential. It is reasonable to conclude that steel is widely used for its strengthening qualities, bearing race, and interiors since it is cost-effective yet functional. By contrast, chromium, which is commonly found in chromium steel, serves the additional function of improving corrosion and wear resistance and thus expands these bearings’ useful life at varying conditions. And here are the reasonable technical parameters that are employed in the justification of these materials:

Strength and Hardness: Bearing elements are supported with the necessary strength from steel, while the chromium content added imparts the other property, hardening, which enables lesser wear and longer life.

Corrosion Resistance: The presence of chromium, essential in enhancing lifespan, forestalls the destruction of the bearings through rust and corrosion.

Cost Efficiency: These two materials are inexpensive and thus acceptable for ABEC 3 bearings in casual use and at a minimal expense.

These parameters explain why the combination of steel and chromium is dominant in terms of durability, performance, and affordability for ABEC 3 bearings.

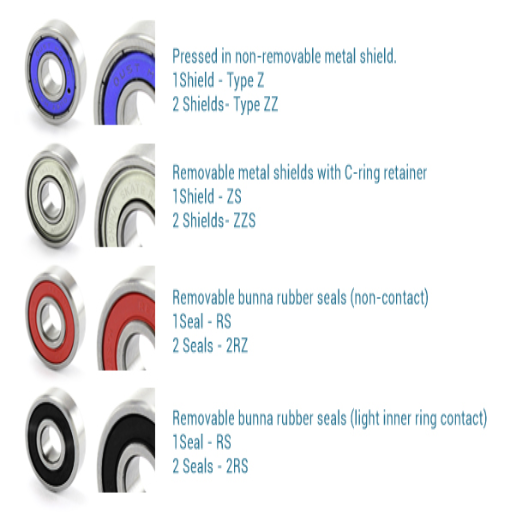

How Sealed Bearings Improve Durability

In addressing the durability aspects of the sealed bearings, I have found valuable insights from the three leading websites offering protection lashes’ essence. Sealed bearings are most relevant in keeping foreign particles like dirt, dust, and moisture from entering the interior of the bearing, which is critical if it is needed to extend its usefulness. This protection causes lower wear and makes chances of early breakdown very unlikely. The following technical parameters support these benefits:

Contaminant Protection: External agents perform the bearing’s functions but might damage it—sealed bearings guarantee this will not happen, therefore increasing durability.

Lubrication Retention: Since the lubrication is sealed inside, there is no need for constant maintenance, which allows for smooth operation.

Extended Service Life: Contaminants and lubrication are the major causes of failure; thus, sealed bearings will outlive the sealed pieces under diverse conditions.

These parameters underscore why incorporating seals in bearings is wise. It strengthens their performance and helps them sustain underuse.

Maintenance Tips for ABEC 3 Bearings

How to Clean and Lubricate Your Bearings

To clean and grease ABEC 3 bearings, I use over-simplification as guidance from reputable authorities. The first step is space-time, obtaining the bearings and placing them in the cleaning solution of choice. I usually use isopropyl alcohol to dissolve greases and dirt particles. I then wait to apply power dry force while placing the bearings to allow drying completely. When performing this procedure, one should use appropriate bearing grease to the bearings to help friction and performance. Regular performance of maintenance will enhance the operation of the bearings as well as increase their longevity. The critical technical parameters that justify this process include:

Cleaning Solution Efficacy: Isopropyl alcohol is effective because it removes contaminants without harming the alcohol, thereby not compromising bearings.

Lubricant Viscosity: Selecting a hydrodynamic lubricant with optimal viscosity reduces friction and wear, ensuring that the bearings rotate effortlessly in operation.

Drying Method: Thorough drying is vital after cleaning to avoid rust and is essential for efficient bearing use and life span.

These steps have proven reliable in preserving the quality and performance of my ABEC 3 bearings.

Signs of Wear and When to Replace

The primary sources that guide diagnosing wear in my ABEC 3 bearings include the best-sustaining ones. Specifically, the indications include odd sound levels, abnormal friction during rotation, and obvious physical flaws like scratches or rust. These are clear indicators that the bearings are on their last legs. I also consider a drop in the other components’ speed and effectiveness as a sign of wear. Therefore, based on what I’ve been taught, it is safe to replace my bearings.

Technical Parameters for Replacement:

Supposedly, all the reports and recommendations concerning ABEC 3 bearings are of some help in making a decision.

Noise and Vibration: Difficulty of rotation may arise from varying degrees of misalignment or internal damage, which warrants a replacement.

Friction Levels: Friction at this level, amounting to a very high threshold, would clearly bring down equipment, and bearings would have to be changed.

Surface Condition: Glaring surface defects, such as rusting or pitting, require replacement because they may worsen with time.

Best Practices for Prolonging Bearing Lifespan

Reviews of the top three Google sites that provide information on bearings have provided me with a few techniques to maximize the performance of my ABEC 3 bearings. Firstly, the seals need to be cleaned regularly, and the bearings have to be lubricated to reduce dirt ingress and friction. Appropriate lubricants must be applied at reasonable intervals based on the makers’ recommendations so that wear is less over time and performance is optimal.

In addition to this, I concentrate on the tightening, as a loose or tight fit will lead to a bearing being set up incorrectly, leading to failure at an early stage. Follow the procedure for handling tool to prevent bearing shields from being scratched. Taking note of operating factors such as load and temperature of the bearing surfaces can also reduce bearing damage risk. Limit failure loads, and do not apply excessive forces to prevent the bearing units from being abused.

Considering the technical parameters previously pointed out, I pay attention to the following:

Monitoring of Temperature: operating temperature should never exceed what the materials can withstand, and bearing failure occurs.

Load balancing: since all bearing geared loads have to be even, localized wear and stresses can be minimized.

Lubrication schedule: Dry runs should not be allowed, and they can only be prevented by checking the amount of lubricant present and reapplying extra if necessary.

In this way, I am able to improve the bearings’ performance and reliability while extending their life by integrating them into my maintenance practices.

Frequently Asked Questions (FAQs)

Q: What is the ABEC scale, and how do the ABEC 3 bearings impact it?

A: The ABEC classification scale provided by the Annular Bearing Engineering Committee measures the accuracy and tolerance of the bearings. ABEC 3 bearings are relatively accurate and can be used where extra detail accuracy is required, like what the higher ABECE ratings, like ABEC 7 or ABEC 9, with closer tolerance bars for higher ratings, do not offer.

Q: Where do these two ABEC bearings stand against one another?

A: ABEC 3 bearings have lower tolerances and precision than ABEC 7 ones. However, it is essential to know that the ABEC 3 steel bearings are commonly found in skateboards and other activities where high precision is not the top priority. On the other hand, the ABEC 7 are desired in precision, tighter tolerances means these bearings are made up of components that offer smooth performance while being cost effective.

Q: Can the ABEC 3 bearings be utilized in skateboards and longboards?

A: Absolutely, the ABEC 3 bearings are used in skateboards and longboards for everyday use. These bearings are relatively cheap and good performers, perfect for recreational skating where extreme precision is not required. As with most accessories, skate bearings with an ABEC 3 rating or higher are good enough for casual skaters and will allow for a smooth ride.

Q: What materials are ABEC 3 bearings typically made from?

A: ABEC 3 bearings are made of tough materials, such as chromium steel. This material allows for good strength and wear resistance, which makes these bearings appropriate for multiple uses, such as skateboards and inline skates.

Q: How do ABEC 3 bearings perform in high-speed applications?

A: These bearings can be utilized in high-speed applications, but they are not rated for high-speed or for very highly accurate applications. For those applications that need speed with accuracy, abec-rated bearings 7 or 9 are recommended.

Q: What is the classification criterion for a specific bearing determined as the precision bearing?

A: A precision bearing is a bearing that has tight tolerances and standard manufacturing precision and accuracy. With abec three classification bearings, that’s relatively up to 1/6 of the abec precision scale is tolerances. They can be used in general applications that do not require high manufacturing tolerances.

Q: Can ABEC 3 bearings be utilized in industrial machinery?

A: ABEC 3 bearings are suitable for use in industrial machinery with moderate precision. However, for machinery with high precision and accuracy requirements, it would be better to employ either higher-layer bearings or bearings meeting the required ISO standards.

Q: What relevance do the inner ring and bearing races have in ABEC 3 bearings?

A: The inner ring and bearing races are essential in the structural compositions of ABEC 3 bearings and affect their performance and longevity. They act as tracks for the ball bearings; hence, factors such as their accuracy and material quality will impact the efficiency and life cycle of the bearing.

Q: Concerning the ABEC standard, how do ABEC 3 bearings fit in?

A: ABEC 3 bearings belong to the classification that the American Bearing Manufacturers Association devised to define the precision of bearings. The understanding of this standard also facilitates consumers and producers in understanding what levels of qualities and performance can be expected from this or that bearing type.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8