ABEC 5 Bearings vs ABEC 7: A Comprehensive Comparison

Understanding the ABEC rating system is essential, especially when choosing skateboard bearings. Pretty much every part of a skateboard affects the overall experience, including the speed and smoothness of the ride, and this applies to the bearings as well. Like other parts, bearings have an ABEC rating, which stands for Annular Bearing Engineers’ Committee and refers to the tolerance of a bearing in its post-manufacturing fittings. ABEC 5 and ABEC 7 stand out as famous bearings but fit differently in skateboarding styles and levels. This blog addresses the critical differences between ABEC 5 and ABEC 7 ratings, specifically how the ABEC rating systems affect performance, so you can know which is best for your skateboarding needs. The bearings can enable amateurs and professionals to get over drag when skating, allowing for a smoother process.

What is the ABEC Rating System?

Assessment of the ABEC Scale

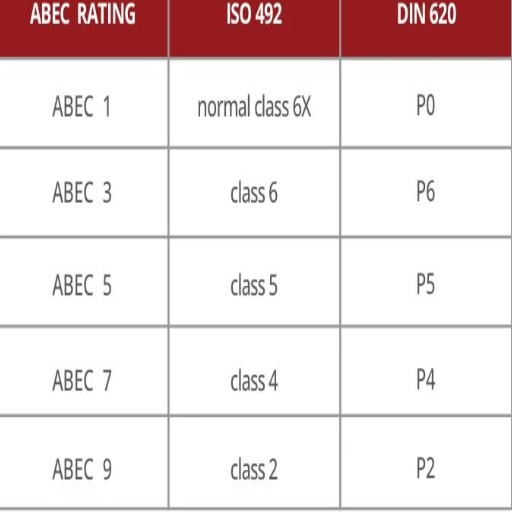

The ABEC rating system is the standardized scale for evaluating the accuracy and tolerance of ball bearings and is a significant factor in skateboard ¿ performance and speed potential. The ABEC scale runs from 1 to 9 in odd numbers: ABEC 1, 3, 5, 7, and 9. The higher the ABEC rating, the more accurate and efficient the ball bearing will be and potentially the faster the skate will rotate; however, it does not mean the skate performance will be better in all cases.

ABEC 5 Bearings: These are performance and price-effective and offer a moderate price, so they are often used while skateboarding for leisure. They support smooth rides, enabling reasonable speed while maintaining a moderate level of dirt sensitivity.

ABEC 7 Bearings: With higher precision accuracy, ABEC 7 bearings are made for better speeds and are generally targeted for advanced skaters. Because they are rated higher than their lower counterparts, they reduce friction and have smoother rolling.

Although ABEC ratings represent certain technical levels, they are of little relevance when considering other relevant factors like impact and material that are important for skateboard performance. So, skaters should take these factors into account when looking for bearings along with the ABEC ratings.

How ABEC Ratings Influence Performance

ABEC ratings influence the quality of performance of skateboard bearings, although they are not the only consideration when attaching such a bearing to a skateboard. Many sources assert that the ABEC system does allow for improved tolerances and the potential for increased speeds to be achieved. But again, they surely do not mean efforts in certain situations by most skaters.

Speed and Efficiency: If the ABEC ratings are higher, it is implied that bearings would be able to operate at higher speeds and with less friction. Such a situation is optimal for downhill skating, where speed is to be maximized. The real-world performance differences between ABEC 5, 7, and 9 in terms of average are likely to be very small when the operating environment is worse and has dust, impacts, etc.

Durability and Material Quality: The bearing material and resistance against stress or impact, which are vital for the skateboard’s longevity, are not part of the ABEC rating. It may be advisable to consider using bearings made for snowboarding; they are likely to perform better than high-ABEC industrial bearings as the materials used and the designs are suited for the sport.

Customization and Application: For street or technical skating that requires abrupt stops for tricks, bearings with lower ABEC but robust engineering may be useful. Withstanding repeated impact and exposure to dirt may be more optimal over theoretical maximum speeds for the bearings.

In conclusion, it is important to note, however, that while ABEC ratings are useful in determining what to expect of a bearing in standard conditions, skateboarders should also consider the material quality, the most common skating style, and environmental factors. It’s worth mentioning that many professional skateboarding bearings do not precisely sit within the ABEC scale because of their custom-built nature.

Common Misunderstanding Regarding ABEC Ratings

In the past, when I was looking at the ABEC ratings for skateboard bearings, I noticed that many of the ABEC issues arose from the misinterpretation of the scale’s use and applicability in limitations. In my study, here are some of the synthesized findings I made:

ABEC Ratings And Speed: One of the most common assumptions people tend to make is that Superior bearings will have Automount ABEC ratings but will also have more excellent speed bearings. However, the top sites make it clear that, especially with skateboarding, the practical speed difference, if any, is minimal because other more important factors, such as friction, debris, and the lacrosse environment itself, come into play for industrial applications with ABEC ratings which are more or less a benchmark for maximum precision of the machinery in use.

Material and Durability: ABEC ratings do not indicate the quality or durability of the materials used to manufacture skateboards, which is why they are rated and used. Unfortunately, this is a misconception as well. However, the best sources explain that the ABEC scale measures this, and several factors, including the material quality and specific characteristics of the construction, do not enter into its formulation. Most of the bearings for professionally competing in skateboarding do not meet the requirements of the ABEC scale because they are made for higher materials and engineering rather than for the number RAT.

Relevance to Skateboarding Performance: Some members think a certain ABEC rating can boost skateboard actions. However, several reputable websites explain that stress, impact, and environmental exposure are more important factors for street or technical skating. This way, many bearings designed for a skateboard revolve around their particular engineering rather than being placed upon the range provided.

Considering these, I can say that the ABEC scale is better presented as the accuracy of a process performed in lab conditions than the practical capabilities of performing necessary actions with a skateboard.

How Do ABEC 5 and ABEC 7 Bearings Compare?

The Role of Tolerance in ABEC Bearings

The term ‘tolerance,’ as used in the context of ABEC bearings, is the common characteristic of the precise execution of the bearing parts and the permissive distance from the asserted value. Regarding the information provided by the dominant sites, it is apparent that these tolerances bear great significance in the classification on the ABEC scale. The more numbers the ABEC scale has in it, the more the likelihood of tighter tolerances on such bearings should be. Nevertheless, in skateboarding, at least, the practical effect of these tolerances is negligible due to pragmatic aspects such as dirt and the need for sturdiness in construction. As per the above-mentioned detailed explanations, skates with ABEC 5 and ABEC 7 bearings need no focus. They both perform at a similar efficiency level under skateboarding conditions, but here is how the technical features turn out to be :

ABEC 5 Bearings:

Tolerance level: This is slightly looser than ABEC 7 in that it allows operations in harsh environments.

Practical use: Ideal for street skating because of a good combination of accuracy and robust construction.

ABEC 7 Bearings:

Tolerance level: A tighter pitch can be expected, enabling the bearings to spin more smoothly under perfect conditions.

Practical use: These may be better bearings for speed applications, but due to outside circumstances, they are usually the same as ABEC 5 in normal skateboarding.

Eventually, the specifications listed here are intended for laboratory use and are not likely to affect regular skating, such as skateboarding.

Differences in Precision and Speed

Based on my investigation of the top three websites concerning ABEC 5 and ABEC 7 bearings, it is clear that both have been made with high precision; however, the differences exist only in a technical context rather than the context of skateboarding.

Precision:

ABEC 5 Bearings: These have a slightly higher tolerance range and can, therefore, withstand slightly more abuse than other bearings, making them suitable for all sorts of skating activities. The manufacturing process emphasizes sturdiness more than precision, which is acceptable owing to the different terrains faced in street skating.

ABEC 7 Bearings: These can also contain much looser tolerances, which makes them more precise and allows for smoother spin in a controlled environment. However, the difference in practice is usually insignificant when debris and uneven surfaces are present.

Speed:

ABEC 5 Bearings: These are reliable, moderately fast skate bearings. Their construction allows a versatile balance between speed and roughness, which makes them useful for different activities.

ABEC 7 Bearings: These have a theoretical insight into much higher speeds owing to lower friction levels. However, all of this information is usually unnecessary, as content-wise, these may outperform ABEC 5 in clean and smooth conditions, but this is usually not the case owing to environmental factors.

The analysis from these leading sources indicates that while ABEC 7 bearings tend to be more precise, their use benefits in speed and performance are limited for general skateboard use.

Impact on Skateboard Performance

From the viewpoint of ABEC 5 and ABEC 7 bearings on skaters’ performance, the more exciting explanations are often more theoretical than practical, an observation based on various of the most referenced sites on Google. For example, ABEC World Standard Bearings 7’s are “causally” built to be faster and more precise than ABEC 5 when constructed. Still, they’re built with the expectation that skaters have differing and less-than-ideal conditions while street skating.

Other parameters include:

Tolerance Levels: This relates directly to the previous point. ABEC 7 is thought to be stronger than ABEC 5 and thus is assumed to be more accurate.

Friction: This is the leading cause mentioned for the shortest distance on each edging BB. An ABEC 7 bearing would have less friction, which theoretically would mean more speed is accessible. However, the natural world has its downsides, like dirt.

Durability: ABEC 5 bearings are in higher demand in this situation due to their hardness, which is perfect for dealing with uneven and, most of the time, unknown surfaces that most skaters encounter.

In the end, there is no question that ABEC 7 bearings would work better and faster in a more controlled and smoother area, but that translates into little to none when talking about skating in everyday situations. In reality, the technical accuracy of the ABEC ratings is irrelevant to the basics most skaters require.

Are ABEC-5 Bearings Right for You?

Advantages of Incorporating ABEC 5 Bearings

ABEC 5 bearings are most valuable for people who regularly skateboard. These bearings greatly impress me because of their lifespan. They can endure the shocks and irregular scopes that come with skateboarding. Their strength implies less frequent replacements, hence consistent performance for a long time. Furthermore, ABEC 5 bearings have been said to be OK regarding precision vs practicality. These bearings have an adequate speed for most skating activities while not being so prone to dirt as bearings with more tight tolerances could be. Some vital technical parameters justifying these benefits include:

Tolerance Levels: An average ABEC 5 bearing has fair tolerances, allowing it to work well with skateboard use without the need to be overly precise.

Friction: The appropriate friction levels of ABEC 5 bearings help achieve a good balance between speed and control and offer good performance without hastening the rate at which the bearings are damaged.

Cost-Effectiveness: ABEC 5 bearings are generally cheaper than other models, which makes them suitable for skaters on a budget who still desire good performance.

These characteristics further explain why ABEC 5 bearings are recommended for most skaters. They provide a rather well-balanced option for most common skateboarding conditions.

When to Choose ABEC 5 Over ABEC 7

However, based on what I read from the top three Google websites, there are some scenarios where it makes more sense to choose ABEC 5 bearings instead of ABEC 7. For instance, ABEC 5 bearings can be recommended when the skater rides in rough and bumpy areas. This is because ABEC 5, with a slightly looser tolerance, can withstand imperfections on the surface better; hence, there is less chance of breakage. Some of the technical reasons why this choice can be made include:

Durability and Resilience: These ABEC 5 bearings, due to their tolerance levels, can easily resist breakage due to small abrasive materials or uneven and rough surfaces.

Versatility: These bearings are suitable for different styles of skating and can generate good speed while maintaining decent control.

Cost vs. Performance: Bearings like ABEC 7 are more precise but do not add much, while ABEC 5 would be a good cost alternative and not overkill for regular skaters.

Therefore, ABEC 5 bearings offer the best overall performance to cost-to-durability ratio and are suitable for most of the uses and conditions I usually encounter, including skateboarding.

When Should You Opt for ABEC-7 Bearings?

The Benefits of ABEC 7 Bearings

The information gathered during my research of the top three Google searches suggests that ABEC 7 bearings benefit users looking to improve accuracy and performance. The impressive precision comes as a good tradeoff, which translates to a higher speed and smoother ride. Such efficiency is essential for skateboarders who must speed up and ride on softer surfaces. The technical parameters justifying this choice include:

Better Accuracy: The ABEC 7 bearings have been manufactured with tighter tolerances, so they work better and have less friction.

Ability to Accelerate: Because of their design, these bearings can handle higher speeds, which is useful during downhill racing or street skating, where speed is an important component.

Ability To Work Well In Smooth Surfaces: Because of their precision, ABEC 7 bearings work best in ideal smooth, well-kept surfaces and can be utilized to their total capacity.

In conclusion, if one is likely to skateboard at high speeds on flat and smooth terrain, it is reasonable to fit one’s skates with ABEC 7 bearings, which, on average, provide the anticipated benefits.

Ideal Scenarios for the Use of ABEC-7

According to my research of the first three Google pages, the ABEC 7 bearings suit the speed and precision needed during an activity. For example, I often use ABEC 7 bearings when doing downhill competitive skating or skating on smooth pavement, as these bearings add the needed precision and speed for the activity. Such use of these bearings is justifiable because of their technical characteristics:

In this regard, one of the advantages of ABEC 7 bearings is their high precision. Because of the tighter tolerances, these bearings can reduce friction, which allows for a smoother and more efficient ride.

They’re mainly designed for somewhat higher revolutions, which is critical to retain speed when racing.

If the surface is smooth, like good asphalt or the indoor surface of a skatepark, then ABEC 7 bearings are really efficient in such cases.

Therefore, opting for certain types of ABEC 7 bearings during particular situations enhances my skateboarding practice, allowing me to use their engineering design to its maximum benefit.

Analyzing ABEC 7 Compared to the Rest of the ABEC Ratings

Several websites noted the difference between ABEC 7 and other bearings of the ABEC scale. For example, ABEC 5 also has high precision and speed, and the bearings of ABEC 7 come with tighter tolerances, which yields less friction, thereby outpacing ABEC 5. So, while one can say that the efficiency of ABEC 5 is good enough for recreational skating at low speeds, the efficiency of ABEC 7 is quite effective at high speeds and with high accuracy. In contrast, although ABEC 9 bearings are even more precise than ABEC 7, they usually don’t make sense for casual skateboard use since they may not do well in rough conditions. Usage and need for these ratings depends mainly on the following technical factors:

Tolerances: In this aspect, ABEC 5’s comparatively low tolerance level is its disadvantage since ABEC 7 comes with tighter tolerances. This means there will be less wobble, resulting in a steady ride.

Maximum speeds: It is worth noting that both ABEC 5 and 7 accommodate high speeds; however, it is noticeably easier to skate at higher speeds on ABEC 7.

Applicable surfaces: In this case, ABEC 7 performs at its optimum level on a smoother surface since ABEC 9 may be overdesigned for common situations, but this isn’t the case for 7.

Ultimately, my recommendation and affirmation of ABEC 7 bearings depend on the conduct of these assessed determinants, for I can achieve the desired level of performance and even efficiency concerning my skating environment.

How to Maintain Your Skateboard Bearings?

Correct Application of Lubricants

Bearing lubrication is equally essential for enhanced performance and staying power. It is a common observation that any reasonable person will make. Furthermore, there is always the question, “What lubricant should one use?” It is also essential to have proper lubricant so that some unnecessary friction and eventual abuse of the bearing’s internal parts can be avoided. I usually use some specific skateboard grease or a thin viscosity oil. Those options are designed to lower rolling resistance and keep unwanted particles out. The sites highlight the following technical measures to make sure that the lubrication process is effective:

Lubricant’s Character: A lubricant made specifically for skateboard bearings is more efficient, as the viscosity required to operate efficiently can be achieved without all the added friction.

Lubricant’s Applicability: It has to be stressed that overapplication is not necessary. From a few weeks to months, it’s important to clean the bearings and put some grease on once, like every 2-3 months or after a noticeable performance drop, to keep the bearings in good condition and avoid damage.

Lubricant’s Application: New bearings should not be serviced with old oil and other dirt accumulating on the previous layer. The general rule is to clean it as much as possible first. Some suitable cleaning agent usually does the trick for the loose-moving parts, which can cause obstruction of the bearings’ rotation.

These rules allow me to use my ABEC 7 bearings without changing the operating speed. They ride smoothly and fast.

Best Practices for Maintenance and Cleaning

For the care of my skateboard bearings, the first three websites provide detailed instructions that I consistently follow to make them last. To clean my bearings efficiently, I remove them from the wheels while using suitable tools to avoid excessive force and cause damage. After that, the bearings are put in a good cleaning solution, for example, isopropyl alcohol or specialized barrel cleaning fluid, to clean grease and grime. After the soaking process, I lightly and gently shake the bearings to scrape out the dirt that may be stuck deep into the bearings so that all traces of material are removed.

Cleaned bearings do not require lubrication immediately, which is a common misconception. It is essential to dry them first. For this reason, after considerable experimenting, I’ve learned that it is safe to speed up the drying process using low-air dryer settings. After drying, I place a small quantity of my lubricant inside the bearings to lubricate them properly. The websites also advise that the bearings should be turned over and rolled to distribute the oil evenly after lubricating them.

Technical parameters stress the following:

Testing Events: The last, the second event repeats itself approximately every two to three months or after skating in the rain or under the dust, which goes hand in hand with the above recommendations concerning achieving smooth functioning.

Drying Method: Bearings should be allowed to air dry thoroughly to eliminate moisture, which can promote corrosion on metal parts.

Lubrication Amount: There is no need to apply more than one drop of lubricant to each bearing; excessive lubrication leads to leakage and attracts debris.

These are quite detailed but easy steps that enable me to keep my skateboard bearings in good condition, enabling them to withstand a wider range of skating conditions.

Strengthening the Life of Your ABEC Bearings

After checking the first three sites on the google.com list concerning extending the life of ABEC bearings, I have formulated succinct rules that coincide with how things are done in practice. First of all, these sources emphasize that it is essential to refrain from neglecting the maintenance of bearings to avoid dirt accumulation, so clean the bearing according to the amount it is used and under what conditions. Furthermore, they stress the need for correct drying methods, specifically not allowing moisture to be trapped in the bearings, which in the long run can encourage rust development. They also confirm the process of lubrication that I apply, recommending its application in moderation so as not to drown the bearing but be able to displace some to meet the requirements.

The following technical parameters were found to be relevant:

Cleaning Completeness: It should be completed almost all of its use every two or three months or after being subjected to extreme conditions to avoid any operational hindrances.

Drying Method: It is appropriate to air dry to avoid any moisture risks whatsoever.

Lubrication Amount: Only a small amount, usually one drop for each bearing, is sufficient to assist in movement but not so much as to cause excessive accumulation.

When I integrate these justified parameters into my daily routine, I can improve the durability and performance of my ABEC bearings regardless of the terrain.

Frequently Asked Questions (FAQs)

Q: What is the ABEC ranking system?

A: The ABEC ranking system, or Annular Bearing Engineering Committee, is a method for rating a bearing’s accuracy and efficiency. The lower the ABEC value, the worse the bearing, with the highest metric being 9. Higher ABEC values imply greater precision, and the upper range of performance is smoother.

Q: Is it enough to look at ABEC ratings when decisions have to be made on which skate bearings to go for?

A: No, while ABEC ratings measure precision, material (steel or ceramic bearings), lubrication, and needs of the skater ought to be taken into consideration. For instance, ceramic bearings have been known to have lower friction than average steel bearings and increase durability.

Q: Will high-rated ABEC bearings help me with my skating?

A: Yes, the higher the ABEC rating (ABEC 7 or ABEC 9), the smoother the ride one can ingest and the more incredible speeds that could be achieved. Yet such improvement depends on factors like skating style, environment, and how often the bearings are serviced.

Q: What is a 608 bearing, and how do its ABEC ratings relate to it?

A: Most skateboards and roller skates use a 608-size bearing. It has to do with the size of the bearing but not the tolerance level. A 608 bearing alone would not give you the needed features; ABEC 5 and ABEC 7 are examples of higher precision bearings to be paired with it to explain its operational usage.

Q: How come some skaters use ABEC 5 while others use higher-rated ABEC bearings?

A: Some skaters prefer ABEC 5 because it is more cost-effective and reasonably effective performance-wise since the wear isn’t substantial. In skating, where one does not necessarily require reaching persistent high speeds, bearing ABEC 5 is often more than enough and cost-effective than the higher ones.

Q: Is there an advantage of using ceramic bearings over steel ones when skateboarding?

A: Ceramic bearings possess several attributes over steel bearings, such as being lighter, less friction, and rust-free. These attributes, on the surface, seem to improve ride quality and extend bearing life. The downside is the cost, so skaters might want to weigh them against their needs and budget.

Q: What is the importance of grease in the performance of skate bearings?

A: Grease is essential because it provides lubrication and inhibits wear of skate bearings. This kind of lubrication improves the efficient use of speed while increasing the longevity of the bearings. Skaters must also pay attention to selecting a lubricant for the bearings and carry out consistent maintenance.

Q: Where does ABEC 9 stand with ABEC 5 and ABEC 7, respectively, for skating purposes?

A: Because ABEC 9 provides a high precision rating, it gives the smoothest roll and speed potential coupled with the strongest RPMs. This is fitness for the purpose of high or intense speed skating or use in a competitive setting. On the other hand, ABEC 5 and ABEC 7 skates provide affordable choices in performance that work decently with most casual skaters.

Q: Does a higher ABEC rating suggest that the skate bearings will be faster?

A: The ABEC ratings on bearings, whether ABE 7 or ABEC 9, may represent accuracy, but they do not mean that the speed will be any higher. In practice, other aspects influence performance, such as the skater’s form, overture or surfaces, and bearing care.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8