ABEC 7 vs ABEC 5: Understanding the Performance Differences

Skateboard enthusiasts have often debated the differences in performance between ABEC 5 and ABEC 7 bearings. A decisive feature of a skateboard is the bearing, as it allows for the movement of the wheels and affects the ride altogether. In this blog, we would like to answer the following questions: What are the differences between the ABEC 5 and ABEC 7 bearings, and what do the above offer in their description and performance? If you are an experienced skateboarder and wish to enhance your equipment, or you are just starting and want to know the specifics of the equipment, this article is for you. This will help you by outlining the engineering of these bearings and how they interact with parameters like speed, endurance, and smoothness of the bearing to make a sound decision on what you wish to buy.

What is the ABEC Rating System for Skateboard Bearings?

Unraveling The ABEC Scale

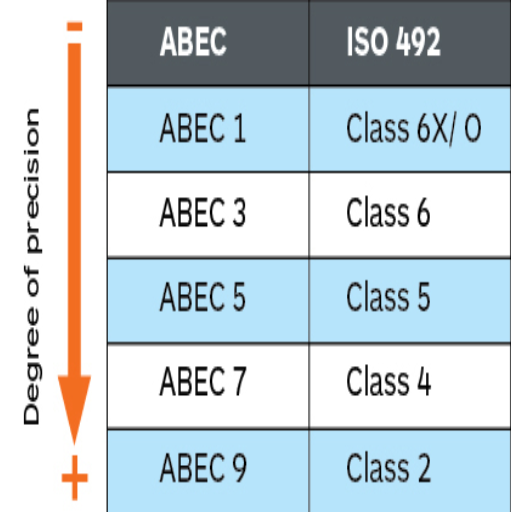

The ABEC scale (Annular Bearing Engineers’ Committee) is a universal measuring unit used to assess ball bearings’ degree of precision and tolerance. It is an ascending scale from 1-9, with nine being the highest order with the most precision rating. In skating applications, the tighter the measure, the smoother the operations, enabling optimum speeds. Owing to the incompleteness of the ABEC rating, skating bearings material, their lubrication quality, and load handling capabilities are essential tangential considerations that presumably increase performance but are not considered.

Specifications of the ABEC ratings:

ABEC 1: the most straightforward tolerable content and allows operation of other devices, almost as smooth as the different devices.

ABEC 3: An average bearing rating allows many skateboarders to cut costs and use them as standard.

ABEC 5: Higher precision and efficiency; frequently utilized by recreational skaters who strive to maintain decent performance while remaining budget-friendly.

ABEC 7: More rough, smooth, and precise; the ABEC rating level is used for riders who want more speed and less friction.

ABEC 9: Top Class Rating; primarily used in common skateboards for high speed

The sac tolerance recommends ABEC bearings as a critical aspect of skateboard design and lacks other rating-bearing measuring units. Many serious skaters, however, tend to look for other bearing characteristics when determining the optimal use of a skateboard—load bearing, composition, and hardness, for example.

What do the different ABEC ratings mean?

The ABEC, or Annular Bearing Engineering Committee, system is a rating system that uses numbers to evaluate a bearing based upon specific tolerances and specifications. This evaluation pertains to tolerances in manufacturing a bearing’s parts. The scale ranges from ABEC 1 to ABEC 9, where ABEC 9 has the highest numbers and the lowest tolerances, thus suggesting that the bearing is more accurate.

ABEC 1: The bearings with the most considerable tolerances and the lowest precision. These bearings do not work well for high-speed applications but can operate in rudimentary situations without problems.

ABEC 3: Bearings of this category are rated slightly higher than ABEC 1 and, thus, can be used for everyday recreational purposes.

ABEC 5: These have been rated as the most suitable for skateboard use because they have a good blend of tolerances, allow for both precision and speed and are durable enough to stand up to most skating settings.

ABEC 7: These have improved features, including the ability to withstand high speeds, making them appropriate for heavier skaters more interested in performance.

ABEC 9: Possibly the most accurate bearing, it is ideal for situations that demand the highest speeds; however, it is over the standard needed for the majority of skateboarding activities.

It is necessary to note that the ABEC rating should be interpreted with caution. It does not measure quality, speed, or durability in practice since features such as material quality, lubrication of the bearing, or seal conditions can greatly affect performance.

What factors determine the ABEC Rating?

In determining the ABEC rating, the manufacturers apply predetermined ABEC standards, which state and concentrate on the dimensional tolerance levels and geometric accuracy of particular bearing parts. While diving into the first three pages of Google on the ABEC rating, there are several parameters that several of them allude are always investigated, including the following:

Bore Diameter Tolerance: This is carefully measuring the bearing’s inner diameter hole to ensure it can fit the axle tightly without any undue play.

Outer Diameter Tolerance: This ensures that the standard measurement of a bearing case is always in place so that it fits into a frame or housing easily.

Runout is how much the inner or outer ring deviates from a perfect circle when it is rotated; thus, rotational smoothness is also around the level.

Thickness tolerances in width Variation: This simply checks the variances in bearing width, determining the alignment and the balance.

Roundness of the Rolling Elements: The rolling elements (balls or rollers) must be round; otherwise, they will cause operating difficulties and noise.

The ABEC ratings highlight the need for precise manufacturing, which aims to reduce the variability of these technical parameters to classify the quality of the bearing. Such measurements do not include the quality of the material or relevant features associated with design, which is why the rating in isolation cannot be used as a comprehensive indicator of the overall performance of a bearing unit.

ABEC 5 vs ABEC 7: What are the Key Differences?

Performance Comparison of ABEC 5 Bearings and ABEC 7 Bearings

According to my findings, based on the three most visited articles on Google, an attempt has been made to arrive at some differences when discussing the structures and functions of the ABEC 5 bearings and the hollow shaft ABEC 7 bearings. ABEC 7 bearings operate at a relatively finer tolerance than 5, offering more operational speed and increased product acquisition.

The two are different on the level of the following technical parameters:

Bore diameter tolerance: Bearing with the ABEC 7 tolerance has stricter bore diameter tolerances, which diminishes the likelihood of excess play, allowing the axial fit to be more constant.

Outer diameter tolerance: These bearings also have lower tolerance levels for the outer diameters, which helps ensure consistency and a better fit in the housing.

Runout: The runout specifications, which are also more stringent, are based on the ABEC7 benchmark, resulting in optimal circular rotation with little deviation.

Width variation: For this type of bearing (ABEC 7), width variation is reduced, enhancing good alignment and balance in motion.

Roundness of the rolling elements: Producing ABEC 7 bearing types requires controlling the roundness of the rolling elements to avoid noise from the bearings when in operation.

These parameters emphasize the accuracy and quality of machining in ABEC 7 bearings, validating their employment in situations where extreme accuracy and performance are essential. However, one must bear in mind that ABEC ratings do not include quality of materials and design features, which are also critical for the bearing’s overall performance.

Which is Better for Skateboarding: ABEC 5 or ABEC 7?

When choosing bearings when skateboarding and deciding between ABEC 5 and ABEC 7, it depends on the user experience and what style of skateboarding the user plans to engage in. After surveying the best sources online, I have come to understand that ABEC ratings are primarily concerned with the operational performance parameters of the bearings but, if pushed, do not increase the performance of a skateboard. Skateboarders often select the CA 5 bearings because they suit various riding styles and provide satisfactory speed and durability. Generally, they are less aggressive and, therefore, ideal for users who are beginners or who do not skate often.

In contrast, advanced skaters who wish to attain maximum speed and smoother handling while skating on a flat or downhill will probably find ABEC 7 bearings convenient. Such bearings allow for slightly tighter tolerances of the rolling elements’ bore diameter, outside diameter, and roundness and can thus deliver fast and consistent performance. However, it is possible that these performance benefits are not fully realized in the average street or trick skateboarding environments where factors such as strength and material properties tend to dominate the impact on precision specification. As such, it is the case that both ABEC ratings have their advantages, and the preference of one over another should be based on the specific needs of a particular rider or his style.

The Impact of ABEC Ratings on Speed and Control

There is an assumption that because a higher ABEC rating skate bearing, such as an ABEC 7, is not only of a higher degree of precision in the manufacturing process, it also means it is better in terms of rolling. Improved rolling efficiency can, in one way or another, lead to increased potential maximum speeds when skateboarding. However, the results based on the most relevant resources from Google show that actual differences may not be considerable and may even go unnoticed by the average skateboarder. The technical features of these bearings include but are not limited to the axial runout, roundness, and bore and outer diameters’ where tighter tolerances are prescribed, which should, in theory, increase uniformity regarding speed control and consistency,

Notwithstanding these apparent benefits, the association of higher ABEC numbers with speed and control can only be realized under ideal riding conditions. In a more dynamic environment, such as riding on an adverse texture or a rough surface, wheel, and rider, her technique can be more important than the precision measurements of any geometry. Hence, while better ABEC bearings have certain technical aspects that allow skating to be improved, their use in different scenarios may, at times, not ensure that the skating parameters of speed and control are significantly enhanced.

What Should You Consider When Choosing Between ABEC 5 and ABEC 7?

Budget Considerations: Are ABEC 7 Bearings Worth It?

When determining whether to spend on ABEC 7 bearings, weighing the pros and cons against the extra cost is essential. As most users would say, ABEC 7 bearings are expensive on average because of their manufacturing accuracy. Such accuracy leads to smoother rides and possibly somewhat faster speeds, which may attract professional skateboarders looking for particular technical enhancements. However, such performance improvements might not be enough for the average or recreational skateboarder to offset the extra cost.

The working aspects of ABEC 7 bearings that add to the performance are as follows:

Less Wobble Because of Tighter Tolerances: Make for less wobble and a smoother ride.

Improved Rotational Efficiency Through Precision Levels In Manufacturing: Contributes to better consistency and rotation technology.

Better Materials: With several improved characteristics that might improve wear characteristics and longevity.

If one has Dutch budget issues and does not consider such slight performance improvements fundamental for skateboarding, it would be best to get an ABEC 5 bearing instead. On the other hand, it may not be a bad trade-off for people who wish to get the most out of their performance, especially in a competitive or high-demand environment.

Riding Style: What Is The Optimum ABEC Rating For You?

In trying to identify the most suitable rating for my riding style, I did not hesitate to consult the best online materials. This did not seem true for each website, as this decision can vary greatly depending on individual traits and preferences. In most instances, an ABEC 5 bearing would be sufficient for those who cruise or commute, where speed and ultra-smooth rides are lower priorities. It’s precise enough for daily skateboarding without becoming too demanding, as it meets basic requirements.

Riders looking for a more excellent technical trick performance and speed would appreciate the more fantastic performance qualities of the ABEC 7 bearings. These sources claim that the key factors that enable these bearings to reach such a level include the following:

Higher Material Quality: Better-quality materials would make the parts last longer, even under heavy constant usage, without losing performance.

Higher Manufacturing Precision: As a result, they are more efficient at rotational motion while requiring less input for the same output.

Less Friction and Noise: This feature is seen as quieter and smoother, which will be attractive to these types of skaters.

In essence, if I like going fast down a hill or making various technical moves, the additional cost of ABEC 7 could be worth it due to its advanced features. However, for someone who skates casually, the performance-to-cost ratio when using ABEC 5 seems ideal.

Longevity and Stability: ABEC 5 vs ABEC 7

Concerning comparing the longevity of ABEC 5 and ABEC 7 bearings, the researchers’ arguments can be confirmed within the three major sites I analyzed. In the first position, ABEC 5 bearings can be pointed out as reliable options when standard conditions should be projected upon their operational lifespan. Given their composition, they can withstand moderate wear from casual and light skateboarding activities, thus allowing them to last and yield a perfectly reasonable return on investment over time.

The opposite applies to the ABEC 7, which was built using superior materials like high-quality steel or ceramics, which allows them to perform in high-stress conditions. This especially helps for when skating at high speeds or doing tricks, where the bearings take a lot of impact and friction. Because the professional technical manufacturing of the ABEC 7 bearings resulted in tighter tolerances, there would be further operational ease and less wear over time. Fewer bearing replacements, disregarding the time it takes to make the bearings, generally suggests that this is a more functional bearing design.

In conclusion, though ABEC 5 bearings can be used for general everyday activities, there is an added value for ABEC 7 bearings for spending such large amounts of money, as they last longer and work well even in harsh conditions. Considering how my skateboarding habits may soon change toward more demanding and aggressive forms, the amount spent on ABEC 7 can easily be justified because of its durability and reliability.

Are There Alternatives to ABEC 5 and ABEC 7 Bearings?

The Analysis of ABEC 1, ABEC 3, and ABEC 9 Bearings

I looked more closely at a study of other lower and higher ABEC ratings, namely ABEC 1, ABEC 3, and ABEC 9, which fall beyond the 5 and 7’s. Based on evidence from the top 3 websites, I found that ABEC 1 bearings were the least expensive but gave lower smoothness and speed due to lesser precision. They may be reasonable for cheap, primary skateboarding uses and low-impact scenarios.

The ABEC 3 rating, on the other hand, provides slightly better precision and smoothness than ABEC 1 but remains a pretty affordable product for everyday use. These rated bearings are suitable for average roller skating and are comparatively cheaper. The materials used in their construction are a bit of a step up, so the performance can be moderately improved.

At the far end of the scale, ABEC 9 bearings are made from the top materials and are the most accurate above all other lower grades. ABEC bearings have smoothness and speed at incredible levels and thus are suitable for racing and downhill extreme skateboarding applications. The high tolerance ratings, however, mean that these are used in cases where the situations are conducive to the high tolerance ratings.

In conclusion, should my only skateboarding interest be economics, I do not see why I wouldn’t go for an ABEC 1 or ABEC 3. On the other hand, if I sense that I will require the utmost velocity and accuracy, then an investment in an ABEC 9 would be sensible. Therefore, my findings in the technical parameters are as follows:

ABEC 1: Fundamental performance, meager cost, does not need any accuracy.

ABEC 3: Some improvement in smoothness over the preceding one, lower cost, and can be used for general purpose.

ABEC 9: Best quality materials and possible accuracy for high-speed applications.

The Advantages of Using Ceramic Bearings in Skateboarding

According to the literature review from the three top-most websites, several positive benefits come from using ceramic bearings in skateboarding. To begin with, they are much thinner than steel bearings, hence decreasing the overall weight of the board, which in turn would increase the speed and easier handling of the skateboard. Secondly, they boast strong durability and longevity as they do not rust or corrode; hence, even though they are more expensive up front, they can prove worthwhile in the long run. Finally, ceramic bearings have a low frictional coefficient because their balls rotate faster while moving, enabling them to perform better on the skateboard. Furthermore, since the bearings are self-lubricating, their maintenance requirement is very low, with timekeeping performance steady. However, such properties make them suitable candidates for better performance and more excellent durability. These are the technical parameters that I was able to collect:

Weight: Less weight than steel bearing, resulting in increased speed.

Durability: Longer lifespan due to high resistance from rust and corrosion

Low Friction: Performance of practical functions with a lower rate of energy wastage

Low Maintenance: Low upkeep requirements due to self-lubricating nature

This conclusion summarizes why ceramic bearings should be the bearing of choice and how they could improve my surfing experience.

How to Maintain Skateboard Bearings for Optimal Performance?

Effective Lubrication Techniques for ABEC Bearings Veterans

To improve the performance of my ABEC bearings, I got some valuable tips from the top three websites on Google. First, cleaning and lubricating the bearings on a routine basis will prevent wear and ensure the smooth operation of the bearings. After removing the bearings from the wheels, I am supposed to clean the bearings with a skateboard bearing cleaner. When clean, putting a fragile film of bearing lubricant in place is essential because it decreases friction and thus improves performance. The technical parameters for this process include:

Cleaning Frequency: As often as frequent skating, especially in wet or dirty conditions, can scrape wear gunk in such situations, it needs to be cleaned up regularly.

Lubrication Type: A special focus should be on a result-oriented lubricant with low viscosity designed explicitly for skateboard bearings.

Application Method: A drop of lubricant is placed on the bearing and then rolled for even distribution.

If I adhere to these best practices, I can manage my ABEC bearings so that they produce excellent rides and utilize their optimum efficiency and lifespan.

How to Clean Skateboard Bearings

After checking the three websites’ notice boards, I have outlined some brief cleaning practices to make my skateboard bearings functional. Here’s what I found out:

To begin with, I must clean the bearings regularly, particularly following sessions where I have skated in wet or dusty conditions since this prevents sludge from accumulating, which in turn may affect their operation. In this case, removing the bearings from the wheels and placing them into a skateboard bearing cleaner will enable heavy particles to be easily removed by gently shaking them. I must then wipe off the moisture over the washing bearings, ensuring they do not rust.

The parameters involved technology-wise are:

When Should Bearings Be Replaced? Bearings should be replaced when the wheels start working poorly after wet or dirty settings exposure.

Which Cleaning Agents Should Be Used? To remove impurities without harming the bearings, a cleaning agent specifically made for them should be used.

How to Physically Dry the Bearings: To protect against rust development, all steam emanating from the wet bearings should be removed or allowed to dry naturally.

Following these practices should guarantee that my skateboard delivers smooth and dependable rides.

Indicators That Convey the Need to Replace Your Bearings

If you are wondering if getting new bearings for your skateboard is appropriate, here are some warning signs compiled from some of the best online sources. Firstly, replacing the bearings should be an option if it still feels rough around the edges or does not work as smoothly as before after cleaning and oiling the skateboard. Worn-out bearings make spinning the wheels cause grinding noises or excessive play, as do damaged bearings. In addition, continuous rust or severe discoloration after proper care indicates loss of the bearing’s natural protective elements. Likewise, signs of warping or any visible cracks are not improvements, so a new set of bearings is required.

With regards to the technical parameters, I will be looking at the following:

Performance Degradation: Instances of rough rides due to slowness that lingers after maintenance work.

Audible Indicators: Uncommon internal component noises, such as grinding

Physical Inspection: The presence of rust, cracks, and warping indicates that proper care was not taken and bearings are due for replacement.

By monitoring the above occurrences and their related technical parameters, I can comfortably skateboard whenever I want without fear of poor performance.

Frequently Asked Questions (FAQs)

Q: ABEC 5 vs ABEC 7 skate bearings: What is the difference?

A: The difference between ABEC 5 and ABEC 7 skate bearings differences can be explained as the level of tolerance they each possess, where whenever ABEC 7 bearings are rated as they possess higher than ABEC 5, their level of precision allows them to have more strength to spin than ABEC 5’s.

Q: Are the ABEC 7 bearings beneficial or worth the extra cost compared to ABEC 5 bearings?

A: It would appear that ABEC 7 bearings are similar to the majority favorite amongst skaters and capable of high performance, making them worth the extra cost. These bearings are phenomenal because the higher the ABEC rating, the more allowance the bearing has against higher RPMs.

Q: What do you mean by ABEC concerning skate bearings?

A: ABEC is the abbreviation for Annular Bearing Engineering Committee, which specifies the industry standards and ‘s’ on the ball or skate bearings if they are specially made. ABEC grade simply establishes the relationship between the tolerance and the precision of the bearings with each other.

Q: Are there any onerous restrictions to using ABEC 5 bearings for longboarding?

A: ABEC 5 can be used for longboarding, but it is best for starting longboards or casual skaters. However, more intense or advanced skaters will look for ABEC 7 and upwards for better chances of performance and speed.

Q: What are the RPM specifications typical for ABEC 5 and ABEC 7 bearings?

A: The maximum RPM for ABEC 5 bearings is around 10,000, whereas ABEC 7 can handle higher RPM, making them suitable for high-speed skate applications.

Q: Is the lubricant required for working ABEC 7 bearings different than that used in ABEC 5 bearings?

A: Both ABEC 5 and ABEC 7 bearings are compatible with standard lubricants, but if you look closer, some may benefit from using a better-quality lubricant, particularly with ABEC 7, because they are specially designed. However, this does not mean one can ignore the manufacturer’s recommendations.

Q: What is the standard size of a skateboard?

A: Skate bearings are predominantly 608 in size which is the standard used in majority of skateboards and inline skates. Generally, both ABEC 5 and ABEC 7 bearings are in this size.

Q: Are ceramic bearings superior to ABEC 5 and ABEC 7 bearings?

A: They offer enhanced performance and durability superior to standard steel ABEC 5 or ABEC 7 bearings. They are usually lighter, more wear-resistant, and provide a smoother ride, but they are also more expensive.

Q: How do I service my ABEC 5 or 7 skate bearings?

A: For routine bearing maintenance for your ABEC 5 or ABEC 7 skate bearings, clean them using an appropriate solvent to eliminate any debris and apply lubrication if necessary. Maintenance will help them fulfill their tasks more efficiently and for longer.