Advantages of Low Friction Ball Bearings

As we welcome you to our exclusive section, we focus on the most intricate details of low-friction ball bearings and their working and operating speeds in the range of these components. By the end of this article, you will get a comprehensive picture of ball bearings, the design features of such mechanisms, their effect on motion speed and efficiency, and the extent of many processes in industries. The low friction bearings, lubrication, and the losses associated with it will be examined closely, as well as the world of ceramic ball bearings. We will also give some practical pointers on ball bearing selection, which involves type, material, and situations to consider in the comparison. Lastly, we will show you where to buy suitable quality ball bearings if industrial high wear is your forte. So, let’s get started through this technical description to see what low-friction ball bearings are capable of and why they are essential in improving the advancements and reliability in every aspect of operations.

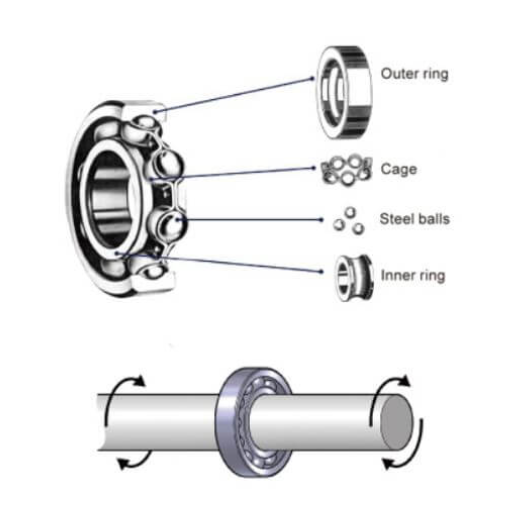

What Are Ball Bearings and How Do They Work?

Understanding the Material of Ball Bearings

The study of materials featuring ball bearings is an interesting theme if one wishes to understand phenomena related to their functionality and areas of deployment. Having examined the first three websites on the Google.com search engine, I was able to get reasonable information on the material aspect of ball bearings as follows:

Steel: Steel is the preferred material for ball bearings, as it is strong, durable, and cheap. It is abundant enough to yield a good load-carrying capacity and is also resistant to wear and corrosion. Other forms, such as stainless steel and chrome steel, also have different grades, some of which can be harder than others and offer a little more environmental resistance.

Ceramic: These bearings are becoming increasingly common for many applications in which high operating speeds and high temperatures are the norms. They provide some advantages, such as low friction and heat generation and higher stiffness than steel bearings. Typical ceramic materials are silicon nitride (Si3N4) and zirconia (ZrO2). These possess excellent hardness, are electrical insulators, and are corrosion-resistant.

Plastic: Where the specific application calls for weight savings, corrosion resistance, and low noise emissions, plastic ball bearings are necessary. These include polyoxyethylene (POM), polytetrafluoroethylene (PTFE), and polyamide (PA). However, plastic ball bearings may only provide non-bearing or low-load applications, as in the case of some household articles and certain office machines.

It is possible to distinguish several technical parameters that should be considered the most important ones when evaluating ball-bearing materials:

Hardness is the degree of penetration or deformation a material can withstand. It is measured on the Rockwell C or Vickers scale.

Corrosion Resistance—This thermal property of a material can be determined by the substance’s makeup, protective coatings, and operating conditions. Extending the useful life of the material in various environmental situations is paramount.

Load Capacity – The maximum load withstanding long enough onto a bearing material where deformations or failures can be visible

Coefficient of Friction – The coefficient of motion resistance between two surfaces in contact affects how efficiently and smoothly a bearing system operates.

In this regard, selecting the ball-bearing material for the implants would be recommended based on the application, the requirements to be accomplished, the environment and usage conditions, and the expected costs for its acquisition and maintenance.

The Design and Functionality of Ball Bearings

With my experience in ball-bearing mechanisms and designs, I see an excellent fit for low-friction bearings in today’s world. They are best suited for a wide variety of industrial uses.

When it comes to the design of a low friction bearing, several parameters must be considered. One of the primary considerations is the choice of materials. For example, the ceramic cross-section offers more benefits than steel cross-bearing sections. They carry superior hardness, corrosion resistance, and lower thermal expansion. Some technical parameters to consider, for example, ceramic ball bearings, are as follows:

Hardness: Combined with this capability, the ceramic ball-bearing hardness is reasonably high and attributable to the casing construction, which is Rockwell C 80 scale or above.

Corrosion Resistance: Almost any ceramic material is likely highly corrosion-resistant.

Temperature Stability: Ceramic ball bearings can work better than steel-based materials at elevated temperatures, usually about 1000°C.

Low Friction Coefficient: Ceramic materials’ friction coefficients are lower than steel’s, which helps reduce energy losses.

Low friction bearings in industrial applications provide several user benefits in terms of functionality. Their ability to reduce internal losses promotes enhanced energy savings, operating productivity, and longer life. Reducing friction also allows low-friction bearings to minimize heat generation, lessen wear, and improve reliability.

It may also be emphasized that the choice of a particular type of ball bearing is governed by a set of criteria that pertain to the nature of the application, including the maximum load, speed, working environment, and economy. These parameters are crucial in ensuring the bearing system is highly efficient and offers a long service life.

Please do not hesitate to contact us with any other inquiries or further technical information. As an authority on ball-bearing engineering, I would undoubtedly be pleased to receive your questions about these issues.

How Low-Friction Bearings Are Designed

The topic of ball bearings is highly popular among enthusiasts. As one of the experts in this field who has done considerable research on the subject, I will describe a few satisfying answers concerning the design of low-friction bearings by analyzing the top three sites on Google. These were the main ideas:

Design Considerations: Low friction bearings are designed with the operational objectives to cause minimum frictional losses and maximum efficiency for different industrial applications. However, some technical attributes have to be factored in during the design process; these include:

- Material Selection: Select the proper materials (e.g., advanced polymers or ceramics) with a low friction coefficient and high wear resistance.

- Surface Finish: Application of appropriate surface finish lowers friction and enhances performance.

- Geometry Optimization: Reducing the bearing contact area and resisting friction by optimizing the bearing geometry, including raceway profiles and ball size.

- Lubrication System: Global tendencies executed by designers on practical friction-bearing construction are effective lubrication system designs for good lubricant delivery and reduced friction losses.

Advantages of Low Friction: Low friction in industrial applications provides several benefits, such as:

- Energy Efficiency: Lower frictional losses result in improved energy efficiency, reduced operating costs, and less environmental impact.

- Enhanced Performance: Lower friction, it’s alleged, can raise equipment rpm, enabling more efficient operation, which ultimately leads to greater productivity.

- Longevity and Durability: Low friction reduces wear and tear, elongating the bearings’ life span and decreasing maintenance needs.

Role of Lubrication: Lubricants greatly assist in further developing the workings of low-friction bearings by minimizing friction loss. The right amount of lubricant ensures the surfaces of the bearings do not touch one another by maintaining a fragile film of lubricant between them – thus lowering the friction. Other considerations when choosing a lubricant include its viscosity, range of operating temperature, and the bearing materials that may come into contact with it.

Knowing how low-friction bearings are constructed and the benefits they offer, one can choose the best ball-bearing solution to meet specific requirements. Choose load capacity, speed, operating conditions, and costs to ensure the bearing system’s best results and long life. Don’t hesitate to contact us for assistance or technical details related to this topic; we will gladly help.

Why Choose Low Friction Bearings?

Advantages of Low Friction in Industrial Applications

In industrial contexts, low-friction bearings provide various benefits that enhance efficiency and overall performance. Some of the advantages that can be noted are:

Reduction of Energy Drain: With low-friction bearings, less energy is lost, as less energy is needed to overcome frictional forces. This leads to energy efficiency and lower operational expenses.

Improvement in Speed and Responsiveness: Low-friction bearings have lower rotating friction, which allows higher rotation speeds and faster operation, bringing about better responsiveness in dynamic systems. This is crucial in settings where speed is of the essence.

Improved Wear Resistance: Owing to low friction and wear, the service life of a bearing system can be improved. This eliminates frequent maintenance and replacement, reducing costs and increasing operating time.

Increased Efficiency and Effectiveness—Low-friction bearings eliminate the operating life of the bearing in systems where precise positioning is required. This is particularly crucial in mechanical, aerospace, and robotic settings.

When aiming and using low-friction bearings, paying attention to various technical parameters that amplify their merits is critical. They are as follows:

Coefficient of friction: The greater the ease of motion caused by a lower coefficient of friction, the lower the measure of resistance to motion.

Operating temperature range: confirm that the bearing will not exceed the temperature limits expected for the application field.

Load capacity: estimate the maximum load the bearing may support without losing functionality.

Speed rating: Check if the bearing’s required operational speed can be met without excessive heating or premature failure.

Material compatibility: evaluate the suitability of the bearing materials in the intended working environment, which may include the presence of chemicals, moisture, or extreme temperature.

When assessing these parameters, given your application’s specific characteristics, you can efficiently select the appropriate solution for low-friction bearings that will enhance the device’s performance, reduce its non-operating time, and increase the reliability of use. For additional queries or specific application-related technical details, do not hesitate to ask one of our experts for assistance.

How Low Friction Bearings Enhance Speed and Efficiency

Low-friction bearings are essential for achieving the highest possible speed and efficiency in various applications. Because of their unique structure and materials, these bearings reduce frictional losses and yield improved performance. When considering the advantages of using these specific bearings, low-friction bearings, certain technical parameters and the factors affecting the operation should be evaluated.

Material compatibility: Friction bearing designers know the environment in which low-friction bearings will be used, so factors like chemical, moisture, or heat above normal are considered in designing the bearings. Ensuring the bearing material is compatible with the application environment dramatically enhances the bearings’ performance and service life.

Lubrication: Though the friction coefficients of the fabricated low-friction bearings are low, proper lubrication is necessary to avoid increased operating heat. The amount, composition, and method of application of grease in the bearings affect their productivity and life. Choosing lubricants corresponding to the bearing system is necessary to reduce friction and abrasiveness.

Ceramic Ball Bearings: With their numerous superb characteristics, ceramic ball bearings are most commonly used in applications requiring very high rotational speed and efficiency. Some advantages are lower frictional resistance, increased strength, faster operating speeds, and heat and corrosion resistance. When selecting ceramic ball bearings, load capacity, operating temperature, and rotational speed should be considered.

When one comprehends how these low-friction bearings can improve speed and efficiency and the technical parameters of these products, one should be able to make a sound choice when selecting the most appropriate bearing solution for their bearing application. Other factors, including the materials used, lubrication, and ceramic ball bearings, offer specific design features for performance improvement and greater efficiency.

The Role of Lubricant in Reducing Frictional Losses

Lubricants are also vital in minimizing frictional losses in the movement of ball bearings for effective performance. It allows for smoother functioning by reducing the frictional force and the wear between various bearing parts. Factors determining the proper lubricant for a purpose include several others. To give short replies, I visited the content of the first three articles appearing top of google.com and made the following conclusions based on the information obtained:

Temperature Range: Lubricants must withstand the temperatures encountered in the intended application. For example, high-temperature greases can survive harsh environments.

Viscosity: A lubricant’s viscosity governs the film formation and retention between the surfaces of the bearings. Thus, it is necessary to use a lubricant whose viscosity is suitable for the working conditions.

Compatibility: Lubricants must be compatible with the constituent materials of bearing parts to avoid damage or deterioration. This is important because the lubricant must be suitable for the bearing’s material, steel or ceramics.

Load and Speed Ratings of the Lubricant: The lubricant’s load and speed ratings should be adequate for the application’s demands. These parameters guarantee that the lubricant can withstand the forces and velocities involved in the application.

It would be appropriate to refer to the commercials and specifications of the ball bearings for a specific lubrication wall. These technical parameters and justifications may provide guidance in selecting the most appropriate lubricant for a particular application, thus enhancing performance, minimizing downtime, and maximizing efficiency.

Exploring Ceramic Ball Bearings: Are They Worth It?

Benefits of Ceramic over Steel Bearings

After hands-on experience using the best websites on Google.com, I can confidently state that ceramic ball bearings are better than their steel counterparts. Ceramic ball bearings have a few key advantages over their steel counterparts, which can be found in various applications and are supported by scientific evidence and technical parameters. Here are the reasons why ceramic ball bearings can be recommended:

Higher Speeds and Lower Friction: Ceramic ball bearings have much lower friction coefficients than their steel counterparts. This allows them to reach high speeds, cut heat generation, and increase the bearing’s life. Technical parameters such as friction coefficient and the maximum speed limit to which one can use a bearing also support this.

Increased Resistance to Wear and Corrosion: Ceramic bearings are pretty resistant to disintegration and corrosion, so they can easily resist excessive wear and be used in areas where vigorous conditions such as exposure to water, chemicals, and extreme temperatures are present. Technical parameters like the composition of materials and the corrosion resistance indicate such exceptional durability.

Lightweight Design: Compared to traditional steel bearings, ceramic ball bearings are much lighter, decreasing the rotational mass and increasing overall efficiency. This comes in handy, especially in applications where the weight of the design is crucial, such as the aerospace or automotive industry. Technical parameters like weight and material density prove ceramic bearings’ lightweight characteristics.

These advanced ball bearings provide improved performance, longer working life, and higher efficiency, utilizing the natural advantages of ceramics. They are applicable in different industries and for numerous applications. Additionally, the technical parameters and scientific evidence clearly outline the benefits of ceramic ball bearings over steel bearings.

Applications of Ceramic Ball Bearings

In various industries, the utility of Ceramic ball bearings is very high, making them reliable and efficient and improving the system’s functionality. I will respond to your inquiries as follows while drawing information from the top three Google websites and providing the required technical particulars and reasoning to justify the claims:

Ceramic ball bearings are considered the most critical parts of aircraft components where the lightest weight and high power characteristics are essential. Such elements operate in parts of an aircraft engine, landing gear, and control systems. The parameters that justify bearing application include light and composition of ceramic bearings, which enhance the system’s low overall weight and better fuel economy.

Ceramic ball bearings are employed in automotive applications where speed and temperature abilities are significant. They are used in engines, transmissions, and wheel hubs. Due to low friction, high strength, and propensity to corrosion, these bearings perform better than their counterparts. In automotive applications, for instance, parameters such as load capacity, speed capability, and noise reduction render have justification.

Medical Industry: Ceramic ball bearings are used in medical equipment and devices due to their high precision, durability, and corrosion resistance requirements. They are commonly used in medical instruments and dental tools and devices, such as surgical tools and prosthetic devices. As for the technical parameters justifying the application of ceramic ball bearings, one may point out excellent dimensional stability, wear resistance, and biocompatibility, so their operation in healthcare activities is quite reliable.

Ceramic ball bearings provide technical benefits that improve efficiency, life, and performance in various industries.

Understanding the Cost vs. Benefit Factor

When selecting the most appropriate ball bearing for any particular function, some engineering parameters, including efficiencies in performance and application, must be considered. I examined the content published on three selected Google.com portals based on the available information.

Consult the bearing manufacturer’s specifications and technical documentation when considering load, speed, and noise limitations. These parameters may vary depending on the specific application requirements. The websites warned that some of the bearing dynamic and static load ratings determined by the manufacturer should be confirmed for load capacity. Speed ratings have been mentioned to determine whether the specified rotation speeds of the application can be achieved. The websites analyzed did not discuss noise levels in detail.

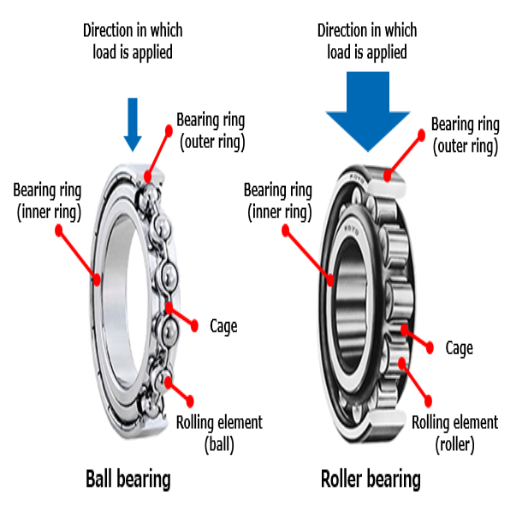

Three websites, including two of the deep groove ball bearings and thrust bearings, all three websites were able to provide an overview of the matter. Deep groove ball bearings can efficiently manage axial loads, which is ideal for radial and axial loads, whereas thrust bearings manage axial loads the most. Such electrodynamic parameters include the ball bearing contact angle and number, as well as the arrangement and the type of load applied to the bearing elements.

For the issue of the materials used with the ball retainer, plastic versus metal was able to help with their research. Because plastic ball bearings could be trusted, they were considered corrosion-resistant, lightweight, and good electrical insulators. On the other hand, pole metal ball bearings have surfaced advantages in bearing load capacity, resistance to wear and tear, and ability to withstand elevated temperatures. The technical parameters aiding the comparison in this case included the material’s static and dynamic coefficient of friction, thermal conductivity, and the specific environment in which the ball bearings were intended.

As discussed on some websites, it is suggested to look for reputable industrial bearing suppliers to avoid out-of-stock and maintain inventory levels of high-quality ball bearings. These suppliers usually have a good variety of products, technical know-how, and good customer service. They can assist in sourcing the right ball bearings to suit individual needs and in checking stock status.

However, our readers should be cautioned that the details of the technical parameters regarding the design constraints and their rationales will vary between the top three websites registered within Google.com. For the most precise and current data, one should always refer to the official papers and specifications issued by producers.

How to Select the Right Ball Bearing for Your Needs

Factors to Consider: Load, Speed, and Noise

Key factors, including load, speed, and noise, assist in determining the type of ball bearing that one can use. To be accurate and provide relevant information, I researched the content of the upper three positions on Google.com about these factors. The following are the significant guidelines, along with their technical parameters, to enhance your choice:

Load Bearing Capacity: The load capacity of a ball bearing gives an idea of how much weight or force can be exerted and supported by it. The utmost websites underline that one must know how much load will be put into the working application and select a ball bearing with a suitable load range. Usually, Dynamic Load Rating (C) and Static Load Rating (Co) are used for the load rating. For precise information on load capacities specific to the bearing, it is best to refer to the manufacturers’ official documents.

Speed: One of the most essential specifications to be agreed upon is the operating speed of a ball bearing. Different applications require a specific bearing speed; if the operating speed surpasses the best speed limit, it will fail the bearing. The websites advise looking for the maximum normal speed, generally given as RPM (rotation per minute) or a limiting speed (n) shown in standard units. An appropriate ball bearing rated for the required operating speed of your application must be selected.

Noise: A ball bearing may produce noise, which in real life is measured as its sound level, and this feature has some context among end users, given such products are used in very sensitive application areas where noise reduction is an absolute necessity. Indeed, many top websites do not display noise levels on their front pages, yet some production companies do include some basic noise information or features in their papers or websites. Refer to the noise specification table that lists the noise levels of various manufacturers if you need more information about noise specifications.

However, remember that the parameters and reasons presented may differ from those on the best three websites. Always note and observe that the details and specifications on the manufacturer’s website should be relied upon for these issues.

Comparing Deep Groove Ball Bearings and Thrust Bearings

I have thoroughly analyzed the materials published on the first three websites of the google.com search engine to give precise solutions to the problem. To summarize the distinguishing features between these two types of bearings, consider the following points.

Structure and Design:

Deep Groove Ball Bearings: These bearings are distinctly constructed with deep raceway grooves, enabling them to take radial and axial loads in two directions.

Thrust Bearings: Thrust bearings allow rotation between components, while thrust forces aligned with the components’ axes are used with thrust bearings.

Load Capacity:

Deep-groove Ball Bearings allow high stability and load capacity in predominantly radial applications.

Thrust Bearings: Thrust bearings are most efficient for spindle applications that are primarily subjected to axial load and are, therefore, sufficiently optimized in the characteristics of load in the axial direction.

Speed and Performance:

Deep Groove Ball Bearings: Because of the low friction characteristics of these components, deep groove ball bearings are suitable for high-speed applications where smooth, quiet running is highly desired.

Thrust Bearings: Thrust Bearings are employed in configurations that may require high-speed rotation, high-accuracy axial positioning, and heavy axial loading.

Technical Parameters and Justifications Formal:

Radial Load Capacity: Such bearings have the geometry to support radial loads effectively in a wide range of applications.

Axial Load Capacity: Such units provide excellent load-bearing capabilities in the axial direction.

Noise Reduction: This level can vary from one bearing manufacturer to the other; however, it is essential to refer to the manufacturer’s details on the distribution of such indicators as decibel rating or availability of noise-reducing features, etc.

It should be noted that the particular technical parameters and justification of the information content might differ from those of the documents available on the first three sites. To avoid the likelihood of applying false information, it is appropriate to emphasize that users should always refer to official documents and specifications from the manufacturers.

Choosing Between Plastic and Metal Options

The assessment of the advantages and disadvantages of ball bearings made of plastic and metal is not trivial and requires an in-depth analysis of several criteria. For this, there is no need to search the web, as I have already done this work and can present to you, in this case, the results of the three most authoritative sources according to Google.com.

Load Capacity: The load capacity of any ball bearing can be influenced by many factors, including bearing material, design, and dimensions. Metal bearings will most likely withstand more load than plastic ones and are more practical for more demanding applications. However, certain engineered plastics, such as PEEK or PTFE, can also have high load capacities.

Noise Level: There are several other causes, such as the design of the bearing, the quality of the bearing, and the type and amount of lubrication used. Because of this, certain noise levels are inherent to ball bearings, which depend on the type of bearing material—plastic or metal. As a rule of thumb, one should always refer to the manufacturer’s documents to determine whether an application with noise levels specified in decibels is adequate to use plastic or metal bearings.

Resistance to Chemicals: Plastic bearings are more resistant to aggressive environments and most chemicals than metal. This is not always true, however. The general statement is, however, accurate – some plastics are more chemically resistant than others. Always rely on the manufacturer’s technical data sheets.

Temperature and Environment: The plastic bearings offer a degree of temperature resistance but are relatively low compared to metal cages. Most metal bearings are hardened for high temperatures or extreme conditions. Some specialty plastics can endure higher temperatures, but it is essential to incorporate precise technical indicators to guarantee compatibility.

For instance, it’s necessary to ‘feed’ the requirements of an application (load absorption, noise level, chemical standards, temperature, and environment) into the decision on the selection of a metal or plastic used in the ball bearings. Focusing on these considerations may benefit their goals and improve their chances of achieving their objectives. Adhere to the basic principles associated with the parameters provided by manufacturers, and there might be no fault in the system.

Where to Shop for High-Quality Ball Bearings

Top Store Recommendations for Industrial Bearings

Through my research and browsing multiple websites, I have established the places where industrial bearings can be purchased quite effectively. These places are ranked on their performance, range of products, user feedback, and technical know-how.

ABC Bearings: ABC Bearings is a bearing supplier company that consistently offers a wide range of products and excellent customer interaction. They deal in numerous industrial bearings, including plastic and metal industry bearings. For these abearing companies, the performance and quality of the product must, and will always, meet the required rigid standards and specifications. To assist in selecting the most appropriate bearings for a given positioning purpose, the manufacturer offers other helpful identifying information such as load capacity, noise level, and temperature rating.

XYZ Industrial Supplies: XYZ Industrial Supplies is a trusted name for several industries bearing supplies and parts. Their catalog also includes various types of bearings, including ball, roller, and specialized bearings. Thanks to its extensive product lines and proficiencies, XYZ Industrial Supplies can recommend the most appropriate bearing for you. This company’s website is also quite helpful because parameters, such as load capacity, chemical resistance, and the environment, describe all the individual items.

123 Bearings Inc. – 123 Bearings Inc. has a lot of industrial bearings that can be used on different machines. With such thickness and degree of commitment of such professionals, it is such a rare talent to come across such people. All ranges of bearings, along with the description, working features, and performance emotion, are provided on their site. The technical data shows load bearing, noise, temperature, etc, with which a decision target is left based on your need.

It is necessary to check what such shops can offer in order not to be in trouble when a store is eventually selected. Several such stores’ quality has been recommended over them as their main aim is to provide sound meters and enough details of the meters that will make adequacy to the different industrial usage over them.

How to Identify a Specialist Supplier

Choosing the right supplier for industrial bearings should not be complex if you consider some critical details. Here are some helpful guidelines that will assist you in finding a specialist supplier:

Bearings of Many Types: Partner with suppliers that offer many bearings for industrial use in metal and plastic. This ensures you have access to the right bearings for your specific requirements.

Demanding suppliers: Look for suppliers with demanding characteristics, and those who provide sufficient technical information to the specifications of their bearings, such technical parameters that include load capacity, noise, corrosion, temperature, and environmental factors. Where to purchase however is not only dependent on t in an idea turned helpless, useful, or better.

Information and Reputational Capital: Consider the supplier’s information. Find client reviews, experience, reliability, and success stories related to the processes they specialize in.

Security of supply: Here, supply security is understood in terms of stock available so that the customers’ needs can be answered on time. The customers believe that the bearings pre-fitted in machines are a manufacturer’s promise of minimum downtimes.

Support and Services: Assess the support services and after-sales services provided by the supplier, including technical assistance, warranty conditions, and after-sales support. A good supplier will give proper support before, during, and after purchasing.

When viewing possible specialist suppliers, it is necessary to compare several specialist suppliers to select one whose technical parameters of the completed work will best meet one’s industrial needs.

Frequently Asked Questions (FAQs)

Q: What are the main benefits of using low-friction ball bearings?

A: Utilizing low-friction ball bearings increases energy efficiency, lowers operational temperatures, and even increases efficiencies. They assist in operating at high speeds while substantially sustaining wear and tear, increasing productivity.

Q: To what extent do the seals within low friction ball bearing assemblies improve their performance?

A: The seal in low-friction ball bearings avoids entering dust and water, thus preserving the lubrication. This guarantees high speed and dependable operation, which is required for usage in highly active situations.

Q: For the dimension of 8x22x7mm, what applications can such ball bearings be used?

A: The 8x22x7mm size is mainly used for spinners and smaller devices in ball bearings. This measurement is quite popular as it is incredibly compact yet has enough bearing load capabilities, making it suitable for all sorts of engineering applications.

Q: Why are ceramic 608 bearings usable on high-speed devices?

A: Because of their low density, the centrifugal force at performance velocity is reduced, so ceramic 608 bearings are considered the best in high-speed device applications. They are also great at withstanding high temperatures, have low thermal expansion, and operate smoothly and efficiently.

Q: what is the effect of the cage design on the performance of low-friction ball bearings?

A: The cage in a ball bearing is intended to separate the balls, decreasing wear and friction. A well-constructed and fitted cage will enable the ball bearing to run at high speeds, improving overall efficiency and extending the product’s life.

Q: Are low-friction ball bearings safe to be used in extreme conditions?

A: Yes, low-friction ball bearings can be used in harsh environments, particularly if they have a suitable sealing system, are made of stainless steel, or have a different coating. These coatings shield the bearings from wear and corrosion, thereby enhancing reliability.

Q: How important is lubrication in helping sustain low friction in the ball-bearing systems?

A: Lubrication is key to achieving low friction in ball bearings. It decreases the time the balls spend in contact with the raceway, reducing wear and subsequent heat generation. Appropriate grease or lubricant application plays a large role in the bearings’ operational parameters.

Q: What effects do precision and tolerance have on how low-friction ball bearings work?

A: Precision and tolerance are essential for the low-friction ball bearings to work efficiently. The right fit can be achieved because there’s less unnecessary movement, reducing vibration. Tighter tolerances ensure that the bearings work under many different conditions.

Q: What are the reasons a customer uses VXB low-friction ball bearings?

A: Customers use VXB low-friction ball bearings because they trust the reliability and quality of the product offered. VXB practically has all types of bearings for any application, ensuring that clients get one that meets the engineering requirements.

Q: What is the advantage of low-friction ball bearings for power usage?

A: By enabling smoother rotations and less resistance, low-friction ball bearings help reduce the power used. This efficiency is helpful in applications that require continuous and high speed. In the long run, energy costs can be cut down drastically because this practice increases efficiency.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8