Applications Explained: What Is a Slewing Bearing?

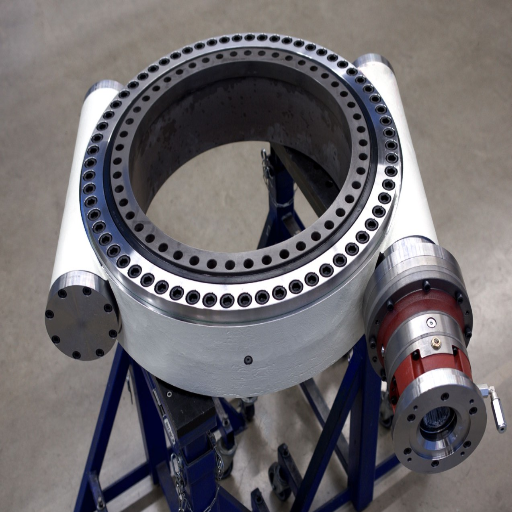

Slewing rings, or slew bearings, are sometimes regarded as the most essential cogs in the machine. But like most crucial components, they are occasionally overlooked. Slew bearings are critical to the easy turning of significant structures. They find employment in many industries, including construction, renewable energy, mining, and transport. Slewing rings are required to provide sufficient structural support for cranes, wind turbines, and anything else that turns and absorbs large forces. This article deals with the scope of slew bearings and their applications in various fields. By the end, the readers can enjoy these complex industrial wonders essential for engineering progress and industrial evolution.

What is a slewing bearing, and how does it work?

Understanding the basic structure of a slewing bearing

In large industrial machinery, slewing bearings can handle substantial weight while allowing slow slewing movements. A slewing bearing comprises the following components:

Inner Ring and Outer Ring: Each ring containing the raceways fitted on them expanded vertically for greater load-bearing capacity. High-grade steel manufactures these rings, providing functionality at high durability conditions.

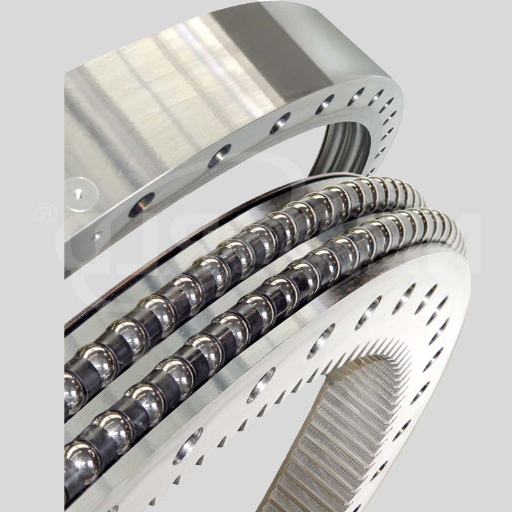

Rolling Elements: Between the rings, rolling elements, usually balls and cylindrical rollers, are sufficiently used due to their low frictional properties and high efficacy in rotational movement. Ball bearings are ideal for lighter applications, whereas roller bearings, due to their enhanced contact surface, are most appropriate for higher-capacity loads.

Spacer or Separator: This component helps maintain uniform spacing between rolling elements, reducing bearing wear and ensuring an evenly applied load.

Seal: Seals play an essential role in shielding the internal components from dirt, dust, and moisture that can begin to erode the bearing’s effectiveness.

Therefore, Slewing bearings are designed for various operating conditions in the construction, wind, and material handling industries. Their enabled features and customizable parameters are robust enough to withstand all harsh conditions.

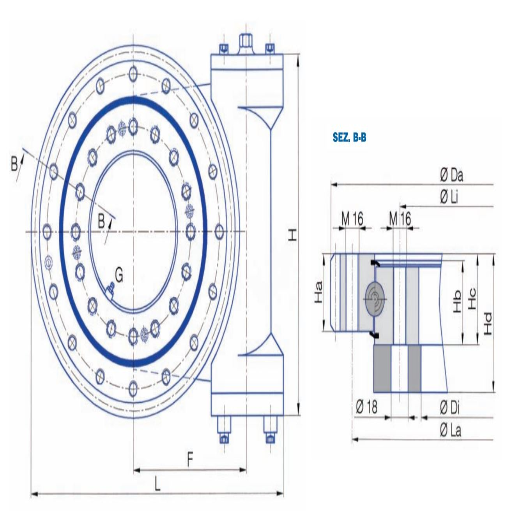

The role of inner and outer rings in slewing bearings

A slew bearing comprises three main parts: the inner ring, outer ring, and rolling elements. The inner and outer rings are the main structural elements that are crucial in permitting rotational motion between two parts that are in connection. Together, these two components transfer the load during the working of the bearing, with one component fixed or rotating in the structure while the other component remains where the load rotation takes place. These rings help in holding concentric positions while taking in radial, axial, and even tilting moment loads, which are necessary under high torsional applications in manufacturing.

Material Composition:

The inner and outer rings are mainly made of high-grade alloy and forged steel to ensure high strength and resistance to deformation and wear and tear.

Applying heat treatments such as quenching and tempering improves the ring’s surface hardness and load-bearing ability.

Dimensions and Tolerances:

Outer diameter (D): 50mm to 10000mm can be the range depending upon the application.

Ring width (H): it is made to compromise the weight and its rigidity.

ISO-based tolerances on precision are critical to ensure great alignment.

Load Capacities:

Axial loads: Usually in kN, which vary from a few to thousands depending upon the application.

The radial loads and moment amounts must be operationally required to smooth the device’s operation.

Surface Finish and Coating:

Phosphate or chrome plating, which are crucial coatings to increase the durability of the surface, are applied to top off the design.

The increased lifespan of the bearing is directly proportional to the lowering of friction by the smooth finish.

For the slewing bearings to work effectively even in the most extreme operating environments, both rings are constructed to be perfectly interfaced with rolling elements and gears. This careful interaction between structure and material characteristics allows these components to operate in various industrial applications.

How rolling elements facilitate rotation in slewing bearings

Steel balls or cylindrical rollers, frequently referred to as rolling elements, are the primary devices facilitating rotation in slewing bearings. These elements are inserted between the two rings in raceways, thus minimizing friction and evenly distributing loads. The energy expenditure of the bearing is also enhanced as rolling elements decrease sliding friction to rolling friction, thereby improving the perfect action of the bearing that can accept axial, radial, and moment loads.

The diameter of rolling elements generally ranges from 10 mm to 50 mm, depending on the bearing’s size and load capacity requirements. Increasing the diameter is often suggested to improve load-carrying capacity but decrease precision.

Material Composition: Hardened chrome steel (usually 100Cr6 or its equivalents) is the most common material used to make rolling elements due to its high strength and resistance to wear and deformation under load.

Number of Rolling Elements: Drag based on load requirements for particular purposes; extra rolling elements are also helpful since they increase the extent of load but at the cost of slightly increasing friction.

Contact Angle: The most common angles for the contact are between 15° and 45°; the contact angle is optimized based on the determination of the type of load the bearing is expected to provide more support, axial or radial.

Lubrication Clearance: Sufficient lubrication is crucial as it keeps the friction level under 0.0015, wears out, and heats the bearing during operations at bay.

These parameters are prudently designed and assessed so that rolling elements can withstand the severe requirements of industrial operations and, at the same time, perform consistently and reliably.

What are the key types of slewing bearings?

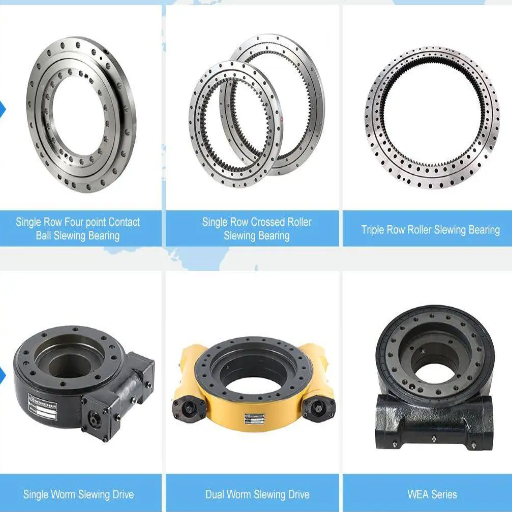

Four-point contact ball slewing bearings explained.

The author believes four-point contact ball slewing bearings are universal because they cater to axial and radial loads and tilting moments. These bearings comprise an inner and an outer ring with a single row of steel balls in contact with the rings at four discrete points. This feature is unique in that it provides sufficient stability under combined stresses. In addition, slight deformation is achieved so that such bearings are suitable for use in cranes, excavators, and wind turbines.

As far as technical parameters are concerned, those bearings are endorsed due to their particular inner geometry, which is relatively well optimized for:

Load Capacity:

Axial Load: A bearing can be expected to support loads as high as 70 percent of the rated dynamic capacity.

Radial Load: a bore/sleeve can be expected to handle about 10 to 15 percent of the axial rated load capacity.

Justification: This was achieved by using four-point contact wherein a steel ball is retained in each corner of the bearing, hence able to hold a significant amount of loads.

Material Strength:

Rings usually are produced from 50Mn steel or 42CrMo steel, which have good toughness and hardenability.

Justification: These items guarantee maximum wear resistance and functionality in extreme conditions.

Lubrication:

Maintaining a grease lubrication clearance is necessary, which results in a friction coefficient of less than 0.0015.

Justification: The lubrication used should be adequate to allow motion rotation without excess heat, preventing overheating in high-load applications.

Rotational Precision:

All tolerances conform to ISO 281 standards, which is expected since the components will be used in high-precision cases.

Justification: Preserves the smooth running of operations and minimizes the possibility of non-optimal surprises.

Due to their proper combinations, the engineered features of four-point contact ball slewing bearings are reliable and effective even in the most demanding industrial environments.

Eight-point contact ball slewing bearings: When and why?

An eight-point contact ball slewing bearing would be used in applications with greater load-carrying capacities and higher stiffness, such as those utilizing four-point contact bearings. These bearings improve the number of contact points between the balls and raceways, increasing their ability to sustain axial, radial, and tilting moment loads. They perform better when high dynamic loads or multidirectional loads are acting simultaneously.

Load Capacity:

All axial or radial load ratings are also high due to the eight-point contact load rating design.

Justification: An even load distribution will alleviate or eliminate stress risers and allow these bearings to function efficiently in heavy-duty applications.

Stiffness:

To work precisely, greater stiffness is required for cranes, high-capacity turntables, or heavy machinery applications.

Justification: Less deformation occurs with higher loads.

Diameter range:

These slingers have relatively larger diameters (e.g., 500mm—over 3000mm), which aids industrial purposes.

Justification: Large structural components will be used to improve and stabilize the task.

Material and Coatings:

Steel that is properly heat treated and has better anti-corrosion surface coatings.

Justification: It will last long and perform well under harsh conditions like the sea or mining.

Eight-point contact ball slewing bearings are perfect for wind turbines, excavators, and other large cylindrical platforms. Their design helps them achieve stellar performance even in the worst conditions, thanks to their capabilities and precision. They can take on heavy loads and operate smoothly.

Crossed cylindrical roller slewing bearings: Applications and benefits

The crossed cylindrical roller slewing bearing has vast applicability due to its construction, which empowers it to handle heavy loads and has absolute stability. Their design enables the roller to be placed at 90° to each other, allowing the beneath surface to swivel freely and bear the entire weight. This makes the device appropriate for contexts that require significant axial, radial, and tilting moment forces.

Crossed cylindrical roller slewing bearings are key in cranes, construction equipment, and robotics because they offer optimum performance in small spaces and are light. Due to their smooth moving mechanism and accurate rotation are also used in CT Scanners and other medical aides.

Technically, the outer diameter of such a bearing lies between 200 and 6000 mm, allowing it to sustain a large load under optimum conditions. These parameters differ depending on the cross-sectional design and roller heights deployed. Additionally, incorporating such systems eliminates extra space between rollers, increasing the bearing’s functionality. This makes them suitable for placement in settings that counter dynamic environments but require collar positioning.

How do slewing bearings handle heavy loads?

Load capacity and distribution in slewing bearings

The load capacity of slewing bearings is distinguished by the unique design of their fabric structure, which efficiently distributes the load across the contact surfaces. These bearings’ load-carrying capacity is due to their cross-roller or ball configurations, allowing them to simultaneously take boundary axial, radial, and tilting moment loads simultaneously. For example, double-row ball slewing bearings with multiple contact points that automatically distribute axial and radial forces are much more effective in cranes or wind turbine applications.

Axial Load Capacity: Several thousands of kilonewtons (kN), depending on the design and size of the bearing.

Radial Load Capacity: Radial loads are lower than axial, but higher capacity vessels can still contribute an estimated figure of ten to twenty percent of the proper volume of the axial load capacity.

Tilting Bearing Load: The bearing’s sectional area and roller configuration primarily determine this load, rounded off in kilonewton meters (kNm).

Rotation Precision: The preload structure is designed to eliminate voids and increase precision cutting.

Dynamic Factors of Shear Bearings The above factors are carefully justified by the characteristics of materials used in the structures, highly sealed systems, and the maximum output interior space of the slewing bearings.

Axial and radial load management in slewing ring bearings

Both axial and radial loads are considered since it is a matter of technical requirements of the whole system regarding slewing ring bearings. Rolling elements generally support axial loads uniformly about the axis of the bearing, thereby making it stable against great vertical forces. This is to say that the axial capacity of the bearing can be around 50-60% of the static capacity depending on the heat treatment process and material properties used in the manufacturing process, which may provide strength and wear and tear resistance features.

By contrast, the roller arrangement and the design of the axial raceway ensure the management of radial loads. These bearings resist radial forces in the range of 10-20% in terms of their axial capacity, and this value depends on the diameter-to-height ratio and the machining accuracy of the raceways. Preloading mechanisms are, however, more often than not, included to improve the load distribution to manage the deflection and performance as uniformly steady as possible.

Justifying these parameters requires using high-grade steel in the bearing’s construction, proper lubrication to reduce friction, and advanced sealing devices to prevent contamination. These combined elements help the bearing engage with high axial and radial loads, increasing its lifetime.

What are the maintenance requirements for slewing bearings?

Lubrication essentials for slewing bearings

Proper lubrication practices are necessary for slew bearings’ operation efficiency and durability. The first step is selecting a grease with better load adhesion and low Smoothness. I also prefer grease with EP additives because they enable handling heavy loads and reduce wear on the rolling elements and raceways.

Those two are concerned regarding the technical parameters and the correct interval for lubrication. Commonly, I maintain these parameters for lubrication and maintenance:

Lubrication Type: NLGI Grade 2 Lithium-based or calcium Complex grease.

Application frequency: Standard regreasing practices (daily) and re-lubrication (once in 50-100 hours of work) or every time a high load, dirt, or water is present.

Grease quantity: Adequate grease should fill all the pack lubrication points to the maximum required level to prevent heat frustrations from overlubrication.

By observing adherence to such measures and watching out for intrusions or grease deterioration, I can boost performance and minimize the chances of damage under different environmental conditions.

Seal types and their importance in bearing protection

Bearing protection uses various seals, each depending on the specific application’s requirements. From my perspective, I usually make it a point to choose seals that will preserve the lubricants within the bearings and protect the bearings from external agents. This is a summary of the types I use and their technical requirements:

Contact seals: These work by providing tight interfacing, creating a tight seal that can adequately protect the rotating components from solid and liquid contaminants. However, tend to cause slight friction, therefore, I use these in applications where mass contamination protection is the most critical issue – for example, during dusty and wet applications.

Noncontact seals: Noncontact seals facilitate thermal expansion, thus alleviating speeding effects and creating heat while offering a modest level of protection. I like using this type on high-speed rotating bearings because of minimal wear and efficiency concerns.

Labyrinth seals: These spiral-shaped seals do a good job in areas with high dust and dirt, requiring long-lasting reliability. I use labyrinth seals in regions with a lot of contamination since the seal is complicated, making it hard for dirt and moisture to enter while reducing friction.

When selecting a particular seal, I look at operating speed, temperature ranges, and contaminant exposure. In many applications, ensuring the right seal type is chosen seems to provide better performance and less maintenance, and the risk of failure due to wearout is also minimized. All these, combined with monitoring and maintenance of lubrication, enhance the life and reliability of the bearings in various operating regimes.

What factors should be considered when selecting a slewing bearing?

Matching bearing type to application requirements

Bearing type and correctly matching it with the application is crucial. This is why the first step is to consider the operating and functional requirements of the equipment. For instance, if the application has a cross roller bearing slewing ring, I would consider using it if there are high axial and radial loads, as it can carry the combined loads efficiently. If, on the other hand, axial rotation is most important, then it would be sensible to use a ball-bearing slewing ring as they tend to have lower friction and, thus, better performance.

Load capacity: Confirm that the bearing can support static and dynamic loads and consider the incidents that may cause it to be loaded. Quality cross-roller bearings, used in highly demanding applications, would meet this demand.

Rotational speed: Rotational designs, such as ball bearings, can dramatically increase the rotation rate per minute (RPM), making them ideal for high-speed designs.

Temperature range: Consider whether the bearing, bearing materials, and lubrication can sustain the specified temperatures. Example application includes standard bearing application of large temperature ranges (-20 degrees Celsius to 120 degrees Celsius)

Environmental conditions: Considering an application’s environment includes exploiting sealed bearings such as double-row or labyrinth bearings in moist places.

Following this order in an application aids in choosing the correct bearing that fits all the requirements specified by the manufacturer or even yourself.

Size and load capacity considerations

Keeping the size and load capacity in mind, I have a particular principle: that the space meant for a bearing in an application has to be correct. At the same time, the bearing should accommodate the bearing diameter requirements. For this, I look at both static and dynamic load capacity. Choosing a sufficient-sized bearing is crucial to avoid distortion or functional difficulties while under load.

Dimensional limits: Emphasis is placed on minimizing excessive dimensions to ensure bearing dimension compatibility with the space criteria set during assembly.

Bearing constant, static, and bearing constant, dynamic: Where K is added to the ones expected to be subjected at the point where the bearing rim circumferential portion and the rolling elements meet such that at the onset of rotation, bearings positioned nominally will be subjected for operational purposes under load conditions where C and C0 are expected.

Forces concerning the applications: These will include checking whether the directed stresses in the bearings are axial and radial forces from violence or the elements.

This directed evaluation enables me to aim at a space-effective density slackening weight, ensuring that the service after performing the function is efficient over time.

Environmental factors affecting slewing bearing selection

Other aspects that I consider in my approach to selecting a bearing include the geographical region, the climatic conditions, the temperature range in which the bearing can operate, and even the bearing’s protection and material composition.

Depending on a specific operational climatic zone, the compactness of a bearing unit and its protection from aggressive environmental factors are considered.

Sealing requirements: For specific applications exposed to dust, dirt, or water, where contamination is an issue, I integrate strong seals into the bearings to control internal contamination and minimize wear.

The first is the shipping area. Depending on the bearings’ materials, shipping sites can be hostile due to dirt and ambient weather conditions. Having bearings consisting of rugged steel and Zinc-coated rust-resistant properties minimizes the chances of corrosion attacks.

Corrosion resistance is closely related to the materials this hard steel is made of. For instance, bearings exposed to marine environments and chemical industries’ humidity and aggressive substances require some coatings. Therefore, stainless steel is always a better choice as it minimizes the chances of rusting.

Vibration and shock loads: Environments with high impact or vibration levels necessitate bearings with higher dynamic load ratings to withstand the bearing stresses without damaging the structure.

All of this information can best be summarized by saying that overreaching performance reliability can be achieved while meeting the specific requirements by including certain physical characteristics of the bearings without sacrificing.

Frequently Asked Questions (FAQs)

Q: What is a slewing bearing, and how does it work?

A: In technical terms, it can be articulated as a lower geometry of an articulation joint: a slewing ring, an outer ring, and an inner ring having ball or roller-style bearing housings. In mundane language, Slew bearing, also termed slew ring, can be defined as a machine part that allows two structures to rotate relative to one another. In the construction and handling industry, cranes, excavators, and wind turbines, among other structures, require rotating mechanisms, and these rotating joints are accomplished using a slewing bearing.

Q: What are the main types of slewing bearings?

A: The main types of slewing bearings include a 4 point contact ball bearing slewing ring, an 8-point contact ball bearing slewing ring, a crossed cylindrical roller bearing slewing ring, a single row ball bearing slewing ring, and a three-row roller bearing slewing ring. All types have distinct bearing performance characteristics according to the application to which they will be used and the load conditions to which they will be exposed.

Q: What is a four-point contact ball slewing ring, and where is it used?

A: A slewing ring with a four-point contact ball bearing will be widely used where considerable radial and axial loads are applied. The versatility of this bearing has made it suitable for use in construction equipment, cranes, and even robotics that require high accuracy with a certain amount of load.

Q: How do slew bearings differ from knockout or regular ball bearings?

A: The main difference is that while both are rolling element bearings, slewing bearings are usually much more significant and accommodate sideways load. Standard ball bearings rotate around the axes. However, asteroids are suspended in a ring to support more substantial structures and often have gear teeth around them for rotational drive. They have counterpart dynamic and static races equipped with internal and external rings to allow complete revolution to any angle.

Q: In your opinion, you would come across slew bearings in which industries?

A: Slewing bearings are used in numerous industries. For example,1) in building and construction where they are used in bulldozers and cranes. 2) in renewable sources of energy such as fields with Wind Turbines; 3) in maritime or oceanic, for instance, harbor cranes and tower cranes; 4) in the space industry and surgery where CT and MRI devices for me to scan pictures with high accuracy are used.

Q: What role does the bearing manufacturing process play in the performance of slewing bearings?

A: Manufacturing the bearing is very important as it affects the performance and lifespan of the slewing bearings. Therefore, making them has to be of a high standard with all the correct tolerances, heat treatment, and the right material. You will find that reputable bearing companies such as SKF and Kaydon Slewing know the bearings technology and materials well enough to use the right ones. Their products have good load capacity, easy rotation, and serve for long enough.

Q: What bearing maintenance for slewing bearings is required?

A: Good maintenance of the slewing bearing usually involves: 1. Lubricating with recommended grease on a routine basis 2. Conducting visual checks for wear or damage regularly 3. Cycling the module’s pre-load and/or clearance to the specified level regularly. 4. Applying effective measures to seal the units against polluting agents 5, measuring the operating temperature and vibration of the rotational movement. Regular maintenance also assists in enhancing the life span of the bearing while operating in an optimal state.

Q: Can slewing bearings be made for different applications?

A: Yes, slewing bearings can be adjusted for any particular need or specification provided. Various sizes, load capacities, numbers, and shapes of gear teeth, sealing solutions, and materials used can also be modified. Custom parts are probably mostly needed for aerospace, defense-related work, and other industries that require specialized industrial equipment for many operational purposes.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8