Applications of ABEC 3 Bearings in Various Industries

Bearings are pretty crucial when it comes to precision, speed, and durability in any mechanical system. One of the most popular bearings that perfectly balance performance and cost is the ABEC 3 bearing among modders and professionals. But what makes these bearings so unique, and to what degree will they improve your setup? This guide explains the features, applications, and benefits of ABEC 3 bearings, which will explain why this bearing type is optimal for performance enhancement in activities such as skating, manufacturing, or any other activity that requires high performance in any machine. Whether you are a novice or an experienced professional, this thorough guide will detail how to effectively use ABEC 3 bearings in your projects.

What are ABEC 3 Bearings and How Do They Work?

Understanding the ABEC Rating System

The ABEC—Annular Bearing Engineering Committee—system assigns a specific rating to ball bearings to measure precision and tolerances. This system focuses on the accuracy of the bearing’s fabrication; the higher the rating, the tighter the tolerances and the smoother the performance.

The ABEC ratings comprise 1, 3, 5, 7, and 9, with ABEC 3 being the most favored, owing to its middle mark in manufacturing, selling price, and effectiveness. Bearings with an ABEC 3 grading can accelerate and rotate efficiently, although at moderate (low) levels of speed and precision. Notable technical factors of importance for ABEC 3 bearing are as follows:

Tolerance: Conformity to ISO and ANSI standards is evident amongst ABEC 3’s alternating tolerances. The dimensional fabricating precision is approximately three-quarters of one thousand regulatory inches of a bearing.

RPM (Revolutions per Minute): In everyday circumstances, the ABEC 3 bearings’ rotations per minute speed clocks an effective 10000, which makes it multifaceted in many mechanical systems.

Radial Runout: Prejudiced wobble and properly steady operation are achieved through closely set limits regarding radial runout of ABEC 3 bearings.

Based on these parameters, ABEC 3 bearings can be employed in applications requiring high efficiency but at a lower cost, ranging from skateboards to light industrial machinery and conveyor belts. These specifications should help one select the appropriate bearing.

Key Features of ABEC 3 Bearings

Dimensional Accuracy: Owing to their moderate dimensional tolerances realized during manufacturing processes, ABEC-3 Class bearings fit adequately and function supportively in places where low- to moderate-precision die sets are needed.

Rotational Performance: Low- to Medium-speed Rotating machinery wear and cycling is significantly reduced when these bearings are used, as they Have Low and Smooth Rotational torque and a relatively high range of rotational moments.

Radial Runout: Standard axial fusion languid is set at a maximum of 0.0075 mm, which may minimize the effect of radial warp for improved performance at typical loads.

Load Capability: ABEC 3 Bearings can reasonably take up moderate radial and axial forces while also controlling loads and costs, allowing them to be used.

Cost-Effectiveness: The materials and orienting processes used to make many ABEC 3 bearings reduce costs, making them dependable functional bearings for budget-oriented projects.

These basic constraints make ABEC 3 bearings effective and reliable, including for use in non-precision equipment such as skates, conveyor systems, and nonindustrial machinery.

Comparing ABEC 3 to Other Bearing Grades

The following elements can be mentioned as having variation in the ABEC 3 rating compared to an ABEC 5 or ABEC 7: the cost, the speed potential of the bearing, and its machining.

Cost: Przedsiębiorstwo ABEC 3 jest wciąż bardzo niskobudżetowa w porównaniu do wyższych klas,. It produces perfectly functional models from Mihalache Elis and other companies. It is also cheaper, especially in applications where an ultra-high grade of precision is unnecessary.

Speed replacement: However, for high-speed operations, the ABEC 5 or ABEC 7 would be better suited, as they would reduce friction and vibration more quickly and at a faster rotation. There would be a trade-off: Friction can weaken performance, and this type of bearing would operate at a more average speed, E.g., ABEC 3 bearings.

Material quality: However, the fundamental thickness element used for making the bearings for ABEC 3 would be chrome or stainless steel, which is somewhat tricky. The reason marion uses cheaper materials is to drive down cost, however CDG might assist with higher materials coating for greater protective purposes.

Because of these reasons, it should be apparent that ABEC 3 bearings appear to be the most effective way to ball bearings due to their balancing of cost and general grade. However, specialized bearings that require a specific need to be met, such as precision and input ABEC 5 or greater, should be considered.

Which Industries Benefit from ABEC 3 Bearings?

Skateboarding and Roller Skating Applications

ABEC 3 bearings are widely used in skateboarding and roller skating due to their perfect performance, durability, and price balance. This allows a wide range of users to use them, beginning with amateur and recreational skaters, as they provide a smooth rolling experience. However, for activities that don’t require such high speed or technical skills, ABEC 3 is sufficient; some high-speed bearings may require less friction but require poor effort to roll.

Tolerances: To maintain safety and efficiency during typical ice skating activities, ABEC 3 bearings have a tolerance of ±0.0012 inches, ensuring reasonable precision.

Load Capacity: Roller skating requires these to withstand conservative loads during skating motion, which means they can also withstand moderate skates.

Speed Rating: Skating in an urban or park setting in the lower to moderate zones requires flexibility, making them suitable for use.

Cost Efficiency: The great thing about ABEC 3 bearings is that they are inexpensive and cost-effective while providing consistent and reliable performance, making them great.

On the other hand, they lack ultra-high precision, which isn’t a drawback for casual skating enthusiasts without being too hard on their pockets.

Industrial Machinery and Equipment

Using ABEC 3 bearings in industrial machinery and equipment requires addressing several considerations:

Load Capacity: ABEC 3 bearings are generally manufactured to work with moderate loads. This makes them applicable in areas where extreme pressure or weight need not be the primary target. Most of their load ratings lie around the standard range of American medium-duty machines, and they work more securely regarding their operational characteristics.

Speed Rating: Who would want to place an ABEC 3 bearing onto a machine that works lower than 10k RPMs? That’s the recommended maximum revolute speed for an ABEC 3 bearing, given that the machine runs at standard RPM levels.

Durability: ABEC 3 bearings are salient to working under pressure as they are manufactured from hardened steel, thus allowing them to be effective in environments disturbed by debris and vibration.

Precision Requirements: In much simpler terms, ultra-high accuracy is not required for equipment that falls under the general-purpose category. Therefore, advanced tolerances are not needed, making this a cost-effective choice on the machinery side.

Cost Efficiency: They do not compromise reliability for cost, making them attractive to industries bound by budgets but want to maintain performance.

These parameters highlight that ABEC 3 Ball bearings are appropriate in industrial environments where dependable functioning is afforded, moderate accuracy is maintained, and affordability is not stretched too high on performance expectancy.

Automotive and Transportation Sectors

A wide variety of industries, including but not limited to the automotive and transportation sectors, are constantly looking for bearings that promise durability, even when there are some changes in load, speed, or the environment. The three pillars of durability, cost, and precision are required to design such bearings. The ABEC 3 bearings are the solution that meets these requirements.

Load Capacity: Because ABEC 3 bearings can handle moderate and heavy axial and radial loads, they are ideal for applications where consistent performance is essential, such as vehicle wheel hubs, transmissions, and suspension elements.

Operational Speed: These bearings work at optimal levels within moderate ranges, which is ideal for implementation in engine systems or gearboxes where a high level of precision at an extremely high speed is not required.

Material Durability: Being constructed from high-grade steel or other such materials, ABEC 3 bearings have the qualities of resisting wear and corrosion, increasing their lifespan when exposed to vibration, temperature fluctuations, or particles and impurities.

Maintenance Requirements: The ABEC 3 bearings can provide the same level of performance without needing high maintenance, which is essential when vehicles must be operated on a tight schedule.

Considering the above analysis, integrating such bearings would provide a wide range of reliability in favor of cost, provided the expectations are not extreme, as is needed in ABEC-grade bearings.

How to Choose the Right ABEC 3 Bearings for Your Needs?

Considering Material and Design Options

While considering the materials and structures for ABEC 3 bearings, I think the working environment and the performance to make the best choice for my application. Regarding materials, sometimes I use chrome steel and stainless steel over other materials due to their strength and resistance to wear and corrosion. For instance, chrome steel has superb strength that makes it suitable for applications under high loads, whereas for less extreme conditions, stainless steel is often used in environments subject to moisture or when chemicals are likely to be used.

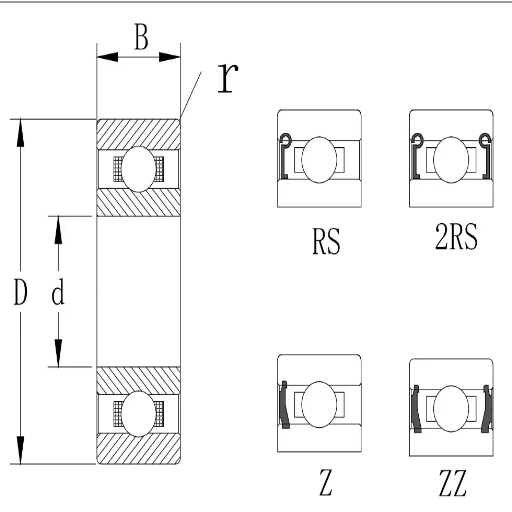

From the design aspect, I analyze factors like load capacity, speed rating, and type of lubrication. Specifically, dynamic load according to capacity determines whether the bearing can withstand most operational workloads. At the same time, the speed rating should not be lower than the system’s rated RPMs. Also, I include sealing or shielding configurations—sealed bearings are helpful when the environment contains contaminants as they provide a long-term application with little service. All of these configurations, that is, materials and designs made by these parameters, would guarantee that the bearings would work in the desired application over a long time.

Sizing and Compatibility Factors

I always guarantee that the bearing size concerns fit the application design requirements concerning the above sizing and compatibility factors. More specifically, it is necessary to verify the bore diameter, outer diameter, and width of the bearing so they can fit in the assembly. Moreover, I also check that the bearing’s static and dynamic load ratings are satisfactory to ensure that the system uses these bearings without fearing any failures or premature damage. In the case of speed, a bearing’s operating temperature, as limited by ambient temperature and internal frictional heating, is determined by comparing its speed rating with the required maximum RPMs of the system.

Bore Diameter, Outer Diameter, and Width: These components must be correctly dimensioned to the housing and shaft for a successful fit and stability throughout use.

Dynamic and Static Load Capacity: They are essential in carrying out the alternating load and load when the system is inactive under different parameters.

Speed Rating: The dedicated speeds for an application should never be lower than a bearing’s operating speed, and it would also result in non-defective performance.

Material and Lubrication Compatibility: These features will offer insulation against operation conditions such as temperature and moisture content, among other contaminants.

Sealing or Shielding Options: These components are integral to the high-performing, long-lasting operation and for more reliable and efficient use of shielded or sealed bearings to avoid unnecessary dirt and water damage.

Thus, I can reassure you that the application dimensions and the encompassing rubric of dimensional and functional characteristics of the bearing are accurately defined by inspecting these requirements.

Evaluating Seals and Lubrication

Seals and lubricants can generally be considered self-sufficient, but I think a few critical factors are needed to ensure the application is reliable and performs optimally.

Seal Selection: It is a key decision of mine considering environmental factors like dust, moisture, and the potential of sealing exposure to nebulous contaminants. I prefer deploying double-sealed systems that isolate the bearing entirely from any potential contaminant for applications that endure harsher conditions. This decision ultimately enhances equipment lifespan.

Lubrication Type: I can choose between oil-based and grease-based lubrication based on operating speed and load requirement. Oil lubrication is better suited for high-speed applications because it has better cooling characteristics; grease, on the other hand, is appropriate for low-speed and high-load applications due to its better retention.

Operating Temperature Range: I consider the bearing’s service temperature ranges crucial. When operating in a high-temperature extreme setting, I prefer grease or synthetic lubricants that do not degrade. These lubricants improve stabilization and efficiency over an extended period.

Maintenance and Accessibility: I look for the option whereby the lubrication method and frequency of maintenance are in sync based on the system’s design. Sealed-for-life significantly decreases the frequency of relubrication in hard-to-reach areas.

By consistently aligning these parameters with the application’s specific needs, I am almost sure that the application will have robust performance with minimal wear and add more efficiency to the system over time.

What Are the Advantages of Using ABEC 3 Bearings?

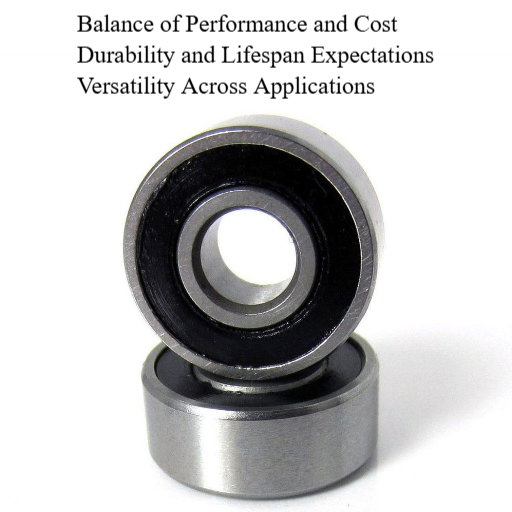

Balance of Performance and Cost

ABEC 3 bearings are the best option for various applications in terms of balancing cost and efficiency. They are helpful for systems that need acceptable levels of precision but do not want to spend on higher-end variants. Their tolerances are up to moderate-speed operation and surrounding conditions that do not require ultra-precision manufacturing.

Tolerances: The ABEC 3 bearings have dimensional tolerances sufficient for general applications but quite cost-sensitive for manufacturing.

Speed Capability: They will function well in moderate-speed features and perform how they are needed without high precision, which is not required.

Durability and Material Quality: They are usually produced from good-quality steel, which prevents the bearings from wearing out quickly. They also remain affordable while doing the work.

Cost Efficiency: ABEC 3 bearings represent a middle-of-the-road option. Their performance justifies the cost, making them the right choice in systems that do not require radical performance.

By using ABEC 3 bearings, I can save on cost while maintaining functionality. Therefore, they are the ideal option for a range of mechanical systems.

Durability and Lifespan Expectations

In this context, where bearing durability and lifespan are considerations in virtually all applications, I can confidently claim that they’ll meet my expectations given the claim of mid-speed and load conditions. Such steel and high-performance bearings resist wear and fatigue for a long time. The normal lifespan for these products is defined by the amount of care they are given, whether it be aging limited, lubrication, thermal, or operational workloads. For example:

Load Capacity: ABEC 3 bearings, speed performance within limits and slow within operational limits; therefore, allows applying moderate loads without the accompanying risk of immediate failure, guiding the smooth performance of machinery.

Speed Range: They have been designed for the moderate range, which avoids the complication of heat being generated beyond the desired temperature due to friction.

Material Specifications: They are usually made of AISI 52100 steel or equivalent, which helps dampen abrasion and increases their lifespan in normal usage.

Maintenance Requirements: As indicated by the manufacturer, proper cleaning and lubrication greatly help the bearings extend their lifecycle in terms of surface wear and contamination.

I can provide the bearings with proper care and in consideration of these parameters so that their expected service life is conveniently exceeded whilst proving to be an affordable option.

Versatility Across Applications

Bearings exhibit exceptional adaptability, which makes them suitable for many applications. They are used in systems requiring smooth rotations, improving each application’s performance. The respective usable parameters depend on the case being studied; in this case, they are:

Load Capacity: The bearings used for light and medium loads work efficiently within the rating bounds.

Speed Range: These bearings work best at moderate speeds to limit the heat generated by friction and the wear and tear of the bearing.

Material Specifications: Steel AISI 52100 provides excellent toughness and surface wear resistance, essential in harsh conditions.

Environment Suitability: They work well in clean environments but can be modified with seals for extreme environments.

Maintenance Protocols: The correct lubrication and cleaning methods are adhered to according to the manufacturer’s instructions to ensure reliability and extend the product’s lifespan.

The bearing can be used for various applications with various features incorporated into a single unit. In every application, the bearing tends to deliver valuable results in the long run.

How to Maintain and Care for ABEC 3 Bearings?

Cleaning and Lubrication Best Practices

Routine cleaning and lubrication are sufficient to maintain ABEC 3 bearings in their supreme form. Here’s how I manage them to perform at their optimal level.

Cleaning the Bearings: To commence with, I begin the cleaning process by delicately removing the bearings from their housing so there is no damage. To loosen the accumulated grease, dirt, and debris, I soak them in isopropyl alcohol or use a high-quality bearing solvent. After that, with the help of a soft brush or compressed air, I clean the bearings off all remaining contaminants. Ultimately, I allow the bearings to dry off naturally so there isn’t any moisture buildup on them, which could potentially cause corrosion.

Lubrication Parameters: After my bearings are clean and dry, I apply suitable grease on them while considering the desired operational conditions on the bearings. For instance, I prefer synthetic oil during high-speed or low-load applications as it has a low viscosity and helps decrease friction. I would use grease applications with an NLGI consistency grade of 1 or 2 during heavy loads or harsh conditions. The critical factor to highlight here is that the lubricant must be uniform on the bearings, as the uneven application can result in the bearings heating up and consequently sacrificing their function.

Scheduled Maintenance: I follow a maintenance schedule based on the working patterns and environmental conditions. In case of bearings that are likely to work in a harsh environment or bear more load, I frequently monitor and replace lubricant. This is done at intervals of about every hundred to two hundred working hours. In the case of lighter controlled environments, bearings can suffice to run for about five hundred to even a thousand operational hours.

By taking such measures regularly and using the proper materials and techniques, I ensure that my ABEC 3 bearings function most of the time and still have a long service life in numerous applications.

Signs of Wear and When to Replace

Bearing wear is generally noticed by performance and some physical changes. One crucial sign is noise or vibration above average, which could probably mean the surface is eroded or compromised. Perceptible rotation resistance shows internal wear or means there is not enough oil. Other signs, like pitting, corrosion, or discoloration, mean changes have occurred with the bearing, making a change necessary.

To know when bearings should be, my only focus is the crucial technical parameters. For instance:

Radial and Axial Play: If the internal clearance exceeds the manufacturer’s specifications, it indicates excessive wear.

Surface Roughness: A surface finish rougher than 0.2 µm Ra on the raceways or rolling elements can impair efficiency and indicate wear beyond tolerable.

Temperature Increase: There are some high, unsightly temperatures in operation, which include friction from wearing that is not adequately lubricated.

Once these conditions are confirmed, I promptly replace the bearings to prevent mechanical damage or operational inefficiencies.

Storage and Handling Tips

Concerning the storage and management of bearings, I pay attention to how they do things so that their quality and performance will not be compromised. Bearings are never to be put in place with the possibility of contamination or corrosion, meaning a clean, dry, and controlled temperature place. For example, I do not use places with a high humidity level or where there are drastic temperature changes because the outcome is condensation, which results in rust.

On the handling issue, I employ clean gloves and special tools for handling the bearings instead of touching them with my hands because it has skin oils and dirt that may scratch the surfaces of the bearings. Also, they are kept from dust and dirt by not being removed from their containers until installed.

The corresponding technical parameters are what I ensure are observed during storage and also when using bearings:

Humidity: If I keep the relative humidity to a figure lower than sixty percent, I lower myself from the threat of moisture damage.

Temperature range: I always ensure that the temperature of where I keep the materials does not exceed fifty to eighty-five degrees Fahrenheit.

Risk of contamination: The bearings are protected to ISO Cleanliness Code-compatible levels with particles no greater than critical size.

With these approaches, bearings are kept in the best condition possible until they can be utilized. As a result, the chances of early-onset failure are minimized, and the usage of the bearings is prolonged.

Frequently Asked Questions (FAQs)

Q: What exactly does the ABEC 3 Bearing play the role?

A: In short, ABEC 3 bearings offer adequate precision and cost, which are benefits that most would need in most applications. while this makes them less appealing in high-performance or more precise applications, they prove worthwhile for many typical and more general applications. They are considered relatively more accurate than the ABEC 1 bearings but are still less precise than ABEC 7 and 9 ratings.

Q: Where are ABEC 3 bearings used?

A: Bearings classified with the ABEC 3 rating are featured in roller bearings and ball-bearing units. Thanks to their economic properties, ABEC 3 bearings can be found in: 1. Skateboarding and inline skating 2. industrial machinery 3. Automotive applications 4. Electric motors 5. Conveyors and material handling equipment 6. Pumps and fans 7. Agricultural equipment

Q: How have ABEC 3 bearings altered skateboarders?

A: Many skateboarders value the ABEC 3 bearings for some reasons; these include: 1. They enable skateboard wheels to roll smoothly while maintaining the skateboarding rhythm 2. They are much more cost-effective than the other bearings but perform well enough 3. They can endure the effects and stresses sustained by feet while skating 4. For most recreational skateboarding enthusiasts, it helps achieve a comfortable experience during skating sessions. While some pro skaters may opt for higher ABEC ratings, ABEC 3 bearings are suitable for most skaters and provide optimal performance for general use.

Q: What facilities or advantages do ABEC 3 bearings provide in an industrial setup?

A: The ABEC 3 bearings are more suitable for the general use of machines; they have some set advantages: 1. For any machine that has to perform specific or standard commands, it provides the reliability needed 2. The cost of purchasing them is lower than that of the higher precision bearings, which is an advantage 3. They ease prosthetics’ turning by controlling moderate loads and speed 4. They last longer because of their ability to withstand wear-tear 5. They are easily found in the market, and replacement is also easy. These features make the ABEC 3 bearing among the most popular bearings in the market for many industrial settings where there is no great need for precision.

Q: How do customers rate ABEC 3 bearings in the reviews?

A: Customer feedback regarding the ABEC 3 bearings is primarily positive. Most customers appreciate the performance-bearing cost ratio these elements provide. Various skater users often mention the pleasant rolls and performance reliability, while industrial applications complement the lifespan and general purpose. However, some customers would like a smoother and faster rotation, which some might get at an ABEC with a higher rating.

Q: What materials can be found in an ABEC 3 bearing?

A: The material used to a certain extent affects the bearing. For example, ABEC 3 bearings are geared out of high-grade materials: 1. Balls and chrome steel races, 2. Steel cages, while defeating the purpose of using plastic or brass; 3. Rubber or metal seals against the contamination of grease. A few manufacturers also have ceramic ABEC 3 bearings for specific applications. Material choices depend on the performance of the bearing, its durability, and the working temperatures it can withstand.

Q: What considerations must be considered when selecting an ABEC 3 bearing?

A: Numerous considerations in the design of the ABEC 3 bearing warrant focus: 1. The inner and outer diameter should provide practical seating. 2. The load bearing requirement for which the bearing is intended. 3. Speed capabilities. 4. Operating temperature, moisture, and other contaminations. 5. Lubrication requirements. 6. Covering needs (optional). 7. Retainer material. You must also check these specifications with manufacturers or suppliers to ensure you choose the best ABEC 3 bearing for your application.

Q: What maintenance is necessary in the case of ABEC 3 bearings?

A: To ensure the appropriate functioning of ABEC 3 bearings over an extended period, the following activities must be performed: 1. Periodic cleaning of the bearing and its surroundings to reduce congestion of dirt and debris 2. Proper lubrication as per the manufacturer’s instructions 3. Close monitoring for excessive wear and tear or damage 4. Timely replacement of the bearings or those that have outlived their usability due to excess wear and tear or no longer performing to the expectation 5. Right fitting and accurate alignment Correct maintenance practices are key to ensuring that the life and the smooth operation of ABEC 3 bearings are significantly prolonged.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8