Applications of End Rod Bearing in Machinery

Regarding modern mechanical devices, rod end bearings stand out due to their nature and application. They assist in controlling motion precisely, allow for misalignment, support heavy loads, etc. Such machines are key in improving performance and efficiency in industrial, automotive, aerospace, and even agricultural, to mention a few. The purpose of this guide is to provide an in-depth understanding of rod end bearings, which includes their design, the aims, and considerations that should be made regarding the application of rod end bearings in machines. Whether you are an engineer, technician, or merely interested in mechanical systems, this document is intended to provide you with the information required to appreciate the potential and significance of rod end bearings as an enabler of future technological advancements and the efficiency of operations. Let’s explore how such small pieces enable several mechanical systems today and how they are effective.

What are Rod End Bearings, and How Do They Work?

Understanding the Basics of Rod End Bearings

Rod end bearings, sometimes called rose joints, heim joints, or spherical plain bearings, are a type of bearing consisting of a housing containing a spherical bearing. These handle rotation and allow for angular alignment of links and systems. The rod end bearings are helpful in precision tasks, enabling movements such as car steering, certain types of machines, and even parts of aircraft.

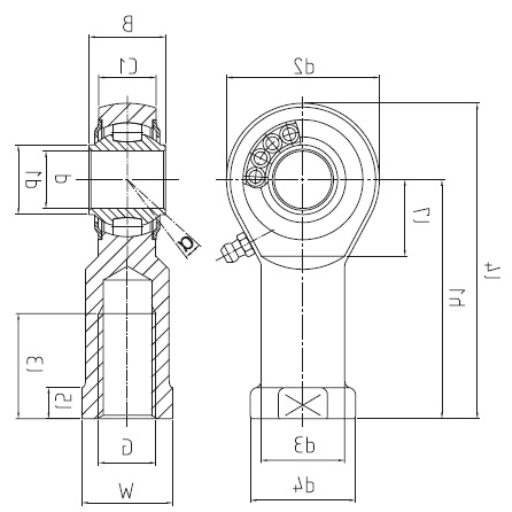

Inner Diameter (Bore): Specifies the size of the shaft that can be fitted, with most ranging from about 4mm to about 50 mm, depending on their needs.

Thread Size: This indicates the size of the connecting rod, which is either given in metric measurements (e.g., M6 and M10) or imperial measurements (e.g., 1/4″-28).

Material Composition: Usually composed of alloyed metal, steel, or stainless steel. The material used will influence properties such as strength, corrosion resistance, and even how much load each bearing can carry.

Load Ratings: Consists of static and dynamic load requirements measured in kN (kilonewtons); kn is a measure of force that constitutes applied load.

Operating Angle: In specific designs, let bearings slide angle, usually not more than ±15°.

Lubrication Requirements: Certain types may have self-lubricating liners, while others require external lubrication after a certain period of use.

These parameters also allow rod end bearings to function under numerous operational and environmental stresses, making them necessary in today’s mechanical systems.

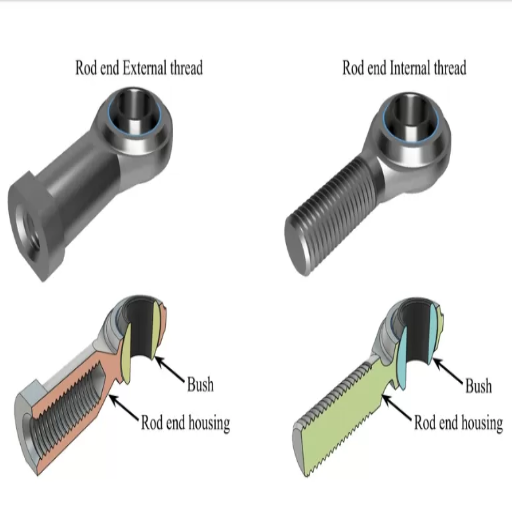

Types of Rod End Bearings: Male vs. Female

When distinguishing male and female rod end bearings, it is important to note their attachment styles and structural interconnection. The external thread of a male rod end bearing is in an outward position, while an internal threaded bore is an attachment on a female rod end bearing. Thus, the use of the assembly configuration depends on the mechanical requirements and the assembly configuration.

Thread Type: Mating components are determined by whether the bearings are male or female, with external threads or internal threads, respectively.

Load Capacity: Both types’ basic designs allow them to withstand axial and radial loads; however, the entire load direction and magnitude should be considered during selection.

Space and Alignment: In linear applications, male rod ends are generally less space-consuming than female rod ends, which could make assembly easier in cramped configurations.

Ease of Installation: Assembly can be easier with female rod ends as the threaded bore can be screwed directly into the rod end, which can simplify a task.

Application-Specific Requirements: Male rod ends can be ideal for applications requiring finer tuning due to the exposed threads.

Last, both designs are dependable and flexible and can be used in various application scenarios in mechanical systems.

The Role of Ball Joints in Rod End Bearings

Ball joints are integral parts of rod end bearings, which offer specific degrees of movement and freedom. These are designed to provide multi-axial motion without sacrificing load-carrying ability, which is vital in situations requiring rotary or oscillating motion under different loads.

Ball Joints’ Key Functions include:

Angular Misalignment – Ball joints facilitate the mechanical connection by compensating angular misalignment between the connected bodies.

Load Transfer – Ball joints prevent stress, wear, and tear of prominent portions by transferring even pressure across the joint. This promotes longevity.

Swinging Movements – Ball joints effectively limit and control peripheral oscillation and movement of the required body.

Technical Specifications:

Construction Material: It is mainly made from hardened steel or certain alloys that prevent corrosion, ensuring sufficient tensile strength for prolonged usage.

Static Load Capacity: It is critical to know such loads are accurate data to use under specific ranges, typically contained on datasheet documents (for instance, up to 30 kN in heavy-duty ones).

Operating Angles: They also can support an assortment of misalignment angles ranging from 10-30 or more degrees, varying with the model.

Thread Size and Bore Diameter: The range of thread sizes from M6 to M30 and bore diameters of 6 mm to 25 mm falls well within the dimensions requiring the specific mechanical set-up.

Overall, in substance, ball joints in rod end bearings allow for accurate motion, load transferring, and system dependence for various mechanically functional purposes. These parts must be designed in a way that would be able to perform particular functions.

Why are Rod End Bearings Essential in Industrial Applications?

Enhancing Machinery Performance with Rod End Bearings

Rod end bearings are intricate yet provide a fair amount of performance as they accommodate misalignments and reduce strain on machines. These components, however, are built to allow force transfer in most situations because they allow for specific angular dispersion, thus making it vital for usage in the industry. Furthermore, these parts are built sturdy and have many specifications, making them reliable.

Some basic technical parameters include thread sizes ranging from M6 to M30, bore diameters ranging from 6mm to 25mm, and load capacities dictated by the system’s needs. A good example would be that with dynamic axial loads being quite variable, choosing a bearing deemed acceptable for the mode of operation to avert undue wear and tear of the equipment or bearing failure is key. Carbon steel, stainless steel, or alloy steel are commonly used, offering durability and corrosion resistance depending on environmental conditions.

Rod end bearings ensure reasonable load distribution and help guarantee that a machine moves in the right direction. This correction of movement reduces machine stoppage time, elevating efficiency in multiple applications across the industrial sector.

Reducing Friction and Wear in Moving Parts

It’s no secret that it is essential to reduce friction between moving congruent surfaces in mechanical systems to prolong the mechanical systems’ efficiency and lifespan of operations. This can be done through the application of appropriate types of lubricants, the proper selection of materials, and the control of the working environment. Lubricants, including oils and greases, coat the surfaces to prevent them from rubbing against each other, reducing the rate of wear and heat dissipated at the interface. Materials selection also matters; for instance, if a component is required to take a particular load, one should select high-strength alloys and composites that would tolerate the load and offer nice wear resistance.

Coefficient of Friction (μ): Materials with a low coefficient of friction should be aimed at as they will increase energy efficiency and lower heat production.

Contact Surface Hardness: Hardness increases wear resistance in high load conditions; surfaces clad above 60 HRC would fit this description.

Load Capacity (Dynamic and Static): Bearings and bearing surfaces only have to support a certain amount of force without fracturing, that force would be the maximum load applied, this measurement is most commonly expressed in kN or N.

Operating Temperature: Make sure the applied materials and lubricants work within the working temperature range of the system, standard lubricants can work in -20°C to 150°C range.

RPM (Revolutions Per Minute): The lubricants and components used in appropriate bearings must be compatible with the system’s working RPM to prevent mechanical binding and wear.

By properly analyzing these parameters, selecting the appropriate material, and selecting an appropriate lubricant, friction and wear in moving parts can be reduced to an optimum value, enhancing performance and lifespan.

Accommodating Misalignment in Mechanical Systems

Several aspects and configurations, however, must be paid attention to while designing mechanical systems that can withstand internal or external mechanical misalignment. They are:

Flexible couplings permit angular, parallel, and axial displacement between shafts. There are elastomeric couplings that apply to powers with moderate application angles. There are also gear couplings that can use a greater angle. Parameters to assess:

Self-aligning bearings: Lubricated bearings that allow for the shaft adjustment for misalignment during operation without appreciable wear or reduced work done. The most common types are spherical roller bearings and self-aligning ball bearings. Key parameters include:

Correct mounting position pursuit and alignment tools: Upon installation, chances of non-preferred angular positions being set can be significantly reduced when precise alignment tools are employed. Parameters to check:

Floating or articulating joints: These are commonly used in piping and robotic arms where dynamic misalignment occurs. The parameters to consider:

While all these solutions don’t eliminate the adverse effects of misalignment, they enhance a system’s performance and increase durability and wear resistance.

How to Choose the Right Rod End Bearing for Your Machinery?

Factors to Consider When Selecting Rod End Bearings

As I set out to find a suitable rod end bearing for the machinery, several factors came into play to help determine the best fit. My primary consideration in this case is the load capacity requirements or the rating of static or dynamic loads. This step is crucial in determining whether a bearing will withstand a certain amount of force, and it entails selecting the maximum axial and radial loads that can be withstood without failure. An analysis of the working environment’s temperature, moisture, and degree of contamination will be required as a rough estimate of the working conditions. Using the right materials for bearings, such as stamped or heat-treated steel or stainless steel components, becomes necessary in high temperatures or hostile environments.

The angle of rotation of the specific device is essential as well. In scenarios requiring high flexibility or angular misalignment around the bearing, I choose bearings designed to have adequate angular displacement tolerance. I also note the thread type and size, as these dimensions can determine how well the bearing will integrate with the assembly type of the entire machine. Maintenance requirements are also important to me, and whenever routine maintenance is unlikely, I prefer using low-maintenance or self-lubricating bearings. In analyzing these parameters, the range of motion that the rod end bearing will be exposed to and the operating conditions and lifetime of that bearing are never in doubt.

Metric vs. Imperial: Understanding Thread Options

When faced with using threads, be it metric or imperial, my choice is informed by the use of precedents and the standardization in the region. Commonly, Metric threads are utilized in sectors where an international standard is required because they conform to the ISO standard; thus, those threads are an advantage in global trade. Such threads are defined in terms of the pitch which is the distance in mm between the peaks of the threads, and the diameter of the thread, thus, very easy to specify. On the other hand, imperial threads, which are more common in the US and Canada, rely on the diameter in inches and the number of threads per inch (TPI) for their measurement, which is convenient for older systems and legacy equipment.

In making informed choices, I evaluate the other technical parameters as such:

Thread Size and TPI: To be appropriate for the task and durable enough to withstand stress.

Load Requirements: Validating that the designed TPI dimensions can withstand shear and pulling loads.

Material Suitability: To ensure that the type of thread used does not corrode or wear off the material relatively quickly.

Standards: Focusing on a thread type compliant with the standards that apply to the given project.

Considering these issues, I am confident that the selected thread type meets the bearing and work rate requirements.

Self-Lubricating Rod End Bearings: Pros and Cons

Pros:

Vernacular lubrication: These bearings virtually eliminate downtime owing to the cost of fault lubrication, the lack of periodic lubrication, and lower maintenance.

Decreased Friction: The self-lubrication factors result in reduced friction, which, in turn, increases operational efficiency and the service age.

Application Range: Wide-ranging operational temperature from -300°F to 750°F, depending on the materials used.

Rust Free: Most self-lubricating bearings are rust-proof and protect against environmental impacts, making them highly efficient in challenging situations.

Lightweight: Lower weights than norms, the bearings are practical for use where weight is an issue.

Cons:

Load Bearing Capacity Deficiency: These bearings mostly take load losses from low to medium with such parameters as static load losses in the 10,000 to 50,000 psi range.

Cost Efficient but Expensive: More consumable but standard bearings should have lower expenses due to increased endurance.

Wear Tremendously: At some point, the lubricating layer deteriorates and requires replacement according to environmental conditions and application.

Material Restrictions: The self-lubricating materials are ineffective in aggressive chemicals or highly abrasive surroundings.

By considering the advantages and limitations alongside particular technical parameters such as load limits, temperature limits, and environmental limits, you will be able to determine whether self-lubricating rod end bearings are beneficial for your project purposes.

What are the Common Applications of Rod End Bearings in Various Industries?

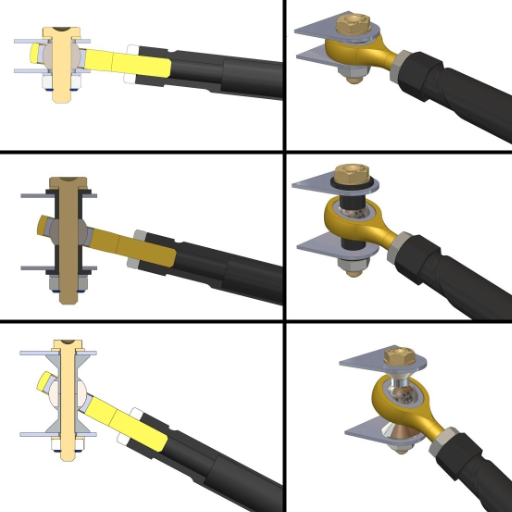

Rod End Bearings in Hydraulic and Pneumatic Cylinders

A rod end bearing’s role in a hydraulic/pneumatic actuation system is to enable smooth motion transfer while addressing operational misalignments. These bearings allow relative movement of parts between them, ensuring the system’s stability and efficiency under dynamic loads.

Load Capacity: Rod end bearings must bear axial and radial loads to secure both safely during their productive life. Although the rated load is gauged based on the bearing’s material and dimensions, it still has to match the output force of the cylinders.

Operating Temperatures: The operating scope for bearings is commonly between 30 F and 250 F, with -34 being the lowest and 121 the highest amount.

Material Compatibility: The best highly corrosion-resistant materials should be used in stainless steel or coated surfaces where moisture levels or chemically active environments are high.

Lubrication Requirements: According to the application and maintenance requirements, self-lubricating or externally lubricated bearings are usually applied.

Angular Misalignment Tolerance: Bearings would have to withstand the angles of misalignment brought on due to the isotropy motion of the cylinder, usually a few degrees, so that effeminacy and, friction, system malfunction are eliminated.

Considering the parameters mentioned above, the rod end bearings can be ensured to correspond to the operating requirements of the hydraulic and pneumatic systems and, therefore, serve for many years.

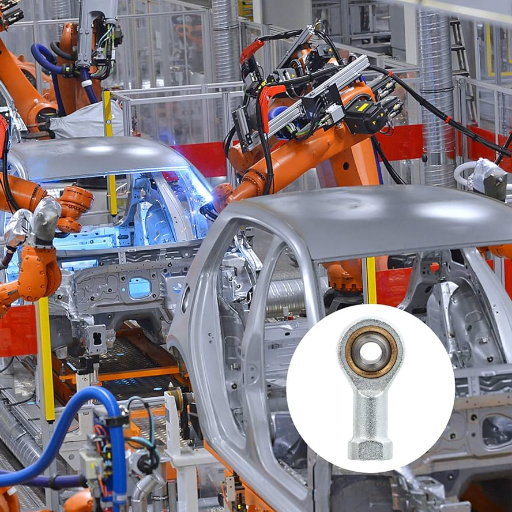

Aerospace and Automotive Applications

Rod end bearings are crucial for aerospace and automotive applications where accuracy, strength, and reliability are essential. Below are succinct responses to the parameters involved and their technical reasons:

Material Selection: Aerospace applications preferably use more substantial, lightweight materials, such as titanium or aluminum alloys, to reduce weight and ensure structural strength in high loads. Automotive applications may also use steel or composite materials to achieve stability, cost-effectiveness, and wear resistance.

Lubrication Requirements: Aerospace bearings sometimes contain sophisticated self-lubricating composite liners to reduce maintenance in hard-to-reach places. Automotive uses may incorporate conventional grease fittings or sealed designs based on temperature, dirt, and exposure.

Angular Misalignment Tolerance: Rod end bearing strength and motion direction vary depending on the application. Due to the sophisticated joint motion of flight control systems, bearings with a tolerance of up to ±5° angular displacements are required for aerospace systems. Similarly, automotive applications such as suspension systems will need a tolerance of more or less ±2-3° to function smoothly during the road dynamics effect.

Operating Temperature and Environment: Aerospace bearings are expected to perform in temperature ranges between -65 °F and 500 °F, which depend on the altitude and the distance from the engine. On the other hand, automotive bearings are designed to perform between -40 °F and 300 °F, which are adequate for engine compartments and exposure to all weather roads. In the aerospace sector, cadmium plating or PTFE are corrosion-resistant coating systems applied to avoid the effect of hostile environmental conditions. In contrast, zinc plating is sometimes used in the automotive industry for the same reasons.

Both industries guarantee the efficient service of rod end bearings by addressing these technical parameters and customizing the materials, lubrication systems, and design tolerances to the required demands.

Industrial Machinery and Equipment Usage

Rod end bearings are vital components in industrial devices as they are precise in their intended motion, robust, and can carry loads efficiently. These components are regularly integrated into devices that need applying torque, such as robotics, conveyor systems, agricultural machinery, and material handling machinery systems. To meet the requirements of the load-bearing setups, several of the technical parameters are to be taken into account:

Load Capacity: The bearings should withstand a quasi-stationary and dynamically varying load. The load ratings vary according to the type of practice and trade stress on a particular machine, enabling it to last longer.

Material Selection: Industrial bearings are usually made from carbon steel, stainless steel, or alloy steel for heavy-duty or harsh-condition use. These steels provide strength, prevent rust, and endure wear.

Lubrication Systems: Maintenance-free self-lubricating bearings made of PTFE are preferably used to reduce maintenance and minimize friction, even in high-stress industrial applications.

Operating Temperature: A working temperature range of around -40˚F to 400˚F is required for bearing use across different industrial setups.

Environmental Conditions: In dirty environments, dust seals or wipers are fitted around the bearings to cover or conceal them.

Alignment Adjustability: Rod end bearings are spherical, allowing geometric adjustment for ease of use in their systems. They enable the systems to which they are attached to rotate about different axes, which is ideal for systems that require motion.

By comprehensively assessing the above-listed technical parameters and making suitable design choices, industrial machinery can maximize its performance while minimizing the amount of operational operational and time and steady-state maintenance costs incurred.

How to Properly Install and Maintain Rod End Bearings?

Step-by-Step Guide to Rod End Bearing Installation

Preparation: Make sure all the necessary equipment is readily available. This includes wrenches, lubrication products, and protective gear. Rod end bearings should be checked for any specification requirements for your application, including load rating, thread size, and operational temperature range (for example, from -40 degrees Fahrenheit to 400 degrees Fahrenheit). Clean all the surfaces that will be joined so that all contaminants are cleared off and do not affect the quality of the bond.

Alignment Check: Examine the assembly that will accommodate the bearing to see whether the axis is off. Spherical rod end bearing is flexible, hence it is prudent to check that the housing and the shaft are in alignment before the operation to avoid any strain or misalignment during the operation of the bearing.

Lubrication: Use the correct type of lubrication according to the norms of the bearing’s operating conditions, including temperature. Wherever the bearings are exposed to the sea or similar environments with a lot of moisture, better-sealed greases will be required to improve performance and reliability.

Mounting: Fix the rod end bearing onto the particular shaft or the mounting point by screwing it into place. If the connection is in the form of threads, a TNC mating parts thread should be free from dirt or damage. Secure the assembly based on the torque values appropriate for the thread type and material.

Sealing and Protection: Install the recommended dust seals, wipers, or protective covers on parts exposed to dirt or debris. This step increases longevity and guarantees that the operation will perform as expected, even under extreme conditions.

Final Inspection: Inspect the completed bearing to ensure its assembly has been done correctly. Confirm that the bearing can pivot and that all required adjustments to the alignment and fit have been made. Ensure there is no unnecessary friction or wobble in the whole assembly unit.

By following these procedures and the specifications of the rod end bearing—the load capacity, axial dimension, temperature limits, and environmental effects—you will achieve satisfactory results when using your equipment. Remember to heed the suppliers’ recommendations to avoid using inappropriate bearings for your application requirements.

Maintenance Tips for Extending Rod End Bearing Lifespan

Regular Lubrication: An economical quantity of lubricant lowers friction and rubbing and thus increases the service life of the bearing. It is recommended that a good quality grease or oil is used that is suitable for the working temperature and load of the bearing. For instance, some lubricants have been designed to operate at -40°F to 250 °F for bearings in extremely low temperatures.

Routine Inspection: It is essential to regularly examine the bearing assembly for any signs of corrosion, deformation, or muddiness. Observing wearing of the bearing surfaces caused by induced loads and ensuring all the surfaces are well aligned so that no additional forces are induced on the bearing components to increase wear.

Compliance with Load Ratings: Verify that the application is within the bounds of the bearing’s static or dynamic load ratings provided by the manufacturer. Going beyond these bounds can damage the bearing or cause mechanical failure. For example, if a bearing’s dynamic rating is 10,000 lbs., ensure the working load does not exceed this rating.

Environmental Protection: If the application is subjected to dust, moisture, or chemicals, use covers, wipers, or seals as appropriate. These accessories protect the encasing from contamination and exposure and keep the application efficient under challenging conditions. Choose seals suitable for the environment and the temperature range used.

Do Not Overload or Misalign: Severely damaging the rod end bearing is caused by its misalignment and the application of excessive load.

Use alignment tools or gauges to ensure proper orientation, keeping within the axial and radial load limits specified within the design datasheets at all times.

Dirt and Components Storage: Before fitting, it is essential that all parts are intact and void of dirt particles, as contaminants can hasten wear. Keep bearings in a dry, cool environment to enhance service performance and prevent corrosion damage.

By following these maintenance procedures and reviewing the necessary technical bulk of information the manufacturer provides, you can significantly enhance the expected duration of use and reliability of rod end bearings in practically every mechanical application.

Troubleshooting Common Rod End Bearing Issues

When looking into problems related to rod end bearings, the below-mentioned would give some guidance and solutions depending upon the technical data:

Excessive Wear or Premature Failure: In the first instance, excessive wear would indicate lubrication, the lubricant materials being compatible with the operational loads, and other surfaces not rough. Such conditions would mean contamination, which would accelerate degradation. Recommended parameter checks would include radial and axial load ratings, operating temperature range, and intervals for lubrication.

Noise or Vibration During Operation: Abnormal noise or vibration would suggest misalignment or improper bore fitting. Whether this alignment has been achieved could be established by using alignment tools while confirming that the required bore dimensions are within tolerance limits. Check for any signs of damage or fatigue. Most importantly, key parameters such as the nominal bore diameter and the spherical plain clearance must be addressed.

Corrosion or Environmental Damage: Corrosion can indicate the absence or improper selection of seals or the choice of wrong materials. Ensure the bearing material selection is by its intended use. One may choose stainless steel or surface-treated bearings for harsh conditions and make sure proper sealing is functional, including the IP ratings if required.

Cracking or Fractures in the Bearing: In many cases, cracks occur during bearing usage due to unguarded load-bearing or improper installation. Once again, this emphasizes the need to evaluate static and dynamic load specifications, review the torque values used during installation, and apply them again.

The Stick-Slip Motion or Binding: This Jones and Childress provided remedy could surface out due to lack of lubrication or improper finishing of the candidate for this remedy. Explore the articulation of the joints and ensure that the desired grease or oil is introduced as anticipated.

By systematically tackling such issues accompanied by the reason’s sensitivity, adding technical parameters brings a pragmatic and straightforward approach toward rod end-bearing repair.

Frequently Asked Questions (FAQs)

Q: What purposes do end rod bearings serve in the machines?

A: End rod bearings are used in various industries and applications, such as automobiles, aircraft, agricultural machines, and other industrial tools. They permit rotation or controlled motion in the drivetrain, suspension, and steering linkages. In machines that need rotary or oscillating movement, these bearings reduce friction and wear on the components.

Q: What distinguishes end rod bearings from other varieties of ball bearings?

A: End rod bearings, instead known as rod end bearings or heim joints, comprise a self-aligning ball bearing inserted into a rod end bearing housing. They are unlike the ball bearings as they do not have to be mounted parallel to the shaft’s center line and can bear radial and axial loads. This makes them suited for areas that require self-alignment and flexibility.

Q: What are the advantages of using female rod ends in machinery?

A: Female rod ends are advantageous in machinery applications. They form effective connections because they have a female thread designed for easy attachment to threaded rods or bolts. This design also enables speedy installation, adjustments, and even replacements. Female rod ends are also highly load-bearing because they can accept both right—and left-hand threads, making them suitable for multiple machine setups.

Q: Are end rod bearings available with different thread options?

A: End rod bearings come with several thread variations per the customer’s requirements. Right-hand threads and left-hand threads are the most common. These two types of threads facilitate using different thread types in the same machine, which is plentiful. When purchasing end rod bearings, you should inform your seller of the exact thread type you need for the end rod bearing used for your machinery.

Q: What rod ends series is suitable for my machinery?

A: When addressing the question of what rod ends series to use on the equipment, it depends on load capacity requirements, the operating conditions of the application, and the space available. The size of the rod end ball and the material it is made of, e.g., a steel rod end ball, and the type of series, such as POSB8. We must also determine the degree of freedom of the robotic end effector or a finger design and the environmental conditions so that [disc] s rubbings are dustproof. Should you require advice on a particular series selection of rods, talk to a bearing expert or browse a bearing manufacturer’s catalog.

Q: Rod bearings can also be used instead of connecting metal rods in machines—is this correct?

A: In most circumstances, end rod bearings, such as pre-existing bearings, can replace end rod bearings on the same machines. However, this should work too on the condition that the bearing to be put is identical if not the same as needed for the application, particularly bearing dimensions, load bearing, and thread design. To ensure proper installation and optimum interface properties, when changing bearing pay attention to their position relative to the transfer shaft, crossways lubricating oil, apart from that has replacement to upgrade.

Q: Where can I find a large inventory of end rod bearings for the machine I need?

A: Many end rod bearing manufacturers specialize in making end rod bearings, including National Precision Bearings, which maintains a large rod ends inventory, including popular sizes like large rod ends. Most of these vendors are dealers, and you can contact them to get needed information on end rod bearings, such as their replacement manufacturing or installation. If they have difficulty deciding online, they can also ask customer service representatives for any queries.

Q: How do I maintain end rod bearings to ensure optimal machinery performance?

A: Remember that end rod bearings require replacement at times, so to do that effectively and maintain end rod bearings, the rod end’s maintenance is lubricated and periodic inspection. Regularly clean contaminated and corroded rod ends and ensure they are not damaged. To avoid corrosion from dust and other environmental factors, bind rod ends with seals or boots. If a rod end makes strange noises, vibrates, or has excessive play, immediately replace it.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8