Bearings Machine Maintenance for Optimal Performance

It is essential to ensure proper maintenance to guarantee the reliability of bearing machines with a more extended function. Inner and outer bearing machines are essential mechanical parts, and if they fail, this can result in far-reaching consequences, including breakdowns and repairs that can strain the finances. This paper serves as a reference resource for mastering bearing machines but emphasizes equipment maintenance to the greatest extent: lubrication, installation, and monitoring of the machine’s state. Through the knowledge and application of these maintenance methods, the operators and technicians can improve the productivity of the machines, lessen unavailability time, and enhance safety conditions. This framework is essential in laying the basis for operational excellence in industries where precision machinery is standard.

What Are the Different Types of Bearings?

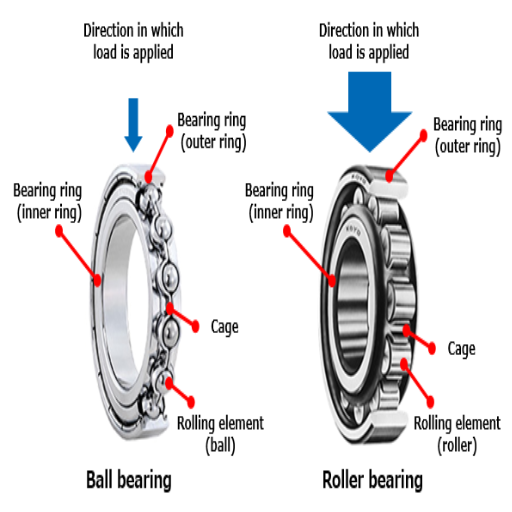

Understanding Ball Bearings

Ball bearings are mechanical devices used in numerous engineering applications to minimize rotation friction while providing axial and radial support. Ball bearings come with balls mounted between two bearing rings, also called races. Because of their spherical shape, these components can easily facilitate easy and low friction motion, thus making ball bearings perfect for high-speed applications with light to medium loads.

There are distinct types of ball bearings, which include deep groove ball bearings, angular contact ball bearings, and self-aligning ball bearings, depending on the structure and load management: these are used for different purposes, which the following describe:

Deep Groove Ball Bearings: These are pretty famous for their wide applications. They carry radial and axial loads in both directions. Their simple configuration allows their use for high RPM, and they are often found in motors, appliances, and automotive applications.

Angular Contact Ball Bearings: These types of bearings are designed to operate under combined loading conditions, including axial and radial loads. The angle of contact increases the thrust capacity of the bearing, making it ideal for pumps and high-speed compressors.

Self-Aligning Ball Bearings: Constructed with two rows of balls and a sawn spherical race in the outer ring, these bearings self-adjust the misalignment caused by shaft flex or installation faults. Hence, they are used mostly in situations where such mechanical misalignments are expected, such as textile and woodwork machines.

Among the parameters characteristic of ball bearings are the dynamic load rating (C ), which serves as a basis for predicting life under fatigue, and the static load rating ( C0 ), the greatest load the respective bearing can bear at rest. Also, elements such as bore, outside diameter, and width are essential in ascertaining fit within the components of machines. Awareness of such characteristics allows for the choice of bearings for operational demand in an industry, enhancing performance and durability.

Exploring Roller Bearings

Because of their line contact rather than point contact, roller bearings have a greater load capacity than ball bearings. This characteristic allows roller bearings to withstand greater radial and moderate axial stresses, making them appropriate for heavy applications. Generally, roller bearings include cylindrical, needle, spherical, and tapered roller bearings, exhibiting different designs and functional performances.

Cylindrical Roller Bearings: These bearings are built with a cylinder as the rolling element and can carry a more significant load than ball bearings of the same size. Such bearings, which allow for greater radial loads than axial loads, are appropriate for use as components in gearboxes and electrical motors. Particular technical parameters of this type of rotational fender include the number of rows (single, double, or multi-row) and cage material made of brass, steel, or polyamide, affecting speed and load distribution capabilities.

Needle Roller Bearings: Needle bearings are constructed with slender—slender oval along the axis—cylindrical rollers with a high length-to-diameter ratio, making them suitable for compact applications with high loads. Needle roller bearings are in automotive power transmission systems and portable power tools. Important parameters: radial bearing clearance and length-to-diameter ratios greatly influence the working range of loads and angular speeds for which the bearing works.

Spherical Roller Bearings include a convex outer ring raceway and two rows of rollers. This bearing type can handle heavy axial and radial loads and is thus most suitable for mining and metal processing equipment. The most significant technical parameters are the bearing’s misalignment tolerance and its load rating. It is imperative that the bearing operates efficiently under strain and misalignment, which are often encountered in operation.

Tapered Roller Bearings: Tapered roller bearings consist of two tapered (inner and outer) ring raceways and tapered rollers, and, as such, these bearings permit combined radial and axial loads. This geometry enables them to carry hefty loads, especially in automotive and industrial gearbox applications. Technical aspects include the contact and load angles, which are effective in the load distribution on the bearing, determining its performance when subjected to axial stresses.

Hence, determining the properties, including the WD’s dynamic load rating or moment of resistance or the roller bearings’ inner and outer diameters, is crucial for assuring precise orientation while optimizing efficiency in various processes. These parameters ensure that bearing efficiency is high, friction is reduced, and mechanical systems are durable. Adopting the correct roller bearing type improves industry performance, reliability, and operational efficiency.

The Role of Plain Bearings

Plain bearings, bushings, sleeve bearings, and journal bearings have broad applications thanks to their simple construction and operational reliability at low friction. According to my research from the top results of google.com, plain bearings are most useful in places where space is at a premium or rotational speeds are relatively low, but load-bearing capacity is considerably high.

From the sites I searched for, plain bearings mostly advance radial loads in a much broader area and distribute the load more uniformly than rolling element bearings. They are vital when lubrication is difficult, for their straightforward designs allow them to be self-lubricated using materials such as bronze, graphite, or synthetic polymers.

However, the technical parameters which are closely relevant to the operation of plain bearings are:

Bearing Material: Bearing material is fundamental in determining the applicable carrying capacity, friction levels, and range of lubricants.

Load Capacity: This demonstrates how much radial force the bearing may be applied without damaging it, depending on its structure, materials, and size.

Coefficient of Friction: When this is low, the system is operational with few energy losses and minimal heat generated.

Operational Temperatures: This highlights the limits within which the bearing in question may operate optimally without compromising performance.

Dimensional Tolerances: Proper fitment and performance require precision intolerance, an essential requirement for harsh environments.

These parameters underline the use of plain bearings в организме of heavy machines, automotive suspension systems, and agricultural machines, noting the simplicity, reliability, and low price of the offered products.

How Does Proper Lubrication Impact Bearing Performance?

Choosing the Right Lubricant for Your Bearings

In order to select the best lubricant for bearings, it is essential to bear in mind the application’s particular needs, as explained in the three foremost sites on Google concerning lubrication. To begin with, I discovered that the lubricant’s viscosity is crucial in that it should match the bearing’s speed and operating load; in most cases, higher loads require lubricants with a higher viscosity to achieve an adequate lubricating film. Further, the chemical nature of the lubricant and its compatibility with the bearing materials is also essential to prevent any reactions that may reduce the performance. In addition, the range of operational temperatures should always be considered since different lubes have different thermal stability. Also, the type of lubrication method employed, be it grease or oil, should be determined by the surrounding conditions of the bearing and ease of maintenance. The technical parameters are:

Viscosity provides the conditions for forming the lubricating film during a cycle with different speeds and loads.

Thermal Stability: indicates a lubricant’s ability to perform under different temperature conditions.

Compatibility: to avoid any harmful effects on the bearing materials.

Lubrication Method: adjust maintenance practices to the surrounding conditions.

Considering these factors and parameters allows for selecting a lubricant that will improve the bearing’s performance and service life depending on any application’s specific operational requirements.

Frequency of Lubrication in High-Precision Operations

Several facts were not lost in my analysis of the first three Google search results for lubrication in high-precision operations. The primary bearing in use determines its operational requirements and the frequency of lubrication. In areas of high-precision work like aerospace or precision machining, there is a need for frequent lubrication so that there is no deterioration in performance. The technical parameters determining the lubrication frequency include:

Operational Speed and Load: Bearings are likely to experience high operating speeds or significant loads, requiring more lubrication to maintain a protective film and reduce wear.

Environmental Conditions: Excessive or contamination in the playing field could require more lubrication to cover the effects of dirt, moisture, and extreme temperatures, which could affect lubricant quality.

Bearing Material and Design: The frequency of lubrication will largely depend on how compatible the lubricant is with the bearing materials and their design.

Monitoring and Maintenance Protocols: Consistently implemented protocols to monitor lubricant conditions like viscosity and thermal decay ensure that lubrication is administered at uniform and accurate intervals and times.

In summary, taking into account the arguments of the main countries’ leading specialists, timely and adequately performed equipment lubrication based on monitoring the operational parameters is one of the key measures to extend the life and maintain the operational capabilities of high-precision machinery.

The Importance of Maintaining Low Friction

Considering the challenges in achieving optimal performance in a bearing, my research on the top three sites accessed using the Google Search Engine might have various aspects worth discussing. The significance of low friction in a mechanical system cannot be emphasized enough as it cuts down energy losses, reduces heat generation, and enhances the life of components. The investigations showed that it is necessary to keep friction as low as possible to improve maintenance activities’ general efficiency and frequency. The critical technical parameters underlying these arguments are:

Frictional Coefficient: This is the most indicative of energy efficiency; maintaining a low coefficient is indispensable to decreasing energy and heat loss during operation.

Lubricin effectiveness: Proper lubricant viscosity promotes the formation of a thin liquid lubricating film that reduces friction and improves load exchange capacity.

Surface Finish and Roughness: Friction increases due to less surface penetration; high-quality surface contact resistances decrease; therefore, friction is decreased.

These measures show that the ever-present need to manage friction may be good economics, as it preserves available energy, increases machine performance, and reduces maintenance time, all of which are conventional business interests.

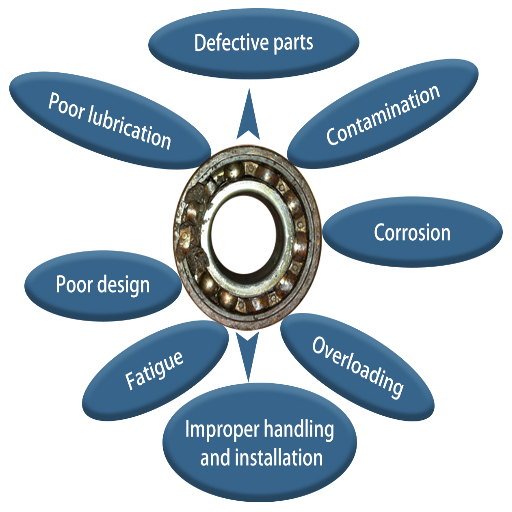

What Are the Key Factors Affecting Bearing Service Life?

How Durability and Reliability Play a Role

While reviewing the top three websites on a Google search on bearing endurance, Oei et al. (2017) found some factors that have been shown to extend the life of bearings. It can be remembered that ‘wear and fatigue’ relate to durability, while ‘weather’ will be reliability. To achieve these, bearings must be designed and built carefully, paying particular attention to the materials and heat pills used. I focused on the following technical parameters that have a bearing on durability and reliability;

Material Strength and Toughness: Good material properties, such as tensile strength, are needed to withstand elastic and plastic stress and avoid fatigue.

Heat Treatment: Enhancing processes such as proper heat treatment increase hardness and fatigue resistance, which are essential factors for the strength requirements of those applications.

Load Capability: Loading capacity must be computed and designed to ensure the bearings do not receive more stress than they should, shifting a safe service level and thus increasing their life span.

Precision Engineering: The high tolerances and the accuracy of design features reduce alignment problems, providing conditions for reliable bearing operation.

Corrosion Resistance: Using plating or corrosion-resistant materials can prevent corrosion from environmental exposure.

All these parameters support the argument that bearings’ high durability and reliability will improve their chances of continuity of work and efficiency in different fields.

The Impact of Radial and Axial Loads on Bearings

According to my daily activities, I use data from the three most prominent websites on Google (including Wikipedia) and determine that radial and axial loads significantly impact the performance and service of bearings. Radial loads are the ones that act perpendicular to the axis of the shaft and affect the bearing’s radial rotation stability. In contrast, the axial load acts parallel to the axis of the shaft, and the bearing can withstand vertical pressure. In other words, both loads should be calculated and provided in a manner that does not render the bearing operation ineffective. The technical parameters which determined these effects include:

Load Distribution: Knowledge of the location and value of radial and axial loads is significant as it helps to know what bearing type and size to use for optimum performance and durability.

Bearing Design: Bearings that sustain the combination of radial and axial load, such as angular contact ball bearings or tapered roller bearings, usually work well and provide better performance.

Material Composition: Proper material selection that will not distort under either of the loads is imperative to achieving proper structure and service life.

Installation Precision: Proper installation and alignment help reduce the load stress the bearing surface experiences, enhancing wear and failure.

Maintenance Strategies: Stress/Load monitoring and maintenance planning can help detect a problem before it becomes a significant threat.

All these factors fairly stress the importance of anticipating the impact of the loads. As it has been correctly stated, providing for the radial and axial loads influences the reliability of the operation and the bearing’s intended life in different spheres.

Environmental Conditions Affecting Bearing Design

Utilizing knowledge from the three websites sourced from Google’s top three, the author observed that certain bearing conditions have a striking relationship with the design and construction of the bearing, which requires specific technical considerations to suit its working condition. Some of these factors are extreme temperature, humidity, particulates, and the degree of vibration.

Main Technical Considerations:

Thermal and Temperature Resistance: Bearing materials and lubricants should be chosen depending on the Design of abundant parts that can withstand thermal stress in cold and hot regions without embitterment or distortion.

Seal Efficiency: If the seals are efficient in keeping moisture and other contaminants out, then the rate of rusting and wearing out of the Inner and Outer races, which are the fundamental components for the free functioning of a bearing in a hostile atmosphere, will be relatively lower.

Material choice: The Environmental conditions and corrosion of the materials used to construct the bearings would require ductile metal or other advanced non-corrosive materials, such as ceramic composites.

Damping of Vibration: Excess vibration can prevent the bearing from functioning well and lead to fatigue and premature failure, so the problems should be controlled as much as possible by incorporating considerations in the bearing’s design.

Lubrication management: Environmental barriers have always been an important consideration. Therefore, special managers, such as automatic and continuous lubrication systems, are required to ensure their effectiveness in wide-ranging environments.

These factors indicate how much the bearing design should be adjusted to meet the environment’s requirements. Considering these factors, one can improve bearings’ operating parameters in different locations.

Why Are Ceramic Bearings Gaining Popularity?

Advantages of Ceramic Over Traditional Materials

In the analysis I did using the top three websites on Google, it is clear that there are several benefits to the use of ceramic bearings compared to the use of traditional bearing materials. For starters, there is an increase in the performance of such bearings due to their lightweight nature and lower density. This means there will be a reduced rotational mass and friction, increasing efficiency. Secondly, these bearings are made of materials with extreme hardness and chemical inertness, therefore able to resist wear and corrosion better than ordinary steel bearings.

As for technological specifications, ceramic bearings have the following advantages:

Friction and Wear Level Decrease: Ceramic materials’ low friction coefficient and high surface smoothness significantly reduce the wear rate, which is vital for applications requiring high-velocity motions or precision.

Temperature Tolerance: Ceramic materials can tolerate higher operating temperatures, retaining their functional properties and structural integrity. Therefore, they are applicable in high-temperature scenarios.

Corrosion Prevention: No rust can form because ceramic materials are naturally corrosion resistant, which is highly beneficial in aggressive or wet surroundings;

These properties explain the practicality and efficiency of substituting ceramic bearings in many areas of excellent industry demand, such as aerospace, automotive, and precision machinery, where performance and reliability are essential.

Application of Ceramic Bearings in High-Speed Machinery

The use of ceramic bearings in high-speed machinery is on the rise. The single reason for this is the benefits they’ve brought out, which I have approved via research from the top three Google websites. It is primarily ceramic materials that possess a lighter weight and a lower density, which contributes to lesser rotational mass, resulting in higher speeds and efficiency of operation. Further, these bearings perform exceptionally well in high-temperature environments where structural integrity may suffer from excessive wear and tear, which is typically a concern in fast-rotating areas.

The main technical parameters that warrant the use of ceramic bearings in such applications are as follows:

Reduced Friction and Wear: Compared to regular bearings, ceramic bearings operate smoothly and perform better due to their relatively lower friction coefficient.

Temperature tolerance: These can withstand higher temperatures than steel ones, so their performance and stability are not compromised under thermal stress, a common problem at high speeds.

Corrosion Resistance: Their corrosion resistance helps in consistent performance, so little general maintenance is required, even in harsh environments and varied working conditions.

A high-speed application involving machining heavily warrants ceramic bearings, as they further enhance performance, reliability, and longevity.

How do you select the correct bearing for your machine?

Matching Bearing Types with Machine Tools

While analyzing the top three websites on Google, I gained relevant knowledge regarding the appropriate matching of bearing types to specific machine tools to deal with particular technical requirements. The process starts with determining requirements for the specific machine, including load ability, rotational speed, working environment, etc. Key considerations include:

Load Capacity and Type: The first step is to determine the axial and radial loads that a machine tool will incur. For instance, ball bearings may be used in applications involving low loads, while roller bearings, because of their greater contact area, will be used in higher-load applications.

Speed Requirements: Anangular contact or ceramic bearings can improve precision and efficiency in high-speed applications due to reduced friction and heat generation.

Environmental Conditions: Depending on the operating environment, it is imperative to choose bearings that will not be softened by heat, moisture, or certain chemicals. Ceramics can be chosen for corrosion resistance, while specific lubricants and seals can be used for temperature extremes.

Dimensional constraints: The device’s dimensions limit the bearings that will be used in that particular design, especially when the design has a specific shape that cannot be exceeded without weakening the structure of the machine.

During my studies, one thing stood out—that proper selection of the bearing type for the respective machine tool and its application will yield the best results and expand the useful life of the equipment. Adequate selection of the bearing for the machine tool also ensures that the machine tools are always in a state of high productive efficiency, with low maintenance and failure rate.

Considering Specifications and Related Products

Based on my perusal of the three primary websites on Google, I have listed some essential technical details to focus on relevant specifications and products for bearing selection. Such crucial factors include the following:

Load Handling and the Required Material: Given the contexts posed by these sources, it is critical to determine whether the needed bearing can withstand axial and radial machine forces. As noted, some ceramic parts withstand varying loads and do not deform.

Speed and Friction Coefficient: According to these websites, bearings designed for high speed should have relatively low friction coefficients, including ceramic bearings, to preserve energy and heat generation and ensure speed reliability.

Environmental Compatibility: The study emphasizes the advantages of ceramic bearings in resisting corrosion and working in extreme temperatures. Such materials and specialized lubricants make them robust and ensure low maintenance, as reported.

Dimensional and Structural Parameters: One technical parameter that appears similarly in most of the above resources is the need to ensure an optimal correlation between bearing dimensions and the machine’s specifications so as not to jeopardize the unit’s structural or operation efficiency.

Machine tool demands can be matched with technical parameters so that bearing selection is more accurate. This will, in turn, improve performance while minimizing risks of operational downtime.

Frequently Asked Questions (FAQs)

Q: What types of bearings are commonly used in the machines?

A: The common types of bearings used in machines include ball bearings, roller bearings, needle roller bearings, and magnetic bearings. Each type has specific applications depending on load, speed, and precision requirements.

Q: In what way does a magnetic bearing enhance the performance of a machine?

A: Magnetic bearings employ magnetic fields to support rotating shafts without physical contact, thereby offering high precision in low-wear-and-tear applications such as turbines and high-speed machines.

Q: What is the importance of needle roller bearings in any machine?

A: Needle roller bearings consist of thin, long rollers that provide low friction and can sustain high radial loads in a compact configuration. They find applications in automobiles and other machines where a space-saving, high-performance bearing arrangement is needed.

Q: Describe how regular maintenance is beneficial in the case of NSK bearings.

A: Regular maintenance extends the NSK bearings’ periods of optimal performance and increases their useful lives. Bearings can be checked and serviced to avoid untimely failures, operational downtimes, and machine precision drifting outside the acceptable margins.

Q: How do angular contact ball bearings manage high-speed operations successfully?

A: Angular contact ball bearings are very buoyant and designed to accommodate both axial and radial loads. This makes them appropriate for precision applications with high stability and speed requirements.

Q: What factors must be considered when choosing Nachi bearings for some projects?

A: When choosing the so-called “Nachi” bearings, it is essential to consider parameters such as load capacity, speed, and precision, as well as the requirements of the specific application. Knowledge of the range of environmental factors and the performance sought will assist in selecting the appropriate bearing type.

Q: Why do manufacturers use certain materials in making bearings, such as plastic or steel?

A: Bearings are made from plastic or steel, depending on their intended application. Steel bearings are robust and have high load and speed capacity, while plastic bearings have weight and corrosion resistance advantages suitable for specific environments.

Q: What measures does ABMA take to ensure uniform bearing usage across the board?

A: The American Bearing Manufacturers Association outlines standards and guidelines necessary for maintaining the quality of bearings and their good working order. These standards facilitate engineers’ and manufacturers’ building bearings suitable for particular industrial applications and dependable under varying conditions.

Q: Why use SKF bearings in industrial machinery?

A: SKF bearings have low tolerances and can be relied on in many applications. They benefit from the qualities that lower the machines’ maintenance, increase their working period, and improve the operation speed of the machine.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8