Benefits of Using Friction Bearings in Machinery

Friction bearings, an essential machinery element, are responsible for the efficient functioning of mechanical systems. Unlike the moving parts of a machine that employ rolling bearings, which also aid in motion transmission, these moving parts are restrained and use bearings that use sliding motion. Friction bearings provide a perfect solution for different mechanical applications due to their uncomplicated design, economy, and load-bearing capabilities. This article discusses the key benefits of friction bearings, focusing on the longevity, preservation, and efficiency of usage. Through these aspects, the reader understands how friction bearings improve the performance and reliability of machines in the engineering field.

What is a Friction Bearing?

Understanding the Friction Bearing Concept

Friction bearings are also known as sliding bearings because they depend upon the sliding of two or more bearing surfaces toward that of rolling bearings, where balls or rollers are used to effect rotation. Its simple structure enables them to endure high stresses and even facilitate higher velocity operations. In most cases, the friction bearings find application where high revolution speed and weight balance of the object under rotation are essential.

Technical Parameters:

Load Capacity: Radial and axial loads are endured by friction-bearing structures and help perform tedious functions with friction-bearing structures.

Friction Coefficient: This should actually be of interest as it also impacts the performance of the bearing. The coefficient of friction for plastic friction bearings can range from 0.001 to 0.3, considering the material.

Operational Speed: Operationally, such bearings can function at all ranges of speeds, but the best performance is exhibited at lower and medium speeds, where the heat produced by friction is kept within limits.

Material Composition: Metal matrix composites, bronze, and transparent polymers such as soft plastic are the most used materials, although the sleepwear resistance versus load should be optimized for selection purposes.

Maintenance and Lubrication: When wear and overheating are dealt with, the service life of the bearing is assured; thus, regular maintenance has to be conducted with the applications. Self-lubricating bearings are maintenance restrictions reducing progressive improvement in extensive work or redevelopment construction of new techniques embedded within the load-bearing element.

Temperature Range: In general, their working temperature range varies from -200°C to about 400°C, depending on the materials and lubrication used.

Friction bearings have remained useful and widely used in different industrial areas for a long time due to their efficacy and durability, which are backed by these technical aspects.

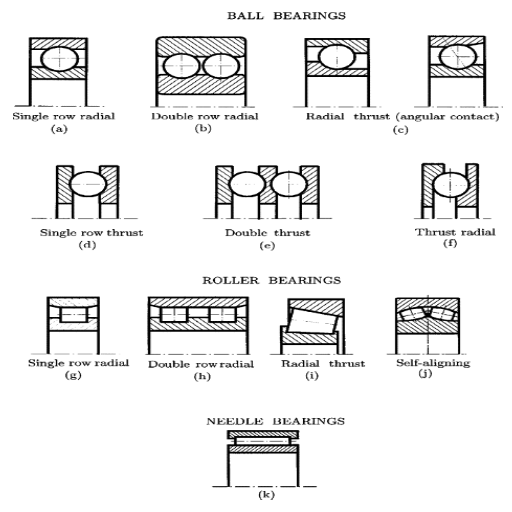

Types of Bearing Systems

While I was attempting to find out the differences between different types of bearing systems, I found information using the top three Google websites that bearing systems can be classified into two broad categories: plain bearings, which are also referred to as bearing friction systems, and rolling-element bearing systems.

Plain Bearings: Such is what I called friction bearings in the previous section. These transfer the load through surfaces in relative motion. Some of the significant technical features are:

- Load Capacity: These are the radial and axial loads available as high as seen earlier.

- Friction Coefficient: This factor is usually shallow, which makes it more productive.

- Material Composition: Wear and load-bearing components are fabricated from bronze or other advanced materials.

Rolling-Element Bearings: The ball and roller bearings reduce friction because of the rolling elements between the races. The technical parameters revolve around the following:

- Load Capacity: Though useful in both radial and axial loads, this is usually lower than that of the radial bearings, as per the axial load design.

- Operational Speed: Their operational characteristic being effective at high speeds, this is caused by low friction.

- Material Composition: This type of bearing is mainly made of steel or ceramic; this is because of its strength and heat resistance.

This brief body of website documents has given the understanding and willingness to directly evaluate and draw comparisons regarding the efficiencies and utilization of different types of operations when dealing with bearing systems.

How Friction Bearings Differ from Ball Bearings

I researched Google’s three most popular websites, which compare and illustrate the distinguishing factors and appropriate technical parameters of friction and ball bearings. Friction bearings or plain bearings rely on sliding action to constrain the motion. They are well known to have high carrying capacity and can assist radial and axial loads. The material also has a low friction coefficient, which gives it advantages in operating efficiency. It is made from bronze, which is more resistant to wear and offers durability.

In the same fairy tale, ball bearings, on the contrary, belong to the rolling-element bearing class with balls instead of rollers to decrease the internal friction of the bearing races. They stand out because of their low friction and ability to operate at higher speeds. However, ball bearings can take both rotary and thrust loads, but in most cases, the load loading capacity, depending on the design, becomes less than that of friction bearings. Ball bearings are made of steel or ceramic, making them exceedingly solid and heat-resistant. Therefore, the options concerning the two types of bearings differ regarding the speed demanded in the application area, the loads to be carried, and the longevity required.

Why are Friction Bearings Preferred in Machinery?

Advantages of Low Friction in Industry

Lower tribal friction in industrial usage makes several key operational advantages possible that help improve productivity. First, efficiency is enhanced because, due to lowered friction, less energy is wasted in moving parts of a machine, thus leading to cost savings and increasing productivity. Second, reducing friction causes erosion of parts, and therefore, the equipment will last longer, and maintenance costs and downtime will decrease.

From the perspective of technical parameters, a low friction coefficient, which is usually attributed to the use of materials such as bronze in friction bearings or high-quality lubricants, is necessary to attain such benefits. Fewer temperatures that arise from excessive heat generated during operations are mitigated, thus making operations safer and enhancing performance in the industrial environment. In addition, low friction helps avoid ‘jerkiness’ in processes, particularly in precision machinery, which has to consistently and reliably perform, making the speed and materials of the bearings chosen for every application to say where the speed and load capacity are concerned, longevity and efficiency of the bearing are trumped.

Lubrication Methods to Improve Performance

Having researched the lubrication methods for improved performance, I gathered some valuable information from the first three relevant websites on Google. Knowledge of those sources’ content shows that the issue of lubricant choice, in particular, is of utmost importance. First, it is essential to select lubricants that do not exceed the maximum allowable value of the friction coefficient and improve the bearing capacity and thermal resistance. It is expected to have high-temperature synthetic oils that are effective across a wide temperature range with good resistance to thermal aging and oxidation.

One commonly raised issue is hydrodynamic lubrication, where a complete film of lubricant is between two touching surfaces so that wear and friction are minimal. The case where fundamental surfaces are operational along their axial motion has to add good ones. These add to the lubricant’s performance over a range of lubrication conditions.

Also, applying proper lubricants and automatic devices like automatic lubrication systems is underscored. These systems help deliver consistency of these unmodified lubes and manage the correct levels of such lube. It is also emphatic that some technical aspects should be known, such as the viscosity index, which tells how much a lubricant’s viscosity differs when temperatures vary. Lubricants of high viscosity indices are generally necessary for devices that endure varying temperatures because they do not change composition as the temperature changes. All this information, taken together, makes it clear how and where it is better to use lubrication so that the necessary machine performance is ensured.

Reduction of Frictional Losses

While pursuing the goal of reducing frictional losses, one factor I also found recommended by the first three ranked web pages on Google was the selection of the right lubricant. Synthetic oils are preferable because they can maintain a low friction coefficient and thermal stability under different temperatures. Such lubricants work efficiently in reducing oxidation and other thermal degradation. It should be noted that there is also a method of lubrication called hydrodynamic lubrication. It is very effective in guaranteeing the presence of a complete film between moving surfaces, thus reducing frictional wear.

This includes, in particular, the addition of biological activity modifying surfaces and friction-reducing composition additives to AWS lubricants. These strategies are correct as they focus on coping with extreme conditions. In realizing operational factors, such as structural features, the viscosity index is also applied to reveal the extent of viscous forces of a lubricant when subjected to heat. A low viscosity index lubricant simply would not perform underneath use if it had extensive temperature changes because its thickness and performance would change significantly. On top of this, incorporating the use of automatic lubrication systems has been very useful in maintaining proper application rates and proper amounts of lubricant. I am therefore able to prevent the friction loss by these measures.

How Does Lubrication Impact Bearing Efficiency?

Frictional Resistance: Cause and Control

Every numerical bearing friction measurement system depends to a large extent on the lubrication method used. Toward this purpose, the first three sites that Google recommends stress the need to choose the right lubricant, be it oil or grease, according to the workload of each bearing. One important consideration is the lubricant’s viscosity, where there is an ideal thickness that should be maintained such that sufficient film is left between the energized parts to prevent them from impacting against each other. In the same breath, anti-wear additives play a crucial role because they build protective layers on the surface that improve the surface resistance to fatigue & wear from high pressures.

Further, additional unique technical specifications must be implemented to determine how much load the lubricant can carry to maintain a lubrication film. In those utilization scenarios, including some extreme temperatures, the impartial rule of thumb in such conditions means choosing a lubricant with a higher operating temperature range. This helps to keep the functionality of the lubricants as well as their stability throughout the performance. The last one, however, is that since the operational environments change, so do the types of lubricants used and how they are used. These considerations do not leave bearing lubrication in doubt and concern.

Selecting the Most Suitable Lubrication for Different Bearings

In seeking the correct lubrication for different types of bearings, there are several technical parameters that I even benchmarked with the best three websites in the Google search engines. To begin with, how lubricant viscosity is vital to the film separating moving parts as the degree of viscosity dictates the film thickness. An optimum viscous rating would limit metal-to-metal contact and help smooth the system’s operation. The second place is how lubrication is done, for instance, oil or grease. In high-speed applications, oil is preferable because it can cool better. At the same time, focusing more on grease is effective in conditions that require high loads because it has better sealing and is more resistant to contamination.

Also, I regard the lubricant’s adequate load-carrying capacity, which shows the load ratio of the lubrication-maintaining capacity to the load applied relative to the lubrication film breakdown. The use of anti-wear additives in the lubricant is essential because they are responsible for protection layers, which minimize wear and tear of surfaces, thus prolonging the life of the parts. In addition, I select lubricants with a broad operational temperature for applications with high temperatures or severe conditions to ensure that their performance and stability would not vary within that temperature range. Considering these parameters, it can be helpful to make sure that I understand the most appropriate means of applying lubricants on every specific bearing operational situation, hence improving efficiency and prolonging the bearings.

Exploring Different Types of Friction Bearings

Qualities of Straight Bearings

Going by my assessment of the most explored three sites on Google.com, plain bearings, also referred to as sliding contact bearings, have unique features worth noting. Most importantly, these bearing types support the loads slidingly without rolling elements. This feature makes them less complex and generally cheaper than other bearings. Concerning technical parameters, it is possible to expect plain bearings to provide adequate support to median masses with little or no repair work.

The range of materials utilized for plain bearings is essential since it determines performance and endurance. Bronze is a standard metal, while PTFE is a thermoplastic, common in many applications due to its low friction coefficients. Furthermore, these bearings are applicable in circumstances that involve broad movement range or oscillations. Stress must be clearly understood to avoid the degradation of function and life span with primary materials such as base oil with appropriate viscosity and pregnancy with ease of use with the bearing debt. These characteristics, coupled with the fact that they have some capability to bear misalignment, make plain bearings very useful in various fields of engineering as they are affordable and work well.

Functionality of Sleeve Bearings

In discussing the functionalities of sleeve bearings, it is crucial to understand the melting role against inter-part friction, which is mainly the purpose of the design of such devices. According to the top three sites on Google.com, sleeve bearings and their extended supports, which form part of plain bearing types, are primarily meant for linear as well as rotary motion in machine devices. Instead of rolling elements, they consist of a cylindrical shaft cradling within its bearing surface.

The technical parameters, such as material, are critical to these parameters, which is crucial since the bearings have to perform effectively under varying load conditions. Prevalent factors include bronze, graphite, and ceramics, among other synthetics, and are used since they do not wear quickly. Due to the reduced operational maintenance, these bearings are much appreciated for their performance in medium radial load supporting ability and rapid rotation bearing applications.

Maintaining these bearings also requires appropriate lubrication for efficient utilization, which usually entails oils or greases that do not react with the bearing composition. Oiling reduces friction and heat production, thus increasing the working life of the bearings and making operations smoother. Sleeve bearings are preferred in various applications, which require the system to be quiet and the bearing to be aligned precisely, all at a lower cost in engineering performance.

Journal Bearing Analysis

As I explore some journal-bearing concepts, I realize that these elements are crucial for supporting and guiding rotating shafts, ensuring they retain their position with the rest of the machine. As I found information from the three leading sites on Google.com, journal bearings are essential because they help lower friction by using a lubricant that creates a thin film between the bearing and the shaft. They find applications on machines with very high load-carrying capabilities and operate at low speeds in which smooth motion is prioritized, and wear reduction is appreciated.

The significant journal particulars bearings are material, lubrication type, and dimensional specification. Other low-friction materials such as mono-metal babbitt, bronze, or polymer binders are used for load-carrying applications, are galling resistant, and can withstand pressure. However, the lubrication of bearings is necessary; oil or grease films are standard for this purpose, and they operate to reduce frictional losses and enhance energy efficiency in the system. The dimensional tolerances also assist in proper assembly and load application, which is crucial in the performance of the bearings. Looking into these parameters allows me to understand why journal bearings never wear out, how they make machinery more reliable, and how they prolong the operating life of machinery parts.

What are the Maintenance Tips for Friction Bearings?

Regular Lubrication Practices

Friction bearings remain functional and in good condition only if correctly lubricated regularly. I have learned several lubrication best practices by researching the top three websites via Google.com. First and foremost, utilizing appropriate lubricant types is essential – finding a lubricant that fits the material of the operating bearing and the environment helps minimize wear and tear. There is also the need for periodic re-lubrication, which is done to avoid damage to the bare metal surfaces through the drag of dirt. The comfort of scheduling lubrication procedures at any time regardless of equipment usage and operational self-driven conditions does not exist, however about equipment usage one does not need to be told every time before lubrication is done.

Also, unwanted abrasive contamination of the lubricants that are used is eliminated by the use of clean and well-filtered lubricants. Controlling the amount of applied lubricant is also vital, as too much can raise operating temperatures. In contrast, an inadequate amount creates a rubbing of metal over metal conditions. Planning and scheduling regular bearing inspections and maintenance help prevent the problems that might cause faults in the bearings. By appreciating and applying these lubrication practices correctly, I am in a better position to ensure completeness and specificity in toiletries for friction bearings.

Inspection and Replacement of Worn Bearings

When it comes to inspecting and replacing worn bearings, I believe it is imperative to undertake a set of procedures to guarantee the longevity and dependability of the machinery. First, visual examinations should be carried out over time due to the risk of excessive wear of the bearing surfaces, where scoring, pitting, or discoloration can appear. If these issues are noticed, it would be reasonable to replace them to avoid other damages or failures.

Other technical parameters that warrant consideration in this operation include the radial play in the bearing, the surface finish of the bearing, and the load-carrying capabilities. The correct clearance measurement is necessary to determine the bearing’s ability to take up misalignment and still source the essential lubrication. The surface finish assessment includes determining the boundaries for irregularities that could limit efficiency or increase the resistance more than required. Finally, assessing the load-carrying capability substantiates whether or not the bearing is suited for that operational purpose without any threat of premature failure.

Since replacement is carried out by looking for a replacement bearing with the exact specifications as the original in terms of material, size, and lubrication, these requirements consider the manufacturer’s instructions. By following these procedures and paying attention to the technical parameters, I can preserve the functioning and prolong the operation of friction bearings in the machine.

Bearing Proper Rotation Rehabilitation

As I seek to rehabilitate or rectify the rotation of the bearing, I find it necessary to focus on a few critical areas based on data from primary online sources. The first thing you should determine is if the bearing is pushed into place correctly, as being misaligned results in overloading specific points and more wear and tear. Every maintenance procedure must always include observation on whether or not vibrations or unusual sounds are emanating from the unit that may indicate other rotational concerns. The other important element is lubrication, where either a lack of or wrong lubricants will result in sliding friction among the bearing surfaces.

Some of the technical parameters that concern me include the clarity of the positioning tolerances, the method of lubrication, and the type and amount of lubricant. These parameters will also assist in minimizing the imbalance in load distribution and speed. I can solve impending rotational defects in the machinery bearings by following these parameters.

Frequently Asked Questions (FAQs)

Q: What are the main advantages or merits of using friction bearings in machinery?

A: Friction bearings, such as roller bearings and thrust bearings, are often used in machinery to prevent excessive friction and abrasion within the machine. Thus, the bearing surface permits a decrease in the coefficient of friction for the rotation of the component parts, tending to increase the overall efficiency of operation.

Q: How do friction bearings help decrease machinery’s wear and tear?

A: Friction bearings help minimize damage by being the softer surface on which rotary parts turn. They usually have rolling members and are constructed to reduce bearing pressure in all directions, lessen friction force, and increase the operational life of machine parts.

Q: How does the coefficient of friction influence bearing operation?

A: The coefficient of friction is an essential element in bearing operation as it influences friction felt by the rotating shaft, which, in turn, influences power losses. Less energy losses in heat and wear lead to less efficiency and longer lifespan of the machine.

Q: What is the difference between the radial and thrust bearings?

A: A radial bearing is meant to take on loads acting in an average direction to the shaft, while a thrust bearing supports loads in the axial direction. Both types of bearings are important in machines because they can withstand various types of loads without excessive friction.

Q: What is the necessity of lubrication in friction bearings?

A: Lubricating in friction bearings is vital since it helps to alter sliding friction and wear of the bearing surface relative to the moving shaft. Friction lowers the motion of the parts, causing overheating and loss of the intended purpose.

Q: What are hydrodynamic bearings? Describe their operating principle.

A: Hydrodynamic bearings use a bearing fluid film that carries the load. Thus, in this case, as the bearing turns, the bearing fluid exerts pressure in the formation of a bearing to reduce friction and wear.

Q: What are the primary materials used to produce friction bearing?

A: Steel and bronze are the most common bearing materials, but ceramics and polymers are sometimes used. The materials have been noted on their strength, tmh which can capabilities, ability to sustain bearing internals loads, and a very low friction coefficient to bear performance further

Q: What distinguishes the rolling element bearings from the contact type?

A: Rolling element bearings contain either balls or rollers that keep the bearing surfaces apart within the structure and are low in friction. They are opposed to contact bearings, which operate with surface sliding contact, which is high in friction. This allows rolling element bearings to withstand higher operating speeds and loads.

Q: What are the advantages, if any, of incorporating antifriction bearings into machinery?

A: Antifriction bearings, thin-walled needle bearings, thickness unbent rolling bearings, and other types of rolling bearings have mechanisms that innately reduce friction torque through rolling elements. This cuts energy losses, heat emissions, and friction-induced wear, thus extending the devices’ life span and increasing performance.

Q: Why is the bearing design concept relevant, and what are the benefits when applied to the performance?

A: Some factors that may be changed in bearing design influence its performance in load capacity, rotational speed, and friction. Load distribution within a bearing is well taken care of, frictional forces are meager, and the bearing meets the functional demands of the machine.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8