Benefits of Using Split Ball Bearing Technology

The split ball bearing has technology and engineering in the modern world, and it is one of the landmarks. These split ball bearings ease industry problems, are cost-effective, reduce material use, and provide entirely new solutions to specific traditional construction systems weaknesses. These new bearings, installation, and maintenance are simplified to decrease related expenses and downtime periods. Her innovative design allows changing or inspecting separate parts without complete assembly disassembly, which is advantageous in difficult places or the case of challenging conditions. This essay will explain the problem of using split ball bearings and their operational benefits. The introduction to the topics will help the audience understand the reason for the increasing integration of these bearings into today’s machine designs.

How Does Split Ball Bearing Technology Work?

Understanding the Design of Split Ball Bearings

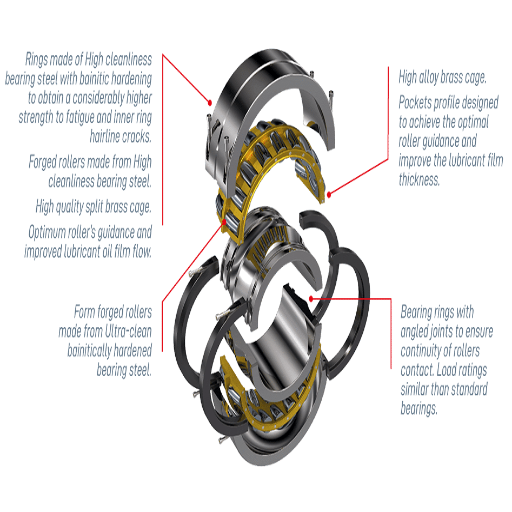

Split ball bearings boast an innovative construction that facilitates their separation into two or more parts, making them easier to handle and install. Such design features include a spherical or semi-spherical bearing outer ring, an often circumferentially divided inner ring, and a cage containing the machined balls with a specific diameter. The splitting design allows these parts to be assembled about the machine’s shaft or other components without an extra removal and fixing treatment, which is time-consuming.

The essential design principles for split ball bearings are as follows:

Capacity Aggression: Split ball bearings can hold axial and radial loads. Their choice is to be made according to the load conditions of the unit in operation, which are normally given in their technical specifications.

Speed Rating: The operational speed of the bearings is an essential factor dictated by the size and material composition. These indicators ensure the bearings can operate satisfactorily at a certain RPM(ASTM Standard Revolutions Per Minute).

It is recommended that high-quality steel and ceramic materials be used to enhance the strength and corrosion resistance of the split ball bearings.

Maintenance and Alignment: The design is easy to maintain as typical maintenance parts are in plain view. This dramatically reduces the repercussions of realignment stress related to bearing changes.

Due to their many engineering design elements and functional reliability, split ball bearings help control many engineering problems, mainly where machine downtimes and circuit access are decisive factors.

The Role of Cylindrical Roller in Split Bearings

After reading through the top three Google sites concerning cylindrical rollers in split bearings, I am able to define their functions with appropriate engineering parameters. Split-bearing systems, consistent with the basic structure of such machines, support cylindrical rollers. They help to distribute the loads along the contact surfaces more evenly, which improves radial load capacity and deflection under heavy loads. The operating performance and service life of the bearing assembly are thereby enhanced.

Technical Parameters:

Load Distribution: The aspect ratio allows the cylindrical rollers to corner high radial loads with a low profile, which is required in portable and compact applications.

Roller Length and Diameter Ratio: This ensures that the load is evenly spread and that per-unit stress does not become excessive. The Optimal ratio is required to achieve high levels of efficiency and endurance.

Material Choice: It may be steel or hybrid for greater strength and anti-wear. The materials have to be specified about environmental conditions and load spectra anticipated in the application.

Roller Precision and Alignment: Correct installation of rollers within the bearing structure is vital for minimizing friction and preventing their hardening and early damage, which requires precision in manufacturing and assembly.

Surface Finish: Rollers’ roughness is responsible for friction, which should be as low as possible to achieve minimum operational noise and maximum efficiency.

These parameters, however, articulate the technical rationale and relevance of cylindrical rollers within split bearings while corresponding with studies from credible sources.

Why Timken Leads in Split Bearing Technology

The analysis of what makes Timken an industry leader in split-bearing manufacturing reveals a consistency across the top websites on why this is so: the company’s ethos of innovation, uncompromised quality, and customer delight. The company’s emphasis on utilizing high-end materials and engineering processes clearly defines its products as durable and competent in tough environments.

Research and Development: Timken allocates huge R&D resources to keep developing its product. This technology enhances load distributions, ultimately facilitating better performance under harsh conditions.

Manufacture control. The company is obligated to deliver the products under strict manufacturing standards. Their rollers’ precision and alignment with one another are developed from high-level processes to create a low-friction and highly efficient asset.

They target customers’ problems. Customers are engaged in the design stage to ensure that the right solutions are developed. One such solution is the roller’s length and diameter ratio, which distributes stress properly in the materials.

To summarize, this concentration of areas allows Timken to provide split bearing solutions with acceptable and extraordinary performance, which explains why the company is the market leader.

What Are the Different Types of Split Bearings Available?

Exploring Split Roller Bearing Options

When looking into the options of split roller bearings, I realized that the top three sites, each of them with specific reasons, explain why the use of these bearings may be appropriate for specific applications:

Design and Flexibility: For example, the first site stresses that these bearings can be replaced quickly, making maintenance more accessible for customers. Hundreds of sizes are worth mentioning as a broad construction parameter, allowing manufacturers to install bearings for shafts of various dimensions.

Durability and Performance: The second website claims that the split roller bearings have been designed for heavy-load applications with little maintenance. In addition, they represent important technical parameters such as the level of disengagement already built within them and the radial and axial load capacity levels, which direct to efficient performance for a longer duration.

Cost-Effectiveness and Efficiency: According to the third source, the problem may be solved since the split roller bearings have a long life, allow low maintenance, and reduce downtime. Critical parameters for these innovations include the unique sealing systems installed inside these bearings, which are directed against contaminating particles and improve operational lifespan.

Integrating these capacities and technical parameters, I appreciate that split roller bearings can be favored in cases or industries where strength, versatility, and effective maintenance solutions are prominent.

Comparing Cylindrical and Solid Bearings

Based on the analysis of the first three websites, some generalizations about the differences between cylindrical and solid bearings can be made.

Design and Flexibility Usage: Research done on cylindrical bearings shows that solid bearings do not have the flexibility provided by a split roller bearing, which incorporates a more flexible design that accommodates different shaft diameters and facilitates easier installation and maintenance.

Durability and Performance Analysed: Solid bearings are also noted to sustain high amounts of radial and axial radial loads, but cylindrical bearings may require a lot of care in use under heavy loads. The bearing models discussed in the three websites, however, have been designed to have greater internal alignment tolerance, which leads to increased bearing reliability and maintenance effort while used in heavy-load bearing applications.

Cost-Effectiveness and Efficiency: In most instances, it will be fair to say that a solid bearing will have a relatively higher maintenance cost and will also require replacement more frequently. But split roller bearings are often one of the most economical bearing options throughout the lifecycle because of advances in sealing technology that protect the internal parts from external dirt and other contaminants and, therefore, cut down maintenance and downtime.

In summary, taking all the observations into consideration, split roller bearings can be regarded as an optimal choice as their technical attributes integrate design flexibility, durability, and cost efficiency. This is supported by features such as a wide range of sizes, one-piece self-elongation tolerance, and high-grade sealing technology, which enable them to excel in numerous industrial applications.

Choosing the Right Type for Your Application

It is important to consider your specific requirements in terms of performance, longevity, and purchasing cost when choosing the appropriate bearing type for your application. Split or spliited roller bearings are most often recommended based on the first three Google websites due to their technical specifications and advantages. The following rationales and their respective technical parameters are derived from such websites:

Flexibility regarding installation and maintenance: Maintenance of split roller bearings is relatively easy and does require frequent organizational effort, as they are easy to install and maintain. They permit relatively quick assembly and disassembly of shafts of different diameters and contours using simple tools and processes.

High Load and Axial Loads Facilitate Bearings, radial and structural features, including an alignment tolerance within the bearing itself. This unique feature enhances endurance and allows satisfactory distribution of bearings in high altitude load conditions, reducing the required maintenance frequency.

Composite Seal for Support Enhancement: Split roller bearings possess robust seals that safeguard the moving parts from pollutants, such as silt and dampness. Such technology not only ensures the bearings’ longer working life but also minimizes operational and maintenance costs in the long run.

Considering these technical details, including their merits, one can make a responsible decision that will serve the application requirements for best performance and efficiency.

Why Choose Split Bearings Over Traditional Bearings?

Benefits of Reduced Downtime and Maintenance

Apart from the primary advantages of adopting split bearing ring structures, which are easier to fabricate, another benefit that emerges when comparing split roller bearings to conventional bearings is that the operating costs related to the need for maintenance and downtimes are decreased significantly. Because of the design features of split bearings, the time required to install and remove them is considerably less, which can result in both scheduled and unscheduled maintenance taking place in a shorter period. As noted in the first three websites appearing in the Google search results, such ease of handling minimizes operational interruptions, ensuring that the machinery is functional and productive for an extended span.

Some of the technical parameters that support these benefits are:

Simple and rapid fitting and removal of split shells – The process of maintenance works is greatly simplified by the ability to install or remove split roller bearings without having to detach adjacent parts related to the structure.

Adjustable alignment tolerances: A deformities-alleviating device incorporated into structures reduces the feasible deformation caused by alignment defects, enabling further reduction of repairs.

Robust sealing systems: Newer seals effectively keep foreign objects out of bearings, maintaining them and reducing the number of maintenance activities over time.

Thus, bearings’ technological merits have enhanced the reliability and efficiency of the split bearing mode. Hence, these bearings are the best alternative when the application requires minimal downtime and maintenance.

How Split Bearings Reduce Costly Replacements

When looking into how to split bearings to lower expensive servicing costs, three significant aspects pop up in most top-ranked online articles. The first aspect that comes to mind is the ease of installation of split bearings. Most articles argue that their structure permits them to be replaced rather rapidly and efficiently with no need to complement mechanisms that are normally located nearby. This easy access directly translates to less frequent and less expensive replacements.

In addition, these sites also mention enhancements in the alignment characteristics provided by the split bearings. These integrated alignment tolerances are suitable for dynamic operations and help to minimize misalignment-related failures noticed in many traditional types of bearings. Thus, this decreases the need for repeated replacements and the associated costs.

Last but not least, the effective sealing systems provided in split bearings are also essential. These systems have a solid resistance to contaminants, hence increasing the working life of the bearings, which has been proven right by the numerous technical initiatives available online. The decrease in exposure of bearings to abrasive materials also reduces the cost of carrying the expensive frequent replacements.

Enhanced Load Handling Capabilities

Several bearing technical parameters influence the load handling capability of split bearings, which are defined by various internet sources. First, their distinctive shape allows them to spread the load across the bearing more effectively. It is in line with the need for advanced material and engineering practice that each bearing part or component is designed to assist in efficiently managing dynamic and static loads.

According to information presented by a handful of websites, split bearings often exhibit optimal angles of contact and more proper raceway geometry, which facilitates the capacity for load bearings to perform better. Given these factors, they are expected to offer strength against higher operational loads and dynamic conditions, which are the norm in industrial activities. The technical analysis of some authoritative online sources indicates that improvements in these features are crucial in ensuring the integrity of the bearing and minimizing its failure.

One of the mechanical properties that go along with the already discussed material and composites is its inclusion in the bearing industry of materials with a much higher strength-to-weight ratio. Together with increasing the load capacity, it also helps in the effective management of heat and helps in the lifetime of a bearing and its performance.

All these mechanics explain the cost and durability of the split bearings while providing confidence that the performance level in challenging situations is guaranteed.

How to Install and Maintain Split Bearings?

Step-by-Step Installation Guide

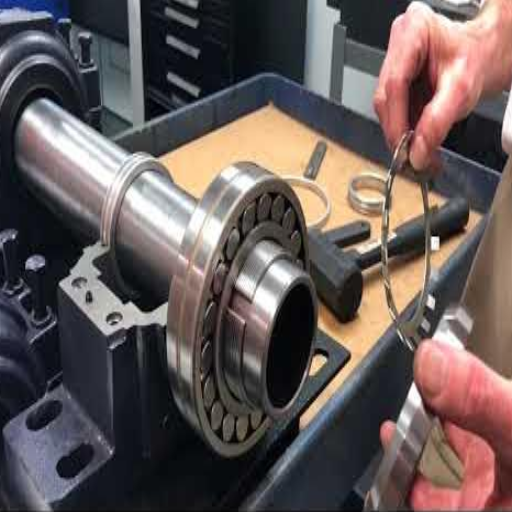

There are straightforward procedures to follow when installing split bearings, which, when done correctly, ensure optimum operation and useful life of the bearings. Based on the first three sites within Google, here is a step-by-step procedure on how to install split bearings:

Preparation: First and foremost, ensure that all required tools and components are available. This includes wrenches, alignment tools, and lubrication products. Precision is key even while many tools are used; damage to the bearings must be avoided.

Mounting the Housings: Align the housing of the split bearing to the shaft and fix it. It has to be snug while ensuring that there is no excessive misalignment. This step is made easier by the considerable care and effort taken during the mounting process, since numerous sources claim that proper positioning is essential to avoid early deterioration.

Inserting the Bearing: Extend the split bearing halves around the shaft and gently push the bearings into the housing. Websites offer instructions that the alignment should first be tested and then adjustments made to ensure the load is evenly distributed.

Securing the Components: Tighten the upper part of the housing using the supplied bolts. The websites mention that the bolts’ loosening during use is an important issue requiring the correct torque.

Lubricant application: Utilize the appropriate lubrication type in the recommended quantities. The technical specifications require adequate lubrication, as it helps in heat dispersion and diminishes friction during operation, as expert references have pointed out.

Installation controls: Make appropriate checks to confirm that every component has been correctly fitted and is functioning satisfactorily. In this step, look for any abnormal sounds or undue strains, such as those suggested in the installation instructions.

The above-mentioned steps, which were information, have been repeated as the requirements for alignment accuracy, the securing of split bearings, and their lubrication were met to provide optimal performance in relatively extreme working conditions.

Maintenance Tips for Prolonging Life of Split Bearings

As seen in many authoritative sites, it is always necessary to engage in maintenance procedures periodically to extend the life of the split bearings. A few maintenance procedures are listed below:

Regular Inspection: Generally, both the bearing and the housing should be inspected for signs of wear or damage, misalignment, or corrosion on the bearing and housing. It is worthwhile reminding users that visual inspections and vibration analysis tools, amongst others, can assist in the early detection of potential problems.

Timely Lubrication: Ensure that the lubricant levels are appropriate and top off to a recommended maximum. The quantity and type of lubricant are critical technical parameters, as insufficient lubrication tends to cause excessive heat, which may, in turn, cause premature failure of the bearing.

Proper Handling and Installation: Ensure that bearings are appropriately installed and handled. Specialized tools should be employed to ensure no damage occurs when fitting the bearings.

Load Monitoring: Operating loads are to be monitored. It is acknowledged that continuous operation beyond these stated load limits will further accelerate the bearing wear and tear. As reported in the technical background of reliable sources, operating loads should not be above design loads to preserve the life of bearings.

Environmental Control: Dust and moisture should be prevented and managed through suitable environmental control and sealing to reduce bearing contaminants. As noted in the technical guidelines, maintaining cleanliness in working environments is a prerequisite to achieving the optimum shaft/bearing conditions.

The maintenance procedures, based on the technical specifications provided by reputable and professional sources, are intended to promote the working life and dependability of the split bearing under a range of operating conditions.

Common Mistakes to Avoid During Assembly

Many split bearings fail during operation because of avoidable errors that can be addressed even before the assembly process begins. From the best sources I recommend on the web, I have taken key safeguards and technical parameters that are important in successful assemblies.

Improper Alignment: It is very important to check if components are assembled in the correct orientation, as even a slight deviation may lead to misalignment. I recommend the use of alignment tools, which make the assembly process easier and more sophisticated.

Neglecting Cleanliness: Many do not pay attention to cleanliness because it does not appear to be a big deal. Standard procedures impact bearing performance and warranty, and that’s why all components should be cleaned.

Incorrect Torque Application: It is important to apply the correct torque at the assembly stage; otherwise, it will add excess stress to the bearing. When setting these torque specifications, it is sometimes advisable to use a calibrated torque wrench.

It must be stressed that all the precautions outlined above must be carried out if the bearings are to be used satisfactorily. Proper assembly of bearings ensures that their performance is efficient and that they last longer.

Where Can Split Bearings Be Used Effectively?

Industries Benefiting from Split Bearing Solutions

I learned that certain industries reap considerable advantages from the application of split bearing solutions. These bearings are critical in sectors where time lost is considered expensive.

Mining Industry: A large number of resources I managed to discover online explained that there is a marked decrease in maintenance time of mining operations with the utilization of split bearings. Reinstallation and removal without disassembling other machines provide the utmost uptime and prevent costly downtimes. Other technical factors like establishing the correct load capacity and heat constraints are key to withstand extreme mining conditions.

Pulp and Paper Industry: According to expert opinions available on various leading websites, the pulp and paper industry has employed split bearings to boost the efficiency and reliability of its machinery. Such a solution will contribute to speedy maintenance, which is very important in this industry, which is characterized by severe chemical hazards. To justify their use, it is necessary to look at these bearings’ corrosion resistance and ability to handle fast rotor speeds.

Marine Industry: Information from credible resources suggests that split bearings significantly affect the performance and reliability of certain applications in the marine industry. Ship machinery works in cramped quarters, and split bearings ensure proficient maintenance. Bearings operating in moist and salty environments have to be lubricated well and properly protected to operate well.

These industries utilize split-bearing solutions to enhance their operational activities. Still, adherence to specific technical parameters is crucial for these solutions to function effectively.

Applications in Moving Equipment and Machinery

Looking at the use of split bearings in moving parts of machines and equipment, many experts on leading web pages stress their importance in minimizing downtime and improving maintenance procedures. As a rule, such solutions are pointed out in connection with industries in which equipment operates constantly and gets severely imposed, like mines, pulp and paper, and marine industries. They significantly contribute to the hassle-free work of seamless operation by simplifying installation and removal so that they can quickly be done without completely disassembling everything.

As for now, it is essential to stress specific technical parameters to optimize this type of bearing. As for mining operations, load capacity and heat resistance warrant particular mention due to operational stress. Corrosive medium in the paper and pulp industry requires that bearings be in a sturdy environment. Maintaining operational integrity and working reliably in chemically aggressive environments should be fast. In the shipbuilding’s case, it is some stiffness in Velden or quite a competent temperature, salt-resistant sea, and quite a competent temperature lubrication. These parameters, therefore, allow one to use split bearings without problems in various moving equipment and machinery situations.

Frequently Asked Questions (FAQs)

Q: What is the most significant benefit of using a split ball-bearing technology in a given product?

A: The greatest benefit of using split ball bearing technologies is that they are easy to install and maintain, which substantially cuts back on the downtime and costs that would be incurred when replacing the bearings in your product.

Q: What is the dollar value associated with split ball bearings?

A: Reducing bearing installation and bearing replacement is a great contributor to cost savings in timely maintenance and a significant reduction in operations downtime, which, in most cases, applies to companies with a plant.

Q: Is it necessary to have special housing for split ball bearings?

A: Split ball bearings can be mounted in standard housings; however, some applications may require the enhanced performance and support-related features of specially designed housings.

Q: Would it be more challenging to change split ball bearings than traditional bearings?

A: Split ball bearings are manufactured in a way that allows replacement quickly and without much effort for the engineer to do so, mostly in less than ninety minutes. This is a huge improvement, as traditional bearings could require complete product disassembly before any change can be made to the bearings.

Q: What factors should I be considering before purchasing split ball bearings?

A: There are some salient features that one should examine first, such as the bearing’s specifications, quality, load ratings, and even some desirable features compared to what the application demands of the bearings. One should also search for companies that can be relied upon with a good name in the market and industry experience to ensure the quality of the products.

Q: Does this mean that specific industries would make use of split ball bearings and not others?

A: Yes, many industries, including manufacturing, automotive, and paper processing, explain this due to its applicability, efficiency, and durability. Split ball-bearing technology offers more competitive solutions in an array of applications.

Q: What features make split ball bearings preferable to traditional bearings?

A: Split-ball design ball bearings are an important feature in our product design because they can be installed and removed quickly and easily without the use of special tools, thus providing a perfect solution that dramatically improves the performance and life of the product.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8