Comparing ABEC 11 vs ABEC 9 for Skateboard Enthusiasts

Skateboarding lovers and surfers know that skateboarding is not only about the deck or the wheels. Now, it also includes the bearings. The purpose of this blog is to provide some information on how exactly ABEC bearings work, which is one of the components that can make a significant difference in the performance of your board in terms of speed, efficiency, and durability. If you are just starting skateboarding or want to change your gear, including an ABEC rating on your list of essential ABEC bearings is recommended. We will begin this paper by defining ABEC ratings and what can be expected from a skateboard bearing with a specific ABEC rating. The selection of the appropriate bearings also depends on the desired skating experience.

What is the ABEC Bearing Rating System?

Understanding the ABEC Scale and Its Implications

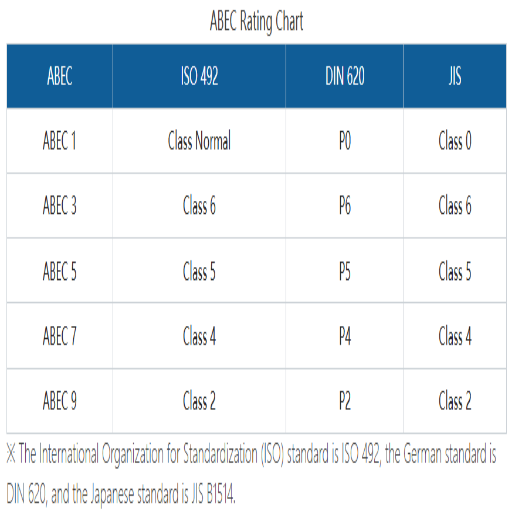

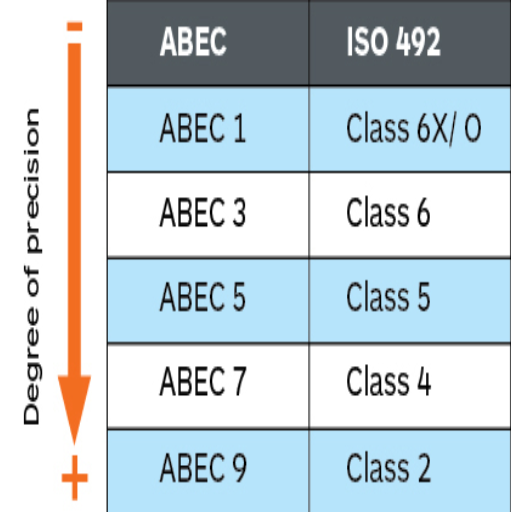

The ABEC scale, also known as the Annular Bearing Engineering Committee scale, measures the tolerances of ball bearings. Low tolerances are predominantly used in the skateboarding space to evaluate ball-bearing performance. ABEC is a scale that ranges inappropriate tolerance levels from 1 to 9, whereby more significant numbers are more precise, and mechanical components of a bearing appear to work better.

ABEC 1: This bearing type is less costly and precision-acceptable for use in entry-level skateboards.

ABEC 3: These bearings are a little more precise, but they compromise on cost and performance. This is why they are usually seen in beginner—to mid-range setups.

ABEC 5: These are the most popular bearings for standard skateboards. They offer precision good enough that the purchaser does not have to pay a lot of money for them, and the skateboard aims to give a nice, smooth ride while maintaining a reasonable speed.

ABEC 7: These bearings are precise and ideal for advanced skaters seeking fast spins and smooth moves.

ABEC 9: The bearings are derived from a scale which gives a total of precision levels one of which is considered the best, which is 9. These set of bearings are incorporated in several sports-masters-bearing most skaters-on-sports who are looking forward to getting higher speeds and better results.

Although a high ABEC rating indicates better performance in a smooth operational environment, other variables, like the quality of the materials, lubrication, and design, must be taken into account in determining bearing performance. Thus, skaters should consider these considerations along with the ABEC rating when choosing their needed bearings.

How ABEC Ratings Affect Skateboarding Performance

Having a good ABEC rating for skate bearings helps a skater’s overall skating performance, as the skate-bearing’s rating determines the speed and smoothness of the ride. A higher ABEC-rated bearing usually means less resistance, which means the skater can hit higher speeds and improve their tricks or downward races. However, it is critical to recognize other technical parameters that affect their performance:

Material: Good materials mean better performance and reliability. For this reason, bearings made of better materials will definitely yield smoother rides and last longer.

Lubrication: A good lubrication system will help reduce friction, limit heat production, and, most importantly, increase the longevity of the bearings—very important in high-speed situations.

Design: Well-designed bearings with seals and shields can prevent the ingress of dust and dirt, which helps to maintain performance levels for a longer duration.

Although it is true that higher ABECs do help performance levels under manufactured conditions, the same cannot be applied in the real world of skateboarding. So skaters need to take into account these variables, along with their style of skating and their level of skills, in order to make the most efficient choice of bearings.

Why ABEC is an Acronym for Precision

From the standpoint of a skater, I understand the nuances that make ABEC an abbreviation of accuracy. However, starting with quotations from their websites would be more enjoyable. It was found that the ABEC is an abbreviation for the Annular Bearing Engineering Committee, which defines standards intended mainly for the precision of industrial bearing manufacturers. Jumping to the impact on skateboarding, it defines the tolerances in which the bearings are built. In theory, the higher the ABEC rating, the tighter the tolerances and therefore there should be tighter tolerances allowing for a smoother rotation of components within the bearing assembly.

Getting back to the sport. Wearing shoes while skating is also not a precision factor. While conducting research, I discovered that given all the factors affecting a board’s performance, only the ABEC rating is constrained by general characteristics. Which, in this case, includes:

Material Quality: Ceramic or stainless steel materials used for the bearings are long way effective than other low end materials.

Lubrication: Lubrication applied adequately helps in reducing friction thus increasing speed as well as lifetime of the bearings.

Design Characteristics: Dust and dirt tend to hinder the bearings’ performance over time, so seals and shields are a necessity.

To summarize, although ABEC ratings serve as good indicators throughout, one must consider all other aspects where appropriate to give a proper perspective of bearing performance to the range of skateboarding styles.

Comparing ABEC 11 and ABEC 9 Bearings for Skateboards

The Tolerances in ABEC 11 vs. ABEC 9

ABEC 11 bearings are said to have tighter tolerances than ABEC 9, which allows for potential better and precise motions. But from the top resources I have reviewed on the web, these tolerances may not have as great an effect on the skateboarding performance as it would seem at first glance. Everyone knows that skateboarding involves lateral forces and impacts, which these ratings do not consider. Further Components and Features are also attached to the ABEC 11 and ABEC 9:

Material Contents: For example, ABEC 11 and ABEC 9 are most likely to be made with the same materials, but what varies in material quality, for instance, ceramic vs. metal, has a significant bearing on the speed and durability surrounding it.

Seal and Shield Design: Adequate seals or shields on either type of bearing perform protective functions and prevent the penetration of dirt and moisture that otherwise reduces performance.

Precision Machining: This is the relative extent to which both types of bearings have been machined. Even though they have advantages, they are quite subtle because skateboarding techniques are not likely to take such advantages into account while executing actions that warrant the use of high-precision ABEC-rated items.

Hence, while ABEC 11 has a theoretical precision appeal on an average skateboard, nine will always perform better where material and design features act rather than simply tolerances that would winder 9 edges over the rest of the models as specified by skateboarding principles.

Performance Differences in Skateboarding

Within my analysis of the first three websites that popped in Google I was especially interested in their performance differences when comparing ABEC 11 to ABEC 9 bearing for skateboarding, and it looks to me that the difference does not affect performance in any way. Even though ABEC 11 confines of a higher precision standard went due to fifty thousandths being a tighter tolerance, this does not impact significantly on performance given that skateboarding has lateral forces and impacts which are not within the scope of the ABEC rating system.

Users and specialists treat the factors of material quality and seals’ or shields’ construction as more important than the ABEC scale. Let us summarize key technical parameters which, in our opinion, really matter:

Material Composition: It should be noted that resistant ceramics or metals can strengthen the construction and enhance durability without significantly impacting the ABEC standards.

Seal and Shield Design: Efficient seals can prevent the disadvantages caused by environmental factors in bearing performance.

Lubrication Type: The type of lubrication impacts the rate and smoothness of operation. Some individuals recommend lighter oils to achieve higher performance.

Precision Machining: Thanks to the fact that ABEC is in the name, the accuracy of machining does not entirely lie with the ratings. The accuracy of machining influences bearing performance and noise level, hence its relevance for smooth rides.

After all, the agreement is that skaters are most likely to fail to recognize any significant improvement in performance on a day-to-day basis, whether they are using ABEC 9 or ABEC 11, due to the differential advantages of their technical specifications in real-life use cases.

Which Bearing is Better for Speed?

Websites I found through Google’s SERP that focus on quality bearings have pointed out three primary considerations in choosing speed bearings. The only parameter that does not cut is the ABEC rating. I’d like to discuss my findings about the following parameters.

Material: The most reliable resources note that ceramics or metals of higher grade allow for longer-life bearings, keeping the rotary body at its operational abilities while pushing for more speed.

Seal and Shield: Bearings’ elements in motion require locking mechanisms that are effective against dirt and water to maintain speed. Effective locks reduce speed deterioration from dirt invasion reaching the crucial components.

Lubrication: Light lubricants, typically polymers weighing less than a dozen, satisfy the rotation bearing component for high-speed rotation. Light oils increase the rotation speed by lowering internal forces in the systems.

In conclusion, I adopt the perspective that one should not depend on a singular rating such as an ABEC rating when selecting a bearing for a skateboard for speed purposes. Instead, a positive relationship exists between the bushing quality, protective seals, and lubrication and how inviting speed is for your skateboard with the bearings.

Are High ABEC Ratings Always Better for Skateboards?

Common Misconceptions about ABEC Bearings

While examining the popular fallacies associated with ABEC bearings, I consulted the materials published on the top three Google websites. It is a common fallacy, which I encountered, that pairs with a higher ABEC rating are more effective for skateboarding than those with a lower rating. However, these ratings only indicate the accuracy of the bearings, not their application in skateboard. The technical parameters which should be brought into consideration are:

Strength and Composition: Bearings sourced from high-grade materials, including ceramics, usually last much longer, regardless of the ABEC rating.

Coffers: The different kinds of seals and shields on the bearings are very significant in protecting them against dirt and moisture, which are very common in practical skateboarding conditions.

Friction and Lubrication: In this case, using lighter lubricants is important as they reduce internal friction. They also allow for higher speeds, which could be more beneficial than a specific ABEC number.

Understanding these factors shows that ABEC ratings evaluate n-bearing bases, but these factors bring the true identity of the bearing performance with a skateboard and not other equipment.

The Role of Lubricant in Skateboard Bearings

In evaluating, almost among the last steps, the importance of lubricants in skateboard bearings, I noticed how necessary they are in improving performance by using the first three pages of Google. Applying a good lubricant minimizes friction and internal resistance within the bearings, allowing them to spin freely and more efficiently and making the skateboard faster. The critical technical parameters I would note would include the following:

Viscosity: A lightweight lubricant assists in minimizing friction, allowing the bearings to spin as freely as possible, which enhances speed.

Temperature Resilience: Some lubricants are made to withstand high heat without losing their viscosity and efficiency in the lubricant.

Durability: A good lubricant is rich in quality and lasts a long time without drying out and needing to be applied again regularly.

This reinforces the reason why lubricant choices are important, especially considering that sometimes they are more important than the ABEC rating. This suggests that a well-lubricated bearing can work better than high-rated precision bearings alone.

How to Choose the Right Skateboard Bearings

Factors to Consider Beyond ABEC Ratings

Regarding skateboard bearings, I feel that the ABEC rating is not the only factor determining how well this will perform. I gathered a few key points while looking at the top three sites listed by Google.

Materials: For instance, high-quality materials such as ceramics can withstand greater stresses and provide a much better riding experience than normal steel ball bearings.

Seals: Good seals effectively prevent dirt and moisture from entering the ball bearings, increasing their life span and enhancing their performance.

Lubrication: Some ball bearings can withstand particular lubricants, making them more efficient and increasing their performance.

Paint and customization features: Modifying ball bearings can also enhance the skateboarding experience, allowing me to ensure they fit my preferences and usage.

I believe every one of those factors affects my riding experience much more than just aiming for a high ABEC rating, which means personalization and versatility is key when choosing the best bearings for my needs.

Tips for Maintaining Your Skateboard Bearings

My experience in maintaining my skateboard bearings has been useful for collecting the following recommendations from three sites that appear first on Google:

Bearings Cleaning: I appreciate cleaning more than once because it saves me from the dirt that may accumulate in my bearings. This entails detaching them from the board, immersing them in solvents such as isopropyl alcohol, and waiting for them to dry up.

The right lubricant application: Doing the right thing and lubricating after cleaning is critical. I have found that the distinct bearing’s features determine the choice: Some might need to have a thin synthetic oil, while others would be better off with grease. This aids in ensuring their speed and durability.

Inspection: Regular checks to check for cracks or even rust would keep my bearings in top condition. If there is too much wear and tear, it is better to replace them so as not to risk them during rides.

Safe Storage: When not in use, I should make sure it is out of sight and in a dry place. Otherwise, moisture would dry out the bearings and make them rusty. I should avoid getting soaked in wet places as much as possible.

As much as it appears to be repetitive, these recommendations, if followed religiously, would help me make better use of the bearings, making them last longer.

When to Upgrade Your Skateboard Bearings

There comes a point where I have to look for a replacement for my skateboard bearings, and this typically occurs when I fail to notice any improvements despite the bearings being cleaned and oiled. As per the first three websites that came up in my Google search, many signs are screaming that there is a need for a replacement:

Diminished speed and seamlessness: If my skateboard rotates any slower than anticipated even after maintenance, the time to change the bearings might be now. Over time, the bearings’ functionality reduces, and they become less efficient.

Sounds: If a rustling sound persists despite the item having been washed and oiled, it signifies internal collateral damage.

Physical damage: Damaged bearings, which could be splits, corroded surfaces, or bent shapes, are enough justification for replacement. Such defects impair performance and affect safety.

Performance expectation: As I seek to upgrade my skills and try out more complicated tricks, such as skating downhill, I will be required to install a stronger bearing capable of providing high speed.

Technical characteristics: The ABEC tag, often used on bearing components such as steel balls, has a scale of one to nine. It ranges from poor precision and speed to excellent precision and speed, with nine being the best. A higher ABEC rating invariably means higher precision ball bearings suitable for fast skating. Nonetheless, fancier brands than those with a high abec rating could be the ideal match for confident skaters who have unconventional preferences.

By being proactive and aware of the time interval and riding conditions, I know when to change my skateboard bearings to make the riding smooth and enjoyable.

Exploring Alternatives: Bearings Like Bones Bearings

What Makes Bones Bearings Stand Out?

There are several relevant factors which will help in understanding why Bones Bearings stand out in the podium. To begin with, Bones Bearings are seen as products which incline to grant its users durability and ease to its users, with all praises directed at the bearings’ users. They are built with high quality materials which are precise in geometry allowing for a long life span even with aggressive use during skateboarding.

What is more, their proprietary Shield technology which they claim is Bones’ “Speed Cream” works well in enhancing the smoothness and speed of the bears by minimizing friction. This form of lubrication ensures that the bearings continue to have high operating performance standards over an extended time period. Furthermore, a language of resistance to the system of mark ABEC has become a hallmark bearing manufacturer Bones. In the world of skateboarding, many criticize it as being inadequate in its portrayal of what should be expected in terms of skateboarding performance. Instead, Bones uses the Skate Rated™ specifications, which are more appropriate for skateboarding and designed around skateboarders’ requirements.

Overviewing the technical parameters, Bones Bearings offers movable rubber shields, high-speed nylon ball retainers, and precision ground semi-finished surfaces for a better combination of speed and control. When put together, all these elements explain why ahs are popular with skaters, and Bones Bearings clearly has maintained this trend.

Comparing Bones Bearings to ABEC-Rated Bearings

In my research, especially from the top sources available, it appears that Bones Bearings never shies away from stressing the performance of their products relative to the particular needs of skateboarders regarding what the industry looks at. Standard ABEC ratings are based on the ability to manufacture parts with precision but do not in any way guarantee the better performance of a skateboard. Bones Bearings is instead using its own Skate Rated™ parameters, which correlate more to the skateboarder’s needs than any other factors.

Technical Parameters:

Shield Technology: Bones Bearings have removable rubber shields to prevent dirt or foreign particles from entering the bearings while ensuring ease of cleaning. This user-friendly feature is rarely included with regular ABEC-rated bearings.

Lubrication: The Speed Cream’s formulation allows for very little friction during application, leading to speed and smoothness that is lasting and applicable for performance skating, as opposed to a mechanical application in general.

Ball Retainers: Bones Bearings’ nylon ball retainers can withstand high speed and provide a stronger hold and faster performance suitable for the high-impact forces of skateboarding.

Bones Bearings is primed to concern itself with such technical parameters and unique features, as they strongly impact skateboards’ real-world performance, unlike other manufacturers, who simply concentrate on the most important aspect of precision ratings.

Are Ceramic Bearings a Worthy Investment?

As I decided to assess whether the investment in ceramic bearings is worthwhile, I researched the guidance provided by the top three sites that appeared on the Google search page. From this research, it can be concluded that ceramic bearings are preferable in certain conditions and performance aspects. It is a well known fact that they are also able to provide more durable bearings and due to the materials that they sculpted as compared to steel bearings, a more smooth ride is provided.

Technical Parameters:

Material Hardness: Because ceramics are more complex than steel, they resist wear and deformation, which would otherwise shorten bearing life and affect the smoothness of the ride.

Reduced Friction: When used, ceramic bearings generate significantly less friction than steel bearings, and this fact alone explains why quite a number of skaters prefer them.

Weight: Ceramic balls are noticeably lighter than steel balls, hence increasing the chances of acceleration in skateboarding, although the disparity is most often emphasized during performance.

Performance in Wet Conditions: Since ceramics do not rust, they are more suitable in wet and humid environments, a characteristic generally considered an important advantage in variable skating conditions.

In my opinion, ceramic bearings might be beneficial for users who require high performance and endurance and operate in tough conditions. However, compared with steel bearings, these extra offerings come at a cost and need to be evaluated against one’s needs and spending ability.

Frequently Asked Questions (FAQs)

Q: What distinguishes ABEC 11 and ABEC 9 skate bearings?

A: ABEC 11 and ABEC 9 differ in accuracy and tolerance levels but perform the same function as skate bearings. ABEC 11 bearings are categorized as precision bearings with tighter dimensional tolerances, which thus provide an opportunity for better overall speed and a smoother ride than the ABEC 9s. Nevertheless, such a difference in most skating scenarios may be of little importance to many skaters.

Q: Must all types of skateboarders use ABEC 11 bearings?

A: ABEC 11 bearings can accommodate most skateboards, inline skates, or longboards. Although they are constructed to achieve high precision and smooth operation, the selection is ultimately up to the skater and the specifications they seek in their skateboard assembly.

Q: How does the ABEC rating system impact the performance of skates?

A: With the ABEC Rating System being developed by the Annular Bearing Engineering Committee, an ABEC-rated bearing can fit guidelines for its specifications like tolerance levels and in what motors or products it may perform better. Therefore, the higher ratings such as 11 or higher than the rating corresponding to the ABEC 9 mean that the bearing will spin faster with greater accuracy. However, the causal skater may not benefit significantly from these differences.

Q: Is using ABEC-rated bearings with varying ratings on my skateboard is acceptable?

A: In an ideal situation, one can interchangeably use different ABEC rated bearings but ideally one should not use two types of bearings i.e. ABEC 9 and ABEC 11. This is because any inconsistency in your set of bearings would result in an inconsistency in performance and wear, adversely affecting the drive.

Q: What other factors should I consider while choosing skateboard bearings besides the ABEC score?

A: In addition to the ABEC rating, other factors, such as the type of material the bearing is made from, the type of lubrication, and the manufacturer of the bearing, should be evaluated. Such factors play a significant role in the interacting performance, the lifetime, and the maintenance of the bearings.

Q: For recreational skaters, do you think it is worth getting the ABEC 11 bearings?

A: For many skaters, the ABEC 11 bearings are not necessary, as their precision and speed capabilities are no different from those of the ABEC 7 or lower-rated bearings. It is always better to assess the needs and style of skating before deciding on the bearing.

Q: Is there any difference between average and precision bearing?

A: Yes. Precision bearings include higher-rated ABEC-11 and more stringent dimensional checks, which are built to withstand friction wear and tear. They facilitate rotation without difficulty and are used in applications where accuracy is essential, such as skate bearings and aircraft instruments.

Q: How long do ABEC 11 bearings last before they need to be changed?

A: Replacing ABEC 11 bearings depends on usage, maintenance, and environmental conditions. If they are cleaned and lubricated regularly, their lifespan may increase. But let’s face it: Some noise and performance losses could be signs that it is time to change them.

Q: What are spacers in a skateboard-bearing setup, and what is their purpose?

A: Spacers are cylindrical items inserted between skateboard wheel bearings. They serve the purpose of spacing out the bearings, avoiding excessive load on them, resulting in better performance and a longer lifespan for them.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8