Complete Guide to Golf Cart Wheel Bearings: Replacement Parts and Seals

Golf cart wheel bearings play an essential role in ensuring the smooth operation, stability, and overall performance of your vehicle. These small yet crucial components are designed to reduce friction between the axle and wheel hub, enabling efficient rotation and minimizing wear. Over time, however, wheel bearings can experience degradation due to factors like environmental exposure, regular wear and tear, or inadequate maintenance. This guide is designed to provide a comprehensive understanding of golf cart wheel bearings, including their function, signs of failure, replacement procedures, and the importance of selecting the correct replacement parts and seals. Whether you are a golf cart enthusiast or a mechanic, this article will equip you with the knowledge needed to maintain or repair this vital aspect of your golf cart system.

What are the signs of failing golf cart bearings?

Common symptoms of worn golf cart wheel bearings

- Typical Indicators Sounds: High-pitched squealing, grinding, or growling noises emanating from the wheels indicate accompanying damages or bearings that show wear over a long period. These noises result from insufficient lubrication or abnormal bearing erosion leading to metal on metal friction.

- Severe free play of the wheels: A considerable looseness or wobble of the wheels can be observed while using the wheels manually to shake them; this primarily suggests a constant bearing degradation. This is likely to result in lack of proper wheel alignment, thus causing considerable irregularity on the tires.

- Operation of the Cart Having Vibration Effects: At higher speeds, the vibrations throughout the golf cart when it moves are attributed to a defective wheel bearing. This situation results from a lack of uniform spinning due to a rogue bearing.

- Tire Wear Is Not Equal: Not just the wheels and their bolts, but also the bearings that form part of the hub can wear out for numerous reasons. Once they do, the alignment and support of the wheel are in all likelihood greatly impaired, thus causing irregular or advanced wear of the tires. To discern the problem, check the pattern of the tread erosion.

- Unusual heated areas: The heating in the vicinity of the hub and the wheel indicates a breakdown of the bearings. They are in trouble, and active friction combined with a hot head is the consequence of constantly being active; they have no rest.

Promptly dealing with these matters will avoid greater deterioration to the golf cart’s suspension and drivetrain, guaranteeing optimal functionality without hindrance or danger.

How bearing quality affects golf cart performance

Premium bearings are essential for a golf cart’s efficiency and performance due to their great impact on effectiveness, dependability, and lifespan. The bearings serve to separate the moving parts from one another and permit friction that is free to work with and aid in the enhancement of operating smoothness and load support capability. Compromised bearings are low-quality, which most definitely will result in higher rolling resistance, heat production, and deterioration or overall inefficiency and absence of protection.

- Load Requirements: The bearings are fundamental parts of machinery and must bear the total weight of a passenger cart and its riders. For example: every bearing has to be capable for a certain amount of dynamic load which is rated in Newtons or pounds when in use.

- Material Wear Resistance: High steel or ceramic grade bearings have these materials that bear the high degree of a changing environment for a long period of time because they do not get corroded or worn out easily.

- Tolerances: Bearings that are created using high precision tools with high tolerance levels such as ABEC for ball bearings have smoother rounds and better alignment.

- Lubrication: With adequate lubrication and the application of heat, the friction between the parts reduces, and the irritation is minimized. A golf cart that is exposed to oil or grease and is durable and flexible with high thermal stability is most suitable. Such oil and grease are exposed to variable weather.

- RPM limits: Custom made bearings are designed in such a manner that they allow the cart to pass a certain number of wheels revolutions effortlessly while still enabling the cart to stay cool, firm, and stable.

Meeting these technical specifications alleviates the maintenance burden and improves the overall performance, energy efficiency, and driving comfort of the golf cart.

When to replace your golf cart bearings vs. repair

As an overview, deciding on the replacement or the repair of a bearing on a golf cart will largely depend on the amount of wear it has, the work environment, and the make and model of the bearing’s technical features.

- Overuse: Any excessive scoring, pitting, or wear deformation will result in replacement being necessary. From a mechanical standpoint, continued operation of these bearings will lead to failure, excessive friction, and overall decrease in efficiency.

- Noise or vibration level: Excessive vibration or constant noise emanating from machines are telltale signs that there’s something wrong with the internal alignment and the bearing of the machine.

- Condition of the lubricant: If lubrication has reached a stage where overheating is present within the bearing unit, a repair attempt by way of cleaning and re-lubricating can be attempted. However, if lubricant damage exceeds permissible limits, bearing should be replaced instead.

- Working life span: A golf cart’s bearing, once rated service life is achieved based on load and RPM, needs to be replaced.

- Value for your money: New bearing is more beneficial in cases when repair cost that includes both labor and parts reaches anywhere from 50-70% of replacement fee.

Evaluation of these factors guarantees the performance, safety, and longevity optimization of the golf cart. The user must ensure that all recommendations issued by the bearing manufacturers are followed alongside the set minimum standard maintenance actions.

How do I replace bearings in a Club Car golf cart?

Tools needed for Club Car bearing replacement

When changing the bearings on a Club Car golf cart, be certain that you have the following materials and tools ready:

- Socket Wrench Set: Used for loosening and tightening the axle’s nuts and bolts.

- Bearing Puller or Slide Hammer: This is necessary to extract the old bearings without causing damage to the adjoining parts.

- Rubber Mallet: Used to help seat the new bearings into the hub.

- Torque Wrench: Required for putting fasteners to the specified torque values to avoid overtightening.

- Grease Packer or high temperature grease: Used to lubricate the new bearings and enable smooth operations.

- Impact Driver: Helpful with stubborn or rusty fasteners that are difficult to remove.

- Jack and Jack Stands: Wording stands use these stub jackstands to properly prop the cart while it’s being worked on.

- Safety Glasses and Gloves: To guard against flying objects and chemicals when working on the unit.

Make sure all tools meet the Club Car service or manufacturer’s specifications. The right tools maintain component integrity and safety during the repair process.

Front wheel vs. rear axle bearing replacement differences

The changes in front wheel bearings are more pronounced than those in the rear axle bearings on account of their structure, purpose, and position within the vehicle.

Front Wheel Bearings:

- Function and Design: Front wheel bearings are usually integrated within the hub assembly and are designed to accommodate steering bearing radial and axial loads. In most instances, these bearings are sealed units which require less servicing, however if the bearings fail, the entire hub has to be replaced.

- Replacement Procedure: Usually, replacing the front wheel bearing requires taking off the wheel together with the brake parts and even the hub assembly. Separating and installing the new bearing or attaching and installing the press may be necessary.

- Technical Considerations: Most vehicles have specified torque provision on the nut of the axle (for example, 175 ft-lbs for most common passenger cars) in case of front bearings. As far as proper torqueing is concerned, it must be followed during the implementation to sustain the service life of the bearings.

Rear Axle Bearings:

- Function and Design: Rear axle bearings usually bear greater radial load because they are connected to the drive axle. These are often individual bearing units not incorporating a hub assembly, particularly in solid axle configurations.

- Replacement Procedure: In the case of rear axle bearings, the removal of the axle is necessary, which includes the unbolting of the differential cover, draining the gear oil, and pulling out the axle shaft. A bearing puller tool is often employed, although in certain instances, it may be necessary to displace other parts, such as seals, to perform the replacement.

- Technical Considerations: Rear axle bearings may depend on the precision fit with the axle shaft to achieve function, along with the necessary lubrication. Regarding rear differentials, it is important to ensure that the correct gear oil viscosity is used, as in SAE 80W-90 for most applications.

These differences must be understood so that the steps taken will lead to satisfactory results and safety. Manufacturer specifications should be respected to ensure that the integrity of the components is not compromised.

How do I install new golf cart wheel bearings correctly?

Common mistakes to avoid during bearing replacement

In the course of replacing the wheel bearings on a golf cart, some mistakes made, if not corrective actions undertaken could lead to excessive failure or inefficiency of components over time. One of them is not cleaning or inspecting the hub before fitting new bearings. Any leftover dirt, rust, or other particles in the hub can certainly ruin the bearing’s performance. Be sure to wash the hub with an adequate solvent and allow it to dry completely.

Another common error would be applying the wrong torque value for tightening the spindle nut. Both over, and under-tightening can create issues. It can cause excessive heat buildup and cause wasting away, or it can lead to poor seating which isn’t ideal and can be dangerous.

Perhaps one of the larger oversights, not using the right grease can easily create problems. Using automotive rated high temperature bearing grease comes highly hanged recommended, especially NLGI grade 2, lithiun grease. Be Sure the grease is adequately filled into the bearing to avoid dry spots that can lead to friction and case damage later on. Lastly, always make it a point that seals are correctly seated to avoid contamination over time.

Required tools for proper bearing installation

Each of these tools and equipment must be prepared to ensure efficiency and accuracy when executing a bearing installation process:

- Bearing Puller or Bearing Pusher: Assists in the removal and installation of bearings, allowing an operator to control the process so that neither the housing nor the shaft is damaged.

- Torque Wrench: It is fundamental to carefully control the application of torque during the installation procedure to prevent the risk of the parts being too loose or too tight, which could potentially cause harm.

- Soft-Face Hammer: Used to tap and work on the parts in locating and aligning them with preset positions without the danger of scratching or bending the parts.

- Proper Alignment Tools: These tools confirm that the bearing is placed on the shaft in such a way that no further friction is imposed in the spinning motion of the shaft or the bearing.

- Dial Indicators and Micrometer: Instruments necessary to check dimensional tolerances of the bearing in question to ensure it is seated according to the suppliers’ arrangements.

- Industrial Gloves and Protective Equipment: Shields against the introduction of foreign materials such as dust, perspiration, or oil on the bearing throughout the process of installation.

- Lubrication Tools: Gun or other such apparatus designed for the application of grease, lithium grease as mentioned above.

If you follow the technical rules and properly use these tools, you will greatly reduce installation mistakes and enhance the working life of the bearing.

What’s the difference between front and rear golf cart bearings?

Front wheel steering bearings vs. rear axle bearings

The core distinction between front wheel steering bearings and rear axle bearings is located in the respective functionality and load anticipations of each component.

- Front Wheel Steering Bearings: These precision bearings are typically placed in the steering mechanism. These bearings are designed to support wheel rotation along with angular movement that modifies the steering response. Generally, front wheel bearings are ball bearings or tapered roller bearings, according to the preferences of the manufacturer. Usual tolerances vary from ten to fifty micrometers which is optimal to provide alignment and minimize wear during operation.

- Rear Axle Bearings: Rear axle bearings are responsible for the majority of the load in a dynamic stance and the rotational effort exercised by the drivetrain for the vehicle. These bearings can withstand a heavy radial load, thanks to the weight of the golf cart itself and any storage the cart has. These bearings tend to come in larger sizes and are typically built in a roller bearing format, while some may also be sealed ball bearings to improve the durability of the bearings by preventing contamination. For maximum efficacy, these bearings tend to have lower friction coefficients while having preset high load ratings, dialed between two thousand to five thousand newtons of load, depending on the model and intended application.

The selection of the right type of bearing, along with adequate installation and lubrication, is paramount for the effectiveness and longevity of both front and rear bearings.

When to replace both front and rear bearings

It is essential to replace both front and rear bearings when there are any indications of wear and damage. The bearings should be replaced under the following circumstances:

- Excessive Noise or Vibration: If a bearing is producing a grinding, humming, or squealing sound while in operation, there is most likely internal wear or miscalculation.

- Heat Buildup: Bearings suffering from unacceptably high temperatures, exceeding the set range of 120 degrees celsius for most sealed ball bearings, are likely failing from lubrication deficiency or internal debris contamination.

- Reduced Rotational Efficiency: Increased friction, notable resistance, or irregular movement in the bearings is, in fact, a signal that the internal components may have degraded.

- Considerable Load Stress: Over a prolonged period, bearings that are subjected to rated capacity loads, 5000 N for industrial-grade bearings, are adept at experiencing wear and reduced functionality.

- Lubrication Breakdown: Replacement is necessary when signs of insufficient or contaminated lubricant appear, regardless of regular maintenance following manufacturer expectations.

Strategically monitoring these parameters of the bearings together with the operational procedures protects the equipment from suffering mechanical damage and also enhances its performance and durability.

How long do golf cart bearings typically last?

Factors affecting golf cart bearing lifespan

A variety of factors affect the life expectancy of golf cart bearings. I focus on a range of factors that involve how the ears are used and maintained, the environment where it’s kept, and how well servicing is done. For example, moisture, dust, or debris, if not sealed properly, can easily hurt the longevity of the device. Conditions such as very high loads or use of the cart beyond the limits prescribed by the manufacturer can also bring about premature failure of the device. I also look into the operating temperature range, the steel or ceramic composition of the bearing, and the amount and type of oil it has (viscosity and contamination thresholds).

- Load Capacity: The load placed on the bearing must not exceed the dynamic load rating of the bearing, which is a maximum stated value in Newtons or pounds.

- Lubrication Viscosity: The lubrication must be kept within the manufacturer’s specification range of 15-400 cSt at the operating temperature.

- Temperature: The bearings need to operate at the prescribed range of -20°F to 250°F (-29°C to 121°C) from standard steel bearings.

- Environmental sealing: The bearings must be properly sealed or shielded on the bearing sides that are open to the environment containing dust or debris.

In consideration of these factors and with routine checks, I ensure the bearings are operating at their optimum longevity whilst simultaneously maximizing the performance of the golf cart.

Maintenance tips to extend bearing life

I have very specific operational measures grounded in technical best practices that I implement to prolong the service life of bearings. Here are a few of these approaches:

- Bearings Lubrication: I regularly lubricate all bearings with grease or oil of their manufacturer’s choice. For example, standard bearings would use lithium grease. Good lubrication reduces friction and overheating and improves performance consistency.

- Cleaning: I ensure that dirt, moisture, and harmful particulates that can compromise functionality are removed, and I do this by cleaning the bearing surfaces very thoroughly. For cleaning, I use a non-corrosive solvent and a lint-free cloth to ensure no dirt gets left behind that can corrode the bearing.

- Load Control: I confirm that loads from the bearing are within the manufactured limits. For instance, standard radial ball bearings are able to support dynamic loads within a certain cap, and as long as that limit is provided in the product specifications, everything works fine. If the load exceeds limits, only negative implications come from that, ranging from faster wearing to complete failure.

- Monitoring Operating Temperatures: Bearings are operated at a temperature which is -20°F to 250°F or -29°C to 121°C for standard steel bearings. Positioned out of those working limits, materials can be severely degraded and negatively affect performance.

- Visual Inspections: During my periodic inspections I try to notice protruding signs of failure like corrosion, pitting, and misalignment and fix them before it is too late.

I can extend the longevity and achieve optimal performance of bearings through proper monitoring and servicing schedules.

Frequently Asked Questions (FAQs)

Q: How do I know if my golf cart wheel bearings need replacement?

A: Signs that your golf cart wheel bearings may need replacement include unusual noises like grinding or humming from the wheels, uneven tire wear, and vibration in the steering wheel. Regularly checking for these symptoms can help you decide when to replace the bearings.

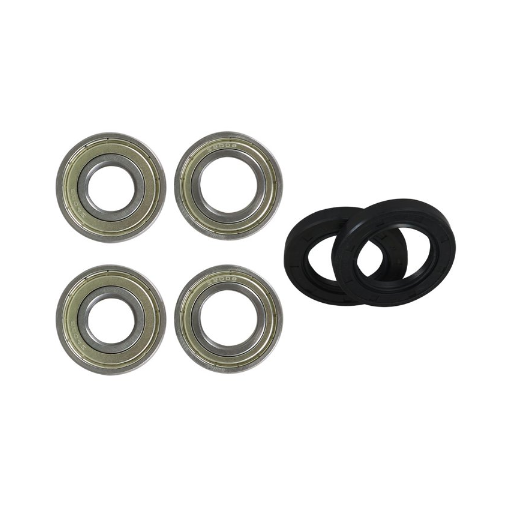

Q: What is the average price for a golf cart rear wheel bearing seal kit?

A: The average price for a golf cart rear wheel bearing seal kit can vary depending on the brand and quality but typically ranges from $30 to $60. Shopping online can help you compare prices and find deals to save money.

Q: Can I use a bearing and seal kit for both gas and electric golf carts?

A: Yes, many bearings and seal kits are designed for use with both gas and electric golf carts. However, it’s important to check the product details to ensure compatibility with your specific model.

Q: How often should I replace the front wheel bearings on my golf cart?

A: Front wheel bearings on a golf cart should be checked annually and replaced approximately every 3-5 years, depending on usage and driving conditions. Regular maintenance can help extend their lifespan.

Q: What tools do I need to replace the hub bearings on my golf cart?

A: To replace the hub bearings on your golf cart, you’ll typically need a jack, socket set, torque wrench, and possibly a bearing puller. Following a repair guide specific to your cart model can assist in the process.

Q: Are there different bearings for 2-cycle gas and 4-cycle gas golf carts?

A: Yes, there can be different bearings for 2 cycle gas and 4 cycle gas golf carts. It is important to confirm the type of engine your golf cart uses and select bearings that are compatible with that specific cycle type.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8