Demystifying Axial Play: Understanding Radial vs Axial Contact Angle in Bearings

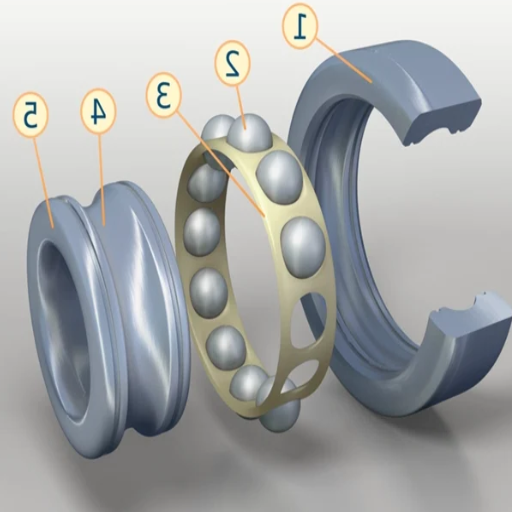

Bearings are a fundamental component in mechanical systems, enabling rotational or linear motion while minimizing friction and handling applied loads. Among the critical factors determining their performance is the precise understanding and management of axial play, as well as the differentiation between radial and axial contact angles. These parameters not only influence the stability and efficiency of mechanical systems but also dictate bearing longevity under specific operating conditions. This article aims to provide a comprehensive examination of axial play, elucidate the distinctions between radial and axial contact angles, and explore their combined significance in optimizing bearing selection, design, and overall performance in various applications. Whether you’re an engineer, technician, or someone with an interest in mechanical systems, this guide offers the foundational knowledge required to better understand these pivotal concepts.

Why is understanding axial play important for ball bearings?

Impact of axial play on bearing performance

The function of ball bearings is significantly impacted by the amount of axial play, which is also called end play. Ball bearings are assigned an axial load with less than total external force where they can move freely. Excessive or insufficient values can lead to problems in the function and operation of ball bearings leading to undesirable reasons.

- Load Distribution: Wear and contact among raceways differ with the degree of contact greater than or less than 90. Therefore, an increase in axial play reduces the vertical component of the contact force, increasing the angle of rotation of the rolling element. With reduced load, imbalance arises which reduces overall bearing resistance which leads to quicker wear of the ball race and a decrease in life cycle.

- Vibration and Noise: An overly negative value of axial play might increase vibration and noise levels due to a greater playing surface. The aforementioned statements become important in areas that use bearing at high speeds and loads.

- Thermal Expansion Compensation: The application of othe ptimum value of axial play should consider the thermal expansion of the ball bearing in operational conditions. In too low values of most axle-bearing folder deployable systems, the thermal strain and binding can cause strong issues in moderate heat regions.

Establishing the volumes of axial play should consider the efficiency of the bearing and service life. It lies in striking a balance between the operational requirements of the application, the physical and thermal properties of the material, and the mechanical tolerances.

How axial play affects load distribution

The defined axial play allows the movement range of the shaft which in turn permits control over the load distribution amongst the bearing surfaces. With too low an axial play, load sharing can be uneven leading to localized stress concentrations that are more pronounced and a greater wear on the bearing. At the same time, with too large an axial play, there is a loss of rotary accuracy and coordination which brings along some form of loosening of the structure or the assembly unit which lessens the stability and effectiveness of the assembly.

- Recommended ranges of axial play: The recommended range for axial play depends on the application and the operating conditions. For normal cases, the ranges are classified from 0.02mm to 0.10mm, while extremely high temperatures places will require some changes owing to expansion.

- Material Properties: Bearings made out of materials that have higher coefficients for thermal expansion require greater allowance for axial play when compared to bearings made of low-expansion materials.

- Operating Speed: Excessive rotary motion can cause misalignment even further with excessive axial play. In applications where high speed is the norm, the ranges for axial play have to be controlled (0.02mm to 0.05mm for example).

- Load Type and Magnitude: In cases where there are significant axial or radial loads, the amount of play in the axial direction must be properly controlled to ensure load distribution from all sides. For example, an axial load of over 10 kN greatly increases the probability of needing closer tolerances to prevent any deformation under stresses.

To achieve optimal load distribution which ensures the longevity and performance of the bearing system, axial play must be calculated and adjusted considering these factors.

What causes axial play in bearings?

Factors contributing to axial movement

Some factors illustrate the origins of the bearings’ plays. The first of them is clearly defined as production tolerances which are always problematic form. Certain discrepancies in the measurements of the inner and outer races, rolling elements, or the bearing housing could cause undesired axial movement. For instance, if one deploys machining tolerances above or below ±5 μm, one is bound to get rough contact surfaces which are bound to lead to axial displacement.

Second, expansion due to head is also an important consideration. Variations in temperature between different parts of the bearing can lead to expansion or contraction of the bearing which affects the axial play. For example, steel bearings when operating at high temperatures can expand by around 11 μm per meter per °C and this might impact alignment on the axis.

Third, inappropriate preload setting or absence of it at all becomes important. Preload that is far from optimal permits the rolling parts to displace axially, while too much of it may impose harmful bearing stress which can lead to collapse. Most of the time, axial preloads are fixed at 2% to 3% of the dynamic load rating (C) to ensure sufficient alignment for proper operation.

Last but most certainly not least, other operational conditions such as shaft misalignment or external axial loads also affect bearings play. For instance, external forces that are greater than the rated external axial loads available (Fa) could lead to increased axial displacement which is bound to interfere with the performance and the wear rate.

These factors, when followed to specific standards, can help minimize the axial play, which in turn improves the reliability and efficiency of the bearing.

The influence of internal clearance on axial play

Under no load, internal clearance is defined as the distance the inner and outer rings of a bearing can move relative to one another. This is notably important in axial play. Generally, the greater internal clearance there is the greater the movement in the axial direction. Conversely, less internal clearance allows less movement. As an example, radial bearings that are too tight with insufficient clearance will create too much friction which can lead to wear and tear or overheating. On the other hand, too much clearance reduces stability which can lead to increased vibration.

- Radial Internal Clearance (RIC): For standard deep groove ball bearings, depending on the size and type of the bearing, RICs are between 3 micrometers and 25 micrometers. More RIC allows more potential axial play in some applications.

- Axial Load Rating (Fa): The nominal axial load limits defined per bearing must not be exceeded, qualified Fa should not be rated for excessive values otherwise the axial play effects will be greater and the performance will suffer immensely.

- Operating Temperature: The operative clearing gets compromised because it expands with heat. Increasing temperatures translates to reducing the effective internal clearance which can lead to issues.

- Precision Classes: Internal clearance is often smaller in bearings produced to tighter tolerances (for example P5 or P4 classes according to ISO ABEC) which reduces the effects of axial play.

To manage axial play, bearing clearance should be selected so that they are suitable for the operational requirements. Temperature as well as load conditions must be assessed during operational phases.

How is axial play measured and controlled in ball bearings?

Techniques for measuring axial play

The axial play of ball bearings is usually tested with a mechanical or electronic gauge with high levels of accuracy. I would utilize a dial indicator with a fixture that keeps the bearing in place to make sure that there are no inconsistencies. The bearing is then subjected to axial force in both directions, and a measurement of the total axial displacement is taken. This value is equal to the sum of the two displacements in the bearing’s axial direction.

- Measurement Accuracy: The dial indicator should possess markings that allow rotation on at least 0.001 mm increments.

- Applied Force: There is a requirement for a constant axial force in correspondence with the bearing operating conditions. This force is usually set by the vendor.

- Temperature: Measurements should be taken near room temperature, at around 20 degrees Celsius, because higher temperatures could change the results due to expansion.

This level of justification guarantees that the boundaries of axial play are met, along with dependable bearing action when loaded.

Methods to adjust and control axial play

There are various techniques to modify and manage the axial play within the boundaries of operational limits of the mechanical system under consideration:

- Shim Adjustment: Axial play can be adjusted by adding or removing shim packs that meet the target gap specification and tolerances set by the manufacturer. The shim’s thickness should be calculated using the gap specification’s tolerances.

- Threaded Adjusters: The axial position of the bearing can be set with the use of threaded components like bearing locknuts. The torque applied to the adjuster should follow the manufacturer’s specification such as 20 – 50 Nm depending on the size and the design of the bearing.

- Preloading with Springs: Controlled axial play can be achieved by using calibrated springs to preload the bearing. The spring force needs to be in the range of the desired preload, for example, 100-200 N, depending on the application.

- Spacer Adjustment: Machined spacers can enhance or maintain an axially aligned gap. The spacer must be manufactured within a tolerance range of ±0.01 mm to ensure gap alignment with the defined tolerances.

These methods, when executed by the technical, provide a cost-effective solution for controlling the axial play to the desired level for defined system reliability and performance.

What are the differences between radial play and axial play in bearings?

Defining radial play and its importance

Radial play of a bearing describes the total movement or clearance that occurs during no external load exerted along the radial. This is typically accomplished by placing some force onto the inner ring for it to be displaced relative to the fixed outer ring in both directions. It must be noted that radial play directly affects the operational performance of the bearing, ranging from accommodating thermal expansion and vibration to the manufacturing tolerances incorporated without rendering the part unreliable.

- Measurement Range: Radial play is usually defined in microns (µm), and as with some industrial bearings, they start from 10 and range up to 80 µm depending on the size and type of the bearing.

- Load Distribution: When rheological fluids are employed, optimal radial play must be ensured so that all rolling elements are uniformly loaded so that a reduction of severe stress concentrations can be accomplished.

- Operational Speed: Substantial radial play can result in high rotational instability, however, when devoid of radial spacing, excessive friction and overheating can damage the system.

- Temperature Compensation: In melting conditions, radial play is awarded for material expansion due to increased temperature; a common consideration is a 5-20 µm range depending on the environment which is considered for operational temperature.

To conclude, adequate selection of radial clearance will enable reliable operation of the bearing under expected conditions and, at the same time, will ensure minimum wear and system integrity.

Comparing the effects of radial and axial play

- Radial Play: This is a type of internal allowance that permits motion at the right angles to the axis of the bearing. High radial play can cause vibration and roughness during operation, whereas low radial play can lead to increased frictional force, elevated temperature, and system components wearing out quickly.

- Axial Play: Measure of the radial play which permits motion along the rotation axis. It plays a part in the bearing’s ability to withstand misalignment and axial loads. Very large axial play can result in poor load sharing and support, causing lateral noise and abnormal wear of the bearings. Tight axial play is greatly beneficial in improving the stability of the system but is made worse by extreme thermal or expansion loading, which is not a drawback of so-called precise systems that have less than 1 µm axial clearances.

The need for general and specific tolerances means that no matter the application, optimal selection and balancing of radial and axial play would be necessary to ensure reliability, reduce system wear, and eliminate the operational integrity of the system under different mechanical and environmental factors.

How does axial play affect different types of bearings?

Axial play in ball bearings vs. plain bearings

I can distinguish between ball bearings and plain bearings regarding their operational principles and structural design tolerances in terms of axial play evaluation.

- Ball Bearings: Axial play tolerances for precision-grade applications vary from 5 µm to 20 µm. Excessive axial play may reduce the efficiency of load distribution, resulting in vibrations and severe fatigue. Moreover, decreased axial play enhances positioning clearance to be below 5 µm but requires adequate measures for thermal expansion and lubrication. On the other hand, positioning accuracy is made worse by tightly controlled axial clearance. Placing the upper “pie-in-the-sky” limit at a lower boundary of 20µm means a higher range of unmanageable expansion is welcomed. Increased bound for lubrication oil mitigates uneven distribution.

- Plain Bearings: This bearing type typically looks out for sliding interfaces instead of rolling elements, which simplifies proper clearances. However, axial play shall not be exaggerated as it could violate clearance integrity. Exact tolerances remain extremely material sensitive, so for some multi-material combinations, it shall stay up between 10µm to several hundred micrometers. Reduced tolerances bring on clear disabilities, like impairment in adaptability for conditions of heavy loads or high gasses. g. Efficient clearance shall be unattainably greater than 100 micrometers which is simply anti-alignment smart.

Based on this understanding, it can be concluded that these differences suggest the need to optimize axial play according to the bearing type, working conditions, and intended performance for effective reliability and efficiency. In the case of ball bearings, tighter tolerances are more common in high-precision systems, while plain bearings accommodate greater freedom and flexibility in rigid applications.

The impact of axial play on various bearing designs

The functional life and relative performance of different bearing designs are directly affected by the amount of axial play present in them since this affects load distribution, rotational accuracy, and thermal mobility. In ball bearings, excessive axial play generally leads to vibration, misalignment, and an uneven distribution of loads which reduces the operational efficiency of the system. Multi-axial movement limitations also result in overheating and unwanted wear since the lubrication film is insufficient. The optimal range set for axial play-in for ball bearings is usually between rotative 5-20 micrometers. The exact figure varies based on precision requirements and anticipated loads – tighter tolerances are set in high-precision systems like robotics and aerospace machinery.

Plain bearings do require axial play for suitable thermal expansion compensation and adequate lubrication, but the axial play has a much more profound impact on its functionality. For high-temperature operations and other uses involving heavy loads, ranging from 50 micrometers to several hundred micrometers prove to be more beneficial as they prevent binding or seizing. However, large tolerances can significantly minimize alignment deviations, but they must be used carefully so the difference does not impede system alignment.

It is critical to consider the operational speeds, material properties, thermal expansion coefficients, and the specific load environment. Having axial play adaptive to these conditions would enable the bearing designs to achieve a reliability, efficiency, and adaptability balance.

Frequently Asked Questions (FAQs)

Q: What’s the difference between radial and axial play in bearings?

A: Radial play pertains to the movement of a component perpendicular to the bearing axis, while axial play refers to a movement along the axis of rotation. Radial play allows for movement in different directions perpendicular to the axis, whereas axial play enables movement parallel to the axis.

Q: How does ball diameter affect axial and radial play?

A: Ball diameter influences both axial and radial play in bearings. Larger ball diameters generally result in reduced play, as they fill more space within the raceway. Conversely, smaller ball diameters can increase radial play and potentially affect axial movement, depending on the bearing design.

Q: What is internal clearance in ball bearings?

A: Internal clearance in ball bearings refers to the total radial or axial movement of the outer ring relative to the inner ring when one ring is moved concerning the other. This internal radial looseness is crucial for proper bearing function and can affect performance and lifespan.

Q: How does radial play in bearings affect performance?

A: Radial play in bearings impacts performance by influencing factors such as load distribution, heat generation, and noise levels. Proper radial play ensures optimal contact between rolling elements and raceways, enhancing bearing efficiency and longevity. Excessive play can lead to increased vibration and reduced precision.

Q: What’s the difference between axial and radial contact angles in bearings?

A: Axial contact angles are measured relative to a plane perpendicular to the bearing axis, while radial contact angles are measured relative to the radial direction. Axial contact angles primarily affect axial load capacity, whereas radial contact angles influence radial load capacity and play.

Q: How does axial play change when a bearing is mounted?

A: When a bearing is mounted, axial play can change due to factors such as preload, fitting, and thermal expansion. Proper mounting techniques and consideration of operating conditions are essential to maintain appropriate axial play and ensure optimal bearing performance.

Q: Can you explain the relationship between axial and radial play?

A: Axial and radial play are interrelated in bearings. Changes in one type of play can affect the other. For example, increasing radial play may result in a corresponding increase in axial play, depending on the bearing design and contact angle. Understanding this relationship is crucial for proper bearing selection and application.

Q: How is total radial movement measured in bearings?

A: Total radial movement in bearings is typically measured by fixing one ring (usually the outer ring) and moving the other ring (inner ring) in a radial direction. The total displacement between the extreme positions represents the total radial movement, which includes both the internal clearance and any additional play due to manufacturing tolerances.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8