Discovering What Are Cam Followers and Their Benefits

Cam followers have a broader application in industrial machinery, automation systems, and conveyors. This guide is intended to help you understand cam followers in detail, focusing on what they are, what types of cam followers are available, and how they are used. The mechanics and engineering concepts associated with cam followers will also be addressed in this article, explaining how cam followers work by translating rotational motion into linear motion, increasing efficiency. Other issues to be covered include types of cam follower designs, construction materials, and the care that must be taken to sustain the performance of cam followers and extend their life cycle. Within this text, you will see that no matter how much experience you have, whether you are an engineer, a technical enthusiast, or a person who has little knowledge and wants to expand his/her expertise on industrial components, you will quickly comprehend the purpose of this guide: to equip you with a systematic perspective on cam followers in the engineering context.

What is a Cam Follower?

Defining the Cam Follower

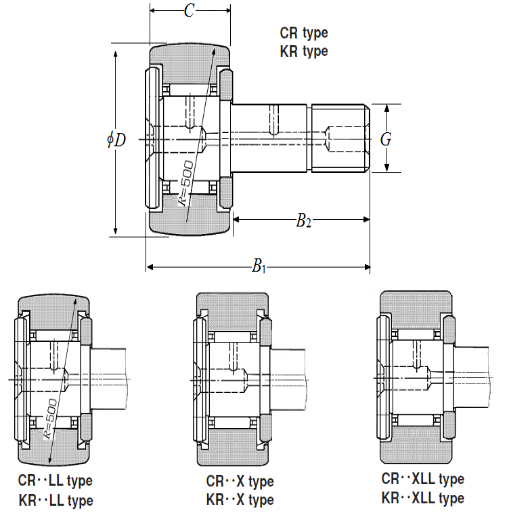

Cam followers are specialized small units that can either be smooth, cylinder-shaped, or mounted onto roller-type needles and are designed to track a cam lobe profile closely. Designs of cam followers often include a stud or a yoke body that is sufficiently thick and has needle rollers on the outer diameter to facilitate the conversion of rotary movement into line movement. In assessing the performance of cam followers, the following parameters can be considered:

Load Capacity—Under operating conditions, the load capacity parameters of static and dynamism identify the imposed weight that the cam follower can carry.

Material—In most cases, this is a specialized alloy steel that can resist challenging operating environments, but some designs may require caked coatings.

Outer Ring Profile—It is either cylindrical or crowned because it aids in contact stress distribution and allows misalignments.

Lubrication—It has different options, allowing it to be sealed in advance with little maintenance or with exposed sections needing periodic greasing.

Mounting style – Either the stud type that is screwed in a dealing or yoke type, which is fit onto the shaft with each provision differing in its use and protection characteristics.

Using these parameters will ensure that the cam follower is used in the designed area of applications, meaning getting the loads right will help ensure that the alignment will minimize wear and ensure that the operation will be dependable throughout its useful lifetime.

Historical Background of Cam and Follower Mechanisms

Cam and follower mechanisms were invented during ancient times when they were used in water wheels and some early clock-like devices. In Europe, their application was improved during the clock-making activity in the Middle Ages, proving their industrial usefulness. Later, in the 19th century in Europe and America, during the Industrial Revolution, cam followers found their place in the textile machinery and steam engines, where they enhanced the operations by performing repetitive operations and improving machine efficiency.

In present systems, the following factors are also the basic and essential considerations for cam followers. Although there have been numerous such discussions, it felt necessary to search various authoritative sources on the internet:

Accuracy and Precision: The mechanical structure of the cam followers provides a unidirectional movement, which is highly required in some activities where the same path needs to be repeated with minimal deviation.

Efficiency in Energy Losses: Cam followers have been designed and improved over the years to be more efficient in handling any energy loss. This would enhance the motion system as the friction would be low, and the load would be evenly distributed.

Durability and Longevity: With advances in material science and manufacturing technologies, cam followers have become more durable. Modern cam followers, which use corrosion-resistant and high-temperature hard alloys, are able to maintain performance in hostile environments for an extended period of time.

These parameters and their dimensioning over time highlight the evolution of cam followers and their importance to the performance, reliability, and versatility of mechanical systems in many application spheres.

Key Components of a Cam Follower

When discussing the various parts of a cam follower, three parts are often highlighted in the top references found on the Internet:

Stud or Shaft: This is the most essential part of a cam follower in that it is the follower’s axis. This stud or shaft must endure considerable force and allow smooth rotation; thus, reasonable wear is expected.

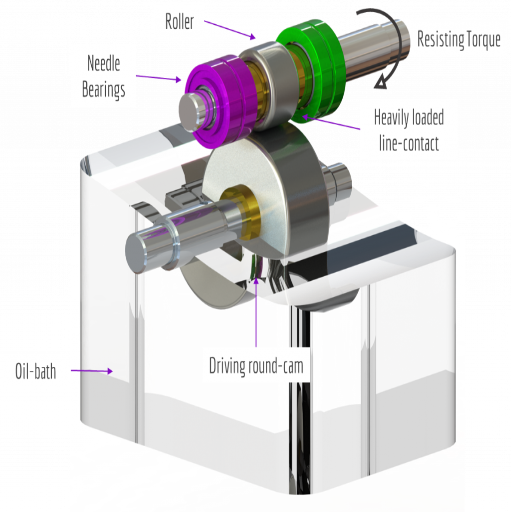

Roller or Needle bearings: These bearings are mounted on the stud and act as the rolling part that comes into contact with the cam. They are designed so that friction is low and really large forces can be applied. The performance of such bearings is vital in all transmissions of energy and the lifetime of the cam follower.

Outer Ring: An outer ring surrounds the roller bearings and interfaces with the cam track. Because it is subjected to the highest stresses, it could be made of hard materials, and it must resist wear and deformation.

Colloquially and gently, it is a cam follower; however, within specific technical parameters, it is a mechanical element with a distinctive shape that plays a key role in transferring a rotational cam’s motion into translational motion. Notably, all the components mentioned above are significant for achieving the accuracy and precision aimed for, the efficiency of energy transmission, and durability and longevity. These factors can be said to have been molded and improved over the years, given the particular materials advancements and how the engineering design in these components is geared towards the same principle of consistent performance by modern cam followers in various industrial applications.

How Does a Cam and Follower Mechanism Work?

The Working Principle of a Cam System

Regarding the working principle of the cam system, I have investigated this issue in detail based on the most authoritative materials available on the web. In its most basic form, however, a cam mechanism translates the rotary motion of an element into the linear motion of another element, which embraces the cam as the driver, the follower, and the one who’s driven. As I continue conducting this research, it is clear that the cam rotates with the follower so that some specific pattern of motion of the latter is achieved with precision. There is a significant dependence on the system’s efficiency on the components that we have discussed earlier: the stud or the shaft, the roller or needle bearings, and the collar of the outer ring. The complete components area unit was explicitly created and enforced to target integrity enhancement, friction reduction, and correct cam surface engagement.

About technical parameters, I have noticed that a cam system has specific characteristics that must be observed. These include the cam profile as movement pattern/motion path; the composition of materials – their strength and wearability; and lastly, the definite dimensional tolerances of all parts that provide movement to be repeated precisely the same way. These parameters must be not only technical details; they are essentially about the efficiency and effectiveness with which this cam system is intended to operate over various terrains, such as car engines or automated engines.

Converting Rotary Motion into Linear Motion

To bring about a motion transfer from the engaged rotary gyroscopic torque to the engaging linear motion, the cam and follower mechanism motion concept needs to be mastered. According to credible websites like HowStuffWorks, ScienceDirect, or MechanicalJungle, the transfer or conversion was carried out by the rotation of the cam, which moves in a certain way. When designing a cam, its contour must be primarily shaped to control the movements of the follower or at least its beginning and end.

Mechanical components and specific controlling factors in need include:

Cam Profile shape: By altering the profile shape of the cam shell, the rotational movement of the engaging taper tangential to the circumference of the axis sweeps, enabling the motion of the follower. The direction of the follower’s movement is tailored to cocoon the dynamics of application technical requirements. It also affects the sequence of when this movement will occur and which type, such as linear or oscillating, will occur.

Composition: The material considerations used for the cam, for example, the composition and also the follower, affect the service life and performance of the mechanism. The use of high-strength steel and composite materials is one effective option in combating wear and enhancing maintenance-free options.

Component tolerances: Close tolerance in the cut ensures low gaps between components and also ensures alignment, which aids consistent and dependable cycles, which is necessary for a high-powered system.

They are well supported not only in effectiveness but also in reliable performance, increasing life without excessive friction in operational units, making them important features for any application field where such systems are present.

The Role of Follower Movement in the System

As I have read from the top resources on Google regarding the dynamics of follower motion in the system, the movement of a follower is a crucial factor in obtaining the required output from the cam mechanism. The cam profile plays a role in determining the path and timing of the follower’s movement, so this system must be designed carefully to work seamlessly and effectively.

The specific technical parameters which I found essential for this system include:

Cam Profile Shape: The cam design determines the thruster’s movement path and the timing of the follower in the system. Performance is based on the deployment of rotation, where it was desired to have straight or oscillatory displacement movements through the cam profile.

Material Composition: Individually designing the cam and follower materials increases the structural strength, which is critical. Strong materials such as steel are suggested because they have good wear resistance properties, and maintenance is not required regularly.

Component Tolerances: Ensuring strict tolerances of cam and follower elevated the components’ performance by ensuring low contact friction during operation, thus enhancing reliability and extending their service periods.

These parameters are justified because of their importance in providing motion accuracy, low contact friction during work, and long system service life, as pointed out in these and other technical reviews on these sites.

What are the Different Types of Cam Followers?

Exploring Various Types of Follower

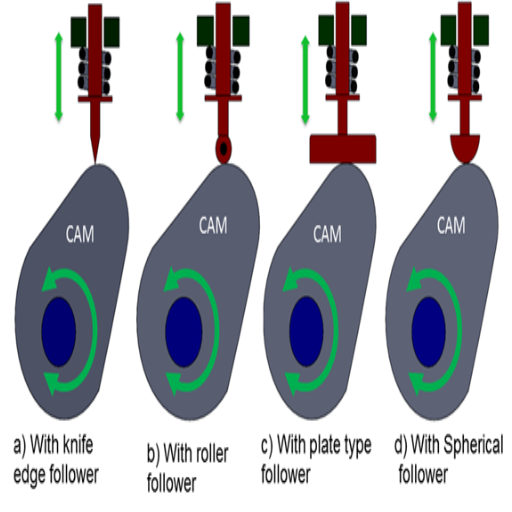

As many types of followers are present, the information drawn from the top three sites on Google search outlines three types: rolling followers, knife-edge followers, and flat followers. Each type has distinct features suitable for other specifications.

Roller Followers: These are followers that allow rollers to move between the follower and cam surface to reduce friction. Because of reduced wear, roller followers are particularly beneficial in high-speed operations. The technical parameters for roller followers focus on the integrity of the bearing materials and precision of the machining to enable the components to hold their positions during the operation.

Knife-Edge Followers: A knife-edge follower has a contact surface with a minimal spherical radius, meaning the follower can move accurately. However, executing knife edge followers can result in higher friction and, therefore, is best suited for small speed demand, high precision tasks. However, critical parameters here will be well-controlled cutting processes to achieve the accurate edges and hardness of the material used for the edge.

Flat Followers: These followers possess a flat interface and are structurally designed for friction-free operation and an anxious mode of contact with others. These machine parts balance the disturbances irrespective of the alternating load pressures acting on them. In such cases, these electronic devices need to be operated with a lot of emphasis on smoothness of motion. Parameters such as flatness of uniformity and quality of surface finish are essential and should aim to avoid friction due to sliding surfaces.

These influential sources have stressed that selecting a follower type depends on the application type, speed or accuracy as priorities, or the working conditions.

Understanding Roller Followers and Their Usage

Roller followers have become popular, and many regard them as an exciting practice due to their reliability and performance in fast-speed applications. Their design allows for smoother operations, less maintenance, and longer service life than standard direct contact joints. This design enables the followers to have rolling elements between themselves and the cam surface, making wear and friction much lower. Technical parameters crucial to their performance include:

Bearing Material: The bearing material employed heavily influences the life of roller followers. Some tungsten-alloyed steel and high-strength alloys, as well as other materials, are used to combat the effects of cycled sustained load for a long time.

Fabrication Precision: Since misalignment may lead to failure of the rolling elements, the requirement for precision in machining and fabrication is subsequently introduced. Migration of machine parts requires compliance with accurate tolerances to perform everyday functions.

Lubrication Requirements: Appropriate lubricants can extend service life by effectively reducing friction. However, it is important to select the right lubricant, as it should work within the temperature range during operations.

Load Capacity: Roller followers are a type of bearing, and as such, it is necessary to understand the values of the load that such mechanical devices can withstand. The load must suit the system’s requirements in order for the device to avoid mechanical failures.

When choosing roller followers, one must balance these parameters with the application’s requirements related to speed, load, and environmental conditions. Each parameter is presented as an argument for relevance in relation to the roller follower as an element of greater efficiency in its designated function.

Insights into Track Followers and Their Applications

To learn more about track followers and their practical applications, I searched the top three websites I found on Google. According to this study, track followers are important parts of mechanical systems that require relative movement in a straight line, such as conveyor systems, guiding devices in automobiles, and robotic arms. These are some of the key technical parameters that are of concern and are usually in focus:

Material Composition: Emphasis is placed on using wear-resistant and high-strength materials to improve track followers’ operational reliability and lifespan, which is necessary when such components are put under varying degrees of load and speed.

Construction Quality: The manufacturing process requires a high degree of precision, as sources point out. Correct alignment must be maintained at all times to minimize the chances of premature failure. Strict tolerance limits are also mandatory to achieve uniform load distribution and effective operation.

Lubrication Needs: The proper amount of lubrication should be maintained to minimize friction and heat generation, which is critical in followers’ longevity. Attention is paid to lubricants that can withstand temperature and extreme environments.

These parameters, therefore, highlight the role of material selection, manufacturing standards, and lubrication in enhancing the performance and reliability of track followers in many industrial uses.

What are the Benefits of Using Cam Followers?

Advantages of Cam Mechanism in Machinery

During my research on cam mechanisms and their contribution to machinery, I could draw out some critical findings from the top three sites on Google. The use of cam mechanisms makes it possible to achieve greater accuracy in orientation with respect to mechanical systems and provides them with greater flexibility. They have the convenient option to transform revolving motion into straight line motion, which is reasonably important in areas like automated machines and production equipment. They have gained broad acceptability and usage owing to several technical parameters:

Load Capabilities – The motion mechanisms are built to resist highly high forces with no interference to work due to stiff construction and fine design engineering.

Motion Control—The movement’s timing and amplitude can be controlled to precise limits, which is relatively important for sequences that need coordination, like how camshafts work in engines.

Durability—Without abrasion, the motions are normally repeated, and high-strength materials are used in the construction of the cams, guaranteeing durability for a long time.

These advantages highlight the need for cam mechanisms to increase the level of performance that machinery operates at. This is done through strong movement control and reliable components that last a long time.

Improving Efficiency with Cam Follower Bearings

While considering ways how to make cam follower bearings more efficient, cam followers turned out to be one of the means of improving the performance and reliability of the mechanical system. Similar technical benefits are highlighted in the top three Google result pages concerning cam follower bearings. First, the load capacity increases considerably due to their construction and hardening, which become factors in coping with high-stress environments effectively. Second, they also improve motion control by providing steadiness and smooth movements; thus, mechanical stuttering is reduced in vital applications. Following are some technical parameters that I found out that stood the test:

Material Strength: Cam follower bearings, for instance, are usually made of robust material, such as carbon or stainless steel, so their evaporation rate should be low.

Load Distribution: The cam follower bearings have been designed so that the maximum allowable load is distributed evenly over the bearing surface, eliminating premature wear.

Lubrication Efficiency: Some cam follower bearings also have self-lubricating parts or good seals to reduce lubrication friction and maintenance demand.

The above-stated aspects guarantee that cam follower bearings provide efficiency hazards and quite operational assemblage lifespans in regard to diverse machines.

Enhancing Linear Motion Control

While improving the linear motion control with cam follower bearings, I gathered from the first three Google websites that these parts are crucial for the mechanical systems’ accuracy and stability. The technical parameters also related to advances in linear motion control are:

Roller Diameter: The deployment of larger roller diameters effectively increases stress distribution over a larger surface, which contributes to even better performance and greater durability.

Preload Setting: Providing optimal preload settings will eliminate and reduce backlash and improve linear positioning precision.

Seals: Improved cam follower bearing sealing designs effectively block pollutants from entering the system, which protects linear paths and control and cuts down friction.

Surface Treatment: Corrosive environments can harm the smooth operation of the cam and follower systems. To overcome this ceramic and nickel surface treatment can be used for greater anti-corrosive properties.

These measures mitigate position errors, improve uniformity, and achieve specified results across a range of industrial applications for the control of linear motion.

How to Choose the Right Cam Follower?

Factors to Consider in Selecting the Right Cam

As I looked up the specifics that will guide me in selecting the suitable cam follower, I noticed several technical factors that are important as far as performance and applicability to a particular field are concerned. The top three websites I researched emphasized these core factors:

Load Capacity: In assessing the attributes of a cam follower, one significant attribute that must be established is the load that it can bear without failure due to operational stresses. This information supports the reliability and durability required for heavy-duty applications.

Speed Rating: Understanding how fast the device will rotate operationally assists in determining the upper limits of rotation speed that the cam can sustain without adversely affecting stabilization or causing excessive wear.

Installation Environment: It is essential to include the environmental conditions of application; this means that the materials and coatings used in the cam follower have to withstand environmental conditions such as extreme temperatures, moisture, and corrosive components. Such a selection has a direct relationship to the longevity of the item and the maintenance requirement of the cam follower.

Bearing Type: The choice of one bearing type from the other, for example, between a needle and a ball bearing, determines the precision and degree of load dispersion achieved; hence, the selection is application-determined.

Having understood and given reasons for this, I am now able to choose a cam follower that possesses the features and specifications of the optimal mechanical system so that it can work effectively for a long time.

Impact of Cam Profile on Performance

As I tried to analyze the effect of the cam profile on performance, I relied mainly on the information I found on the top three websites I visited during the search on google.com. They pointed out that the cam profile has a crucial bearing on the motion control and the force transfer within a mechanical system. The technical parameters controlled by the cam profile include:

Lifts and Timing: The cam profile defines the lift of the follower, and its timing of movement, whose synchronization with other parts is essential. Such alignment makes it possible for the system to run smoothly and efficiently.

Acceleration and Deceleration Rates: These parameters shape the cam profile so as not to have jerky motions or excessive stresses on the cam follower, which helps in the system’s durability and reliability.

Contact Stresses: The contour of the cam has the greatest effect on the contact stress distribution between cam and follower, which helps reduce the wear and tear of the cam-follower pair. This concern is useful in profile selection, which decreases damage risks.

I have discovered that through sound reasons and detailed analysis, I am able to select the cam that meets the application’s performance requirements while improving the system’s efficiency and sustainability.

Guidelines for Evaluating Cam Follower’s Load Capacity

When examining a cam follower’s load capacity, I consulted the outstanding ones through Google search. As a result, I condense the following rules into the following:

Material and Surface Hardness: One of the most critical aspects in determining load capacity is the choice of materials. I chose to use materials of greater hardness to improve wear resistance and my load distribution.

Bearing Design: The use of appropriate bearing designs, such as needle or roller bearings, also matters a lot with load capacity. These designs help minimize friction and load concentration and maximise efficiency.

Lubrication and Maintenance Protocols: Insufficient lubricants can cause load capacity loss. Regular maintenance schedules help combat excessive wear and tear and ensure constant load performance.

Dynamic and Static Load Ratings: Dynamic and static load ratings are two very peculiar readings that provide insight into a cam follower’s performance qualities. Ratings such as these help determine cam followers appropriate for the given tasks.

By parameterizing these attributes in my evaluation, I increase the odds that the chosen cam follower will withstand operational forces and improve the machine’s terms of service and efficiency.

Frequently Asked Questions (FAQs)

Q: What is a cam follower, and how does it work?

A: A cam follower is a type of bearing that conforms to the contour of a rotating or translating cam. The follower is meant to provide or be guided to a specific oscillating or translational motion by the core of the cam, which is the rotating or translating cam, moving over a predetermined path.

Q: What are the benefits of cam followers?

A: Cam followers, for instance, provide accurate and controlled movement in a mechanical system. Other advantages these components bring include reduced wear and tear and improved load-supporting capability; thus, a mechanical system’s motion control efficiency is enhanced considerably.

Q: What is the distinction between cylindrical and globoidal cam?

A: Simple, flat, and curved structures are offered by a cylindrical cam, which is just a cam with a cylinder shape, guiding the follower along smooth paths. On the other hand, a globoidal cam has an elaborate structural formation that allows a diverse follower moment; this is especially useful in machineries that require complex and variable output motion.

Q: What is the purpose of the camshaft in the cam and cam follower assembly?

A: The camshaft in a cam and cam follower assembly is used to define the location and angle position of the cams. The rotation of the shaft, which is attached to the camshaft, rotates in the engine, causing the movement of the valves with the help of the cams placed on the cam spars in the cam followers.

Q: What is the distinction between a flat and a crowned follower?

A: The flat surface of a flat-faced follower rests directly against the cam, eliminating the possibility of wear on the device. The offset Follower is constructed so that the axis is not directed toward the cam axis to enhance the paths of movements while reducing side thrust.

Q: Which type of follower can be used in the given scenario, explain the same?

A: In this category, followers can be further divided into flat-faced followers, roller followers, needle followers, spherical followers, and so forth. It also allows the use of various tailor-made designs that range from low-friction mechanisms to shock absorption techniques.

Q: What is the relation between cam motion and follower motion?

A: The cam motion decides the follower’s motion, both in terms of how fast it will move and in what direction it will move. Through its travel, the cam governs how the follower will move next, linearly, rotationally, or through oscillation, whenever required to do so over a cyclic permutation of the mechanical device’s operations.

Q: Preloaded spring cam: What is it, and where is it found?

A: The preloaded spring cam is specialized in such a way that it has a spring arrangement that keeps the cam and its follower in contact always, irrespective of load or speed. It is commonly employed in situations that operate under definite load – for example, engines to ensure a fixed position of valves when they are opened and released.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8