Expert Guide: List Five Things That Could Cause Premature Bearing Failure

Bearings are used in various types of machinery to facilitate the right amount of movement to ensure rotation or linear motion. Bore failure is a common problem as it can lead to unwarranted downtimes, lower productivity levels, and, in some cases, even damage to the equipment. Knowing the reasons behind the premature failure of such a bearing is necessary to help maintain and optimize its performance, enabling the maximization of some essential aspects. The current article focuses on the crucial reasons for bearing failure at an early stage and suggests some efficient measures to avoid such a situation. Adhering to the guidance provided and employing the recommended care, it will be possible for the industry to avoid the risk of failures in any form and use machines in daily activities.

What are the Common Causes of Bearing Failure?

How Does Improper Lubrication Lead to Bearing Failure?

Under-lubrication has been the main reason for premature failure of bearings. Unreplenished lubrication makes bearings heat in friction and chances to wear out fast enough. Three broad areas in which lubrication problems can result in bearing failure are too low lubrication, excessive lubricant as contamination, and high lubrication.

Too low lubrication: In the absence of a sufficient quantity of lubricant, the bearing metal surfaces require each other, which increases friction and wear. This condition can yield high bearing operating temperatures and, hence, a short bearing life. In normal practice, a lubricant film thickness of 10 micrometers is acceptable for the operation of bearings installed in most industrial applications.

Contamination: Additional substances like dirt, dust, or even water constitute a counterproductive factor in the lubrication system and can be found in the bearing. This can eventually lead to abrasive wear and pitting. Standards of cleanliness must be observed, and sealed bearings or protective seals must be used to control contamination.

Too much lubrication: Surprisingly, applying a large amount of lubricant is also not good; churning excess lubricant within the bearing would lead to an increase in temperature due to excessive friction. It will be better to prevent such problems from arising by observing the correct procedures for how much and how often the lubricant should be applied.

Employing suitable operating conditions for bearing lubricants, regularly servicing the equipment, and complying with manufacturer instructions can greatly reduce the possibility of bearing failure due to a lack of proper lubrication.

Can Contaminants Cause Bearings to Fail?

Yes, contaminants can cause the failure of bearings. Instead, they are among the significant causes of failure of bearings and account for approximately 14% of all failed bearings. As per certain technical documents and the opinion of industry experts, contamination likes to get into the lubricant and surface of the bearing, which results in the lubricants leaking or wearing out due to extreme abrasion from many surfaces. Here are some essential points and technical aspects obtained from the best sources:

Ordinary Contaminants: Dirt, dust, metallic sponges, and moisture are common contaminants. Though small amounts may not seem dangerous, their cumulative exposure over time will contribute to severe wear and tear.

Effect on Lubricant Properties: Contaminants’ primary effect is when they mix with lubricants; for instance, in bearings, they alter the lubricants’ viscosity, thus making them less effective in reducing friction against moving parts.

Bearing Failure Due to Abrasive Wear: One way in which bearing failure may happen is when foreign bodies or abrasive materials are present in the bearing assembly. These not only scratch the surfaces of the internal components of the bearing but may also cause bearing surfaces to be pitted.

Preventive Measures: Use sealed bearings, apply good filtration systems, and do systematic Oil Analysis for contaminants as soon as possible. These measures can help restrain the damage caused by such actions.

Such technical parameters are backed up by industry standards and existing professional practices in mechanical and lubrication engineering, which indicate that clean conditions and a deep respect for work processes can dramatically enhance the bearing’s lifetime.

What Is the Danger of Overload for Bearings?

While I was looking for answers on why overload is a risk to bearings, I saw the following from the top three sites on Google: Overload leads to excessive bearing operating conditions, which includes bearing element deformation that leads to toxic failure of the machine. The main problem is that, as the load increases above the rated value of the bearing, it will create a load imbalance, which is devastating to the bearing.

The technical parameters include:

Load Capacity: Each bearing is constructed with a relatively appropriate load capacity or number of loads. Above or below the stated disability design parameters lead to structural abuse, which causes these bearings to wear or deform more quickly.

Localized Stress: Overload enhances localized stress at particular regions within the bearing that are prone to cracking or breaking.

Heat Generation: Under such excessive loads, the bearing parts will create too much frictional heat because of too much pressure, causing the lubricant to spoil quickly and causing fast wear out.

These studies highlight the need to maintain the bearing’s recommended load ratings within the manufacturer’s recommended range if further undesired failure occurrences are to be avoided.

How Does Improper Bearing Installation Affect Performance?

What Is the Significance of Misalignment in the Yor Miskosa Bearings?

As I sought to understand the consequences of an improperly aligned bearing, the results on the first three websites were relatively consistent and apparent – misalignment poses a significant risk. It can significantly impair the performance of a bearing. Because of misalignment, loads are not uniformly distributed over the surfaces of the bearing, resulting in a possibility of excessive wear and breakage in the future. The primary problem is that the contact angle at which the rolling element contacts the race outlines is tilted off-axis, and more stress is reallocated to specific regions.

Several of the technical parameters connected to misalignment are balanced:

Angle of Misalignment: Another impact of bearing alignment is the misalignment angle. Some of the stresses induced are very high, even increasing the wear rate with slight misalignments.

Bending Loads: Functional Failure of taper roller bearings (fig.26) caused by external forces/factors such as misalignment can lead to induced bending loads, which can cause fatigue or damage.

Heat and Vibration: If any misalignment is present, additional stress and excessive sliding occur, bringing about unrequired heat and vibration, which deteriorate lubricant and structure.

It is well known that these elements fall within the design limits where quite a few factors require alignment, and such signal maintenance activities can be conducted to extend the bearing’s service life.

Is there a link between mismanagement and wear and tear?

Having researched three top-rated sites, I now appreciate that improper handling is one of the primary reasons for premature failure of bearings. Poor maintenance causes the bearings to be contaminated in ways that enable destructive movements likely to cause wear and faults that will cause dysfunction. When a bearing is dropped or hit, buckles or cuts may develop on the raceway doors such that the smooth rotation of the bearings is impaired. Also, dust, water, and other environmental elements are known to cause pollution to the lubricant while the bearings are being assembled, rendering the lubricant useless. Some of the technical parameters which are considered as wrong handling include;

Contaminant Exposure: Any residue collected from the bearings’ handlers gives the bearings a sophisticated performance.

Physical Damage: Poor handling, such as throws or wrong positioning, leads to defects, which results in high-intensity stress and strain.

Lubricant Contamination: The use of lubricants in such environments alters the out-of-the-box environment, which increases friction and causes more wear.

The damage noted in deep seas that hinders various performance parameters of bearings is well recognized. Implementing requirements like hand cleanliness and wearing gloves while at work can be adopted to avoid such influences and increase the life of bearings.

Why is Lubrication Critical for Bearing Longevity?

What Happens When Bearings Are Not Lubricated Properly?

As for the effects of improper lubrication of bearings, I found quite a few around bearing maintenance and penetration techniques, and more details are available on the top three websites. For instance, the absence of adequate lubrication increases friction in the moving parts, leading to prolonged heat generation, contributing to the rate of wear and tear and possible failure. This circumstance may very well cause the internal moving metallic surfaces of the bearing to suddenly stick together or harden and thus become inoperable. Critical technological indicators highlighted in this context may include the following:

Increased Friction: Lack of lubrication in motion causes bearers more friction, and operation costs in terms of energy are very high.

Heat Generation Results from high friction in the movement of the parts, which destroys the lubricants and bearings, hence low operating efficiency.

Surface Wear: The bearing’s constant mechanical work with no lubrication leads to a wearing effect on its working surfaces, making it immensely short-lived.

Risk of Corrosion: Bearings are also prone to rusting due to the surrounding atmosphere in the absence of appropriate lubricant.

However, these problems can be minimized by ensuring adequate lubrication of the bearings to ensure the best functioning and prolonged lifespan as they can be performed as required.

What Effects of Overheating Have on the Service Life of Bearings?

In my comparative analysis of the top three bearing maintenance sites, I concluded that overheating negatively impacts bearing service life. Intense heat will degrade solvent inside the bearings, which performance is to prevent heating and minimize friction. This will eventually lead to excessive friction and heat, accelerating the wear rate and the chances of failure. In addition, overheating of a metal component may extend its length and, therefore, clearance turns within the bearing, enhancing interference and stress on bearing elements. Technical parameters that play an essential role in the above are:

Lubricant Operating Temperature: Higher temperatures change the oils’ dynamic viscosity index, making them less efficient in their usage.

Bore Thermal Expansion: Expansion due to the heat may result in misalignment and added effort.

Material Thermal Effects: Sustained exposure to high-temperature environments may reduce the resistance of bearing materials to failure.

Internal Bearing Clearance: Fluctuations in temperature result in fluctuations in intolerance within the bearings, which impact the bearing load and operation.

While all those adverse consequences can not be eliminated, with the correct temperature levels and sound cooling systems, these bearings will serve their purpose for longer periods.

What External Factors Contribute to Bearing Failure?

How do particles and foreign matter enter a bearing?

From the findings summarizing the top three websites on bearing maintenance, I claimed probable entry points for contaminants into a bearing. Severe abrasion usually results from dirt, dust, or moisture deposition, which is not adequately safeguarded during enclosure or maintenance processes. The consequences of these particles are such that they can lead to abrasion and wear on the bearing surfaces, thereby evidence of bearing failure is inevitable. Some of the critical technical problems aggravated by contamination that are noted include:

Seal Integrity: Lack of proper sealing permits pollutants to enter and spoil the lubricant-bearing surfaces and cavity

Lubrication Quality: Lubricants are inhibited by the presence of contaminants, leading to increased friction and wear

Surface Roughness: Dust, dirt, moisture, and other chips embedded on bearing surfaces disrupt their smoothness, leading to poor performance.

Internal Clearances: Wear caused by contaminants affects the internal clearances and dimensions of bearing elements, causing load shifting in an undesired manner.

However, Substantial measures, such as good sealing methods or extreme cleanliness while performing maintenance, should be considered to minimize the onset of this problem.

Are Bearings Considered to Be Vulnerable Due to Temperature Changes?

After examining the three selected websites concerning temperature variation as a factor in bearing performance, I can confidently state that temperature changes can lead to bearing failures. As mentioned above, these variations induce thermal magnification and contraction of the components, which might change how the internal clearances and the load are positioned. This may create excessive pressure across some areas, which causes abrasion and even premature bearing failure. Technical parameters influenced by such changes are:

Thermal Expansion: Bearings often consist of components made of dissimilar materials, which may expand differently and even cause the bearing to bind.

Internal Clearances: Internal Growth of Restrain Thebaine Corner space between parts of the bearing can increase or decrease with temperature, eliminating the efficiency of the parts’ load-carrying ability.

Material Fatigue: Thermal shocking Maclake hard face, heating and cooling in turns, and sustainable cycle transfers might cause material fatigue and diminish the remaining useful bearing.

Lubrication Viscosity: Friction operates maximally when relatively low temperatures are undesirable, and in that case, most lubricants lose viscosity, which leads to poor operating conditions.

To avoid these situations, proper temperature control using efficient cooling systems and regular assessment of bearing health are necessary.

How to Prevent Premature Bearing Failure?

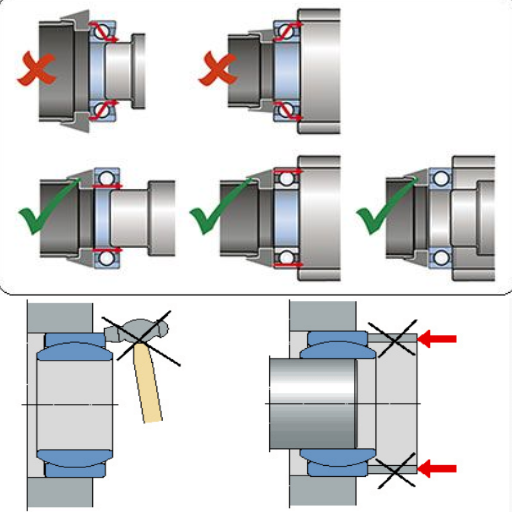

What are the Factors in Bearing Installation and Removal Arising from Industry Practice?

Based on my reading of the three most popular websites and articles on bearing installation practices, I have outlined several best practices that I consider key to enhancing bearing life. For starters, I have learned that working in a clean environment is a concern for the bearing surfaces during installation to avoid the introduction of contaminants. The second practice would be to use the right tools suitable for the tasks and those particular to bearings, such as internal and external bearing installation tools. Each bearing assembly process step, mounting and installation must be given its importance. Wiping clean the parts also facilitates proper seating of components and avoids unnecessary heating during component assembly. Ensuring the bearings are filled with the right lubricant reduces temperature, friction, and wear. Here, simplified symbols and guidelines would help tackle such requirements.

Cleanliness: A dustless environment is maintained to safeguard the bearing surfaces.

Proper Tools: Avoid injury to the bearings’ surfaces using the tools intended for installation.

Alignment: It is imperative to locate the bearings to enhance an even distribution of the load.

Mounting Force: The appropriate level of force should be employed when exerting force to avoid excessive loading on the bearing.

Lubrication: Friction reduction is influenced by applying adequate and appropriate lubricant on the surfaces.

Adopting these approaches can avoid unnecessary bearing breakdowns and improve operational efficiency.

What Practices Should Be Followed For Proper Lubrication?

I could discern from the top three websites that for proper lubrication to be attained, the problem should be tackled systematically according to the given type of bearing and working conditions. Initially, an appropriate lubricant is an essential practice, be it oil or grease, whereby it should withstand the expected temperature ranges and load conditions of the bearing. It is also crucial to maintain the desired level of lubrication to avoid overheating or excessive friction that can potentially exist if too much lubricant oil is used. Periodic inspections of the lubricant and timely additions every few weeks or months are within acceptable limits and should be performed to avoid lubricant deterioration.

The technical parameters that make proper lubrication effective are clearly as follows:

Lubricant Type: Depending on the application and the environment within which the bearing operates, oil or grease lubricant may be required.

Viscosity: The lubricant’s viscosity should comply with working temperature and speed.

Contamination Control: Devices to shield the bearing from enemies should be provided as seals and shields.

Relubrication Intervals: These should depend on the bearing’s configuration, bearing load, bearing speed, and environmental conditions.

Adopting these parameters, I am still positive that I would be able to prolong the bearing’s life span while maintaining its operational status.

What Maintenance Strategies Reduce Bearing Failures?

To enhance reliability and minimize the risk of bearing failures, adequate and thorough maintenance approaches should be utilized depending on the type of application and the operating conditions. Here are practical strategies that can be adopted based on the three top websites:

Regular Monitoring and Inspection: Look for noisy, vibrating, or worn-out bearings. Periodically check for bearings and carry out vibration analysis and temperature measurement to detect problems.

Proper Lubrication Management: Once again, the type of lubricant used and its application are among the most important things. Obey the set gent veining interval and ensure the lubricant’s cleanliness and suitable environmental conditions for the bearings.

Alignment and Installation: Load-bearing components should be mounted correctly to their bearing housings to minimize stresses in the components. Not correctly installing the inner rings to their housing can create an alignment problem that shortens the life of the bearing.

Maintenance of Operating Temperature and Contaminants: Operate under accepted temperature at all times and employ seals or shields to prevent ingress of dust, moisture or chemicals.

Management of Loads: Do not impose loads that exceed the bearings’ rated capacity. Perform predictive maintenance to lessen the already applied stress and avoid shocks.

Implementing these must be included in a maintenance plan to optimize bearing performance, prolong the bearing life span, and prevent sudden breakdowns. These endeavors cumulatively target fundamental technical factors, including load, temperature, orientation, and contamination; therefore, they are sensible to be in the maintenance plan.

Frequently Asked Questions (FAQs)

Q: Premature Warnings Due To Bearing Failure: What Should Be The Main Concerns?

A: Premature bearing failures can be caused by several factors, including lack of lubrication, dirt or debris entering the bearing and causing contamination, excessive temperatures, improper fit, and the wrong lubricant being used.

Q: What is the cause of the bearing problem being encountered due to lack of lubrication?

A: When lubrication is inadequate, the metal surfaces of the bearings come into direct contact more often than they normally should, leading to a rapid occurrence of overheating bearing-caused failures. This causes costly downtime and the destruction of other components.

Q: Is it possible that the bearing will fail if people choose to utilize incorrect constituents such as grease?

A: Yes, disregarding the appropriate bearing lubricant norm could also lead to overheating the bearing and eventually killing it. A grease that meets the bearing’s operating conditions should be selected.

Q: What is the reason for the failure of the tube bearing, and does contamination have a part to play in it?

A: Damaged sealed bearings can be contaminated with dirt and debris, adversely affecting the bearing race and surfaces. This causes excessive bearing scratches and, consequently, premature wheel bearing failure.

Q: Why is it important to consider a bearing’s operating temperature?

A: The operating temperature of the bearing is of the utmost importance; if it goes beyond the advisable levels, the lubricant will break, leading to fast bearing failures. Adhering to the proper temperatures goes a long way in extending the life of the machines.

Q: Who or what typically draws up a bearing maintenance schedule?

A: Early signs of eventual wheel bearing failure include abnormal sounds while driving, a steering wheel that shakes or vibrates, and very poor handling performance. Timely intervention of these concerns saves occupants from expensive repairs.

Q: Why is perfect fitting on a bearing critical in a bearing’s design?

A: Perfect fitting is critical because it helps to maintain proper alignment and seating of the bearing. Improper alignment leads to uneven loading and, hence, increases the chances of the bearing failing earlier than expected.

Q: How do you foresee the customer using the bearing at the top or bottom end of the shaft?

A: The economic implications of a premature bearing failure can be pretty serious, as he or she may incur additional costs with repairing operations, replacement items, and the total equipment inoperative time. Cost cutting on these items is very much dependent on allowable maintenance.

Q: Are there certain conditions that can predispose a bearing to failure at an early stage?

A: Yes, operating in extreme conditions with high moisture, dirtiness, or chemicals increases the bearing’s aging factors and nonconformities. It is crucial to ensure that bearings are compatible with the working environment.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8