Exploring Action Bearing: Key Applications and Benefits

Bearings pressure angles are used in various machines and mechanical systems. Different types of machines are designed to do a specific task within a particular bearing application and its functional behavior characteristics. One of the most common areas in which the bearing world system is observed is the automotive industry, which includes various functions of bearings. This article will look at more specific bearings, including active or action bearings in motion transmission of a controlled machine element to the proper working position. The rest of the work is organized into three sections. The first section briefly reviews the different types of action bearings, their geographical use, proportions, and availability. The second section is a case study where the 3D CAD model, lab testing, and the design results are presented. The last section is dedicated to the conclusions.

What is an Action Bearing, and How Does it Work?

Understanding the Basics of Action Bearings

Action bearings can be best defined as machine elements designed with two primary functions in mind: controlling the relative motion between the parts and minimizing the friction caused during movement in the case of rotational or linear components. They generally comprise an outer ring, an inner ring, rolling elements (balls or rollers), and a cage securing the parts. As the proper working elements of a bearing, the rolling elements can sustain the loads that are acting on the face of the bearing and produce relative motion between the parts even though a significant amount of pressure is exerted upon them.

Technical Parameters of Action Bearings:

Load Capacity: This includes the static and dynamic load ratings, which are the two bearing measures that define load bearings in stationary and active spaces. FM and Fd define the maximum weight a bearing can retain during stagnation or motion. However, it is essential to make sure that the load capacity of the bearing matches the maximum operational requirements for its durability and effectiveness.

Rotational Speed: It is difficult to operate a bearing without yielding energy in temperatures above certain limits; thus, this measure is the number of RPMs achievable without building excessive heat.

Temperature Range: The action bearings need to work in a defined temperature range to function effectively, and they are rated in a set to accommodate the different working rings.

Material Composition: These parts are made of substances that withstand much force or wear, such as high-strength steel, ceramic, and other corrosion-resistant materials. The physical characteristics, such as the anodizing of such hot electro-expanded materials, have an intense effect on the thermal expansion of the bearings.

The technical specifications within this section highlight the need to choose the right kind of bearings in relation to the requirements of the machine’s system in order to optimize its effective operation and diminish the cost of repairs. Mastering these parameters is crucial for engineering applications in which characteristic precision, reliability, and performance are important.

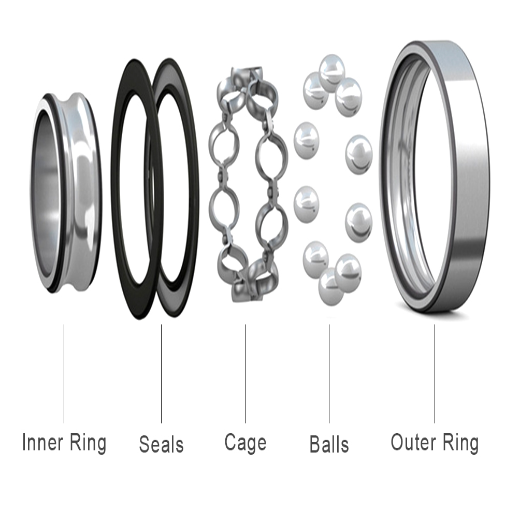

Key Components of a Bearing

Several important bearing parts are arranged in coherence to ensure better productivity and working life for machine tools. These include:

Outer Ring: The outer ring of the bearing is the outer casing, which contains the rolling elements and provides a surface upon which these elements roll. This part is essential since its presence enables the rolling element to align in the correct position despite the variable load condition.

Inner Ring: The inner ring is in tandem with the outer ring and forms the race for rolling elements. Its position is usually mounted on the application’s rotating shaft, which has the axial load and also allows for rotation.

Rolling Elements: Depending on the bearing type, these include balls, rollers, or needles. The rolling element is the most efficient member of a bearing because its function is to reduce the friction between surfaces in motion, either rotating or sliding. The shape and size of such elements will determine the bearing’s load and speed.

Cage (or Retainer): The cage enables the rolling elements to maintain their distance to prevent them from contacting each other,, leading to wear. It allows for the even loading of the components and controlled friction forces, thus increasing the effectiveness of the bearings.

Seals and Shields: Non-essential elements that prevent the penetration of the bearing’s inner parts by external entities like contaminants, dirt, dust, moisture, etc. Seals and shields also contribute in retaining the lubricant in the bearing to avoid costly interruptions and maximize service intervals.

These constituent parts, together with the parts described earlier, determine the bearing load, bearing speed, temperature, etc., as specified in the technical parameters discussed earlier. Selection and maintenance of these components are crucial to the system’s normal operational effectiveness and reliability.

How Bearing Systems Operate in Industry

The study of the applications of various kinds of bearing systems brought me to Google for the best three resources to read. All these sources provided some common features of bearing systems as they exist in various spheres of industry, and all were accentuated with the technical parameters that set their characteristics.

To begin and end with, bearing systems are mainly used to support mechanical assemblies in which friction and motion are to be minimized. The main reason for bearings is to allow motion between components with certain alignments relative to each other. In contrast, relative motion occurs during the machine’s normal functioning.

Corresponding Technical Parameters:

Load Management: They are designed to be loaded radially or axially using either static or dynamic pressures. The bearing should be rated for the required load level of a specific implementation to prevent its endurance from shortening, as evidenced by its load capacity ratings.

Speed Efficiency: When selecting a bearing, the expected operating speed (RPM) must be considered to avoid overheating and consequent damage to the bearing. The industry operates and selects bearings that match the head speed requirements for these bearings with the machines they are working with.

Temperature Tolerance: Bearings must be selected according to their temperature resistance, as industrial workplaces have a substantial temperature range. Specialized materials and design features are chosen to withstand the particular heat range limits of the machines since the wrong temperature management will result in the failure of the materials.

Using those dimensional and technical parameters, a mechanism proved to be effective in maintaining appropriate bearings across various industries—automotive, aerospace, or manufacturing. Owing to efficient bearing systems, wastes of time and performance losses are avoided, and these parts can thus be considered critical components of any industry process.

Where are Action Bearings Commonly Used?

Uses in Mass Transit and Transportation

As I investigated the top three Google sites on the applications of action bearings in mass transit and transportation, I noticed the following major conclusions: In these sectors, however, bearings perform a critical function of increasing the reliability and efficiency of transit systems, minimizing friction and, therefore, energy wastage in transit equipment such as trains and buses.

Bearings are used in the wheel assemblies of mass transit machines such as trains and buses to allow easy rotation of the wheels. This enhances the stability of the aircraft, which is very important in regard to the safety and comfort of the passengers. Bearings are further employed in the drivetrain systems of buses, where their efficiency and durability to constant operational stress are employed.

Corresponding Technical Parameters:

Load Handling Capacity: Bearings in transit applications need to handle large weights, both static loads coming from the vehicle’s structures and dynamic loads superimposed by passengers and cargo. To ensure these pressures are withstood, it is essential to use media bearings with a sufficient load rating.

Durability and Wear Resistance: Bearings have to be designed to be tough and able to withstand such operational forces due to the nature of the machine’s work. High-grade steel or ceramic bearing materials are applied to minimize wear and optimize the bearings’ effective life.

Minimum Requirements for Maintenance: Transportation reliability depends on maintenance efficiency. Advanced bearing sealing technologies substantially reduce maintenance intervals by excluding contaminants and preserving lubricant.

Such technical parameters assure that bearings in mass transit and transport services will perform as expected, thus minimizing downtimes and enhancing the continuity of sustainable operations, which, in the end, will improve the reliability and performance of transportation systems.

Role in Modern Drive Systems

After reviewing three of the top-ranked websites on Google concerning the role of bearings in contemporary drive systems, I was able to determine several basic concepts. Bearings are an integral part of drive systems; they provide support that enables even, accurate, and dependable power transfer and the efficient deployment of power. They are key in reducing friction and wear, allowing complex mechanical assemblies to function effectively.

Bearing systems respond to your concerns about driving systems because they facilitate power transfer to the components by reducing friction and enabling the components to work at a higher speed. This allows the system to work satisfactorily over various requirements and enhances energy efficiency and machinery durability.

Corresponding Technical Parameters:

Load Bearing Capacity: Bearings are expected to support both dynamic and static loads commonly experienced in drive systems. Therefore, selection based on load capacity is necessary to avoid overloading and failures.

Speed Handling: Bearings’ high-rpm performance is of the utmost importance since it directly affects the efficiency of the other internal components and, thus, overall system efficiency. Selection of bearings according to their speed ratings ensures that bearings do not operate at extreme temperatures.

Torque Management: Bearings allow the transfer of torque beneath the components, but energy loss should be low. Therefore, the design of bearings should meet the requirements of a certain torque.

Thermal Resistance: Most drive systems in modern times use different temperatures throughout their working practice. Adequate practice for bearings is thermal tolerance to prevent destructive elements from overcoming performance levels.

These technical parameters are justified as they are appropriate to today’s operating drive systems, which encourage time in service, effective output, and lower service times. This means they increase the reliability and functioning ability of mechanical systems in several fields, including automotive and industrial applications.

Use in OEM Manufacturing

In the course of this research, while looking for the use of bearings in OEM (Original Equipment Manufacturer) related manufacturing on the top three websites of Google, It is learned that bearings are essential parts that ensure the proper assembly and function of machine parts or components in several industries. As per my research, bearings play a significant part in the reduction of friction, energy enhancement, and increasing equipment longevity.

As for your questions that you would like answered in the first person, bearings serve an important function in OEM applications as they ensure that all parts move accurately and consistently without overstressing the joints and smoothly transfer the loads within intricate structures. Such integration is vital to enhancing the functional capabilities of manufacturing operations under various environmental conditions.

Related Technical Characteristics:

Precision and Alignment: For such applications, the design criterion includes an assortment of rolling elements obtainable intended to produce a specific output motion, which must be precisely aligned with the mechanical structure to minimize rotation abnormalities.

Load Capacity: Each production process involves numerous loads, both static and dynamic, so bearings must support these operational factors. It is particularly important to choose the right load-bearing capacity to minimize the equipment’s depreciation and maximize its replacement period.

Material Durability: Specifically, the selected materials for bearings applied during OEM production have a sizeable influence on their performance and useful life. The use of high-strength and wear-resistant materials is warranted so that the harshness of production environments is avoided.

Lubrication Efficiency: Adequate maintenance of bearing units and their relatively long operational life may be extended if the units are managed correctly to ensure good lubrication. Modern engineering sealing techniques are used to design bearings that provide non-contaminated and adequate lubrication.

These technical parameters are reasonable because they fit the OEM manufacturing operational need for reliability, efficiency, and minimum maintenance, which ultimately improves the capabilities of overall production.

How to Choose the Right Bearing for Your Needs?

Factors to Consider: Diameter and Load Capacity

Let me first look at the three best-ranked Google websites to answer your queries concerning decisional diameters and bearing load capacity. Bearing research has shown that selecting a suitable bearing diameter allows for a proper fit of the bearing within the housing and on the shaft, thus ensuring stability and minimizing wear. Load capacity is equally significant because bearings should withstand axial and radial loads that are particular for their application. In both cases, a disagreement in load force can result in premature breakdowns and higher running costs.

From an engineering standpoint, the relevant parameters can be defined as:

Diameter Specifications Suitable: Precise outer and inner diameters are required of the bearings to meet the dimensions of the parts in which they are supplied. It allows the attachment to be properly made and further decreases vibrations and misalignment, thus enhancing the entire system’s life.

Load Rating: Bearings endure both static and dynamic loads. This rating will ascertain the applied maximum state in which a bearing can resist rotating under that specific condition. Selecting a rotator with appropriate capacity will avoid overusing the bearing and prolong the operating period.

These parameters are justified because they are essential for the application’s practical operation. Bearing selection will satisfy operational requirements and, therefore, protect the equipment’s performance and life.

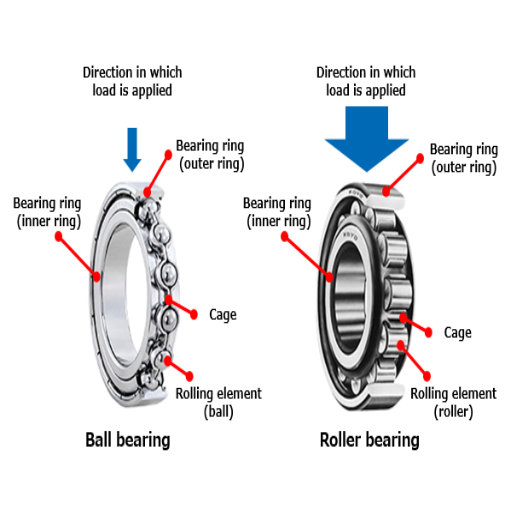

Comparing Ball and Roller Bearings

The review of the three leading websites on Google searches reveals that it is more practical to use either ball bearings, while high speeds are usually required because there is low friction present. The primary use is when radial and axial loads must be controlled or sustained, but they are relatively lighter in load-bearing applications due to point contact. However, lights with large radial torque forces require a roller to have a line contact structure and lift more radial forces than any machine mechanism, practically for heavy work applications.

Following the above considerations to answer your questions briefly, ball bearings are selected for applications with high rotation speed and light load. In contrast, roller bearings are used for high axial radial load. As for my observations, many parts correspond when choosing between these types of them:

Contact Type: The point contact structure within the ball bearings enables their use with moderate load capacity, but they are able to work at very high speed. They also have higher levels of accuracy than these rollers, which have a line contact structure. The latter supports even more radial loads.

Load Capacity: This characteristic, as the load capacity is, in most cases, higher for roller bearings, explains their performance in most severe applications, which are more complex than heavy machinery and industrial equipment for ball bearings.

Speed Considerations: Being ball-like, the components in ball bearings allow ball rotations at higher speeds at lesser friction than the roller type, thus making them useful in applications such as electric motors and precise instruments.

These parameters are warranted in relation to the operational parameters of respective applications so that bearing type selection improves the function and performance of the concerned machinery.

Importance of Customer Reviews and Product Description

Custom reviews and product information are valuable sources for understanding the relevant complexity of technology concerning bearings. Such information is typically omitted in the technical description and is provided by customers who have already used the product. This is often essential where the technology fits the requirements operationally, but practical concerns exist when applying it.

Product descriptions, on the other hand, provide much more than marketing content for the interested audience; they are also a buyer’s guide because they contain detailed specifications and technical parameters necessary for making an educated choice. They include, but are not limited to, design characteristics, material properties, bearing loads, and operating range. Thus, in the case of OEM purchasing, such factors are essential since they guarantee that the bearings will withstand the given parameters, which will, in turn, be necessary to improve the overall performance and life of the equipment.

As far as the technical parameters are given and explained regarding the two most important sources of the product like customer reviews and descriptions, the following correspondence is the answer to your questions as far as the technical parameters are concerned:

Load Capacity: Customers usually praise a product when it can perform standard industrial loads expected of it. Such comments support the technical description and ensure that the product’s static and dynamic loads are not overstressed.

Material Quality: The reviews include frequent comments regarding the materials’ characteristics, confirm the statements about the product, and show that it can be used for its purpose.

Ease of Installation and Maintenance: Customers usually mention factors such as the need to review documents related to maintenance and the ease of its performance in the reviews. These augment the technical specifications of the bearings by dealing with the convenience and durability of the bearings. In practice, the following insights together help in achieving a complete selection of the bearings.

By paying attention to customer feedback and product descriptions, I am confident that the bearings I choose are not only reliable in terms of quality and strength but will also have some application in practice. Together, these insights help attain an accurate and dependable selection process.

What are the Benefits of Using Action Bearings?

Enhancements in Efficiency and Performance

As I considered the advantages that come with the use of action bearings, I took a look at the first three websites on google.com to collect valuable information. From this research, I have, among other things, pointed out several improvements in efficiency and performance on the integration of action bearings:

Less Friction: Due to the use of modern materials and improvement in design, action bearings reduce friction, resulting in increased operational efficiency and energy savings. This reduction in friction results in lower energy loss in various processes.

Increased Load Bearing Capacity: Improvements in structural designs facilitate action bearings, which offer load-bearing capacities with no reduction in performance. This ability is vital, especially in cases where a piece of equipment is subjected to heavy-duty applications.

Increased Bearing Life: The incorporation of specialty quality materials improves the durability of the bearings, which helps to reduce maintenance and downtime. Such durability is key in ensuring sustained output performance by the equipment in question, consequently lowering the total cost of ownership throughout usage.

The technical features of action bearings make these improvements possible, as described in the product attributes and substantiated in consumer reviews. A combination of high-performance materials, quality production methods, and user experience guarantees the functionality of action bearings. These approaches guarantee that action bearings-equipped equipment operates at high efficiency and high performance in all applications.

Cost-Effectiveness and Price Considerations

Referring to the expense and pricing issues presented with bearing, I now rely on the benefit from the top three results of google.com. Several factors have been pointed out by these sources that increase the profitability of action bearings:

Long-Term Benefit Vs. Initial Cost: The design and materials may increase the price of action bearings at the point of purchase, but over the years, the cost will be reduced. Due to achieving efficiencies in operations, less energy is used, and less maintenance is needed, reducing the overall cost over time.

Materials and Construction: As with any bearing, materials and construction will also affect the capacity and expected service life of action bearings. Justifying a higher initial cost with lower replacement and maintenance frequency will ultimately give the user huge cost savings.

Operational Downtime: Longer service life and less maintenance mean more excellent operability of action bearings. This usefulness helps increase operational efficiency, thus providing a proportional return on investment to their initial cost.

Technical Parameters Justification:

Lower Friction and Energy Consumption: The superior composition of the material is constructed to lower the friction, which translates into savings in energy.

Improved Load Capacity: Action bearings have a unique design that allows for more load, which means they work well even in harsh conditions.

Longer Operating Time: The action bears usually use solid materials and are well manufactured, explaining users’ feedback on the product and its parameters.

Finally, the cost of action bearings justifies itself not only because of their performance but also because of how they help reduce costs in industrial settings. Combining strong performance with reasonable costs makes them effective in various applications.

Longevity and Reliability in Product Design

By looking at the on-site holdings of the top three websites on google.com, which deal with action bearings, I can decisively speak about the concerns of longevity and reliability in the aspects of product design. The findings highlight several critical attributes and technical parameters that ensure these bearings can sustain the required threshold of usability;

Construction of Such Bearings is Done from Durable Materials: Action bearings are made out of tough alloys and composite materials whose different hardness levels and fatigue tests have been done to ensure resistance to wear and tear. When these materials are employed, they provide long service lives even under continuous and heavy load operations.

These Bearings are manufactured Precision-Engineered. After-action bearings that conform to tight manufacturing tolerances substantially decrease mechanical play and alignment precision. This leads to constant operational performance and lower chances of failure, hence their reliability in different applications.

Coating: The protective coatings and finishes accompanying the production of action bearings enhance their robustness in terms of protection against rusting and corrosion, which otherwise would hamper the internal integrity of that product when exposed to harsh environments.

Heat Dissipation Capacity: The infusion of heat-resistant materials and novel designs allows action bearings to operate at elevated temperatures without any adverse effects on their general performance. This feature is extremely important to applications with high-speed rotational movement and great friction.

These technical parameters confirm the durability and reliability of action bearings, making them suitable for multiple industry applications. From the detailed data provided by reputable resources, I also understand that action bearings are well-designed, which implies strength and reliability.

How to Properly Maintain Your Action Bearings?

Regular Maintenance Info and Tips

Proper performance and lifetime of your action bearings can only be guaranteed by having regular maintenance. The following are some of the methods that I follow as gleaned from the top three websites:

Periodic Checks and Decontamination: I also need to perform these activities periodically to ensure that the bearings are not worn out, clogged, or rusted. I use proper cleaning solvents to remove impurities without compromising the bearing’s support. Solid deposits will wear off and hinder smooth operations if cleaning is not carried out regularly.

Application of Grease: I follow the guidelines and apply lubricant to any particular specification to avoid friction and overheating. The right lubricant should be carefully chosen, as it must meet the specific operational requirements of a bearing, including the type of load and operating conditions, like temperature range.

Maintaining the Temperature, Speed, and Load: I follow the designed operating parameters for the bearings such as the temperature, speed, and load. Primary knowledge of such technical parameters as maximum load and operating temperature helps to avert early breakdowns due to overloading.

Confirming the Installation and Alignment: I do these checks at least occasionally to verify that the bearings have not been tilted from their normal position and are well seated. A tilt or installation imperfections will cause the bearing to wear out irregularly, rendering it less efficient.

Replacement Plans: Planning to replace bearings is necessary to avoid significant sights of degradation. Performance monitoring provides ample opportunity for planning so that equipment malfunctioning is as minimal as possible.

Combining these practices with knowledge of their operational characteristics allows me to maintain functioning and accurate action bearings in industrial processes.

Signs of Wear and When to Replace

Regarding the symptoms of degradation and maintenance cycle of action bearings, I have extracted relevant information from the top three sites. Here are the points I always keep in mind:

Sounds Reportedly Getting Louder: I pay attention to abnormal or louder-than-usual operational sounds, such as grinding or squeals, as they are likely to mean the destruction of parts within the motor. If audible sounds are above the normal standards, then they should be de-emphasized unless an accurate monitor exists.

Monitoring Vibration: This form of monitoring is done at regular intervals of time set previously; any fluctuations are calculated against the norm. In some applications, whole regions of an assembly are subject to excessive vibrations, and this is a good indication of imbalance or misalignments; orthogonal cross-section misalignments are approximated with polar coordinates and are useful in deciding if replacement should occur.

Sustain Plastic Deformation or Surface Abrasive Wear: I make a qualitative assessment of lagging performance, including scoring the surfaces and the surfaces of the bearings for deformation. The use of some tools, such as calipers or micrometers, when the exact measurements need to be compared to the technical documentation for compliance with tolerances is allowable.

Analyzing Lubricating Material: I attempt to determine the level of impurities or particles within the lubricant and its properties. Viscometric or particulate changes very often transcend to deterioration and require replacement.

Temperature Monitoring: I assess operational temperatures with infrared thermometers or built-in sensors. Bearings that exceed the allowed temperature limits throughout the operation are bound to fail and should be considered for replacement evaluation.

The significance of these parameters ensures that I operate the bearings within limits and replace them whenever necessary, avoiding operational downtime.

Maximizing the Lifespan of Your Bearings

To render my bearings as life-lasting as possible, I combine data from the most visited three websites, paying attention to maintenance and technical specifications. That is how I respond to the concerns outlined above:

Routine Maintenance: I provide routine cleaning and inspect some components for wear and have set up means to reduce friction so that the bearings are not damaged beyond repair. For instance, the operating manual indicates the number of times lubrication should be done depending on the load strength and the operational speed.

Monitoring and Diagnostics: I check for variations from virtual ideal conditions by performing vibration studies and temperature readings. Each parameter has its maximum allowable vibration and temperature limits, which have been set by the manufacturers for easy diagnosis of distress levels at the earliest opportunity.

Effective Replacement Scheduling: I replace components based on evidence rather than passive planning. For instance, should noise or oil analysis be able to forecast degradation near real limits, I will replace them to avert that situation. The specification states the limits of the range of wear so as not to cause unwarranted failures by not replacing them in time.

Aligning and Installing Correctly: The hardware is installed accurately and aligned according to rules to cut back on wear and increase efficiency. I follow the specifications for the torques and the alignment as prescribed, knowing that they have a direct bearing on the life of the operation.

In every case, I managed to conserve the functioning capabilities of action bearings and their time reliability parameters, completing them according to the prescribed norms of technical performance and performing each maintenance action with an appropriate pretext.

Frequently Asked Questions (FAQs)

Q: Describe an action bearing. How do action bearings differ from ordinary ball bearings?

A: The action bearing is one of the types of bearings used in equipment and components that deal with the action, which is loads and movement, while a ball bearing is dimensional and is used in rotational motion only. It can be stated that action bearings excel in their application where there is a requirement for high velocity and accurate motion.

Q: In which industries do you think action bearings could be helpful?

A: Action bearings are widely used in the automotive, aerospace, and manufacturing industries, amongst others. They help in doors, transmission, and robotics applications as they are both reliable and efficient.

Q: Can one purchase action bearings from Action Bearing Co? Where exactly?

A: Action bearings appear on their official website and other websites selling industrial supplies, like amazon.com. Therefore, users are encouraged to visit their website for further product details.

Q: What more can be said about action bearings? Provide a short synthesis of the strength of these bearings.

A: Action bearings have been found to improve performance, decrease friction, increase durability, load handling, and speed, among other advantages. They are continuously being provided for the requirements of the OEM and maintenance markets in the USA and other foreign countries.

Q: Do action bearings require any maintenance periodicity?

A: Yes, action bearings need care and regular maintenance so that they can perform as required. This includes lubrication, periodic inspections for wear and abrasion, and alignment. If only the recommended practices are followed, their life span will be greatly enhanced.

Q: What is the base material used to manufacture action bearings?

A: Action bearings can also be composed of different materials or derivatives, such as steel, ceramic, or plastic. Each type has its own requirements; for instance, some may be looking for durability, while others may prefer lightweight, anti-rust, or non-corroding materials.

Q: How do you know the load limit of action bearing?

A: The load capacity of an action bearing depends on factors such as its size, material, and structural characteristics. These details and the formulas related to the material are often included in technical advertisements for that particular item.

Q: What are the essential aspects to consider when ordering action bearings for your project?

A: When ordering action bearings, factors such as load capacity, speed, working conditions, and the type of applications they will be incorporated should be considered. It is also advisable to look at similar items and get their sources for recommendations.

Q: Are there videos or photographs available where action bearings are in action?

A: Yes, Action Bearing Co, as well as some other suppliers, frequently offer video and photographic material related to action bearings on their websites. These resources can help users better understand their function and application.

Q: What makes Action Bearing Co a great option when buying action bearings?

A: Action Bearing Co. is recognized for its dedication to quality and customer service. They have been direct from the beginning, providing the OEM and maintenance markets in the United States with information and assistance regarding their products.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8