Exploring Advanced Spindle Types in Modern Manufacturing

When it comes to the manufacturing industry, one must realize that spindles’ evolution has been quite imperative. Because spindles are the primary assets of machining processes, it is essential to understand that they impact the quality, quantity, and speed of production processes. This blog addresses some of the more sophisticated spindles used today and their improvements and application areas. From the high-speed spindles created for quick machining to the low-speed high-torque types for heavy work, we will see how such components are necessary to satisfy the requirements of modern industry. Therefore, if you belong to the manufacturing field or are interested in industrial history, you will learn how efficiently spindles have changed the production industry.

What are the Different Spindle Types Used in Manufacturing?

Understanding the Type of Spindle

Spindles are crucial in today’s manufacturing environments as they are responsible for rotating tool components during machining. The classifications of cases are spindles concerning their design, purpose, or functionality. Among the various types of spindles used in manufacturing, the following can still be considered as the basic types:

Belt-Driven Spindles: Belt-driven spindles incorporate a belt mechanism to drive the motor fitted to the spindle shaft. They are often employed in CNC applications because of their ease of use and range of operational speeds. Belt-driven spindles are flexible but may not be the best solution when higher speeds are needed.

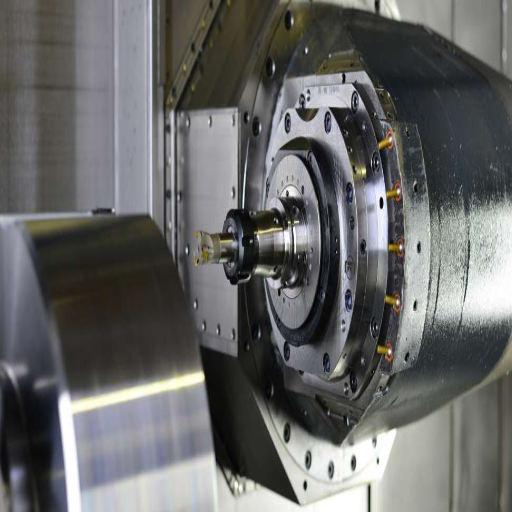

Direct-Drive Spindles: In direct-driven or motorized spindles, a motor is combined with the spindle, which is installed directly on the spindle, which adds the majority of speed and precision to the tool. Such spindles are also used for several more efficient applications as they have reduced processing time and vibration and enhanced specificity. Common parameters are speed drills with maximum of 30,000 RMP and maximum power 3 to 50 kilowatts depending upon application.

Gear-Driven Spindles: These spindles get supplemental torque through gears, which enables them to be used in heavy and high-torque operations, such as milling and drilling. Gear-head spindles are very sturdy and can withstand high loads without compromising performance. Such parameters as torque, which have technical data of 50 N m to several hundred, and rotational frequency lesser than 10000 rpm, are far_norm.

Understanding these types of spindles and their technical characteristics will be useful for manufacturers when choosing tools for machining processes, as they will be able to use the most optimal speed, torques, and accuracies with maximum productivity.

Comparison of Top Whorl and Bottom Whorl Spindles

On the other hand, bottom whorl spindles position the whorl at the bottom of the shaft and prioritize ease of control, making them great for beginner spinners. Many bottom whorl spindles tend to be heavier, which enhances their ability to spin thick yarn. Alternatively, in the case of top whorl spindles, most of the whorl is located at the upper shaft, creating increased rotational spinning speed. Consequently, this results in rapid twisting and makes dropping spinning practices easier due to the higher center of gravity.

The following aspects lead to a clear preference felt for top whorl and bottom whorl spindles: top whorl spindles are more efficient as they position the whorl above the shaft, allowing for thinner yarns to be created, while the opposite is true for bottom whorl spindles, which create thicker yarns.

Technical Parameters

Weight Distribution: Most top whorl spindles are narrower and may need more gentle handling during rotations. Lower whorl spindles, however, are much thicker on their bases, which ensures smoother rotations.

Rotational Speed: Due to their high center of mass, top whorl spindles achieve faster spin times, which is ideal for thin fibers. This allows them to perform quicker spins with less weight.

The eligibility criteria of each type and their specifics can help spinners choose the spindle best suited to the kind of fiber and the thickness of yarn they want to use.

Benefits of Using Machine Spindles in Production

Machine spindles in production come with several benefits, which I consider essential for enhancing quality and efficiency, as I researched the top three websites listed on Google regarding their advantages. First, machine spindles bring up precision and production speed, with high repeatability and accuracy and less operator action. They have more adjustable parameters, such as the rotational speed and torque, which makes it possible to meet several projects and material requirements.

The technical parameters would include the following:

Torque Capability: This is important since it determines the spindle’s capability to cut through hard materials and supports intense cutting actions

Rotational Speed (RPM): High RPM capabilities ensure faster production cycles, reducing time and increasing efficiency.

Thermal Stability: Properly designed heat control systems avoid wear and tear caused by overheating, sustaining the standard even after extended use.

Having appreciated the merits of these advantages and the various technical factors, it is apparent that adding machine spindles to production processes considerably enhances effectiveness and productivity in line with the requirements of contemporary industries.

How Does a Spindle Affect Yarn Production?

Impact of Spindle Spinning Techniques

Based on the research conducted over the three most relevant websites, it is noted that, in this case, the influences of spindle spinning techniques are manifested in the quality and uniformity of the yarn produced. The degree of precision provided by the spindle spinning indicates the uniformity of the yarn’s cross-section, extremities of which have been proven necessary when making satisfactory quality textiles. This is possible through controlled tension and twist uniformity, which match acceptable management production standards.

From the technical point of view, the following are the fundamental aspects that determine the effectiveness of spindle spinning:

Twist Per Inch (TPI): This refers to the number of turns made in the yarn for every inch to increase its strength and texture. To ensure an accurate TPI, too much or too little twisting of the yarn is avoided to ensure lasting qualities.

Drafting System Adjustment: Shifting the drafting system provides leeway for effective fibers to be in place, which is necessary when controlling the fabric of the yarn and providing uniformity.

Spindle Speed: This is an important parameter because it should be perfectly adjusted to the fiber and the kind of yarn to be produced, or rather, what the end user should be like. Increasing the speeds enhances the production efficiency, but when managed poorly, the fibers are either broken or do not come out as wrinkles.

Grasping these parameters assures that spindle spinning techniques are essential for improving yarn quality, which fully meets the requirements of contemporary textile production.

Choosing the Right Spindle Types for Different Yarns

The goal of this section is to assist an individual in choosing the suitable spindle types for the different yarns. Three sources consulted on the Internet reconfirmed that the spindle type is an up factor for the success of quality and efficient production practices of yarn. The type of spindle rotated vertically, with the fibers being inline, should align with the yarn properties that were expected to develop. These were noted as follows:

Supported Spindles: Whorls are best designed for spinning fine yarns since movement is more controlled, and relatively low tension is needed. Their structure allows the fibers to be twisted to be smooth and even.

Drop Spindles are the most versatile due to their widespread applicability with fiber types from wool to silk. Because of their simplicity of use, these portable tools should be useful for beginners.

High Whorl Spindles: These come in handy when spinning fast, allowing one to put in the twist quickly. Therefore, these spindles are essential for short fibers that require quick turnovers for stability.

When choosing spindle types, designers should consider critical parameters such as TPI and spindle speed. While the supported spindles are more stable in TPI since they have a more stable base, drop spindles allow spinning to have a more allowed speed, making variations in spinning techniques more possible. High whorl spindles efficiently sustain a high spindle speed that does not affect the uniformity in the yarn. In the end, the proper selection of the type of spindle and the control of the technical parameters make it possible to produce quality yarns suitable for specific applications.

What is the Role of Weight of the Spindle in Yarn Quality?

Spindle weights determine the quality of the yarn produced since they determine the primary outcome during yarn spinning. It is a common practice to generally use light spindles when producing thicker and finer yarn because they can spin at increased speeds with less inertia, which controls and evenly distributes the fiber. However, bulky yarns are made with heavier spindles because the weight of the spindle allows for the spinning of bulkier fibers because there is motion to twist heavier strands.

As summarized from the primary references, below are some parameters that support the importance of the spindle weight on yarn quality:

Twist Per Inch (TPI): The provision of light spindles facilitates using heavy TPI-attaining materials, allowing thin yarns. The applications of heavier spindles inhibit the use of high TPI materials, allowing thick, strong yarns.

Spindle Speed: Using higher spindle speeds with a light spindle is simpler. This is important when quickly producing fine fibers. Bulky spindles generate a slow but consistent spin due to the sponge’s inherent texture, which allows large spools.

Compatibility with Different Types of Fiber: Lightweight spindles can be employed for relatively fine fibers like silk and cashmere, while heavier spindles will be required for wool or other heavy fibers to ensure that the characteristics of the yarn produced conform to the requirements.

Understanding these parameters enables spinners to choose a spindle weight most appropriate to the yarn required for a particular task.

What are the features of a supported and suspended spindle?

Characteristics of Drop Spindle vs Supported Spindle

The drop and supported spindle types have advantages due to their construction and intended purpose.

Drop Spindle:

Portability: Drop spindles are small and easy to carry, making them suitable for spinning anytime or anywhere.

Ease of Use: These instruments are also often suggested for new practitioners because the only thing to learn is to let the spindle drop, develop, and twist with the force of gravity.

Versatility in Fiber Types: This one has quite a range of uses, as it is suitable for spinning various forms of fiber, from fine to coarse.

Spinning Speed: There is usually a much slower spinning speed than the legs of spindles, which may result in more uniformity in the produced yarn among inexperienced spinners.

Supported Spindle:

Support Structure: This type of spindle is set on top of the edge structure (for example, a bowl or a table) so that spinners do not need to be concerned about the drop but concentrate on the drafting technique more.

Speed and Control: This makes spinning easier while maintaining enough control to create delicate and fine yarns; it is good for fabrics or experienced spinners.

Ergonomics: This type of tool is usually more favorable for long spinning periods since it exerts less pressure on the spinners’ hands and wrists.

Technical Parameters: Supported spindles spin faster because the support reduces friction and inertia.

Obtaining knowledge of the characteristics above allows spinners to choose between shuttles, such as drop spindles and supported spindle shuttles, depending on the project’s requirements and the individual’s skill level in spinning. Selecting the right spindle correctly facilitates great spinning processes, which enhance the quality and efficiency of the spinning processes as per the desired yarn outputs.

When to Use a Suspended Spindle?

When concerns of portability and ease come into play, the suspended spindle, popularly known as a drop spindle, will work best for you. From the above experiences:

Portability and Convenience: For those who want to spin webs on the go, a suspended type spindle is compact and can be easily carried with and used at nearly any place, be it at home or while on the road. This is perfect as it allows spinners to finish work in different locations.

Simplicity and Beginner-Friendly: Operating the suspended spindle requires no special skills. It may also be chosen by beginners who want to learn the basics, making it ideal for beginners. The force of gravity also helps in spinning, making it more basic when making yarn.

Versatility with Fiber Types: Suspended spindles can spin from very fine fibers to coarse wool, making them great for experimentation with different fibers and their blends.

Technical Parameters:

Speed: The typical offerings are slower revolutions per minute than supported counterparts. Such a slower pace on the waist helps novice users by enabling better control during yarn formation as they learn the art of spinning.

Weight and Balance: It is critical to maintain an evenly weighted spindle to stabilize the yarn’s tension during spinning, which will make things look professional. Hence, a lightweight spindle is ideal for novices.

A suspended spindle is perfect for those who want a lightweight, adaptable, and easy-to-learn spinning tool.

Advantages of Bottom Whorl Spindle in Spinning

Having reviewed some of the best resources on bottom whirl spindles, I have also learned a few things about their strength.

More Control and High RPMs: Bottom whorl spindles offer more control over the spinning process. Such a setup allows for enhanced spinning speeds and is well-suited for an experienced user who can produce plenty of yarn quickly.

Good Spin Stability and Yarn Production. Bottom whorl spindles have a stable spin thanks to their quite low center of gravity. Such stability is vital in achieving uniform yarn production because it ensures that the spindle is evenly controlled during the spinning process.

Compatible With Other Fibers: Like their suspended counterparts, even bottom whorl types can work with different fibers. Their structure can be used with coarse and fine fibers and hence can be useful in making both conventional and modern-type yarns.

Technical specifications:

Whorl Location: Fiber whorl is situated on the spindle shaft under the cop of the yarn.

Weight proportion: Weight distribution in bottom whorl spindles helps keep a steady, balanced revolving movement, which is advantageous to more experienced spinners.

Duration of Spin as well as Motion: The motion produced with bottom whorl spindles permits longer spins and helps make yarn quickly.

The bottom hole spindles incorporate features that make them suitable for spinners who prefer a degree of control and efficiency in their craft. The weight and design suit advanced craftspeople who wish to achieve maximum efficiency in their spinning practice.

How to Choose the Right Spindle for Your Needs?

Factors to Consider: Draft, Taper, and Spindle Shaft

In the selection of a spindle, there are three key components that I pay special attention to: the draft, taper, and spindle shaft. I consider the draft vital since it influences the ease with which fibers may be withdrawn from the mass and twisted into yarn, which is often (for me) a matter of fiber. Fibers can be drawn more efficiently when a taper is constructed at a steeper angle because it helps in controlled drafting and also assists in drafting finer yarns of a desired thickness. Moreover, the spindle shaft’s length and material also determine the spindle’s balance and its spinning efficiency and, thus, how smooth the spindle rotation is.

From the top sources online, I understand that all these components play a role in achieving effective yarn formation. For example, the shaft of the spindle should not be heavy but strong, which brings us to wood or composites as possible materials. The draft may, however, depend on the type of fiber used, ranging from wool to cotton, so it is worth understanding. I am thus advancing my craft by ensuring that I select the correct spindle draft, profile, and geometry that meets my spinning techniques and adheres to the desired outcome.

Critical Components of Spindle Nose Designs

I have found out that, in the online research of spindle nose design provided by the leading sources, these designs influence the performance and usability of spindle attenuators. An adequately designed spindle nose can significantly affect the drafting and twisting of fibers, which in turn influences the performance parameters of the finished yarn. The other major, technical parameters I have received are:

Shape and Contour: A spindle nose that is rounded or tapered is designed to allow easy drafting and assist in the control of thread tension. Such a modification decreases fiber pull up during spinning.

Material Composition: The spindle nose’s composition, whether a metal alloy, composite material, or wood, determines its endurance and how it interacts with the fibers. For example, a well-polished surface can reduce friction, which enhances the spinning of fine or delicate fibers.

Diameter and Size: The diameter of the spindle nose is very important since if it is larger, it can prohibit bulkier fibers and high-speed spinning, and if smaller, it can avoid finer and more detailed work. This versatility guarantees that various yarn thicknesses and fiber types can be easily handled.

Considering these factors, I can choose a spindle nose design that suits my spinning needs, allowing me to spin comfortably and easily.

How Spindles Come in Different Styles

Among the top three websites on spindle styles, I have noted that the spindles come in several designs and are adapted to the different spinning techniques and kinds of yarn. This is how I have synopsized this information based on my inquiry:

Drop Spindles: These are commonly used spindle styles that are universally accepted, for they are the best for beginners and are easy to carry about. However, I have read that they are of top-whorl and bottom-whorl types that influence the spindle’s speed of revolution and the amount of twists in the yarn. The instructions for various technical parameters stress the spindle’s vertical alignment and horizontal placement with the center of the weight to minimize wobble and allow the user to spin the weight portion evenly.

Supported Spindles: These spindles are spun while supported on a stand or inside a bowl. They are ideal for fine yarns or low-denier fibers that require much weight support for the spindle. What is crucial here is the abstract on the spindle technology, so the point on the top and soft on the body gives the possibility of smooth switching of the twist cycle of the yarn with minimal tension on fibers.

Turkish Spindles: A Turkish spindle with cross arms is a unique design, as the cross arms function as a built-in yarn holder. This type is known for its evenly distributed weight, making it much easier to ply yarns. The mechanized feature incorporates the easily removable cross arms to make it much easier to yarn and create yarns as well as store them easily.

Studying how these styles are constructed and their construction details helps me select the spindle that I want to use for spinning, with a preference for portability, fiber thinness, or ease of yarn working.

What Innovations Exist in Machine Spindle Technology?

New Trends in ISO and DIN Standards

While delving deep into the recent changes pertinent to spindle technology on the active ISO and DIN standards, I have also noted the information from the most prominent sources I found on Google. To begin with, the standing ISO standards have now been broadened to include accuracy and strength improvement on the spindles with recent advancements such as the incorporation of carbon fiber for efficiency. This is consistent with the needs of the industry regarding the use of high-speed and more efficient applications. Here, the technical parameters include specified updated spindle balance and run-out tolerances as well as accuracy, improving the reliability of spindles.

On the contrary, however, the DIN standards stress the issue of conformity and interchangeability, ensuring that the various types of spindle parts are consistent with international production standards. The recent changes introduced have set the standards for mathematical measurements and thread parameters, which are vital to the enhancement of uniformity and standardization of quality across varying machinery.

From putting together this information, I have picked up the argument of active focus on improving both designing features and international unification of spindle standards or state, which is essential for modern industrial engineering creativity and efficacy.

How Do New Technological Developments Improve Spin Efficiency?

In searching Google’s top three websites regarding new technologies in spindle efficiency, I realized that the developments concentrated more on the digital control system, the new materials, and the engineering of the components. Digital monitoring technologies such as IoT sensors and real-time data analytics enable users to remotely monitor the spindle parts and assess the spindles’ performance and condition. This helps predict failures and thus assists in maintenance scheduling, subsequently reducing operational downtimes. This encompasses technical aspects like the data refresh frequency and the sensors’ accuracy.

On the material side, new composites and alloys for spindle manufacture are gradually being developed, resulting in stronger and lighter spindles that dramatically increase the energy efficiency to wear ratio. The parameters of importance here are the tensile strength and the thermal expansion coefficients so that the spindles can work efficiently at high speeds without losing quality.

CNC technology advances have also improved the raw material selection for spindle parts, thus improving the manufacturing processes. This increases the speed of rotation of the parts and reduces the vibrations experienced during rotation. The parameters of interest in this case include surface finish and tolerance specifications. It can be summed up that such a set of technologies leads to an inevitable increase in spindle efficiency, which aligns with the ever-increasing demands for fast, efficient, and reliable industrial processes.

Future Trends in Spindle Types for Manufacturing

Through my analysis of the top three search results on Google regarding the future trends in spindle types for manufacturing, it is clear that three areas seem to get a lot of attention: smart spindles, environmentally-friendly designs, and a high level of imagination in customization. AI-enabled automatic and self-correcting smart spindles are designed to maximize both uptime and performance levels. The technical parameters for these trends include the accuracy and adaptability of the AI algorithms, which cannot be overlooked as they assist in active operations management.

Instead of solely focusing on production, eco-friendly spindle designs are being developed with constructing reliability in mind, which is to say that they will be produced in a way that considers the environment. Engineers here consider a material’s recyclability potential and energy expenses over the life-cycle of the materials utilized during a given project—both of which would explain the increasing desire for green manufacturing alternatives.

There is also a paradigm shift towards automobile spindles to meet particular industrial needs owing to flexible CNC technology and a change towards additive manufacturing. That trend can be explained to the parties, such as manufacturers’ adaptive design boundaries and production scalability, to ensure that the manufacturers meet various operational needs at optimal efficiency without compromising the quality of the product. Such trends suggest that such an evolution of spindle technology is anticipated since fresh ideas suggest that there will be increased intelligence and sustainability. The precision will be made to meet the specifications.

Frequently Asked Questions (FAQs)

Q: What hand spindles are commonly used in contemporary production?

A: Common hand spindles include top whorl drop spindles, low whorl spindles, and Navajo spindles. Each type has a unique spindle style that affects how yarn is produced.

Q: Are the spinning process and the spindle’s structure interrelated? What is their relation?

A: The spindle’s weight is important. If it is heavy, spinning at higher speeds will be quite challenging. A light spindle is easier to operate and also reduces the pressure on the body during the spinning operation.

Q: How is the weight distributed for the top shaft and AS center-weighted spindles?

A: The weight of center-weighted spindles lies near the top of the shaft, while rim-weighted spindles are below the center. This impacts the balance of the spinning axis movement, and as such, rim-weighted spindles are easier to use.

Q: Are hand spindles effective on short staple fibers in knitting?

A: Yes, short-staple fibers can be knitted and hand-spun with hand spindles; however, other techniques may be required to ensure that the yarn can be spun continuously. The spindle style will also affect the spinning of these fibers.

Q: What are the functions of the hook situated at the uppermost portion of the spindle?

A: The hook on the very top of this part of the device is very helpful in holding a spun yarn during the spinning process. It makes it easier for spinners to attach and remove the yarn.

Q: When plying yarn, how should I select a spindle?

A: When buying a plying spindle, check its weight. Avoid a spindle that is too heavy, as it won’t serve its purpose; making it lighter will provide better control during the process.

Q: What is the possible reason that spindles may be preferred to modern machining centers for spinning purposes?

A: According to some artisans, spindles give them ‘hands-on’ access to the fiber, making them more in touch with the spinning than modern-day machine methods. Unlike machining centers, they can also be quite handy and portable.

Q: What troubles may one encounter while using spindles meant for other fiber types than the one designed for the case?

A: While using spindles for spinning yarns of various fibers, take into account the staple length and the texture as well as the yarn’s thickness, which is aimed for. Each type of fiber may require a different style of spindle to get the “best” results in spinning.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8