Exploring the Benefits of an IP69K Bearing House

In the sphere of mechanical engineering, as well as in the repair of machines, durability, and strength are the dominant properties concerning the performance and functional efficiency of the machines for extended periods. Among the many strategies commended in providing these properties, the IP69 K-bearing house has received quite a recognition. The IP69K rating indicates a type of sealing that typically exceeds the other usual sealing answers because it is intended to work under some of the worst environmental conditions. This is important, particularly in industries such as food processing and pharmaceutical, where there is a high emphasis on the cleanliness and sterility of equipment. The article will focus on the advantages of employing an IP69 K-bearing house, specifically improving overall machine ability, limiting machine downtime, and ensuring adequate equipment operation in the most adverse conditions. In discussing such issues, we will highlight the advantages of implementing the IP69 K-bearing house and why it is essential for industries that aim for long-term stability in their business processes.

What is an IP69K Bearing?

Overview of the Standard IP69K

IP69K describes a protective enclosure classification developed by the International Electrotechnical Commission. It concerns the resistance of electrical housings to dust ingress and exposure to high-jet water or vapor. This standard is crucial in industries with high hygiene standards, such as the food industry, where high-pressure equipment cleaning is the order of the day.

The first two letters, ‘IP’ in IP69K, mean ‘Ingress Protection,’ and the numerals define the type of protection. The figurative ‘6’ signifies protection against further dust ingress, while the figurative ‘9K’ denotes high-pressure power cleaning and steam jet cleaning. Such a level of protection renders the IP69 K-bearing house suitable for applications where frequent and effective washing and disinfection are required.

Related to the technical characteristics of the IP69K rating include the following:

Dust ingress protection level (Level 6): Dust is prevented from entering the equipment so that no operating components are obstructed by dirt.

Water ingress protection level (Level 9K): Protection from high-pressure and high-temperature cleaning methods. The jets used in testing have a maximum pressure of up to 100 bar (1450 psi) and heating temperatures of up to 80 degrees Celsius (176 Degrees Fahrenheit).

These insurmountable limits guarantee that components such as the IP69K bearing house are perfect for the most hostile environments. They require cleanliness and provide reliability and long performance at extreme operational conditions.

How Does an IP69K Bearing Work?

First, let’s examine how an IP69K bearing works, paying attention to the fact that the bearing has been made in a manner that can withstand even the highest of conditions, looking at the sources it provides. Based on the materials I’ve gathered, the working designation of the IP69K bearing offers dust and water exclusion inside the enclosure. Therefore, the IP69K WASH BEARING keeps working even in difficult conditions. When implementing the IP69K method, the bearing is usually packed between hard-wearing seals resistant to water jets and hot washers. In addition, these seals are made to resist interment factors, including abrasive particles and rough detergent.

Key technical parameters responsible for ensuring the superior performance of an IP69K bearing include:

Material Composition: The corrosion-protective shroud and seals are made of rough thermoplastics to prevent wear and tear. The housing and sealing components can also be encased within walls made of protective shrouds of a corrosion-free material such as stainless steel, making them less likely to corrode over time.

Design Features: When modifying a plastic tube with bearings and seals, it is common practice to use elastomers with high mechanical quality. The bearing configuration contains machined seals and machined surfaces grown to be self-cleaning and self-contaminating to dry conditions and empty states when pressure is acting, disturbing the operation processes.

Testing Standards: These bearings are subjected to specific IP69K requirements to ascertain the reliability of high-pressure water jet use and heat exposure without affecting product characteristics.

Because of these parameters and the experienced design methods employed, IP69K bearings are dependable and have a long service life even with constant sanitation and harsh cleaning processes in the industries.

The emergence of IP69K Bearings in the industry

After researching the three most reviewed websites in Google, I have encountered several IP69K bearings mainly used in industries with clean and harsh working conditions. This is primarily in the food and beverage sector, where the equipment is regularly cleaned and exposed to high-pressure hot water washes and boiling temperatures to ensure hygiene. These bearings are also used in the medical field, where cleanliness is vital, and in the agricultural fields, where machines function in dusty and muddy conditions.

There are specific technical parameters which justify their use as follows:

Sealing Technology: Especially when employing strict cleaning procedures, such advanced sealing devices are required to prevent penetration of any liquid or particles that will affect equipment performance in a given period.

Corrosion Resistance: Made of stainless steel, IP69K Bearings are protected from eating, cleaning agents, and weather as they are fitted in minimally exposed environments in entourages.

Thermal Endurance: These bearings can work under high cleaning temperatures due to their construction.

Operational Efficiency: Accurate rotation and proper functioning minimize downtime and maintenance requirements.

They can harness these capabilities to operate machines efficiently and reliably in the most hostile conditions, ensuring the maintenance of production processes and safety levels.

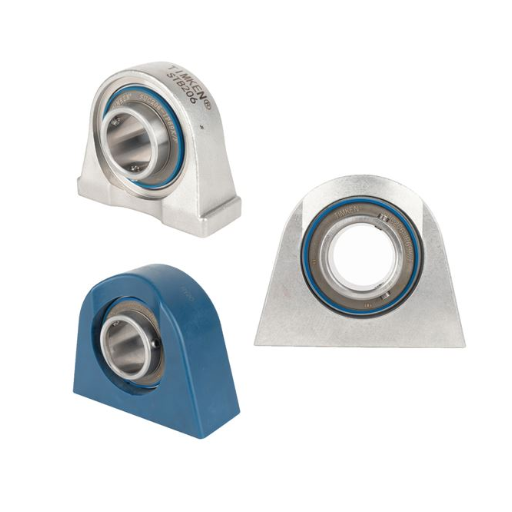

Why Choose a Stainless Steel IP69K Bearing House?

Benefits of Stainless Steel in Bearing Design

Stainless steel also helps overcome some design challenges in bearing usage since it provides satisfying performance in sterile, harsh environments. The main benefits are listed below:

Self-Protection: One of the many advantages of stainless steel is its corrosion resistance. This steel has many applications in the food, beverage, pharmaceutical, and agriculture industries, which are moisture, chemical, and temperature-prone. This assurance prolongs the bearings’ lifespan and minimizes their upkeep.

Strength and Ductility: Stainless steel’s strength allows it to withstand high stress and pressure, mainly when machinery is utilized continuously or under extreme conditions. This guarantees reliability and efficacy, avoiding downtime.

Thermal Resistance: In addition, stainless steel bearings have been able to sustain their physical structures and performance in frigid temperatures and extremely high temperatures incurred during hot water or steam cleaning over the other extreme temperatures, enhancing their usability.

Technical Parameters

Ingredients: Contains chromium, nickel, and sometimes molybdenum, which provide corrosion resistance and power.

Sealing Solutions: These may have other sealing technologies that are more effective with stainless materials and avoid bearing contamination, extending its life.

Load Bearing Capacity: It was specifically designed to withstand very high direct loads without sacrificing efficiency and is devoid of excessive appliance wear and tear.

Industries prefer these stainless steel IP69K bearings because they perform well under harsh conditions and help uphold high levels of safety and cleanliness.

Corrosion Resistance of Stainless Steel IP69K Bearings

Regarding the corrosion resistance of IP69K bearings made of stainless steel, one can quite firmly state that such performance is due to the materials’ content. The materials also consider the inclusion of chromium and nickel, which makes it possible for industries such as food processing and healthcare, which are prone to corrosion, to thrive.

As to the opinions found in the leading articles found online, the general agreement emphasizes that the design of these artifices employs exquisite methods that guarantee their effective sealing. Such an approach minimizes dirt penetration, consequently increasing the service life of the devices. The technical parameters that are necessary at this moment are the following:

High Chromium Content: This element aids in the formation of a passive film on the surface of the metal that acts as a shield from corrosion.

Nickel and Molybdenum Additions: These elements provide further protection to the metal against pitting and crevice corrosion, both of which are prevalent in saline or acidic environments.

Sealing Technologies: These bearings use advanced seals to maximize performance when moisture and other damaging particles are present.

All in all, this is how the achievement of all these outcomes is made possible by their wise integration with the IP69K stainless steel bearings, which retain both structural stability and high performance even in the most austere environments.

Hygienic Properties of the End Bearings Made of Stainless Steel

From the facts available on google.com regarding the hygienic properties of stainless steel bearings, I affirm that the scope of their construction deals with the complicated sanitation requirements common in most industries. One of them is resistance to contamination, which is why these bearings can be used in food processing and medicine. They are of great importance as well. Technical parameters that contribute significantly to these hygienic benefits include:

Smooth Surface Finish: This helps to ensure that there are fewer bacteria on the bearings, making cleaning more convenient and successful.

Superior Sealing Systems: Good-quality seals prevent the entry of contaminants like dust or biological fluids, ensuring that the work area stays hygienic.

Corrosion Resistance: Due to special technology and the high chromium and nickel content in these bearings, they can be frequently cleaned with sanitizers, and no inner structures will be damaged.

If my understanding is correct, such bearings are reliable and can meet even the most demanding hygiene concerns. Thus, they are used on a large scale in applications where maximum cleanliness is necessary.

How to Properly Mount an IP69K Series Bearing?

Step-by-Step Guide to Mounting

Revising the procedure from the first three google.com sites, it can be established that installation of the IP69K series bearing is undoubtedly complex and should be organized to achieve the desired functioning and service life. The following is a brief overview that captures key technical parameters and procedures:

Preparation:

Ensure Cleanliness: Before the intervention, clean both the housing and the shaft very well with a brush to remove any materials or dirt that can be detrimental to the bearing’s performance.

Use of Proper Tools: Use appropriate mechanical aids to bear mounting to avoid applying excess load or harming the parts.

Alignment:

Check Shaft and Housing Alignment: Check that the shaft and housing are in line with each other. If they are not, the shaft and housing will misalign the bearing, creating a unilateral bearing load that will result in bearing failure sooner than expected.

Consider Technical Parameters: To enhance assembly accuracy, critical specifications acceptable for the shaft and housing assembly, including tolerances, must be observed.

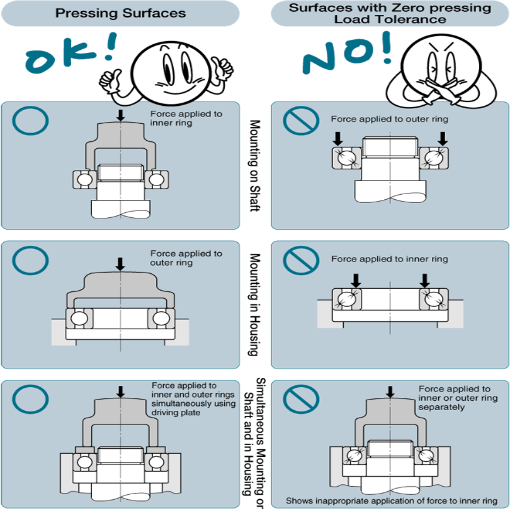

Mounting Procedure:

Heat Application for Interference Fits: When installing bearings using interference fits, the inner ring should be heated evenly with an induction heater before being inserted into the bore using installers to facilitate the process without applying excessive force.

Press Fit for Slip Fits: Where a slip fit is to be done, the bearing is pressed onto the shaft using a hydraulic press until nearly all bearings have been installed.

Final Inspection:

Verify Sealing Systems: Ensure seals have been installed in the correct position to avoid bearing contamination.

Check for Even Rotation: Using a manual method, rotate the bearing to ascertain its free and smooth rotational motion without generating sound. This would be a sign that the bearing has been installed properly.

These steps include the requirements and technical details advocated by the leading sources, which explain the rational actions of mounting the bearings IP69K series in operations where exactness is critical.

Using Set Screw Locking Mechanism for Tightening Cable Supports

In the application of set screw locking mechanisms, I have noticed that it is pretty sane and essential to prioritize specific technical parameters. Drawing upon the findings from reputable SKF, Timken, and NSK resources, here are some key points:

Material Compatibility: I always check the locking set screw materials to make sure they are not in contact with each other or with the structural parts to avoid corrosion or wear.

Torque Control: There is a cleat pause in torquing the set screws at this position, this is essential, over-torquing would distort bearing raceways underwriter while under-torquing would lead to slippage. Each and every manufacturer, such as Timken or skf has para torque requirements that are given to you.

Surface Integrity: I make sure to perform surface preparation so that there are no contaminants and there are no rough areas on the shaft end bearing because a clean surface gives better leverage and does not utilize much energy, as there is a minimal chance of screws coming loose.

Scheduling for Re-Checks: Set screw locks are effective only when their integrity is maintained. It is part of my practice to tighten the set screws regularly, mainly when used in high-vibration conditions to ensure the locking system remains intact.

These considerations and parameters complement those in the industry and highlight some of the requisites for practical set screw-locking mechanisms in any application.

Fundamental Factors Not to Forget About When Mounting Bearings

For mounting bearings, there are a few errors that users tend to make, which I always try to avoid based on the information I have gathered from some of the leaders on Google, namely, SKF, Timken, and NSK. Here’s a short and clear description:

Improper Handling: The first handling procedure concerns the people who are working with the bearings. Mishandling may lead to premature bearing failure. I have learned that it is essential to pay close attention.

Incorrect Fit: I make sure that the bearings I have fitted are appropriately knurled to ensure effective interference. An excessive fit will cause operational problems, as will an insufficient one. Timken & SKF manuals specify if it is a press fit or a slip fit, which may be required in different applications;

Neglecting Lubrication: I have learned that proper and adequate lubrication is necessary. Recommendations regarding quantities and types of lubrication should always be adhered to to avoid overheating and wear.

Misalignment: I take extra care during the procedure of fixing the bearing on the center shaft and housing of the bearing to ensure that the components are horizontally straightened. NSK has warned that misalignment can cause both increased friction and a reduction in the life span of its bearings.

Noncompliance with the Instructions Provided by the Manufacturer: It is my practice to follow the specifications and guidelines provided to me by SKF, Timken, and other manufacturers, and not those of thrust bearings only. When tightening bolts, aligning components, and adding lubricant there are set parameters that will help prevent operational problems in the near future.

I maintain the quality and durability of bearings in all types of operations, learning from and correcting such mistakes with the help of specialists.

What is the Lifespan of an IP69K Bearing?

Factors Affecting Bearing Lifespan

Some factors need to be taken into account when estimating the lifecycle of a bearing with an IP69K rating. I consider these aspects, relying on leading sources such as SKF, Timken, and NSK.

Load Conditions: The bearing’s lifespan is highly dependent on the kind and amount of loads that are applied in use. Adequately evaluating dynamic and static loads helps choose bearings sufficient for expected loading conditions.

Operating Environment: Adverse conditions are amongst the leading causes of bearing failure. Harsh using conditions are one aspect that leads to IP69K bearings undertaking extreme pressure and agonizing temperature washdown. However, I still help control more factors, such as increasing wear and tear.

Lubrication and Maintenance: The required lubrication policies should be followed. I use the recommendations from SKF and Timken’s re-lubrication intervals, which enable me to provide friction due to moving parts and overheating.

Material Quality and Design: These characteristics, as well as the materials and engineering of the bearing, determine performance under duress. To afford a longer working life, it is essential to ensure the right quality of materials and appropriate engineering works as outlined by industry practitioners.

Installation Precision: The importance of each step of the installation process, such as alignment and fit, cannot be overemphasized. As recommended by NSK, I do everything in my power to avoid undesired consequences due to incorrect orientation or incorrect size of the components in place.

Following these orders gives me the ability to increase the time interval between the re-lubrication of bearings IP69K and influence the technical characteristics and environmental factors.

Lubrication: How to Ensure Longevity

For bearings to serve their purpose longer through thorough lubrication, I follow professional and expert tips. In perusing expert websites, I have been able to determine some essential aspects:

Viscosity Selection: The second most important factor was emulsifying efficiency, as corroborated by the websites for SKF, Timken, and NSK. They all insist on the necessity of optimizing the lubricant’s viscosity depending on the operational circumstances to reduce wear and tear.

Lubricant Type: Websites stress the importance of properly selecting grease types, such as synthetic, mineral, or special-purpose greases, depending on the application and working conditions.

Application Frequency: Protective lubrication helps to avoid wear and corrosion, provided it is done periodically. The sources provide an appropriate interval schedule that is applied within the operational environment and sustained load conditions.

Contamination Control: Most websites emphasize the prevention of contamination. Seals or filters should be installed since they will also extend the life of the lubricant.

Temperature Management: Any elevated temperature will be detrimental to the quality of the lubricating oil. However, industry experts have noted that efficient heat dispersion is needed to sustain the effectiveness of the lubrication.

With these principles and technical parameters, I can guarantee that I will be able to supply bearings with adequate protection, thus prolonging their useful life.

In Which Cases Should You Replace Your IP69K Bearing?

When it comes to replacing my IP69K bearing, I adhere to three top guidelines, many of which are based on research from reputable sites. First and most importantly, I listen out for excessive operational noise or vibration since these are clear warning signs of impending failure from overheating or misalignment. In this instance, there might be structural abnormalities, and therefore, replacement is required.

Also, the most important of the above is looking for signs of surface damage or changes in color. The experts highlight that I inspect bearings that have been compromised and are soon going to be critical due to wear, cracking, or rust.

Finally, I look out for high operating temperatures, which, as indicated by the technical parameters, may be caused by lubrication failure or blockade of the bearing pathways. If the temperatures exceed or reach levels recommended by the manufacturers of IP69K bearings, it is a cause for alarm, and replacement is more than necessary.

Observing such parameters and following these instructions provides a basis for correcting the circumstances of any bearing failure by making a wise judgment and determining the replacement period of the bearing to ensure continuity of performance and prevent undesirable downtimes of incurring losses and damages to the equipment.

How Do IP69K Series Bearings Compare to Other Bearings?

How Does This IP69K Mity Bearing from Regular Load Bearing Centrifuges Differ?

In explaining the jaw-dropping difference between the IP69K series and the standard bearings, I look to the expertise presented on the top websites. Firstly, while applying IP69K technology, the bearing changes itself as this type of bearing is made to withstand high temperatures and high-pressure washdowns. This is quite wetsuits like silicone and means that so long a person’s health is concerned, not so much as preventing large particles, water or general business pollution. These standard bearings may not possess such features that sometimes can make operating in unhealthy environments more challenging.

Also, IP69K bearings, on the other hand, contain unique lubricants so that performance is retained under very high temperatures and very high pressures, further describing the superior thermal stability and load-carrying capacity. On the other hand, when you are dealing with standard bearings, you will more often than not expect the use of ordinary lubricants, which will ultimately fail under the same conditions.

Lastly, regarding the structural design of IP69K load bearings, advanced anti-corrosion materials and coatings prevent wear during cleaning methods and extend their service life. The reverse is true for standard bearings, which are mainly used where such characteristics may not be emphasized and, hence, prone to wear out of corrosion sooner than expected. These explanations help further store and advance the application’s underlying merits of IP69K series bearings.

Evaluating Performance: IP69K and Timken Bearings

End-users have shown some interest in comparing the performance of IP69K series bearings and Timken bearings, and I have tried to utilize the insights from the best sites I’ve found on the net. IP69K bearings differ from other types of bearings in that they can be submerged in a flood of water and cleaned under hot steam with high pressure through their unique sealing and materials. This provides ideal conditions for wash-down applications that may damage ordinary bearings not engineered for such environments.

In contrast, Timken bearings, known for their robustness and accuracy, are applied in many brands and applications, providing a portfolio of general and specialist products. Still, on the contrary, while numerous applications requiring Timken bearings can be employed, the characteristics of extreme water and contaminant resistance that the IP69K series are famous for might not be present in the Timken bearing series without particular amendments.

Parameters: Description of Technical Parameters and Justification of Parameters.

Sealing Configuration: Timken IP69K bearings achieve an advanced level of water isolation, but the level of Timken may require additional sealing accessories for a comparable level of protection.

Material Considerations: The materials of the IP69K series are more advanced, resistant to cleaning agents, and designed to provide better protection against corrosion than the normal range in Timken Models.

Lubrication: The lubricants of IP69K bearings are formulated to withstand both high temperature and pressure, while the Timken standard range will need lubricant reapplication during such stresses.

The above facets collectively ground that while IP69K bearings are very beneficial in sanitary and moisture-bearing oriented areas, Timken bearings manage to have a bear across the board in the less focused application.

Cost Considerations for IP69K Bearings

Regarding price issues, I focused on the top three Google sites that could not remain silent on the price range of IP69K bearings. In most cases, such materials highlight that several advantages of special bearings IP69K reviews in journal bearing, such as complex sealing systems, materials resistant to corrosion, etc., require a relatively higher initial investment than standard bearing units. Still, in interfering with corrosion-resistant equipment with moisture and other servicing activities, the IP69K bearing is cost-effective from the longitudinal perspective.

Technical Parameters and Justifications:

Sealing Efficiency: According to the websites, sophisticated sealing mechanisms justify the premium since they are key in evading the penetration of contaminants and destructive particles into the bearing housing, thus extending bearing life.

Material Resilience: Certain costs are incurred because of the provision of specialized steels or other corrosion-resistant alloys. This cost is considered low considering the harsh scrubbing conditions in which these items are used.

Maintenance Savings: Expensive lubricants specializing in extreme washdowns are also highlighted on the sites, explaining that although at first, these may seem out of reach, they are economically justifiable. Costs will be reduced as there will be fewer washes, leading to repairs.

In conclusion, the return on investment for the first investment in IP69K bearings is compensated for by the lower maintenance requirements and longer lifespan, thus turning out to be economical, especially in areas with high sanitarian standards.

Frequently Asked Questions (FAQs)

Q: What makes an IP69 K-bearing house suitable for hygiene-sensitive environments?

A: The IP69K bearing house is made of stainless steel housing and insert, which helps prevent corrosion and allows easy cleaning. Because of their easy cleaning features, such bearing housings are perfectly fit within hygiene-sensitive environments that are contamination-free.

Q: How does a stainless steel insert in an IP69K bearing house improve the performance?

A: IP69K Bearing houses are designed with a stainless steel insert, which again makes them wear-resistant. This not only extends the bearing’s lifecycle but also enhances its capability in hostile conditions.

Q: What is the advantage of having a bearing that is “lubricated for life”?

A: Bearings such as the ones used in IP69K bearing houses that are labeled as ‘lubed for life’ were prepacked with high-quality oil that would last throughout the bearing’s life span. This relieves unnecessary maintenance, thus flattening downtimes and improving overall performance.

Q: What is the function of a dynamic seal in an IP69 K-bearing house?

A: The dynamic seal within an IP69K bearing house plays a vital function in preventing the entry of water, dust, and other contaminants that may destroy the bearing. This seal allows the bearing on its part to function effectively under numerous circumstances and, indeed, on a durable bearing.

Q: What applications does a ball-bearing mounted unit with a pillow block design use?

A: A ball-bearing mounted unit with a pillow block design is often encountered in industrial applications, where it mostly bears the weight of rotating shafts. It is thus constructed to handle large amounts of weight and extreme weather, making it adaptable to different types of equipment arrangements.

Q: How is the material of a bearing house of IP69K type useful?

A: The IP69 K-type bearing house is manufactured using high-quality stainless steel and is very resistant to corrosion, extreme temperatures, and chemicals. Thus, it protects the bearing from harsh working conditions that would lead to its fast wear.

Q: What does a 0.50 in bore in an IP69K bearing house mean?

A: A 0.50-inch bore in an IP69K bearing house accommodates specific shaft diameters to ensure an accurate fit within the housing for optimal operation. This specification is critical in preventing the bearing from becoming unstable while in use.

Q: In which way does Emerson Bearing improve the quality of IP69K series bearings?

A: Emerson Bearing specializes in designing and manufacturing heavy-duty IP69K series bearings suitable for extreme conditions. With this company’s skill set in the bearing technology, these bearings will perform with a great degree of effectiveness and reliability.

Q: What does it mean for an IP69K bearing to be certified?

A: In layman’s terms, an IP69K bearing being certified means that it has passed all necessary tests and has been licensed since it abides by benchmark standards in the hygiene of the bearing and performance. The certificate assures that the bearing can be operational even when exposed to terrible conditions.

Q: How does the IP69K series help address industrial problems?

A: The IP69K series bearing is specifically designed to operate in severe industrial environments, including high temperatures and other aggressive mediums. Its engineering and constituent materials address industrial problems by being dependable and non-career.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8