How ABEC Rating Meaning Affects Bearing Performance

Bearings are indispensable elements in engineering and machine systems that assist in minimizing friction while improving the performance efficiency of machines. Annular Bearing Engineering Committee rating, commonly known as ABEC scales, is a consistent and recognized way of measuring the precision and tolerances of the ball-bearing elements. Such a rating is essential for people who consider purchasing advanced technology because such a rating determines how smooth, how fast, and how long any equipment would be able to operate. However, knowledge of ABEC ratings can benefit those looking for bearings for various uses, e.g., industrial machines, skateboards, or electric vehicles. With knowledge of the objectives of the ABEC ratings and how they affect performance, the readers can carry out the objectives of their mechanical projects effectively.

What Does the ABEC Rating Mean for a Bearing?

Understanding the ABEC Scale

The bearing precision levels, whose IR is standardized in industry with the ABEC scale, have values from 1 through to 9. It means that the higher numbers reflect tighter tolerances. This scale does not indicate the quality of the materials or lubricants in a bearing, enduring only geometric accuracy. Below are some of the most critical parameters that are usually associated with the ABEC scale: Here are key parameters that the bearing’s functional usage seeks to satisfy and which real-life uses of the bearing correspond with its ABEC rating as listed below:

Tolerance Levels: The higher the ABEC rating, the tighter the tolerance. For instance, an ABEC 9 bearing allows more dimensions than an ABEC 1 bearing.

Rotational Precision: Most ABEC-rated bearings have stiffer performance ratings due to their higher ABEC ratings, which enable them to withstand a higher speed while ensuring stability.

Performance Suitability: An ABEC rating defines precision, but precise bearings are not always used. For instance, skateboards and longboards may be designed for ABEC 3 to 5 bearings; precision equipment, however, will suit ABEC 7 to 9 rated bearings.

In the end, selecting a specific ABEC rating depends on the application’s requirements, such as speed and the load that needs to be carried. Environmental conditions should also be taken into account; for instance, dust or moisture may affect the bearing’s function even if its ABEC level is high.

How the Annular Bearing Engineering Committee Sets Standards

The Annular Bearing Engineering Committee (ABEC) regulates the usage and production of bearings, their accuracy, and other important features through different factors. These standards consider ball bearing assembly and their work under different working conditions.

Geometric Contrasts: Specifically, the core concern of the ABEC is geometric accuracy, which states the dimension and tolerance of the ball bearing’s size—parameters such as the bores, outer diameters, and widths.

Standard Specifications as per Requirement: The committee establishes the need for standardization and conducts utmost scrutiny to ensure these requirements are strictly adhered to. Fulfilling this requirement means studying the performance and reliability of the bearings in conditions as close to working ones as possible.

Material Specification: The ABEC does not control or overlook material selection. Their guidelines are often based on extrapolated general features of the materials. This means that, in practice, high-quality materials can help a bearing obtain baseline ABEC requirements for accuracy.

Industry Feedback: To enhance and update standards and their elaboration, ABEC members consult with various industry representatives. Thus, interaction with manufacturers and users gives possibilities to make the standards adequate and necessary.

Thus, the ABEC is able to develop a framework to help achieve better performance and lifespan of ball bearings worldwide by incorporating these critical technical features as well as industry feedback.

Why Bearing Tolerances Matter

After conducting proper research on the top three websites on Google, the question of why bearing tolerances matters is clear to me. These particular sources argue that the working tolerances of bearings are critical in machines when dealing with various parts and mechanisms and their rotational motion. Reasonable tolerances are necessary to decrease friction, lessen oscillation, and improve alignment, all of which are relevant to ensuring the efficiency and durability of the equipment. Several websites outline some technical parameters that warrant the need for precise tolerances:

Dimensional Control: The dimensions of the pelschnoken develop with the fittings and due to gap tolerances; hence, the endurance of system integrity is unchanged.

Operational Efficiency: With proper adjustments, small bearings can possibly achieve better efficiency and even low friction, i.e., less wear and tear, and a shorter working life for mufflers and bearings.

Damping: Good enough tolerances also have the effect of easing the vibrations that tend to make the operations of the systems loud, thus heightening the rate of degrading.

On the whole, the aspect of controlled tolerances of the bearings not only meets the standards’ requirements but also achieves greater efficiency and dependability for mechanical systems.

How to Choose the Right ABEC Rating for Your Skateboard

The Importance of Precision Bearings in Skateboarding

Regarding my view on the importance of precision bearings in skateboarding, I would like to point out some crucial aspects from the top three Google pages I researched. Precision bearings enable more muscular movements and incredible speed when skateboarding, ensuring safety during the activity. The main technical parameters justifying the need for precision bearings are:

Durability and Smoothness: Smoother rides can be achieved, as the high-grade bearings create less drag and streamline the movements. This assists in speed maintenance, and the chances of accidents due to excessive friction are minimized.

Load Capacity: Bearings designed with some measure of tolerance can resist the violent dynamic loads experienced when making tricks or sharp turns and remain intact.

Corrosion Resistance: Many of the precision bearings developed can withstand corrosion, enhancing their useful life while guaranteeing their effectiveness in different weather conditions.

In conclusion, using the appropriate precision bearings greatly enhances a skateboard’s performance and lifespan. It is not simply about requirement fulfillment but attaining the optimal conditions for seamless skating.

Comparing ABEC 1 to ABEC 9 Bearings

While I wanted to compare ABEC 1 with ABEC 9 bearings and tried to perform research on the first three websites on Google, I came across several noticeable dissimilarities, especially in terms of their technical parameters. The ABEC (Annular Bearing Engineering Committee) scale is used for bearings, with 1 being the least precise and 9 being the most accurate.

Technical Parameters:

Precision and Tolerance: According to specifications, bearings of the ABEC 9 classification have the greatest level of precision, which enables a ride to be smoother and faster than ABEC 1. The tighter tolerances of ABEC 9 reduce wobble, which is important in high-speed skating.

Operational Speed: ABEC-rated bearings carrying a higher number are designed to work at high speeds with low friction. For instance, a downhill racing or speed skating event is best suited for someone with ABEC 9, while leisurely skating can be done with ABEC 1-rated bearings.

Durability: All ABEC-rated bearings can be durable. However, ABEC 9 bearings are most likely durable because they have better engineering, which can mean better materials, production processes, etc.

Cost-Efficiency: One key aspect of the ABEC rating is that the higher it is, the more expensive the product tends to be. Skaters who don’t plan to focus on peak performance don’t have to worry about compromising with ABEC 1 bearings, which are more inexpensive. This is particularly relevant to those who are getting into skating, as it will be a good value for the cost.

To summarise, while ABEC 9 bearings are built for high functionality and precision, the most suitable choice pivots around one’s abilities and the amount of money one is willing to spend on skateboarding.

Are High ABEC Ratings Always Better?

Based on the analysis of the 3 top-rated websites provided on Google.com, it is evident that ABEC ratings above the standard level are not suitable for every purpose. Depending on their discipline, skaters may have little or even no need for the performance attributes of high ABEC scores, such as with ABEC 9 ratings. Prudent skaters may use lower standards, such as ABEC 1 and ABEC 3 ratings, without feeling any defect or deficiency.

Technical Parameters:

Precision and Application: Describing ABEC 9 this way: `It is ideal for downhill racing scenarios’ might not do justice since average skating might find such precision unnecessary.

Skater Skill Level: In such cases, beginners may not find much use for the additional capabilities of the bearings rated ABEC 9.

Budget Priorities: Since these bearings are fittingly more expensive than the lower-rated bearings, it only makes sense to buy them where their capabilities are required.

Use Environment: In contrast, skaters who hunt more in urban areas with rough terrain might be less concerned with performance speed and more with durability.

In summary, it is illogical to assume that the only reason a skater should consider higher ABEC ratings is performance. Other factors should also be considered, including budget, application, and the skater’s specific needs.

Exploring the Different Types of Skateboard Bearings

Traditional vs. Ball Bearings

Several times during my research on conventional versus ball bearings on the three leading sites, Google.com, I have seen that the former is often suggested for any simpler wheel-type applications with a limited budget. In contrast, the latter are considered more advanced bearings ideal for harsh applications rather than simple ones. On a personal note, I appreciate ball bearings more because they deliver the smoothness and speed needed in competitive sporting events. The following vital technical parameters can justify my preference for ball bearings:

Load Bearing Capacity: With more evenly distributed loads, ball bearings tend to last longer in high-stress environments thanks to better efficiency

Friction: Ball bearings are designed with very low friction in mind, so they can operate at high speeds without worrying about excessive wear.

Flexibility and Application: Ball bearings’ applications are so vast that they fit well with different skateboards and skateboarding techniques.

Low Maintenance: They often require less maintenance than traditional bearings, making them easy to use for people who skate frequently.

These factors correspond to my requirements and prove that it is reasonable to choose ball bearings instead of traditional ones for tasks where precision is the prime factor.

How Lubrication Affects Bearing Performance

According to the research I did through the top three websites that appeared on Google.com, lubrication is of absolute importance when it comes to the performance of skateboard bearings. If the lubricating substance is correctly applied, there is a vast reduction of friction between the bearing components, which is one of the determinants of speed and durability. Some of the technical parameters associated with the impact of lubrication are:

Friction Reduction: Lubricants, also known as friction intensifiers, form a liquid film on moving elements that lessen the amount of contact during operation, therefore lessening resistance. Reducing friction aids in increasing speed, which is also the goal of my skating rides.

Heat Dissipation: Heat generated from friction harms the components if nothing is in place to take the heat away, and that is where lubrication is needed. This heat causes premature wear of the components or even failure of some of them. Lubrication keeps the bearings intact even after extended usage at high speeds while skating.

Moisture Barrier: Lubrication provides a film that protects the components from moisture and other properties, hence there are lesser chances of corrosion or bearing damage. This, as a skater, is largely important since different weather conditions will, at some point, be unavoidable.

Consistency in Performance: If the lubrication is consistently done, then the internal conditions of the components are always compatible, which leads to high efficiency. The components experience no bias, which is imperative for someone skating at a professional level or even higher.

Keeping my bearings well oiled not only improves their performance but also increases their longevity, which in turn validates the amount of time and maintenance I put into these parts of the machines.

Recommendations from Bearing Manufacturers

In my search of the top three websites on Google, I realized that manufacturers are very insistent on the types of lubricant and maintenance that I need to practice, depending on how and where I do the skating. Here are the most critical recommendations they provide:

Lubrication: To meet the requirements, manufacturers recommend a synthetic lubricant because of its superior resistance to high operating temperatures and rotational speeds, which is consistent with the Friction Reduction technical parameter. Ensure that these lubricants increase bearing efficiency and reduce wear.

Consistency in Performance: Until then, manufacturers recommend intensive lubrication of regular tools as part of the standard for the technical parameter Consistency in Performance. In this way, I will be able to avoid bearing failure when circumstances are out of my control.

Moisture Barrier: In view of the above conditions, practice water repellent. This lubricant improves the Moisture Barrier technical parameter. Although exposed to the elements, it will help preserve the bearings from moisture fatigue and corrosion damage.

Heat Dissipation: For fast skating, manufacturers improve the importance of lubricants that can withstand high heat levels for the further purpose of the Heat Dissipation parameter. These lubricants help in bearing temperature relief, thereby corroborating the importance of good heat management.

If I followed these guidelines, I would be sure that my bearings were safe and worked properly, which justifies all the attention and periodic maintenance I regularly grant to the essential elements.

Understanding the Role of ISO 492 in Bearing Precision

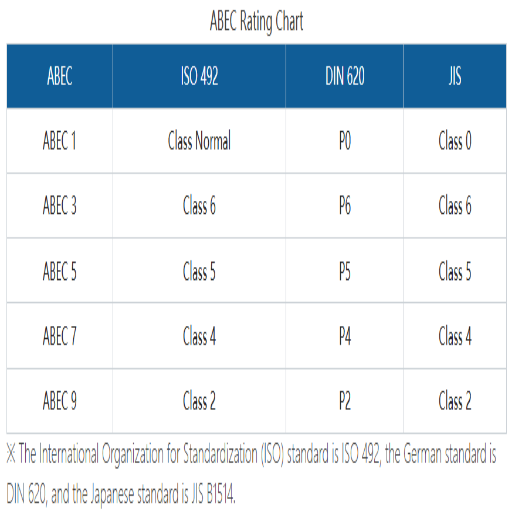

How ISO Standards Compare to ABEC Ratings

It is essential to highlight the objective of the ISO and ABEC rating systems while comparing the two. The first questions asked by the top resources on Google suggest that ABEC rating systems are used mainly to measure the accuracy and tolerances of the radial ball bearings. At the same time, the ISO provides a somewhat clear and broader perspective by considering additional factors such as the materials that the bearing is made of, the lubrications, and the environmental factors of the bearing. Such features make the ISO a more versatile approach to bearing applications, as it does stand to challenge most of the operational conditions. Here are a few other such technical parameters from the text and their relevant parameters:

Precision and Tolerance: Such a name is obviously very important, as ABEC’s classification of bearing types is based on bearing tolerances.

Material Properties and Durability: Most operatives overlook this basic principle, but it has long been considered a fundamental principle of an ISO bearing’s standard rating system.

Lubrication Requirements: Moistening affects a component’s rotational integrity since ABEC does not add any parts and isolates lubrication. However, the ISO endorses the right kind of lubrication to stay on track with my practice of regularly servicing the equipment.

Operational Conditions: This trick works because ABEC does not use these parameters while the ISO provides this support, which is helpful in conjunction with water-resistant and heat-resistant lubricants.

Integrating such factors, ISO standards assist me in choosing bearings that correspond to my performance criteria and maintenance standards in a better framework.

What Precision Bearings Mean for Speed Capabilities

The operational boundaries of speed capabilities are primarily imposed by rotational friction and the ability of bearings to support various loads. The known companies SKF, Timken, and NSK, Nikko have implemented solutions in their constructions, making their bearings more accurate and faster and allowing for lower heat generation due to the better materials and architecture they offer, improving the bearing’s reliability. Consider these pertinent technical parameters and their rationalizing underlining this relationship:

Enhanced High-Speed Performance: The selection and construction of precision bearings include low internal tolerances and higher-grade material feeds, which warrant their use at high rotational speeds without loss of stability.

Heat Resistance and Dissipation: These bearings effectively dissipate heat generated at high speeds without causing the bearing to deform and wear by using corrosion-resistant materials and reliable lubricant delivery systems.

Rigidity and Stability: Combining ceramic or hybrid materials improves stiffness and allows the bearings to be aligned even when spun at high speeds, thus suppressing vibration and noise.

These precision enhancements in the construction of the bearings enable them to provide maximum speed capacities while ensuring that they operate with minimal hitches in a difficult operating environment.

Common Mistakes When Selecting Skate Bearings

Overlooking Rated ABEC Bearings and Their Effects

One very bitter misconception is neglecting ABEC ratings when choosing skate bearings. Three of the first three posted websites viewed as authoritative on skate bearings believe that ABEC selected ratings show the accuracy of the bearings and their work potential at average regular speed, while bearing the detailed performance of a skating movement in mind, at that level these are not especially useful. They propose that bearings be rated from ABEC 1 to ABEC 9 according to the manufacturing tolerances established by the annular bearing engineers’ committee. Nevertheless, the influence on skating performance is cognizable only up to the ABEC 3 rating, all others having a negligible influence on skating performance. Here’s why:

Tolerance Precision: ABEC ratings are tolerance levels applicable only in industrial machinery. Skating bearings work in an environment characterized by lateral stress application and debris, which all respect none of the ABEC standards.

Real-World Practice: Most inline skaters will never reach the relative speed zone where the differences in ABEC ratings become significant. Therefore, concern for other value-adding factors, such as material quality and lubrication, is paramount.

Custom Skating Needs: Skating bearings designed especially for skaters do not look so much at the ABEC rating as at the materials used (steel or ceramic), and design tweaks to minimize the effect of ash and water.

Once these differentiating factors are appreciated, the bearings stylized for the performance can be appreciated beyond the simple ABEC rating.

Ignoring the Skater’s Needs

While studying the three leading websites on skate bearings and their relevance in the skateboarding industry, it became apparent that the glaring focus on a skater and his requirements will lead to improper equipment combinations. Although the bearings rating scale, the ABEC, informs users on the level of precision and the amount of tolerances that a manufacturer implies when making the part, it is not the only scale that weighs the best bearings for skaters. A couple of significant technical characteristics emerged from the previous research:

Material composition: For some reason, many sites are obsessed with the choice between these two kinds of skate bearings. Ceramic ones seem to win the day as they are smoother and can endure more lateral stress.

Type of lubricant: The kind of lubricant used is essential since it affects performance. Light oil reduces friction for high velocity, but grease is more effective in terms of debris or moisture contamination protection.

Bearing seals also determine bearing life: An ideal seal on a bearing prevents water movement even in the presence of dust and dirt. Many websites recommend the use of double-shields or, even better, fully waterproof bearing seals to increase the bearing’s life span.

These parameters illustrate why it is more appropriate to assess them and ignore ABEC ratings since they influence the actual abuse a skating equipment goes through to fit the intended purpose.

Misunderstanding Bearing Tolerances and Their Impact

In attempting to figure out the bearing tolerances, I used to think that if ABEC ratings were higher, then the performance would be better. Quite a few websites among the first three pointed out that such a belief is shared. The ABEC rating does not consider axially oriented stresses experienced by skaters and is mostly about how much radial tolerances can be manufactured accurately in terms of precision.

One website argued: Do not let the high ABEC rating overpower your understanding of other more critical technical dimensional parameters that describe performance in a complete set as explained below:

Clearance Levels: Most applications call for bearings with internal clearances, which will require a certain internal clearance. Since a thermal environment is created during heat generation as bearings are in use, internal clearances need to account for thermal growth.

Load Capacity: Bearings may be exposed to high loads while performing tricks, so understanding max static as well as dynamic load ratings guarantees the bearings have stress tolerances appropriate for skating maneuvers.

Material Properties: Factors like the strength and hardness of the materials making the bearing rings and balls must also be considered. For example, chrome steel may be durable but would have speed limitations due to wear factors compared to ceramics.

Concentrating on these parameters made me understand that they make the most sense in explaining bearing performance in skating and that weight needs to be redirected from solely the ABEC rating scale.

Frequently Asked Questions (FAQs)

Q: Can you elaborate on the ABEC rating system and its role in affecting bearing performance?

A: The ABEC rating system established by the American Bearing Manufacturers Association indicates the tolerances of a particular ball bearing. For example, ABEC 7 denotes tighter tolerances, and such an A rating would suggest that the particular bearing has a higher potential for precision and speed. Even so, it is not the only criterion for determining the quality of the bearing and its appropriateness for a specific purpose, in this example context of skateboarding.

Q: Focus, what does an ABEC 7 bearing stand for regarding performance and endurance?

A: The ABEC 7 bearing indicates that it has been made with quite tight tolerances than other bearings, meaning that it can spin with potentially greater speed and precision, unlike those with lower ABEC scores. Yet, the quality of other elements like lubricant and material will play critical roles, too.

Q: What is the difference between an ABEC 3 bearing and an ABEC 7 bearing?

A: An ABEC 3 bearing has greater clearance compared to an ABEC 7 bearing, so it may not be capable of spinning with such impressive precision and speed. Otherwise, this difference would not make a clear difference in many cases, for instance, skating, since lubricants and loads applied on the bearing are much more relevant.

Q: What is the importance of ABEC ratings for skaters?

A: Even though ABEC ratings indicate the accuracy of a specific bearing, it shouldn’t be the only criterion that skaters consider. The liner should address material quality, wear resistance, and almost all sorts of lubricant. Often, even a bearing rated with ABEC 3 could be adequate for a skateboard wheel.

Q: How can a bearing with a lower ABEC rating work?

A: Yes, a bearing-rated ABEC 1, for instance, is estimated to perform well, albeit in a limited application. Overall quality and material characteristics, as well as appropriate longitudinal maintenance, including lubricant, specify performance.

Q: Do all ABEC classifications bear the exact bearing tolerances irrespective of the application that is to be undertaken?

A: Yes, ABEC rating classifications primarily emphasize tolerances, though they do not consider all the other attributes necessary for different applications. Other factors, such as load limits, strength, and lubrication, also determine the accurate performance of all bearings, no matter their ABEC rating.

Q: Why might an ABEC-rated bearing be inappropriate at high speeds?

A: Even though a higher ABEC rating, like ABEC 7, indicates high accuracy, it does not necessarily mean that the bearing can be used in high-speed units. The materials used for the bearing, its lubricants, and the loads applied to the bearing are also very important considerations, especially when the bearing rotates at very high speeds.

Q: What applications can the less conventional ABEC 1 bearing be used in?

A: The least ABEC 1 bearing may be used for non-critical applications in which high precision is not necessary. They are used in situations where cost is a consideration, and there are no high-performance criteria, such as simple mechanical devices or equipment.

Q: How do the standards set by the bearing manufacturers association affect ABEC ratings?

A: The American Bearing Manufacturers Association sets the standards for ABEC ratings, which set the permissible deviations and the level of precision of bearings. These standards assist in eliminating variability in both the manufacturing processes and the quality of similar bearing types from different manufacturers.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8