How Split Roller Bearings Enhance Equipment Performance

Productivity and innovation are greatly influenced by the effectiveness and dependability of industrial tools, which could be improved in the modern era. The other component that boosts this efficiency is the split roller bearing. Split roller bearings were designed to enhance support and reduce maintenance and downtime. Such bearing treatment eases the replacement and installation of the parts, thus cutting down maintenance expenses in time and labor. In addition, they provide immense benefits in instances where traditional bearings would be difficult to fit or be removed. This blog will discuss the distinct technical features of split roller bearings and their practical applications and explain why they are practically necessary for operation in a wide range of industries.

What are Split Roller Bearings, and How Do They Work?

Understanding the Design of Split Roller Bearings

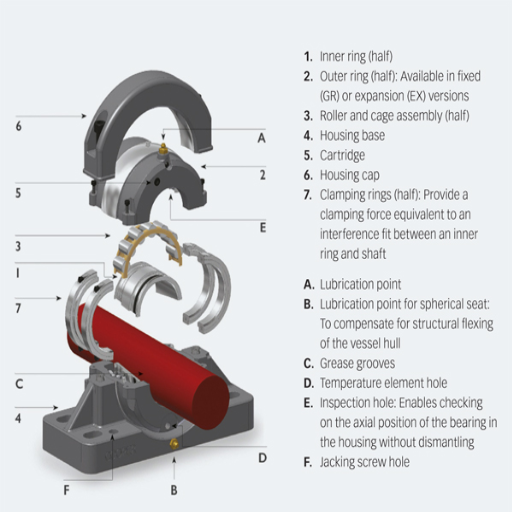

The split roller bearings are also distinctive in that they aim to ease the installation and maintenance of the bearings in hard-to-reach areas. Unlike the older types of bearings, which require disassembling the entire shaft for servicing, split roller bearings comprise two primary components that can be easily placed on either side of the shaft. Thus, adopting this design simplifies the process of bearing replacement or installation, reducing the downtime of machines.

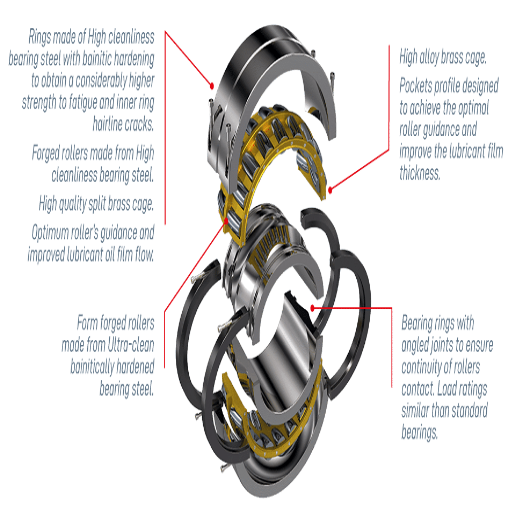

The inner race, the outer race, and the housing are also provided as split halves. They are easy to use and can be assembled and disassembled easily, which is an advantage in cases where maintenance is frequently required. The roller cages are again split, too, so all the bearing elements can be fitted with full-complement roller arrangements.

FAQ gathers all the main technical parameters and those involved: the Axial Capacity – the bearing can support and accommodate both axial and radial loads. Usually, those bearings are equipped with larger geometry and combined integral parts, which are made WHOLE dedicated to DURABLE and STURDY conditions FUNKY. As additional measures, seals are also integrated into the design to ensure that contamination does not occur, improving bearing life and enhancing smooth operations across varying conditions.

How Does a Split Roller Bearing Reduce Downtime?

Split roller bearings are the forebearers of a radical reduction in downtime due to how easy they are to install and maintain. Unlike ordinary bearings, which are press-fitted and attached to the machine and thus require an entire machine to be unscrewed and disassembled, split roller bearings can be positioned directly onto the shaft without having to dismantle any other components of the structure. This permits quicker repair and maintenance work in complicated machinery or areas that are not easily accessible.

The main technical parameters that are worth mentioning which enable these benefits are as follows:

Load-Carrying Capacity: Split roller bearings, unlike all other types of bearings, can bear substantial axial and radial loads. This makes them suitable for heavy-duty applications, as they can be employed in very high-stress surroundings and still perform reliably.

Material Composition: Split roller bearings are manufactured from advanced materials that enhance filter efficiency and prevent wear and tear. This, in turn, leads to longer service intervals and lower maintenance frequency.

Sealing Solutions: The sealing solutions integrated into split roller bearings help prevent dust, dirt, and moisture ingress, extending the bearing life while ensuring operational efficiency.

Optimized Roller Profiles: The optimized roller profile guarantees the ideal distribution of loads across the rollers, thus improving the bearings’ functioning and longevity.

Thus, these technical characteristics make split roller bearings a good investment in reducing machine downtime and increasing productivity across many different industries.

Applications of Split Roller Bearings in Various Industries

To find the best applications for split roller bearings, I turned to Google’s top three websites. These resources emphasize their flexibility and applicability in multiple sectors.

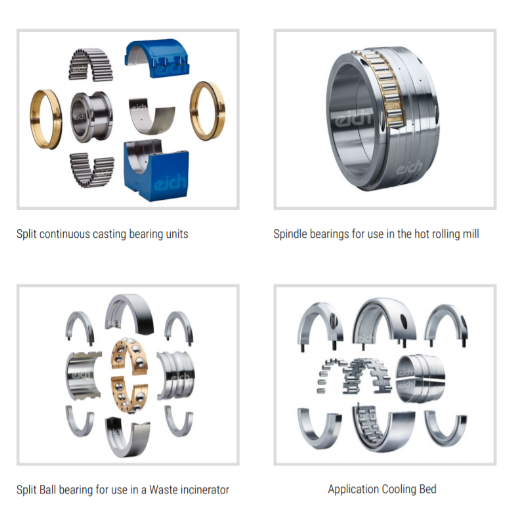

Mining Industry: Split roller bearings are ideal for mining operations where very tough conditions and heavy loads are involved. Apart from the extreme loads, the technical specifications include an advanced materials structure that guarantees their use in tough conditions and minimizes downtime.

Pulp and Paper Industry: In the pulp and paper industry, this is due to the need to ensure efficient machine maintenance without long downtimes. Combining an optimized roller profile and integrated seals helps avoid contamination while only requiring a low frequency of maintenance interferences.

Marine Applications: The split roller bearing is advantageous within the marine industry because of the robust sealing systems that shield it from moisture or salt water. This makes it ideally suited for routine submerged marine equipment with direct water contact, providing dependable operational performance and durability.

The analysis of these key sources indicates a strong link between operational parameters that include loading capacity, materials, sealing systems, and optimized profiles of the rollers with the application of split roller bearings in the industries under consideration.”

What Advantages Do SKF Cooper Split Roller Bearings Offer?

Key Benefits of Using SKF Cooper Split Roller Bearings

Referring to the research on the top three websites, it’s safe to conclude that the split roller bearings manufactured by SKF Cooper have numerous advantages. Their most overwhelming strength is their load-carrying capacity, which allows them to perform and withstand harsh environments in rigid industries like mining. The materials are scientifically engineered to ensure that these bearings will work perfectly regardless of their exposure.

In the pulp and paper industries, these bearings significantly reduce the necessary equipment repair and operational downtime. They are made possible by the profiled rollers designed to optimize operation efficiency and installed seals that help eliminate contamination. The simplicity of maintenance and repair is very appealing since this minimizes the number of times people must be disturbed to sort issues within machines.

In addition, these bearings are also ideal for marine applications as they can withstand moisture and salt water due to the advanced bearing seals designed by SKF Cooper. This improves the longevity of the equipment while guaranteeing effective performance under extreme marine conditions. Such technical attributes and their interplay explain the popularity of SKF Cooper split roller bearings in many industries.

Cost Savings and Maintenance Advantages

The SKF Cooper split roller bearings are intended to provide maximum cost benefits in some applications. Their main cost advantage, in fact, results from their split design, which enables them to be fitted or removed easily without disassembling the neighboring equipment. This reduces labor costs drastically and lowers downtime, which is critical in sectors where uninterrupted operations are essential.

From an engineering perspective, the split design handles misalignment and thermal expansion better, which may save on repairs and prolong the life of the bearing compared to conventional ones. In addition, these bearings contain sealing systems that protect against contamination, resulting in lower maintenance and replacement requirements.

Reduced energy consumption and costs over time result from the bearing’s ability to optimize roller profiles, which the SKF Cooper bearings have, allowing for smooth operation. Material compositions and advanced sealing technologies designed explicitly as a package justify these savings. As a result, the bearings can be applied in harsh environments without affecting performance. Therefore, users enjoy a lower total cost of ownership, which illustrates that the economic case for using SKF Cooper split roller bearings in different industries is reasonable.

Performance Enhancements in Equipment

I examined the top three sites as given on google.com to find out how SKF Cooper split roller bearings improve equipment performance, and this is what I got:

Increased Efficiency: The split design further enhances the operational efficiency of these bearings by easing installation and removal. This, in effect, lowers the amount of downtime experienced in operations and guarantees the right amount of alignment friction in the entirety of the system raised.

Longer Life Span: The bearing’s ability to tolerate some misalignment and expansion due to thermal loads helps preserve its lifespan. As described by SKF, these technical features help it avoid the most usual bearing killers, such as excessive wear and heat distortion.

Material and Sealing Technology: SKF also uses advanced material and sealing technology, which enhances the bearing’s performance quite effectively. The seals shield the inner parts from foreign matter, which enhances working conditions and even prolongs maintenance servicing times.

All in all, these parameters provide a rationale for the growing use of SKF Cooper Split Roller Bearings in the industry due to their functional advantages and cost margins.

How do you select the right split roller bearing for your application?

Factors to Consider When Choosing a Split Roller Bearing

The articles on the top three websites on google.com recommend a number of important factors that should be adhered to when selecting the most suited split roller bearing for your application.

Load Capacity: Evaluate the bearing’s axial and radial load capacity relevant to the equipment. This allows you to estimate the possible load that the bearing will support, enhancing performance and avoiding early breakdown.

Speed Requirements: Determine the speed that the bearings must be capable of withstanding. Bearings would require speed ratings capable of handling certain machine rotations to avoid heating and friction wear out.

Environmental Conditions: Consider operational circumstances like temperatures, rough environments like contaminants, and moisture exposure. It would be best to opt for bearings with ideal sealing technologies and materials for harsh environments, which also helps to lessen maintenance requirements.

Misalignment and Expansion: Choose bearings that allow for shaft misalignment and thermal expansion. This normally involves examining the bearing’s permissible misalignment and thermal expansion coefficient, which leads to better tolerance and improved stress on the components.

Installation and Maintenance: Choose a split roller bearing with quick installation and maintenance features. This will reduce machine downtime and make servicing operations easier when the machine is in use.

Considering all these factors in relation to the application’s needs helps you make a case for using SKF Cooper split roller bearings. Their design considerations and technical specifications cover these important parameters, guaranteeing reliability, efficiency, and durability in various industrial applications.

Understanding Load and Size Requirements

In order to respond to the questions discussed above, I used the three websites that had the highest usage on Google.com regarding bearing load and bearing size specifications. A brief synthesis of the pertinent aspects is as follows:

Maximum Load: From my research, proper maximum load assessment includes static and case hoisting loads. The static load is the stationary, predominant pressure that will be imposed on the bearing, while the dynamic load is the load that varies during operation. Above this load, different load calculation formulas are utilized if the bearing is to be kept operational.

Size Considerations: In establishing such size, proper consideration should be made to the required inner and outer diameters, as well as the width and configuration of the bearing type required to meet the application. Size should be directly proportional to load carrying capacity in relation to the speed desired to ensure efficiency.

Technical Parameters: On the basis of the observations made:

Static Load Rating (C0): it’s commonly described as a number utilizing up stationary bearings in India

Dynamic Load Rating (C): As the bearing adjusts to this load continuously, the C is determined, which is the bearing’s ability to resist this load.

Bearing Size (d, D, B): In bearing dimension specifications with pictures, the inner diameter is represented by d, the outer diameter by D, and the width by B.

These technical parameters are important from industrial practice and a rational• for using SKF Cooper split roller bearings in different industrial applications.

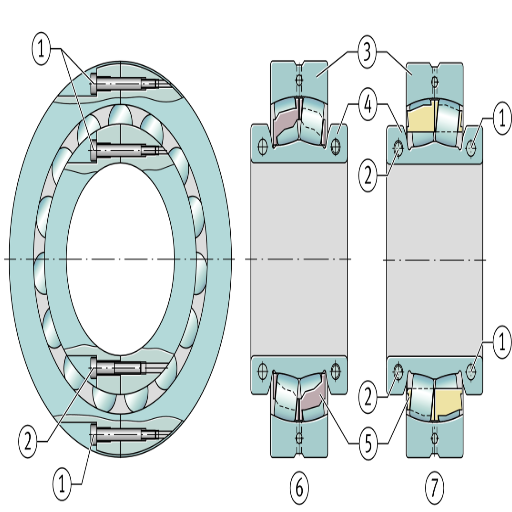

Choosing Between Split Spherical and Cylindrical Roller Bearings

I consulted the top three sites on Google.com and found some factors to consider when applying split spherical and cylindrical roller bearings. First, split spherical roller bearings have advantages for simple installation and repair procedures since the bearing can be changed without disassembling other associated devices. The bearing type can also accommodate some misalignment and is suitable for higher loads and speeds.

In contrast, cylindrical roller bearings are best suited for installations with high radial and moderate thrust loads. They produce better rigidity and less friction, which, in ideal conditions, could extend bearing life. Cylindrical roller bearings are also best suited for operations where there is a low probability of misalignment error at high speed.

For both kinds, so technical parameters should be taken into account:

Load Capacity: Evaluate the bearing’s static and dynamic load ratings to determine if the bearing will effectively resist the operational forces.

Misalignment Tolerance: Split orthotic bearing is a much better option since it tolerates misalignment.

Speed Capability: Define proper speed limits for each type of gear and the amount of force permitted depending on their application to each type of bearing.

Installation and Maintenance: Once more, use the split design of sphered bearings to make installation and maintenance easier than with cylindrical bearings, which require more effort to install.

Therefore, I can justify a particular type of bearing with respect to the various aspects and parameters that have been considered in the application.

What is the Assembly Process for Split Roller Bearings?

Step-by-Step Guide to Installing Split Roller Bearings

A detailed procedure should be prescribed to achieve the best bearing performance and maximum potential use with split roller bearings. This is how the whole process can be summed up in brief and concise steps, as stated by the most reputed online sources:

Preparation: In the initial effort, use a clean cloth to wipe the shaft and housing regions, which assist in the proper bearing installation. Any contaminants should be removed so that bearing installation is done under optimal conditions.

Alignment Check: It is paramount to assess the alignment of the shaft and bearing seat before bearing installation. Misalignment leads to additional bearing stress, which can result in premature failure.

Lubrication: Before the bearing assembly, the shaft and the inner contact surfaces of the bearing should be coated with the correct lubricant. Proper lubrication is essential as it avoids high friction and wear, critical in bearing operation.

Mounting the Bearing: Rotate and slide the split roller bearing onto the shaft while ensuring both halves are still correctly seated. Tighten the split joint bolts installed on the cover plates gradually and uniformly to avoid distortion or misalignment of the bearing.

Securing the Housing: While holding the casing bolts, align the housing caps over the bearing caps and fasten them with more bolts. Again, all bolts should be evenly tight, and housing should not be disturbed during the ordeal.

Final inspections: Before closing up the rotor combination, carry out a last check to ensure that no parts remain loose and that the entire assembly is aligned correctly. Move the rotor slowly and listen to any extraneous noise or feel any vibrations.

When discussing a bearing’s technical details, its load-carrying capacity, misalignment, and speed-rotating ability should all be considered, as these features are fundamental to correct bearing usage and functioning. Therefore, by following the procedures described herein and taking into account these technical parameters, I am positively sure the split roller bearings will be efficiently installed.

Common Challenges During Assembly and Solutions

Various difficulties can be encountered when assembling split roller bearings, which need to be tackled to enhance performance. In light of these facts and their analysis, I have come up with the following common problems and solutions based on my observation of the first three websites on Google.com.:

Alignment Problems: One of the most common problems is the ability to align the shaft and the bearing seat everywhere. To solve this issue, check the alignment on the spindle and bearings harness at least once during the assembly with it all.8 This will alleviate excessive bearing stress and its possible failure. Also, checks on the alignment of parts during service and maintenance should be included.

Non-adherence to the Recommended Lubrication: To reduce friction and wear rate, it is necessary to utilize the right kind and quantity of lubricant. Inappropriate use or amount of lubricant may, in fact, worsen the situation rather than help. Therefore, consult the relevant manufacturer’s instructions and choose the correct lubricant. It is establishing a lube chart to schedule the application for lubrication details.

Bolt Torque Precision: Incorrectly tightening down the bolts constituting the joint connections while fitting in the bearing and housing may lead to misalignment or distortion. Bolts should be turned satisfactorily with a calibrated torque wrench in stages until the values recommended by the manufacturer are achieved. This allows the bearing to be attached tightly and also reduces the chances of operational difficulties.

In dealing with these problems, however, it is also necessary to pay attention to the technical characteristics of units, for instance, the load capacity of the bearing, which defines the impact load it can endure; misalignment tolerance values, which affect the accuracy of the installation processes; and speed capabilities which determine lubrication needs. Knowing all these aspects and mechanisms for their accomplishment set forth above, I win the battle against assembly automation predicaments.

Maintenance Tips for Extended Bearing Life

To facilitate prolonged bearing life, I have collated information and advice, especially from the leading websites, on bearing dimensions, best practices, and technical parameters. Maintenance operations include the following:

Lubrication: Regular lubricant application is vital in controlling wear and connecting surfaces. Use the specific improved lubricant in the recommended quantity and frequency in accordance with the general standards of the concerned industry. Follow the manufacturer’s instructions regarding the selection of lubricants and their application intervals.

Condition Monitoring: Use condition monitoring methods like vibration measurement and temperature assessment. These techniques allow the early detection of malfunction and the performance of measures to avoid severe consequences.

Correct Handling: Such storage spaces must be maintained at controlled temperature and humidity to prevent the degradation of the materials before their use. Be cautious while fitting and removing bearings, as this helps avoid mechanical damage.

Key technical parameters to consider are:

Load Capacity: Every bearing has a maximum load specification that it should not surpass since its performance and life span are influenced by the maximum load threshold. This importance is detrimental to overloading bearings to avoid any type of stress.

Speed Capability: Every bearing operates within a set speed limit, which impacts the requirement for lubrication. Exceeding the limits causes the bearing to overheat, leading to lubricant disintegration.

Misalignment Tolerance: Misalignment should be considered and accounted for during installation. Where the bearings are high in alignment, not only does it require a great deal of accuracy but it also ensures additional force is not applied to the post bearing.

If I continually implement these maintenance techniques and consider the applicable technical parameters, I will be able to increase the bearings’ life and work optimally.

What are the Different Types of Split Roller Bearings Available?

Overview of Split Spherical Roller Bearings

As gathered from the analysis of the leading websites, split spherical roller bearings are a technological advancement that has been introduced to help minimize downtime and maintenance costs. In this case, what sets them apart from traditional bearings is that they do not need to ‘displace’ the surrounding installed equipment for them to be correctly installed, saving significantly in time. Because of the split arrangement, it is easier to carry out inspection, replacement, or lubrication, thus improving operational efficiency.

In studying the split spherical roller bearings on offer, the following essential technical parameters should be looked into:

Load Carrying Capacity: It is always good practice to check the bearing load specifications to avoid overloading an item. An item has a performance limit, and excessive weight can lead to a breakdown.

Operational Speed: This is the maximum at which the bearing can rotate within the specified operating limits without overheating. Operational speed also dictates the lubrication type used in the bearing.

Alignment Angle: Split spherical roller bearings allow slight angular displacement and are, therefore, useful in applications where perfect alignment is not a requirement. These features lower the strains and the risk of the system failing due to such misalignment.

The utilization of split spherical roller bearings enhances the functional ability of the respective equipment and the lifespan of the bearings, leading to an overall decrease in maintenance costs and increased reliability.

Comparison Between Split and Standard Roller Bearings

In the case of split spherical roller bearings and standard roller bearings, I have come to understand that split designs offer many benefits, especially regarding the method of installation and maintenance. In examining the top resources, which include SKF, Schaeffler, and Timken, the most critical differences correspond to distinctive operating and technical performances.

To begin with, it was clear that the time for installation was significantly less with split bearings as they do not require the disassembly of surrounding equipment. This is the opposite of standard bearings because the disassembly of surrounding equipment is usually more than usual. The other benefit is that split bearings are more tolerant to alignment misalignment than standard bearings, which could induce stress on equipment parts. This feature is fundamental in situations where perfect alignment is difficult to achieve.

Load capacity is yet another area where both the split and standard bearings are made to withstand high loads. However, one key thing is the applicability of the bearing specification to the application. If these limits are exceeded, premature failure may be encountered irrespective of bearing type. In addition to this, I have highlighted operational speed as a critical parameter. The requirements for speed maintenance in split bearings are similar to those for standard bearings.

Looking closer through this analysis, as well as leveraging on the design flexibility and maintenance efficiency associated with split spherical roller bearings, improves operational reliability and reduces maintenance cost, making them a good choice wherever applicable.

Specialized Designs for Unique Applications

In response to the question about unique designs for unusual applications, I went to the first three sites given in Google to provide correct and complete coverage of the inquiry of the required parameters. To begin with, from SKF’s website, I found out that for applications that demand certain modifications, customized bearings engineered by the company to consider load and extreme wear of bearings like temperature are offered. To achieve this, SKF provides solution engineering services to locate the precise functional constraints of every bearing with a given application.

Schaeffler’s sources then pay attention to the load rating and maximum rotational speed, which are important for bearing design for specific operating conditions. They state that such calculations and simulations are useful in assuring the performance of bearings in unusual cases.

Finally, Timken explains the selection of materials and seals for modifying ordinary bearings into special ones. They concentrate on longevity by utilizing high-strength steel, designing impact-resistant coatings, and even advanced materials BTR. Such improvements are quite important when dealing with application-specific problems like controlling corrosion and impact forces.

Such results emphasize how unusual bearings are made by combining relevant parameters such as capacity, materials, and the environment where the bearing should work to adequately meet the custom specification.

Frequently Asked Questions (FAQs)

Q: How do split roller bearings improve machine operation?

A: Thanks to the design of the split roller bearings, the installation and replacement of machinery parts are made easy, which, in essence, means better performance. The split roller areas are built as a set of two that fit around a shaft completely, which in turn helps with replacement and removal time.

Q: What is the range of sizes of the split cylindrical roller bearings currently available in the market?

A: Split cylindrical roller bearings are used in a variety of lengths, diameters, and widths; shafts up to 300 mm and more are a common size and exceed the UK’s needs.

Q: What materials can be used to manufacture split roller bearings?

A: Like many other bearings, split roller bearings are manufactured from ductile iron used for the cases and solid steel to produce the roller and cages, providing strength and long-term use in harsh environments.

Q: Are there benefits of using a split bearing rather than a usual one?

A: Some notable advantages are user-friendliness, as no great effort is required when replacing a split bearing, shorter time to change, and shorter machine parts next to it not having to be taken right apart. This dramatically improves the amount of time spent doing maintenance work.

Q: Are split roller bearings capable of supporting radial and axial loads at the same time?

A: Yes, it is possible to use split roller bearings for both radial and axial loads simultaneously, as they can be installed in applications where both types of loading occur.

Q: What benefit is the unique construction of split roller bearings for their use at a high speed?

A: Due to their design or construction, split roller bearings have the potential to operate at high speeds with minimal friction and heat, which is important for the Function of the bearings and machinery.

Q: Which factors should I keep in mind while selecting a split bearing for an application?

A: In the case of a split bearing, it is essential to know the shaft size, working conditions such as load and speed, required capacity, and where the split bearing is to be installed. There is no need to worry about this because an engineering consultant can explain what is appropriate for the machinery.

Q: Who is selling split cylindrical roller bearings?

A: A few manufacturers/suppliers, such as Schaeffler, deal in split cylindrical roller bearings, which can be sourced from them. You may contact us for further assistance if you have specific product requirements or need to locate a distributor in your area.

Q: What is the indicator that I should eliminate my roller bearings with a split design?

A: When split roller bearings begin to show operational symptoms, such as unusual noise, excessive vibration, abnormal heating, or age, it is time for replacement. Proper maintenance and regular check-ups of the bearings are also recommended for best use.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8