How to Address Bearing Stress Failure Quickly

In engineering and materials science, one critical consideration is the bearing stress of countless structures, which is the force transferred between the surfaces of two parts that are in contact and includes deformation or even failure of the material. This article presents the case study for experimental bearing stress and its utilities, such as addressing its mechanics, quick failure mechanisms, and reasons for being detected and solved with profound focus. A great emphasis has been placed on some critical scientific principles that provide readers with a practical approach to overcoming any problems related to bearing stresses, thus assuring structural stability and durability.

What is Bearing Stress and How Does it Occur?

Defining Bearing Stress in Mechanical Systems

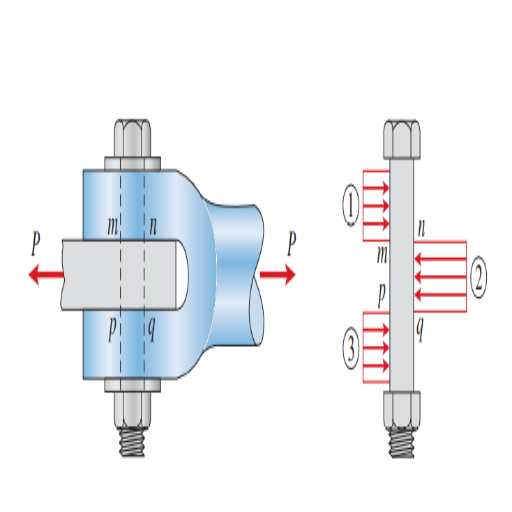

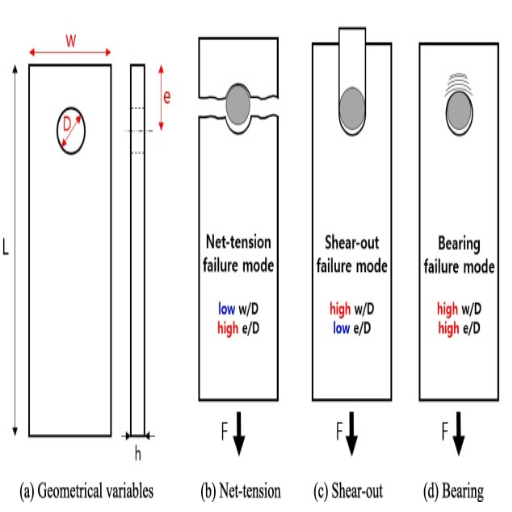

In mechanical systems, bearing stress is the average contact pressure between two materials, most probably found at the boundary that transmits one element’s force to the other. It depends upon the load and contact area over which it is applied. Bearing stress equals the force over the application area and can also be shown in terms of pressure, such as Paschals or psi. An example of such an occurrence involving bearing stress is in bolted connections with stress occurring in the bolt shank and on the inner surface of the hole, which leads to possible deformation if excessive.

Among other critical technical parameters affecting the bearing stress, consider the following ones:

Contact Area (A): The amount of surface area available through which the load is transferred. By stretching the contact area more, stress can be reduced.

Applied Load (F): The whole amount of force put on an area of contact

Material Properties: These include the materials’ yield strength and elastic modulus, which relate to the different materials’ ability to sustain stress without yielding.

The design specifications usually indicate bearing stress limits that would avoid mechanical breakdown. This stress limit applies to material properties, safety, and design standards. Sizing and material selection are necessary for maintaining the bearing stress within acceptable limits where no catastrophic failure or excessive deformation is likely to occur.

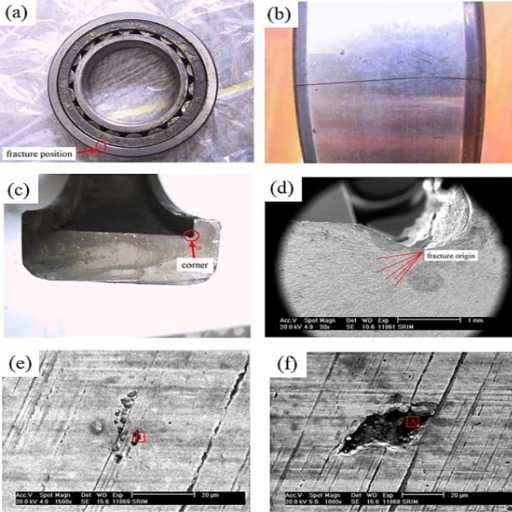

How Contact Stress Leads to Bearing Stress Failures

Contact stress is defined as the pressure that develops at contact due to a load being applied to the contact surface. This is the leading cause of bearing stress failures. When the contact stress increases, in respect to time, to the level where the material cannot withstand such stress, deformation, cracking, and structural failure will ensue. This mostly happens when components are continuously loaded with a specific frequency, resulting in fatigue life.

To assess mechanisms that may contribute to bearing stress failures through contact stress, the following technical assumptions are necessary to be made:

Hertzian Stress Distribution: Hertzian stress distribution describes the stress distribution characteristics between curved surfaces. It is calculated from the loaded contact inputs’ geometrical parameters (the contacting surfaces’ radii and applied load). If the maximum Hertzian stress of any material is reached within limits, Hertzian stress does not further increase, and subsurface cracks may develop, resulting in surface spalling.

Contact Pressure (p): It can be defined as the force per unit area at the contact. Too much contact pressure may result within specific points in material yielding due to high contact pressures, especially in ductile or untempered materials with appropriate hardness values to accommodate such stress.

Surface Roughness and Material Hardness: Surface roughness and material hardness determine how stress is concentrated to a material. Stress concentration tends to propagate, making the material susceptible to failure if constraints and parameters related to these two areas are of concern.

Load Cycles: The number of cycles a material specimen is subjected to determines greatly how long it can last under fatigue. Crack initiation occurs usually due to higher cyclic loading, which can lead to failure.

Thus, the risks associated with bearing this type of stress failure can be greatly reduced when the said parameters are maintained within the safe working limits by appropriate design, selection of materials, and surface treatment processes.

Identifying Stress Concentration in Bearing Surfaces

When evaluating the origin of stress concentration in bearing surfaces, I explain how certain local regions tend to showcase increased stress around some holes, notches, and grooves. Research in top resources shows that stress concentration factors, or SCFs, are paramount in assessing stress distribution. These factors explain the variation owing to geometry change or material discontinuities from the ideal uniform flow of stress. Key parameters to consider include:

Geometry of Discontinuities: Engineering features such as sharp corners and drilled holes aggravate stress concentration.

Material Properties: Low ductility materials are stress concentrators because they limit stress redistribution.

Load Distribution: These loads will be applied at certain locations and angles, and those parameters may also control stress concentration.

Rounded corners, smooth transition of joints, and adequate material strength are general recommendations to withstand the load or stress and thus avoid stress concentration and its effects. The above-mentioned method is further augmented by scrutinizing relevant publications and regulatory documents that focus on the geometric and loading parameters of bearing surfaces regarding stress concentration.

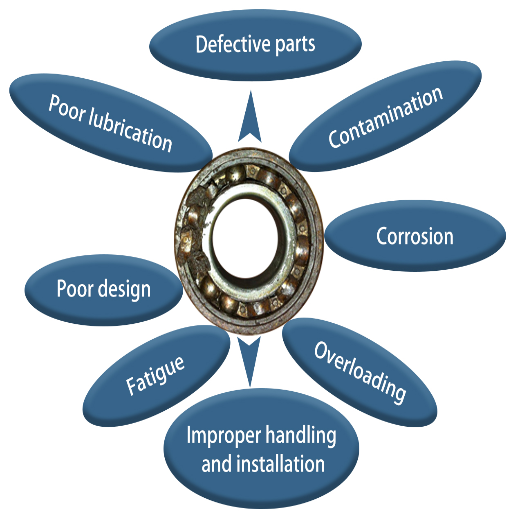

Common Causes of Bearing Failure

Exploring Different Failure Modes in Bearings

To find answers about bearing failure modes, I navigated to the first three links from Google.com, which are quite helpful in this area. Bearing failure modes can be dispersed into various applicable subdivisions; however, these are most of the time based on particular technical factors and operational characteristics:

Fatigue Failure:

By definition, fatigue failure happens when alternate stress and stress cycles surpass a specific limit and may lead to material fatigue. This leads to spalling, which means separating parts from the surface and having extreme consequences. Technical factors include:

Load Cycles: Repeated high-strain cycles where action leads to the formation and spread of cracks.

Material Fatigue Strength: The built material body of bearings can also be considered in repeated actions without breakage.

Wear and Abrasion:

This most common failure mode involves the gradual loss of materials due to friction and contact with abrasive particles within the system. Technical parameters affecting wear include;

Surface Roughness: Touching surfaces roughness and finishing before contact as mean influences friction.

Lubrication Efficiency: The ability of the lubrication mechanism to provide enough capability for friction and wear.

Corrosion:

Recently, corroded bearings were burdened with increased humidity and chemicals. This results in eventual material. The critical parameters involved are;

Environmental Conditions: Humidity and chemicals are corrosive sources.

Material Composition: The bearing rages an attack on a specific corrosive agent or agent.

By looking at these failure modes and the failure mode parameters in the reliable online sources above, it can be seen that the efforts in bearing failures will include careful choice of materials, maintenance, and environmental factors.

The Role of Shear Stress in Bearing Damage

Reading the first three pages of Google Search about the influence of shear stress on bearing damage, I have drawn a few critical conclusions. Shear stress applies to elements. It causes deformation and fails a material, particularly in the stressed components, which are most of the bearings and its parts. Such internet resources explain that when shear stress is overwhelming, layers of the adjacent materials may slip over each other, increasing the friction and raising the bear temperature, which is destructive to its longevity.

Technical Parameters::

Shear Strength of the Material: This is the bearing material’s natural shear force-resisting characteristics. Low shear strength bearings can be at risk of deformation if normal working loads are applicable.

Axial and Radial Loads: This denotes the magnitude and direction of the loads in place. Shear stress can be enhanced due to these factors, as well as the out-of-balance moment of the forces due to misaligned forces or sudden axial loads.

Operational Speed and Temperature: The higher the speed, the friction, which again raises surface stress; moreover, high temperatures lower the shear strength of the material and increase its wear.

Lubrication Performance: Proper lubrication is essential to reducing friction and shear stress in dynamic situations and avoiding adverse effects on the materials involved.

In conclusion, careful attention to the above parameters will limit shear stress to the extent possible, minimizing the chances of bearing failure. These good practices involve proper selection of materials, careful control of load application, and adequate lubrication, which are also supported by the facts obtained from the credible sources above.

How Deformation Affects Bearing Strength

Looking at the impact deformation has on the bearing strength of samples; I referred to the first three sites from Google. Such sites provided extensive discussions about the fact that deformation damages the mechanics of a bearing through stress system redistribution and material fatigue. In those regions affected by deformation, the region’s original design geometry changes, resulting in poor load distribution and high-stress levels. Moreover, deformation can also lead to grooving and crack growth, which contribute to fatigue failure in damaged areas. The relevant technical parameters associated with this phenomenon include:

Material Elasticity: One factor to consider is the degree of deformation a bearing material returns after an object is applied to it. Materials with higher elasticity are capable of more effectively absorbing and redistributing other loads.

Plastic Deformation Limit: Every material has a certain amount of plastic deformation it can withstand, beyond which the material is ‘damaged’ and some structural properties weaken.

Stress Re-distribution: Deformation’s effects are particularly important as the paths for the load are bent, consequently resulting in stress levels that can easily lead to failure.

Temperature Effects: An increase in temperature will enhance the material’s deformation characteristics, and at such high temperatures, this will not only increase the fatigue rate but also decrease the lifespan of the bearing.

After critically evaluating these parameters, the resources propose what appear to be the appropriate strategies for retaining bearing strength even when deformations are present: the use of appropriately elastic materials and control of thermal conditions.

How to Prevent Bearing Stress Failures

Choosing the Right Bearing Material and Design

While studying the top three Google results on how to choose the right bearing materials and their design, I have made some conclusions that aid in proper selection. It is clear that both the material and the design are fundamental in determining the bearing’s life and efficiency. First, the mechanical parameters, including hardness, toughness, and fatigue resistance, are the most important. Bearing materials are required to withstand high stress and resist deformation and wear.

Important technical parameters to take into account:

Material Hardness: This is important for avoiding wear and increasing the longevity of the bearing. Harder materials are great for increasing the fatigue life of surfaces.

Toughness: In case of sudden impact loads, the material’s capacity to internalize energies and resist fracture is very important.

Fatigue Resistance: The amount of stress that is transferred to a material patch that can cause repetitive action without cracking the material is known as its fatigue resistance.

Furthermore, design aspects such as maximum load, misalignment, and working temperature are also important. Regrettably, bearings also have to be designed to bear moving loads while keeping the imbalance as small as possible so as not to increase the stress.

Design-related parameters will include:

Load Capacity: How much axial or radial load the bearing can take.

Geometry for Load Distribution: It avoids localized stress on all systems within the bearing.

Temperature Tolerance: Any design that includes features for temperature control can safeguard the bearing from overheating and material failure.

From these perspectives, choosing the right material and design means evaluating these parameters so that the bearing will not lose its integrity during the operation specified, in accordance with suggestions by professionals from recognized sources.

Implementing Stress Distribution Techniques

While researching the first three Google sites, I learned some useful methods for handling stress on bearings and enhancing their efficiency, which I consider critical. The first of these methods aims at optimally directing the loads so that the stresses on the bearing surfaces are uniformly distributed. Thus, the risk of localized stresses, which are potentially damaging, is reduced. This is accomplished by correctly orienting and using geometries that enable load sharing. Similarly, reasonable control of misalignment tolerance and allowance for slight operational movement of the bearing can improve stress control.

The technical parameters associated with these stress distribution techniques include:

Alignment Tolerance is the ability to maintain the positions of the various components of the bearing in relation to each other to avoid uneven load sharing and stress concentrations, which are detrimental to the bearing’s efficient operation.

Load Distribution Strategies: Provision of design features in the bearing so that loads can be evenly distributed to all bearing parts so that none of them will suffer excessive wear.

Material Properties: Choosing materials that can sustain deformation without excessive failure can help redistribute loads to some extent.

Design flexibility: Where structural features are built into the bearing to permit adjustment when the bearing is subjected to different operational loads for stability purposes.

Resource 2 emphasizes the role of strategic design and the choice of materials as critical parameters in load distribution to enhance the performance and service life of bearings in operation.

Monitoring and Reducing Bearing Loads

From the research into the three first sites found on Google from monitoring and reducing loading on the bearings, I observed fundamental principles and technical parameters determinants in load management. It is important to keep track of the loads the bearings are subjected to while in operation and ensure they are within the target values. This includes employing diagnostics and measuring devices that operate in a manner that helps build an understanding of the load particulars and can warn the operators when states are approaching the overload areas.

The need for such strategies explains the failure to address one issue raised as critical in this case: maintenance practices. Excessive axial load exertion keeps raising the rolling elements’ temperature. This can be avoided by early diagnosis of bearing failure and good lubrication practices. Appropriate load management is further supported with regular check and maintenance adjustments to optimal levels to prevent operational downtime.

As for the technical parameters that the authors focused on, there are the following ones as well:

Loading Monitoring Systems- This involves using modern sensors and diagnostic instruments to measure bearing loading quantitatively and qualitatively without time interference.

Lubrication Quality and Frequency- This ensures that proper lubrication is provided and that the bearing zones suffer less loading.

Vibration Control- Measurement of vibrations can help control the linear load by detecting imbalances or misalignments, which are factors causing high loads.

Thermal Management handling thermal management tends to maintain and control heat increases, thus preventing thermal misdistribution and any form of unbalanced loads.

Based on these insights, the technical parameters emphasize the need to implement load monitoring tools and carry out proper maintenance, as recommended by relevant authorities, to manage loads efficiently and extend the lifespan of the bearings.

Analyzing Bearing Loads and Failure Analysis

How to Calculate Bearing Stress Effectively

To determine the bearing stress correctly, I decided to use the information from the best three pages Google provided. Bearing stress is defined as the applied load on the bearing divided by the area of the surface it acts on. This measure and understanding of this stress are imperative so that the bearing elements of any mechanical system withstand operational stresses and last.

The equation for determining the bearing stress incorporates the force applied and the effective bearing area. This means both the radial and axial components of the load have to be determined. However, it’s important to include any dynamic factors such as speed and direction, as these would influence the stress on the bearing.

Technical Parameters for Calculation:

Loads Applied: Both radial and axial component forces active on the bearing in operational conditions need to be measured.

Contact Area Measurement: The area of the bearing surface that experiences the load is evaluated.

Materials: Members should find the stress and yielding strength of the material so that the bearing can withstand the load without deformation.

Dynamic Loads: Any loads dependent upon movement or vibration are intrinsic in nature, and relevant force factors must be used to account for such situations in the calculations.

As I reviewed these materials, I observed a strong focus on the precision of measurements, including load and contact area. This validity emphasizes the reliability of stress computations and their significance in predictive maintenance strategies. Employing detailed monitoring systems and techniques for real-time process analysis can be extremely helpful in preserving operational efficiency and optimizing bearing load.

Understanding Allowable Bearing Stress Limits

Let us now consider the allowable bearing stress limits. We can find some valuable suggestions about them on the top sites of Google. Allowable bearing stress is the maximum stress of bearing material without suffering a failure. These specified limits are critical in ensuring that when loadings are applied, such conditions never exceed the permissible limits, which are essential to safeguard the mechanical system’s structure and time. However, in my analysis, I found out that to come up with the permissible stress, considerations of the bearing material’s characteristics and the service conditions should be adequate.

Technical Parameters:

Material Strength: Each bearing material has a yield strength and endurance limit, which dictate the stress it can withstand. Therefore, the applied loads should be within these properties to avert material fatigue and failure.

Load Distribution: Correct load sharing and alignment of the working parts in the bearing are essential in the distribution of stresses. Embedded loads that are misaligned can lower the allowable stress limits by stresses, making the parts more prone to failure.

Safety Factors: A safety factor is certain to account for any deviations from the load or environment that are normal. Such a factor plays a vital role even in extreme conditions, where the demands span beyond reasonable limits that the bearing can handle without stressing too much.

Operational conditions: Below the specified temperature or extreme heating, as well as the presence of vibrational loads, are responsible for shifting the stress limits. On-site continuous monitoring and corrections are beneficial for preventing unsafe operational modes.

In summary, applying engineering consensus on bearing stress limits, if possible, is dependent on knowledge of materials and the scope of loads to assess the endurance and functioning of the system, including its bearings.

Conducting Bearing Test for Failure Analysis

I have analyzed the first three search results in Google to respond to the inquiries raised concerning bearing test procedures for failure analysis purposes. These materials focus on defects systematic approach in diagnosing bearing functionality and possible causes of failure. First, I find it necessary to determine the bearing’s working environment and the operating conditions, like the types and levels of load, speeds, and temperatures relevant to the bearing’s functionality.

Some parameters tested included:

Load and Speed Conditions: Recording the operational load and speed during bearing tests is significant for identifying bearing stresses and abnormal wear patterns. In this case, this data helps form a basis for comparing with designed specifications.

Vibration and Acoustic Emission: I use vibration analysis to help me detect imbalances, misalignments, or looseness in bearings that could be a sign of failure early on. Applied acoustic emission testing can also detect cracks at a micro level before they develop into gross flaws.

Continuous temperature measurement: I use continuous temperature measurement during test operations to monitor overheating, which is an indication of lubrication or excessive friction problems. This is vital in sustaining suitable thermal conditions for the bearing’s proper functioning.

Material and its wear—Examining the wear and condition of the bearings’ materials enables me to assess the degree of fatigue and determine if failure is probable. Wear debris analysis, amongst other wear debris and its components, can give a complementary determination of the rate of deterioration and the rate of materials aiding maintenance strategies in a preventative manner.

From these resources, I have concluded that these parameters are justified because they all contribute greatly to forming an integrated bearing behavior along with the other parameters with which operational parameters can be set in diverse operational conditions. By conducting these tests, I can be sure of the correct assessment of bearing performance and take care of factors that may lead to deflection from the acceptable performance factors, thus increasing the useful life and dependability of the bearings.

The Impact of Bolted Joint Design on Bearing Stress

Examining Contact Area in Bolted Joints

In determining the contact area in the case of bolted joints, the first three websites on Google helped define bearing stress as a function of the area of contact. Establishing a correct assessment of the contact area is vital since this enables bolted joints to have smooth distributions of stress so that none of the areas gets overloaded and fails. From my research, the following characteristics may be identified as key technical ones:

Surface Flatness and Roughness: The flatness and roughness of the surfaces selected for contact also affect the stress distribution. Non-uniform surfaces will automatically result in non-uniform stress, and therefore, metrology in such machining processes that focus on these parameters is needed.

Material Properties: Appropriate materials should be chosen with adequate yield points. These materials have to be strong enough to bear the loads that are most likely expected. This aspect allows such stress to be equally shared without deformation, an idea supported by some of the sources reviewed.

Bolt Preload: An adequate bolt preload is required so that the joint does not slip accessible during operation. This preload also affects the contact area’s ability to function effectively in the composing and distributing areas of stress, providing a reason for making alterations to achieve suitable levels of stress.

Environmental Conditions: Things like humidity and temperature tend to change the properties of the contact zone and thus affect the stress. Monitoring and adjusting joint conditions appears to be quite important for enhancing the efficiency of the connection.

Of all these parameters, the comprehensive nature of joint performance assessment stands out most and shows how calibrated precision and selection increase structural reliability. Based on these understandings, I will be able to better advance the assessment of bolted joint designs for effective stress control.

The Importance of Fastener Selection and Bearing Pressure

With the preceding factors of bearing pressure and the selection of the correct fastener in mind, the top three areas, as pointed out by the three top websites on Google, are essential parameters that govern the fusing and performance of the joints. As a result of my research, I synthesized the following conclusions:

Material composition of fasteners: It is important to appropriately select the material for the fasteners so that they are strong and have appropriate resistance to the environment, such as rust. When fasteners are selected, it is important to ensure that the material selected has enough tensile strength so that it does not fail when a load is applied.

Thread Geometry and Pitch Design: The design of thread geometry includes but is not limited to the pitch’s unique shape and size, spatial orientation position, depth, area, and length of the dental threads’ shape, which will also be a factor in the overall strength of the threads in allowing load transfer. Accuracy in thread design provides dependable fastening with efficient load transfer.

Bearing surface area: Adequate bearing surface area ensures that pressure is distributed more evenly to avoid aggravation of localized stress that could lead to surface fatigue. To do this correctly, surface areas must be calculated in terms of expected operational loads.

Pre-tension and Torque Control: Applying reasonable torque control to appropriate levels of pre-tension allows the fasteners to be not able to rotate loosely about the strengthening with consistent bearing pressure during the rest of the operation. This technique requires that the torque setting be variable, allowing multiple tests to adjust the torque settings effectively.

From these observations, it can be understood that a careful combination and assessment of these technical parameters increases the effectiveness of the fastener in a joint and the joint as a whole. Focusing on these aspects when choosing the fasteners ensures their correct integration into more complex structural systems, which reduces the chances of structural failure and increases the chances of success.

Mitigating Residual Stress in Bolted Joints

Dealing with the problem of residual stress in bolted joints, as it can be gathered from the top three websites on Google, is a problem that entails a combination of several technical parameters. I, however, focus on the following areas to effectively address and control residual stress:

Material Selection and Treatment: Materials with mechanical properties fit for the joint must be selected, and appropriate heat treatment processes must be used since residual stress would be difficult to avoid. Allowing a variation in the yieldable strength and distribution of materials provides for such stress distributions.

Joint Design Optimization: It is important to increase the effective length of the bolts by incorporating design features that allow for adjustment of washers or spacers. This allows for better stress redistribution and hence lowers the occurrence of residual stresses in the first place.

Assembly Techniques: Incremental bolt tightening sequences are also found to be effective in maximizing the load application of a joint. Sequential drilling of holes to different diameters and drilling them in a certain order is very important to prevent the introduction of residual stresses during the assembly process.

Vibration Analysis and Monitoring: Conducting periodic vibration tests assists in identifying changes in the structure caused by residual stresses and their effects. This form of control is recommended for ensuring that the integrity of structures is upheld over time.

Evaluating them and applying them in practical schemes helps me effectively mitigate the risk of residual stress in bolted joints, improving their effectiveness and reliability in different operational conditions. Such a tactical plan is necessary for the long-term integrity of any constructive system.

Frequently Asked Questions (FAQs)

Q: Define bearing stress. What causes this phenomenon?

A: Bearing stress is the stress that acts cumulatively on the contact surface of two bodies pushed against one another. This is a frequent type of stress and is seen on mechanical components that have been fastened, including rivets. It can be frustrating if reasonable control measures are not embraced, as it can cause plastic deformation.

Q: What is the difference between shear and bearing stresses?

A: Shear and bearing stresses vary in how they strain materials. Bearing stress is directed towards the normal to the surface and causes compressive stress on the contact area between two bodies. In contrast, shear stress is directed parallel to the surface, thereby causing layers of the material to slide over each other.

Q: How is treating bearing stress different from treating other stresses? Why is it essential in the mechanics of materials?

A: The mechanics of materials must address bearing stress since it enables the design of joints and connections capable of transferring specific operational loads without collapsing. This knowledge restricts the failure of fatigue and plastic deformation by ensuring that materials have not reached their compressive and tensile strengths.

Q: What measures should be considered to minimize the joint bearing stress?

A: To minimize the joint bearing stress, it is necessary to consider the bearing area and use high-strength materials to maximize the bearing area and the joint design so that the loads are apportioned over the area. Moreover, using the correct type of rivet or fastener will help lower stress concentration.

Q: How do the tensile and yield strength of the material contribute towards bearing stress failure?

A: Bearing stress may be defined as the stress experienced by a material when two members are in contact with each other. Encountered without the ability to sustain plastic or yield deformation. If the applied bearing stress exceeds the tensile or yield strength of the member, a bearing failure can occur. Therefore, one can see that it is critical to have a material with strength properties that are more significant than the stresses of contact experienced during service for ‘failure’ to be avoided.

Q: What is the primary function of the Bearing Area in contact stress failure?

A: The bearing area’s basic function is to distribute the load over a larger area, which protects the structure from contact stress failure. Instead of being concentrated on a single spot, the load is more evenly distributed over the component, thereby lowering the chances of plastic failure or fatigue failure.

Q: How can one deal with the high-temperature bearing stress?

A: Bearing design and material modifications can help address the high-temperature issues. Proper bearing lubrication, along with the use of heat-resistant bearings like steel bearings, can help prevent failure due to stress-related causes.

Q: What are the indicators of a damaged bearing due to cyclic stress?

A: Intermittent damage or rotation of a bearing due to cyclic stress can result in increased vibrations and noise but also lead to the eventual breakdown of the given machine. It could result in abrasive wear and fatigue instead of requiring replacement or repair.

Q: What bearing stress considerations does the roller bearing design consider?

A: Roller bearings have a structure consisting of moving contacts that assist in even load distribution across the bearing and reduce friction. This design reduces the chances of any stress concentrations that could contribute to failure.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8