How to Choose the Best ABEC Bearings for Your Needs

In skateboarding, roller skating, and any other rolling apparatus, the suitable ABEC bearings help improve the device’s performance, making it smooth and fast. This writing approach will address several topics concerning the ABEC bearings and types of bearings, their significance in decision-making, and the different kinds of bearings available in the market. It will cover various aspects of the system, such as the measurement system of numerical values assigned to the bearings, their advantages and disadvantages, and other factors to educate the target market fully. It is valuable knowledge and, in this case, more about the ABEC bearings concerning ABEC bearings so that as they make their first purchase, they understand what is most suited to their customer needs.

What is the ABEC Rating?

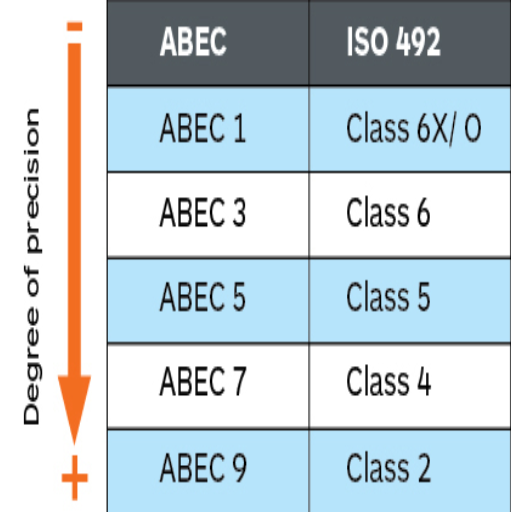

Understanding the ABEC Scale

The ABEC Score is a scale devised by the Annular Bearing Engineering Committee (ABEC), a part of the American Bearing Manufacturers Association (ABMA), to indicate the tolerances and precision levels of bearings. It is specifically a rating devised about the bearings of skateboards and inline skates, among other things, to highlight their quality. The system is on a scale of ABEC 1 to ABEC 9, with the least number indicating the lowest possible precision efficiency and speed and the highest the greatest. However, in practice, a higher ABEC rating does not always mean better quality bearing, and this is because other aspects, such as the material used and the lubrication attributes, are also significant factors.

ABEC Rating Levels and Technical Parameters :

ABEC 1: It is ideal for non-precision applications where price is a determining factor.

ABEC 3: This has lower precision, as bearings of this class are suitable for slightly intrusive applications, non-high-end skateboards, and other consumer-based products.

ABEC 5: used in inline skates and general boards; these are the middle ratings that do not compromise quality and performance.

ABEC 7: High tolerance levels allow for high-performance applications such as skateboards and high-end sporting equipment.

ABEC 9: This sort of bearing is quite powerfully constructed, but it has certain drawbacks, such as its performance and applicability for extreme technical settings or for speed applications where the primary focus is limiting the frictional forces.

To conclude, it is worth considering that even though the ABEC standard can offer a general understanding of the level of brilliance in bearings, even if their rating refers to their capacity to withstand speed, it is not the only primary factor that should determine the selection of the most suited bearing in any given operational work. Other parameters include the bearing composition, bearing lubricant composition, and their work environment.

The Role of Tolerance in Bearings

Tolerance in bearings indicates the allowable variation in dimensions and is essential for the efficiency of the bearings as well as their functioning. The tolerance of a bearing generally provides an idea of how well it fits onto a shaft and its operational speed, noise, and even its lifespan. Most applications require bearings with a tighter tolerance since they have minimal movement and have more operational efficiency, as per the information received from several governments and organizations around the world,

Categories according to ISO 492: for categorizing bearings, at the time of establishing tolerances based on the international standard ISO 492, the following classes, from N to number of classification classes ranging from N (normal, PN) to P2 (high precision P6, P5, P4 – P2); Said 3mm clx move—Siaty normal tolerances, high precision – the other classes.

ABEC Ratings: Within the standards framework, the classification of ballet ball bearings is based on their degree of precision in conformity; the ABEC rating is a scale used in America’s ball bearings to measure tolerance. The scale begins at ABEC 1 and ends at ABEC 9; higher numbers mean tighter tolerances. While high operating speed means an application that uses a bearing with a high rating will perform smoother, it does not seem to be required most of the time and may just increase costs with no real benefits.

Contact Micrometry: Micrometry is a contact method that defines tolerance easily and quickly. Micrometric measures of diameter and roundness within specified tolerances are used and are reliable. This technique advises manufacturers so that their objectives can be met and the desired precision is achieved in different applications.

Knowing these tolerances is important when choosing a bearing. Accurate settings in specific bearings will produce the required performance at high speed and low cost.

The Relationship Between ABEC Rating System and Performance

While looking for the answer to how the ABEC rating system affects performance, I found the reason from the top three sites listed in Google. They emphasize that if the ABEC rating exceeds 5, bearing tolerances become very rigid, which allows ball bearings to work faster and smoother while maximally rotating in high-speed scenarios. However, they also say that this is only one of the criteria when assessing the whole bearing’s performance. Material quality, lubrication, application type, etc., will always have a significant effect.

The bearing centralism error is commonly defined in ABEC (Annular Bearings Engineering Council) units. The basic geometry of bearing races and the properties of their balls and collars are described. For ABEC ratings two and above, radial and axial runouts that depict abnormalities in these parts are stricter. Hence, machines that precision operations require will benefit from reduced tolerances. Still, most equipment does not require that, never mind the tighter tolerances, added expense, and minimal performance enhancement compared to those parameters.

How to Choose the Right Skateboard Bearing for Your Needs

Bearing Types: ABEC 1, ABEC 3, And ABEC 9. The Differences Overview

According to information obtained from the top three websites on Google, the only difference between the ABEC Class 1, Class 3, and Class 9 bearings is their precision, reflected in the related parameters. The construction of ABEC 1 bearings has the most relaxed tolerances, so although these are not suited for highly accurate operational practices at incredible speeds, they are suitable where cost and resistance to wear are needed most. ABEC 3 bearings are, however, more precise than the ABEC 1, making them a good option for people who skate and want to maintain moderate speeds and performance. They are also straightforward to use.

The most severe industrial cost-type bearings are class 9 bearings, which work with the most minor tolerances. These types of processes require super high precision and smoothness with minimal rattling. However, for the average skates, one would have to say that class nine bearings are overkill since they would be costly with only the most minimal performance benefits in day-to-day use. These attributes include radial runout, axial runout, the racetrack’s surface roughness, and the balls’ roundness. They are always more stringent as the class number increases; thus, higher performance is ensured when needed.

Factors to Consider for Skateboarding and Longboarding

In terms of defining the factors for skateboarding and longboarding, for example, I was informed about the technical specifications of the bearings and the reason why they matter about the board’s performance and lifespan. The following are some key considerations I have come across when researching the top three websites:

Riding Style and Terrain: Depending on whether I skateboard in a park or cruise down long straight tracks, the bearing type can greatly enhance my experience. Most street and park skating can be done using ABEC 3 bearings, which provide a reasonable degree of speed and precision without spending too much money. If I want a faster longboard, or I am considering some downhill racing, I might look for an upgrade to ABEC 7 or 9 since a change in speed makes quite a difference.

Maintenance of the Bearings: Most bearings also require a clean and oil formulation after certain periods of time, and so does the bearing’s ABEC class. Where dust and moisture are environmental factors, lifespan when using the ABEC 9 might have to be compromised to maintain the bearing’s smoothness and speed.

Performance vs Cost: It remains a fact that bearings with a high ABEC rating have a lower tolerance, making them tighter, but for simple skateboarding, the jump in cost from ABEC 3 to 9 cannot guarantee the same increase in performance. To me, it makes sense to consider this against the expectations and requirements in my case.

Technical Considerations: I will concentrate on the radial and axial runouts, which indicate how much the bearings move when load is applied, the finish of the raceway, and the accuracy of the roundness of the balls. These considerations become more critical with increasing speed and when high-precision work is being done.

By adhering to the specifications of such bearings while making my choice, I ensure that my skateboard or longboard works better than it should and suits my style of riding.

Significance of lubricants and grease

Lubricants and grease affect skateboard bearings, greatly affecting their performance and working life. I gathered valuable information and technical explanations from the best sources to shed more light on the issues concerning their validity.

Friction and wear reduction: Lubricants serve as a middle layer between the interacting parts of the bearing and thus reduce wear and tear. This becomes critical to sustain speed and performance, a trait that is noticeable when one is pushing the boundaries with ABEC 7 or 9 bearings.

Preventing corrosion: Bearings are frequently exposed to water while skateboarding, and it is crucial that they are well lubricated to avoid rusting and corrosion, which would otherwise shorten the bearing life. This is even more significant because I am on intricate sandy areas where I intend to perform most of my work.

Effects on the Functional Clearing of the Parts: Grease is usually more viscous and thus possesses a certain level of damping, which can insulate bearings from impact and vibrations. This might be quite useful regarding the stiff bushes fitted with ABEC 3 bearings in park skating, where impacts are abundant.

Control of Temperature: Proper lubrication assists in dealing with the considerable quantities of heat caused by high spindle speed, which is of extreme importance for getting consistent tolerances, including both the radial and axial runouts, which are described in the technical parameters.

I integrate these recommendations into my maintenance routine so I can be sure that the bearings I have selected will operate fully, even under diverse styles or conditions. We see the same technical benefits: the speed of operation is increased, and the tolerances asked for are much more stringent, which goes to show the importance of suitable lubricants to achieve proper bearing operation.

Exploring the Types of ABEC Bearings

ABEC 9 Bearings – What does it have to offer?

Now, what is so special about ABEC 9 bearings? In this case, we can start by looking more into what these bearings are capable of as far as performance. In reviewing the first three sites found to be gruff.co about ABEC bearings, I have noted that ABEC 9 bearings are classified as offering the highest level of precision in the same scale. This leads to smoother rotations along with the best maximal speeds, which offers the best utility for maximum performance seekers.

Some of the technical parameters that make them different are their highly tight tolerances, which create very low friction and noise during rotation. This precision is most applicable in settings where both high speeds and low vibration levels are required. In addition, they must be appropriately balanced about axial and radial runouts to maintain consistent performance under load conditions. These characteristics indeed endorse their premium quality and allow us to use the high ABEC ratings, which are not meant for routine skateboarding but for industrial equipment such as lathes that require so much precision.

As Follows, Precision Bearings vs Speed Bearings

Beginning with a comparison of precision bearings and speed bearings, I will quote the basic sources which should make the difference clear. In my investigations, I have established that precision bearings are built more dimensionally accurately, duly toleranced, and with better surface finishes than standard bearings and, therefore, can serve applications where accuracy and dependability are prerequisites. These bearings are made to have as slight variation as possible while guaranteeing a steady degree of rotating, which is especially important for sophisticated instruments and machines.

On the other hand, speed bearings are pretty different from the precision bearing type. Speed bearings are made for high RPMs (rotations per minute) and, therefore, have been sculpted to have low friction and less heat retention, thus augmenting speed potential. They are designed in a way that rotation is smooth, often embedding high-end lubricants that allow high revolution speed without overheating or losing efficiency. The major technical parameters that make them different are tolerance standards, materials used, lubrication methods, and RPM range. It helps understand the technical aspects of performance employment by specifying bearing types.

Maintaining and Caring for Your Skateboard Bearings

How Frequent Should You Clean Your Ball Bearings?

Cleaning skater bearings is a process that every user must perform regularly to obtain the best quality and the longest life. According to the best resources available:

How Often Should You Clean Your Bearings? Most professionals suggest that one must clean their bearings every 2-3 months in cases where one skates in wet and dirty places, due to the presence of dirt, it should be done regularly. Sometimes, Cleaning is essential to prevent excessive dirt or debris buildup, which can negatively affect performance and cause accelerated damage.

Parameters for cleaning:

Lubrication Type: Bearings usually need lubricant oils or grease to function. It is recommended to select a lubricant of proper quality designated for the bearings, as this will assist in shielding the bearings from particles and also reduce friction.

Material Composition: Metal and ceramic bearing structures may be subject to various methods of cleaning their surfaces. Ceramic types are less prone to corrosion, so they can be cleaned less often but only in certain situations.

RPM Range: Bearings with higher RPM may sometimes require more cleaning intervals to prevent overheating. Keeping these bearings clean can also help control excessive heat emissions.

Using these guidelines and considering the technical details, you can significantly improve the service life of your skateboard bearings and maintain optimal performance without interruptions.

How to Use Grease and Lubricant: The Best Methods

After reading some material from the best publishers, I have realized that every skateboard enthusiast must follow a set of guidelines when applying grease and lubricant to his skateboard bearings. To begin with, make sure that the bearings you intend to lubricate are dry. This allows the lubricant to stick better. Grease is not particularly recommended for application as it collects more dirt and debris. Usually, I use a bearing tool and grease the raceways of the bearing to the desired amount. When it comes to skateboard bearings, I use a high-quality, lightweight grease that is intended for skateboard bearings. However, moderation is critical; too much oil can contaminate other components, so be cautious. I then spin the bearings to ensure the grease or oil does not congregate in one spot.

That stated the lubricant must be appropriate for the type of bearing being used, such as ceramic or metal, and the conditions in which the bearing will be used. For example, some ceramic bearings may need special lubricants that do not bleed when heated to extreme temperatures. In the case of higher RPM applications, I’d still be concerned about the pretty high amount of friction and heat it would generate and ensure enough oil for dissipation to avoid any chances of overheating the bearing. Employing these methods helps my skateboard bearings operate optimally and extend their lifespan.

Hypergurl Shifts Skate Bayerts: Often Commited Errors

Skate bearings are not very difficult to use and operate. However, there are a few mistakes that can be made in the process of bearing usage. I have done my due diligence and used some of the best resources. Firstly, one of the common mistakes that people make is not making a habit of cleaning the bearings after use, which accumulates dirt over time and adversely affects the overall performance. I clean my bearings regularly, using proper cleaning agents suitable for both metal and ceramic bearings.

One mistake is applying excess lubricant to the bearings. Over-greasing or oily surfaces attract more dirt and encapsulate the bearings, causing them to slow down or stop interoperating altogether. I am very careful in gauging the amount of grease and oil to use; just a few drops of oil will do, and a smear is all that is needed for grease.

It is also essential to remember the lubricant used on the material for the bearing, which is essentially ceramic bearing polymers that need higher temperature lubricant components. High RPM conditions are crucial in lubrication because if the bearing shaft is not lubed correctly, friction causes overheating, which is very dangerous. Using suitable lubricant not only enhances the performance but also dramatically improves the life span of the bearings.

Understanding the Impact of Bearing Steel and Precision Ratings

Why Measuring Bearing Steel Quality is Very Important

Bearing steel quality is very important because it influences skate bearings’ working efficiency, life duration, and reliability. In most cases, high-quality bearing steel contains high indices of hardness, tensile and compressive strength, wear, and even corrosion resistance critical for extended application once subjected to harsh conditions. A lower grade of steel may lead to premature wear, rust, or structural failure, all of which are detrimental to the bearing performance lifetime.

One leading resource study bears high-grade steel, usually, if there is a large amount of carbon in the structure of the bearing steel and chromium (for instance, SAE 52100 bearing steel). This composition affords good hardness and a better tendency to resist fatigue, which is essential in areas requiring high speed and load. Important also are: cleanliness of the remaining steel (low inclusion content), uniformity of the stretching and economical consumption of the surface (grinding processes). These parameters ensure the steel can tolerate cyclic loads with repeated occurrences without losing its structure and creating economizing. By using superior bearings with superior steel, the maintenance requirements are reduced while improving the long-term performance of the skaters.

Why Precision Ratings are Important in a Performance Evaluation

Precision ratings are among the considerations when buying skate bearings, as they help evaluate rotation and friction minimization performance. According to some major websites regarding leading skaterite bearings, precision ratings are ABEC (Annular Bearing Engineering Committee) or ISO (International Organization for Standardization). These organizations take into account the measurement of tolerance, noise, vibration, and speed efficiency.

For example, the Gabec rating has a maximum figure of 9 and a minimum of 1; thus, higher numbers will mean a tiny space between the bearings, and therefore, the movement of bearings becomes much faster. This does not mean that on a local level of skating, ABEC-rated bearings are meant for heavy use when sufficient conditions like good lubrication and quality materials accompany them.

Microns, surface roughness, and radial and axial play should be considered to justify these ratings. Ball and raceway rigidity and roundness also matter in how low-dimensional variability is maintained. These questions are essential for NVA moderators to agree that performance will be constant even under stress and at high speed of operation. For best-performance skates, selecting bearings with the correct precision ratings would prevent noise and vibration, making skating fast and smooth.

Frequently Asked Questions (FAQs)

Q: What can we remove concerning the Meaning of the ABEC rating for bearings?

A: The ABEC Rating was devised by the Annular Bearing Engineering Committee and measures how closely both races of the bearing are to the intended geometry. As the rating increases towards ABEC 7 and 9, the same rating itself indicates that the inner and outer races are manufactured accurately, which can affect smoother and faster performance.

Q: Do skaters always opt for ABEC-9 bearings?

A: They offer high precision, but not all skaters require such bearings. Skating style, surface, and personal finesse parameters play a key role. For example, some skaters may find ABEC 7 bearings adequate, as they offer a decent speed-to-cost ratio.

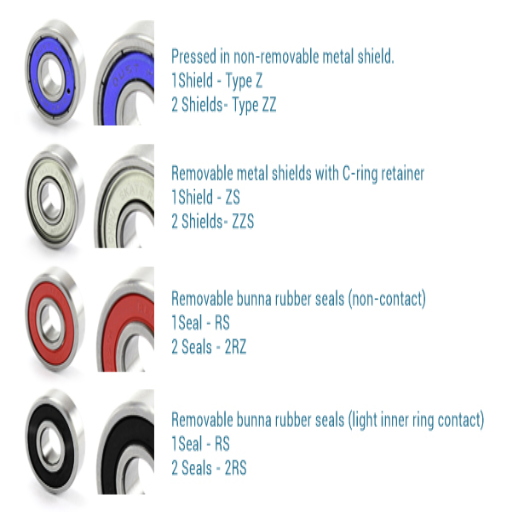

Q: In what manner do 608 bearings differ from 608RS bearings?

A: The 608 bearing is a standard size used in skateboarding and longboarding. The 608RS, on the other hand, is a variation with a rubber seal (RS) that could prove useful in keeping dirt and moisture away, contributing to the longevity of the bearing.

Q: What purpose does a spacer serve in a bearing?

A: One of the most efficient ways to improve alignment and relieve the bearings of stress is incorporating a spacer between the bearings placed on the wheel hub. Therefore, using a spacer makes the ride smoother and extends the life expectancy of the bearings during high-speed or trick skating.

Q: Is it appropriate to put ABEC 3 bearings in my longboard?

A: Certainly, it is possible to use ABEC 3 bearings on a longboard, but they may not be as fast as the higher-rated bearings in smoothness. However, they can benefit beginners and occasional riders because they don’t spend as much.

Q: Why do some skaters consider it necessary to choose bearings with a lower ABEC number?

A: Several skaters go for a lower ABEC rating because they are known to be quite solid and economical. For instance, in rough terrains or for trick skating, skaters might be enabled by using ABEC 1-3 classes, but these skaters do not prefer high speeds.

Q: How are ZZ bearings different from other types?

A: Both sides of the ZZ bearings are shielded with metal covers, which helps prevent foreign materials from dust and dirt. They can be used in conditions with a chance of contamination, but they will not be as fast as open or RS bearings because of the shield’s contact friction.

Q: What factors should I consider when selecting the best bearing manufacturer?

A: Factors such as the manufacturer’s reputation, the materials used (like chrome steel), and the bearing size that is best for the type of skating you perform. It is always a good practice, but reliable skate companies also have bearings for different levels and conditions.

Q: Can you get inline bearings with a rating over ABEC 7?

A: Yes, if we consider ratings like ABEC-9 in inline skating, it may enhance smoothness and speed, helping competitive skaters. In casual circumstances, the difference may not be significant—a bearing with a lower grade might be suitable.

Q: What is the difference between longboard bearings and skateboard bearings?

A: Longboard bearings are intended to endure higher speeds and longer rides than skateboard bearings. Even if the size (such as 608) may be similar, longboard bearings may be manufactured in a variety of sealing or material options that could satisfy longboard needs.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8