How to Choose the Best CNC Bearings

The most precise and efficient CNC machines only operate optimally when supplied with the correct bearing kits. However, for many beginners and industry veterans, it may be challenging to choose the correct kits, given the many options available today. You may choose between different varieties of ball-bearing kits, but other considerations such as quality, compatibility, and cost must also be assessed. This article is aimed at those new to CNC machining and those who are proficient; this way, it helps many people find the exact tools and information they need to make an informed choice.

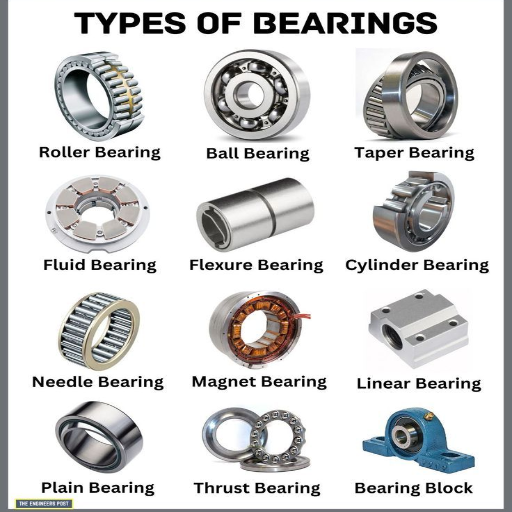

What are the Different Types of Bearings Used in CNC Machines?

Understanding Ball Bearings and Their Applications

A ball bearing in a CNC machine is one of the most common forms of bearing in merchandise. This bearing promotes decreased friction during rotation and supports axial and radial loads. It comprises two races separated by ceramic or steel balls, significantly reducing the material’s friction and wear and tear. This bearing type performs excellently in high-speed tasks and tasks requiring high precision.

Material: Ball bearings are commonly constructed of stainless steel or ceramic due to their abrasion-resistant capabilities and durability.

Load Capacity: Adequately designed to carry radial and axial loads; for example, mini ball bearings can bear up to 35 N of radial thrust.

Size and Dimensions:: This depends on the type of model, for example, the 608 model has a 22 mm outer diameter, a bore size of 8 mm, and a width of around 7 mm.

Sealing Classification: The construction can be open, shielded, or sealed to guard the inner mechanical components from contaminants.

Speed Rating: Usually expected in revolutions per minute. The revolution rate of a high-precision ball bearing can exceed 10,000 revolutions.

Lubrication: Self-lubricating bearings are recommended to maintain a positive performance and to increase the longevity of the bearing.

Many believe that ball plates are essential for machines as they promote more incredible speed and more prolonged use. However, lore states that overheated appliances promote short-lived usage. Hence, it is vital to analyze the purpose of your machine and then select the bearing and its specifications accordingly.

Exploring Linear Bearings for Smooth Movement

The achievement of a specific running motion in a linear direction in CNC machines is aided by linear bearings. Since their design limits the relative motion of the moving parts, they can be effectively employed in diverse applications, guaranteeing efficiency and precision. Nonetheless, linear bearings selection needs to take into account some factors and technical parameters:

Load Capacity: Linear bearings provide a load-bearing function that needs to be specified through various system requirements specifications. High-capacity bearings are suitable for heavy and high-impact applications that verge on reliability and durability.

Material and Durability: Linear bearings generally strengthen materials such as carbon steel, stainless steel, or ceramics to withstand wear and tear, which may enhance their life expectancy. Material selection should be based on corrosion resistance in a moist or chemically active environment.

Precision and Tolerance: Better precision reduces angular misalignment and the potential for movement between the bearing and the shaft, which is beneficial when high-precision CNC operations are performed.

Speed and Friction: Linear bearings should be able to accommodate the determined operational speed. Low friction means that special coatings or pre-lubrication may enhance motion at high speed.

Lubrication: Manual grease or automatic systems must be applied to lubricate the bearing to minimize wear and erosion and ensure its longevity.

Assessing these parameters for application requirements, linear bearings significantly impact the performance and durability of CNC machines. Regular service and correct alignment also enhance their performance, ensuring accurate and reliable linear motion for a long time.

When to Use Roller Bearings in CNC Systems

When discussing the suitability of CNC systems, roller bearings become an important consideration in terms of operational requirements for high loading and controlled motions under harsh working conditions. If the machine incorporates significant radial or axial loads, I suggest using roller bearings designed to emphasize the abovementioned loads on the larger contact surfaces. Moreover, they are ideal for stress formations requiring higher strength and lesser deflections, which, in turn, means that a parameter of potential displacement would remain constant again.

Load Rating: Roller bearings are well suited for applications that involve heavy loads; however, dynamic load and static load ratings would also have to be aligned with the task to be carried out.

Speed: They are effective at moderate speeds, but working with them while exceeding the RPM specifications provided by the maker can easily lead to overheating or straightforward wear.

Rigidity: Their very design tends to be high stiffness, which means that all deflections shall be reduced, and thus, a workpiece shall be more accurately machined.

Material: Using optimum steel or ceramic materials is preferred as they are durable and can withstand heightened temperatures.

Lubrication Requirements: Proper lubrication enables optimal operational speeds and loading conditions to reduce the risk of overheating and physical damage.

Space Constraints: Because they are more significant than ball bearings, adequate space and planning are needed in machine design.

When these parameters are dealt with accordingly, it becomes very plausible to use roller bearings in CNC systems regardless of severe operational conditions and even enhance performance.

How to Identify the Right Linear Bearing for Your CNC Machine?

Key Features to Look for in a Linear Bearing

In my case, to attain a respectable amount of performance and durability from my cnc machine parts while selecting the correct linear bearing, it is essential to consider several characteristics, such as:

Load Capacity: It is implied that the bearing must be able to deal with the static and dynamic loads that my CNC operations require. This should be stated percentioned in Newtons(N) or kilograms(kg) for precise work.

Accuracy and Precision: Positional accuracy is vital. Tight control over machine movements requires bearings with low friction coefficients and verified tolerances, such as +/—0.01 mm.

Material and Coating: The material must be highly tensile, abrasion-resistant, and suitable for high-speed applications. Based on environmental conditions, I usually use stainless steel or modern ceramics for corrosion-resistant purposes.

Speed and Acceleration: Regarding high-speed operations and CNC systems’ performance, I must check whether the accepted maximum linear velocity (3m/s and higher) and acceleration rates are appropriate.

Noise and Vibration Reduction: For better operation, bearings in which the surfaces of contact are optimized or slots for the vibration-reducing mechanisms are integration arm searching bearings.

Maintenance Requirements: To minimize downtime, operating in low lubrication conditions and using self-lubricating bearings are always recommended.

It is my practice to consider these factors carefully and match them with the needs of my particular CNC applications to get the expected performance from linear bearings.

Comparing 8mm and 12mm Bearings for CNC

Although the decision to use 8mm or 12 mm CNC bearings depends on the project’s specific thrust, the loads, accuracy, and intended performance are the primary considerations. My assessment is as follows.

Load Capacity: The 12mm bearings are best used in CNC operations as their high bearing load allows them to be used in heavy operations. 8mm working load bearings suffice for lighter applications and eliminate excessive bulk.

Precision and Friction: The 12 mm thrust bearings deal well with high load forces, as the motion in these systems is highly tensed. The 8 mm bearing can accommodate appropriate precision as the 12mm did but incorporates less inertia, which makes it useful in setups that require speedy motions.

Footprint and Weight: The 8 mm bearings are superior for restricted spaces and weight limitations because they are smaller and lighter. The 12mm bearings are much thicker for rugged applications but will have longer cycles.

Rigidity and Vibration Damping: The natural thickness of the 12 mm bearings makes them stiff and too difficult to bend when stress is applied, so the vibration is sound. This reason can support the argument that 12 mm would beat 8 mm in CNC machines requiring outstanding precision.

Weighing these technical characteristics, load capacity, precision, footprint, and rigidity, I select the bearing size that best fits operational demands and machine specifications required by the given cnc project.

Understanding Radial Load Capacity and Performance

With questions raised on radial load capacity and performance with CNC projects, my strategy is first to analyze load ratings, operational speed, and application requirements specifically. The radial load capacity is specific to the point at which a bearing allows the application of radial force without undue wear or failure of the bearing. For example, with a bearing, operational stresses are best measured in terms of dynamic load rating (C) and static load rating (Co), which provide minimum and maximum thresholds, respectively.

In the bearing selection process, I ensure that dynamic load ratings are reasonably higher than the working loads, considering machine support cycles, machine working speed, and vibration. Static load ratings are also critical, especially when a mass of sudden force or uneven loads are expected. Moreover, the single-row bearing or double-row type and the operating rigidity I submitted work towards the required operating accuracy. My justifications for selecting the specific parameters in each CNC project resulted in my willingness to optimize the performance of the particular bearing configured for those projects.

How to Choose a Ball Bearing Kit for CNC Machines?

Evaluating the Price and Performance of Bearing Kits

Bearings used in bearing kits for CNC Machines can be evaluated in price and performance. First, I estimate the operating speed of the CNC machine in question and compare it with the maximum rated RPM of the fencing. It is no secret that higher operating precision often comes with relatively higher costs, but higher standards may be worth the price. Second, it determines the load it will bear by looking at the dynamic and static load ratings, assuring that wear and tear will not harm day-to-day productivity. For example:

Maximum RPM: It is advised to set an appropriate level that prevents overheating and/or early breakage, whether from using the machine for too long or incorrectly handling it.

Dynamic Load Rating: This rating highlights the overall continuous working loads the bearing must cope with, indicating long-term use.

Static Load Rating: This refers to several motionless forces side or an object applying a static load, they are necessary to control deformation from occurring when put under immense pressure.

On top of that, there’s the matter of what precisely the bearings are made out of and the type of lubrication to be used, as better steel and grease will improve the workings’ life and general working performance. Even tho higher quality kits would cost a lot more, it is a safe assumption that in the longer run, they would be worth the investment as they’re able to cut costs related to maintenance while improving the CNC services being used.

Top Brands and Products to Consider

In my work of research and hands-on practical application, I can name only a few brands and products that stand out in CNC usage both from the technical aspect and reliability. Below are some of my best picks, considering their best technical parameters and practical results:

THK Linear Motion Guides

Dynamic Load Rating: THK products are often shown to have more than 20,000 N dynamic load ratings, which suits those demanding precision tasks.

Accuracy Grade: Almost all models are manufactured at H-grade or above, guaranteeing the high precision required for high-speed CNC tasks.

Durability: These guides have a high-purity steel base with a special heat treatment that guarantees a long life span and high wear resistance.

Hiwin Linear Bearings

Static Load Rating: Hiwin bearings should, with no problem, sustain static load ratings of 15,000 N, which resists the bearing from heavy idle loads.

Lubrication: A Hiwin contains an E2 Self-Lubrication system exclusive to Hiwin and manages to eliminate maintenance problems while increasing life span.

Versatility: This type is well accepted across various applications due to the universal balance between precision and load capacity.

NSK Ball Screws

Precision: NSK ball screws have several features providing them with smooth operation branches free from any vibration and the position accuracy grade equal to or approaching C3.

Efficiency: The bearings incorporate high-efficiency flanged systems, effectively reducing friction and minimizing energy and heat buildup during extended periods of operation.

Load Capacities: This has specific configurations for high-speed machining and heavy load combinations with dynamic load ratings ranging from 10,000 to 40,000 N per model.

These brands have strong technical characteristics that account for their higher prices. Depending on your particular CNC needs, such as high load capacity, accuracy, or low maintenance, these items should be considered, as they are reliable and efficient for many years.

Installation Tips for a Ball Bearing Kit

While fitting a ball bearing kit, I suggest following the following steps for practical use and to increase the durability of the ball bearing further:

The ball-bearing housing must be clean, parched, and free of dirt. For proper fitting clearance, check the bore diameter and see if it matches the bearing’s internal diameter of 25mm.

Do not touch the rolling elements with bare hands while force fixing it into place because the rolling element may get dirt into it, label them bearing, and proceed to the rolling elements. To prevent holding bearings, roll them outside while wearing gloves. It has to be a cold press and done with a low force. Otherwise, the rolling element will get displaced, and the ball will be damaged.

If there is no displacing them, tailor-bearing presses and sleeves are specific to the dimension of the particular end bearing. An example is a ball bearing with a load rating of 10,000N; it will require a fitting of extensive tools so no displacement occurs when being put in place.

Recommended resources are to be applied with purpose based on the bearing’s specifications and the environment in which they are being used. For instance, kits with synthetic grease are recommended for high-speed machining because they increase tolerance against high amounts of heat.

This could be one of the reasons why the lifespan of the bearings is reduced. To prevent this, tools or gauges for alignment must be used to ensure the components are correctly placed and do not aid in deflecting higher-rated models or heavier weight and precision machining.

Following these steps and keeping the aforementioned specifications, such as bore and load capacity tolerances, in mind allows for a successful installation, ensuring that your ball-bearing kit operates efficiently and lasts long.

What Factors Should You Consider for Bearing Replacement?

Signs You Need a Bearing Replacement

In examining bear replacements, it is essential to begin with some indicators. Audible grinding, clicking, or even squealing noises are reliable indicators of possible damage or wear within the bearing. Second, if one operates something, such as a bearing, instability or vibrations could be felt, possibly due to some internal deterioration or poor angle adjustment. An abnormal increase in the working temperature of the bearing is experienced due to increased friction due to lack of lubrication and dirt. Furthermore, jagged edges, rusted areas, mild cracks, and abrasions observed on the bearing surface exemplify that the bearing should be changed.

From a technical standpoint, I am personally concerned that the following parameters are sifted through in the course of the operation:

Load Capacity – High-rated loads should not be carried out too often, as this could promote inconsistency in the system’s long-term functioning. I cross-check the specifications to ensure compatibility.

Lubrication Condition—Lubrication includes grease or oil in the proper proportions. The amount needed is based on the recommended speed, temperature, and working conditions.

Alignment—I also confirm alignment using special equipment to avoid the uneven bearing stress caused by poor alignment.

Operating Speed—Complying with the limits ensures that all speed-rated bearings do not exceed every limit. I seek agreement with what specialists indicate.

Environmental Factors – Besides, I try to consider whether the work conditions, like humidity or pollution, have impacted the bearing’s condition and longevity.

Considering these elements, I can ensure that replacement decisions are routinely made correctly and based on sound engineering reasoning.

Steps to Ensure Precision and Performance in Replacements

The following steps are potentially observable to ensure that questions are effectively answered while all technical specifications are regarded and reasoned.

Check The Load Requirements

The first thing you must do is determine the operational dynamic or static load on the bearing.

It is now essential to correlate these amounts with a bearing’s load lift capacities (e.g., in units of kN, dynamic load Audiences Rating: C).

Check The Rotational Speed

Factor out the shaft speed (in rotations per minute) and ensure it does not exceed the bearing’s maximum speed rating.

Make use of manufacturer charts to know the speed limit according to the type of lubrication used, for example, oil or grease.

Check The Environmental Suitability

Ensure that the materials are suitable for operating conditions such as -20 to 120 degrees for standard bearings and protective coatings against dust, water, or harsh chemicals.

In line with the risk of contamination, decide on the seals or corrosion resistance.

The Fit And Alignment Check

Assess the fitting tolerances for the shaft and the housing, such as ISO tolerance grades E H7 or K6.

The load is supposed to be disbursed evenly and checked for proper alignment.

The Lubrication Requirements

Choosing the lubricant for the viscosity is luckily set for the temperature in anticipation.

Guarantee lubrication intervals to abate overheating or wear and tear.

Through methodical consideration of factors and manufacturer data, you can advance bearing operations, and concerns linked to incorrect replacement become a concern of the past.

Common Mistakes to Avoid During Bearing Replacement

Skipping Pre-Installation Checks: Before installation, the bearing surface must be carefully inspected for compatibility with the application’s set load, load distribution, and manufacturer’s tolerance levels.

Improper Handling – Introducing possible contaminants or damage to the bearing surfaces is brought using improper handling tools or bare hands. I, therefore, put on clean gloves while using the necessary tools to limit wear and contamination.

Incorrect Installation Techniques—Using recommended tools, such as the bearing fitting or press kit, helps distribute the load applied to the bearing during installation evenly, avoiding misalignment and damage due to excessive strain on one part of the bearing.

Failure to Lubricate Properly—Fitting the wrong lubricant or applying enough is gross negligence that invites premature equipment failure. Low-viscosity lubricants are preferred for extreme speed, while thick lubricants are used for the motion of devices under heavy load. The lubricant selection depends on the contact speed, range of the contact temperature, and external elements like dust.

Neglecting Alignment—Even a small amount of misalignment among components will lead to unequal stress distribution and wear of the various parts of the assembly. Therefore, in the case of a bearing, I guarantee thorough checking and adjusting of alignment using gauging instruments and alignment tools.

Using Worn-Out Parts – Refurbishing used housings or seals may seem economical, but this always lowers performance. I also exchange every related part to preserve the system’s integrity and prevent expensive future repairs.

By not committing these errors and by strictly conforming to standardized technical parameters, I can bear injection replacements that are accurate, dependable, and durable.

How to Maintain Your CNC Bearings for Longevity?

Regular Maintenance Tips for Linear Motion Systems

To ensure that CNC machine bearings continue to serve their optimal purposes for a long time, I document my procedures as a maintenance schedule.

Cleanliness is Important – I make sure that the motion control machine components, namely guideways and ball screws, do not collect dirt, dust, or other contaminants since this will cause motion control machine parts to wear prematurely. Therefore, washing these parts with non-corrosive solvents using lint-free cloths at regular intervals is essential.

Lubrication is Important – Proper Lubrication reduces friction and resultant wear on the components. I also maintain the grease or oil that the manufacturers suggest is within the operating speed and load limits. For example, low-viscosity lubricants are used in high-speed systems, while highly viscous lubricants are used in heavy load conditions.

Routine Inspections – These periodic visual and touch inspections will reveal the state of alignments, loose parts, or deterioration. I also listen to the noises and feel the vibrations, as sometimes these are discerning surfaces of conditions requiring attention.

Alignment Checks—Misalignment can cause stress and damage. To check alignment, I use simple tools like dial gauges or lasers to ensure precise alignment, which prevents stress from being exerted in an inappropriate position.

Monitor Load and Speed Parameters – A bearing will wear out rapidly when the load or speed is above the recommended. I pay utmost attention to the manufacturer’s operational parameters set for the specific parts.

Ensuring that the load rating doesn’t exceed the maximum dynamic or static load capacity in the bearing datasheet is a good practice that significantly contributes to sustaining the bearing over its lifetime.

Use Seal Replacements In Time – I immediately change seals, wipers, or even worn or rusted bearings so that the affected part and other allied parts do not suffer additional damage. Reliance on the original or good-quality substitutes assures performance and accuracy.

By performing these processes and observing the proposed technical parameters, I have managed to prolong the service life of linear motion systems without compromising the recommended performance or increasing the needed repair time.

Lubrication Techniques for High-Speed Bearings

Since high-speed bearings must work under the most strenuous conditions possible, I adopt proper lubrication techniques relative to their requirements. More elaborated are the processes below, as well as the technical parameters that I employ:

Choosing the Right Lubricants—In high-speed scenarios throughout applications, I opt to use low-viscosity synthetic oils. These oils can reduce friction and generate excessive heat. For instance, synthetic oils with a viscosity grade index of ISO VG 10-32 would be suitable for a high-speed pump, as they would minimize drag.

Calculating The Correct Volume – Under excessive lubricant, heat is trapped, while minimal application of lubricant accelerates wear out of components. To this effect, I refer to the guide documents of the bearing manufacturers, which specify an average of about 30 percent of the total free internal volume to be filled with the required lubricant in high-speed scenarios.

Adherence to Effective Intervals—Relubrication scheduling is essential to ensure that a lubricant film is not thickened beyond the required minimum. This is particularly important at high speeds, as excessive buildup can lead to malfunctions. For this, I advance relubrication schedules under the speed, temperature, and load conditions, which I set to 500 to 1,000 operating hours in extreme conditions.

Range During Operation Temperature Control – Check that my operating temperatures are within the operational range of the components, allowing a maximum of -278 to 248 according to the maker’s specifications. This ensures that the lubricant does not burn away due to overheating.

Employ the Right Delivery Method—When working with high–speed bearings, I use oil-mist or air-oil lubrication systems. These methods provide continuous lubrication without using excess quantities, leading to proper heat dissipation.

In this case, high-speed bearings are implemented with minimum friction and wear whilst self-sustaining the required service life. Thus, the following practices and compliance with the designated technical parameters ensure an efficient operation.

Ensuring Friction Minimization for Optimal Operation

To achieve optimal operation while minimizing friction, I follow the practices listed below:

Regular Maintenance Inspections—During maintenance, I look for wear and contamination, as well as alignment of components. This step lets me detect problems that could increase friction levels too much. For example, it is immediately repositioned whenever a shaft is found out of alignment.

Lubrication Plan – I have a detailed lubrication plan linked with the bearing operating conditions. Such fittings are used for high-speed bearing where appropriate viscosity fitting for speed and loading is selected.

Thermal Control—Operating temperatures (-20 deg. C to 120 deg. C for most bearings) should be kept within the acceptable range. Excess temperatures should be resolved by modifying lubrication or cooling systems to alleviate thermal degradation.

Delivery Systems—For high—speed use, I use oil mist or air-oil lubrication. These systems help maintain a uniform distribution of cooling lubricant while minimizing strength loss due to overheating.

Assuming all the strategies highlighted above are followed to the letter alongside the technical instructions, friction, and wear are minimal, and the equipment serves its purpose efficiently.

Frequently Asked Questions (FAQs)

Q: What factors should I consider when choosing CNC bearings?

A: It is helpful to consider multiple variables, such as load capacity, maximum speed, precision, and application requirements when choosing NNC bearings. The design and dimensions of the CNC machinery must also be examined so that suitable bearings can be fitted and have superb usability.

Q: Why are deep groove ball bearings commonly used in CNC machines?

A: One type of bearing widely utilized throughout many CNC machines is the deep groove ball bearing because it has a reasonably low level of friction while achieving high-speed rotations and effective radial loads, which makes this type of bearing effective in many CNC applications and accurate movement.

Q: How do I determine the right size of bearings for my CNC router?

A: To determine the right size of bearings for your router, it is vital to take measurements of the shafts and housing diameters in which the bearings will be fitted. It is crucial to consider the speed and amount of load-bearing requirements and how the bearings would fit in with any other parts and components that may already exist.

Q: What is the role of bearings in the z-axis of a CNC machine?

A: Bearings are crucial in the z-axis of a CNC machine as they enable a linear and smooth motion, thereby reducing the friction and wear of the bearing. Such linear motion enables the cutter and shaper to operate vertically, which is necessary for such operations.

Q: Can I use lm12uu bearings with my CNC unit?

A: Yes, lm12uu bearings can be used with CNC construction, particularly in linear motion applications. These bearings are often fitted onto lead screws and linear shafts for ease of use and installation.

Q: What kind of bearings should I choose to cut down and play some thickness in my CNC machine?

A: To cut down the play on a CNC machine, suitable bearings should be high-precision runners that are reasonably thick, covering their housing with minimum spindle clearance. Repeated contact and lubrication can help achieve the desired accurate and stable performance.

Q: How crucial are industrial-grade bearings in CNC machines?

A: Industrial-grade bearings offer key advantages, including improved durability, performance, and service life. They are built to endure robust conditions and offer dependable functionality for CNC routers.

Q: How does the side load capacity of a bearing influence CNC performance?

A: A bearing’s side load capacity affects CNC performance by setting the force sliding in one direction perpendicular to the bearing axis that the bearing might tolerate while maintaining accuracy. Higher side load capacity bearings are preferable where the operational requirements involve lateral forces.

Q: Where can I buy quality CNC bearings?

A: Several suppliers or manufacturers, such as us, can provide CNC bearings. They have different types that are suited for various applications. Please do contact us if you would like to have recommendations or learn about our inventory and supply.

Q: How do I ensure my CNC bearings last longer?

A: A regular maintenance schedule for your CNC bearings must be established to keep them adequately lubricated and limit excessive loading. Proper bearing selection and timely replacement are crucial for optimal performance when wear indications are seen.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8