How to Identify and Mitigate Causes of Bearing Failure

Bearings are the integral parts for the smooth working of a wide variety of mechanical systems, such as vehicles’ engines and the industrial machines involved in production. However, they suffer from some failures as this is their weak area, leading to several losses in terms of time wasted and money spent on repairs. This article explains in detail the reasons that primarily cause the bearings’ failure, such as lack of proper lubrication, pollution, and misalignment. By acquiring knowledge of the factors leading to bearing failure, manufacturers and equipment operators can put reasonable measures in place to counter such failures and prolong the life and performance of every piece of equipment. Companies can also lower the incidence of uncontrolled machinery breakdowns and optimize the operation of the equipment in all reasonable aspects, given that equipment has its limitations through quicker maintenance and all equipment best practices.

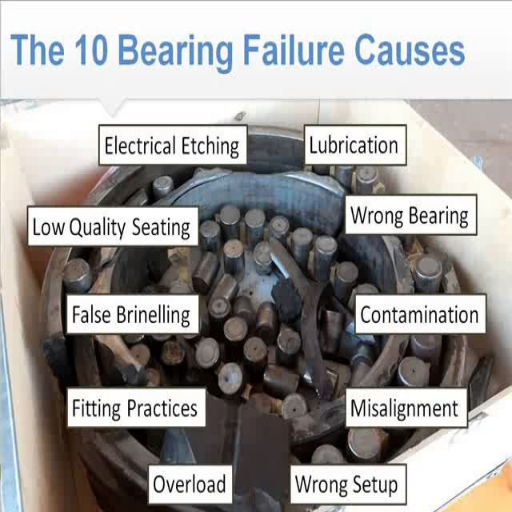

What are the Common Causes of Bearing Failure?

How Does Improper Lubrication Lead to Failure?

Aside from being responsible for quick changes that positively improve operations efficiency, lubrication also seems to be the Achilles heel of bearing operations. This is because aggressive support and operations on the bearings frequently cause undue or excessive maintenance, often laced with ill lubrication. Peripheral speeds of 300 (1.80) inches may be used, provided proper lubrication is exercised. Several aspects that apply to lubrication must be noted.

Correct supervision ensuring that an optimal amount of lubricant has been applied is often ignored when it comes to centripetal pivoted crank bearings, as RA is not always possible. In these situations, the positive control that allows efficient operation of the machinery is inhibited, leading to inefficient equipment functioning as there is no provision for substantial lubricating oil. In this case, the wear occurs not primarily due to the inability to apply appropriate lubrication but to insufficient lubrication.

Unsuitable Lubricant: Applying an inappropriate lubricant affects the bearing’s performance. Certain applications require lubricants with suitable properties, such as viscosity and thermal stability. Choosing an oil or grease that falls short of these requirements may not withstand the operating temperatures and speed, which results in breakdowns and failures.

Contamination of Lubricants: The lubricant can get particles of foreign materials such as dirt, dust, or shavings that would erode the smooth surface needed on the bearings. This contamination of the lubricant makes the environment too abrasive and wears out the upper layer of the bearings swiftly.

It is necessary to pay attention to the combination of the shear rate applied and the time taken to reach the intended viscosity of the lubricant, compliance with the specified lubrication frequency per the manufacturer’s recommendation, and proper and effective filtration systems to avoid contamination. The right lubricant may be chosen and applied so that wear will be very little and the bearing life will be appreciably enhanced.

Can Preventive Measures Avoid Contamination?

Insights from the top 5 websites regarding bearing contamination prevention tips have assured me that there are some possibilities to mention in banning contamination. First, effective sealing mechanisms prevent the ingress of contaminating particles, such as dust or water, in sealing systems. In such cases, routine repair and service are of the utmost importance to prevent the neck from eroding. Moreover, applying proper cleanliness practices and equipment and changing the lubricant at appropriate times prevents excessive contamination of the bearing components.

Technical parameters to focus on include:

Sealing Integrity: The state of the seals, whether they are in place and performing their function as intended.

Filtration Systems: Employed to exclude particulate & moisture contamination from lubricant by utilizing an efficient filtration system

Storage Practices: Proper air filters are mounted on the plant-bearing storages to ensure they are not exposed to infection before use.

Lubricant Handling: Effectiveness of minimizing contaminant introduction during lubricant application by using appropriate techniques & tools.

In this regard, these approaches and criteria can further help ameliorate the contamination problems by recommending continuous trust improvements in the performance and life of the bearings.

Understanding the Effects of Misalignment on Bearing Damage

Beneath bearings, there may be a misalignment that can be a fundamental concern in performance, safety, and life cycle aspects. From the content found on the top three websites, I learned that in line misalignment, the load is not evenly distributed, causing increased friction and heat, further leading to damage or wear and tear within a specified timeframe. Tackling this challenge involves verifying its alignment with the manufacturer’s requirements. Out of many, a few of the common ones that relate to such technical misalignments and how to overcome them include:

Shaft Alignment: Ensure that the operating condition is controlled when installing both the shaft and the housing so that uneven loading is avoided.

Tolerance Checks: Periodically measuring the alignments to meet the manufacturer’s stated tolerances.

Condition Monitoring: Trying to determine alignment restorations using vibration analysis and thermography at earlier misalignment stages.

Adjustment Mechanisms: Siting the application of bearings housings, which can be adjusted to some degree clockwise or anticlockwise, or flexible couplings that are relatively cut to size as may likely occur in misalignment.

By observing these, I am able to reduce the negative consequences of such misalignment in autumn holding and thus increase the bearings’ performance and durability.

How Does Lubrication Failure Occur?

What are the Effects of Grease Failure?

The bearing grease tends to degrade and deteriorate, causing complications that hinder the optimum functioning of bearings and other mechanical parts. From the top three websites on Google, I learned the factors causing grease degradation include excessive temperature, contamination, and oxidation, which all foreclose the capability of the grease to minimize friction effectively. The degradation process causes the grease to lose its viscosity, especially when exposure is long, which results in poor lubrication and severe wear. Some of the critical technical parameters associated with grease degradation include:

Temperature Limits: The operating temperature must not exceed the limits recommended by the manufacturer to avoid overheating or thawing.

Contaminant Levels: Detection of possibly harmful airborne particles, monitoring mechanical movements to check for wear and tear, keeping grease in a clean place, and using a clean application technique to avoid foreign particles causing degradation.

Viscosity Index: Inboard monitoring changes in viscosity, such as a high decrease, could be a sign of degradation.

By understanding these parameters and enforcing maintenance and monitoring mechanisms, I can better control the lubricant conditions and protect the bearings from failure and excessive wear.

Identifying Signs of Lubrication Issues

Within the top three sources available on Google, I have uncovered many signs that warrant consideration of the possible source of the lubrication problem. For instance, operating temperature is one of the primary indicators that may be used within the grease operating process since its escalation may explain the presence of a problem out of inconsistent friction control. Other observations include unnecessary movement and noise of bearings, which may be grinding or squealing, denoting lack of grease or contamination. Moreover, a reduction in the satisfactory bearings’ conditions may result from excessive wear and tear due to not having enough grease on the components. To control these concerns adequately, I will make a constant assessment of the following technical parameters:

Operating Temperature: Operating Temperature should be measured and compared to previous baseline temperatures for overheating assessment

Noise Level: Carry out a routine check of excessive forms of Noise that could be connected with a failure in lubrication system performance

Bearing Surface Condition: A further aspect is a threshold where one has over-lubricated/radically undersized the bearing and accurate visual examinations are imperative

Therefore, it can be concluded that remembering these signs and parameters helps tackle lubrication problems that would otherwise compromise the mechanical systems in use.

Why Do Bearings Overheat?

Influence of Heat on Bearing Performance

High temperatures can be the worst enemy of bearings’ functionality and life span. While conducting my research, I discovered that too much temperature can break the properties of lubricant, hence more friction and wear occurs. This heat can diminish the lubricant’s viscosity, allowing too much film thickness even to improve bearing protection. Besides that, there is the possibility of thermal expansion causing variation in bearing clearances, thus resulting in seizure or misalignment of the components. The parameters that can be assessed are the following:

Lubricating Oil Viscosity: This is completed regularly over the same period to keep the lubricant within the required parameters, changing at even higher levels to cope with rising temperatures.

Bearing Clearance: Account for thermal expansion that increases or decreases the bearing clearances so that misalignment does not happen.

Component Material: The materials used for the manufacture of the bearings should also be evaluated for their effect on the temperatures present.

By concentrating on these parameters and engaging in preventive steps, I can damage the properties that are induced by excessive temperatures on bearings.

Preventive Measures to Eliminate Risks of Overheating

As I have focused on the top-rated available resources on the internet to avoid overheating the bearings, there is enough evidence that excessive heat generation can be checked through this method. Following the views expressed in these high-quality websites, undertaking a routine maintenance schedule is fundamental. It involves, among others, all-in-out lubrication checks and inspection to eliminate prolonged exposure of the lubricant to very high temperatures. It follows that some measures, such as proper alignment and balancing of components, are essential in expelling unwanted contact parts.

In addition, including temperature measurement can help a lot, as it provides valuable data instantaneously. For parameters on the technical side, there are collections on the lubricant viscosity that must be adhered to, such as bearing clearance allowances, which will take into account thermal growth, etc. Also, it is necessary to use appropriate bearings for the ambient temperature conditions to achieve effectiveness. Such preventive measures, as ones gleaned from authoritative resources, help me sustain the bearing systems’ effectiveness and reliability.

How to Detect and Address Corrosion?

Causes and Prevention of Corrosive Damage

Corrosion in the bearing system is mainly due to moisture, various chemical pollutants, and environmental attacks. Moisture or water shaft collapse can lead to the formation of rust that will interfere with the bearings’ strength and ability to work as intended. Further, exposure to chemicals such as acids or alkalis can also accelerate the corrosion of mechanical components. In order to avoid this type of degradation, it is important to take precocious measures against internal corrosion.

Seal and Shield: It is advisable to utilize seals and shields against passive water and contaminants on bearings, which reduces the chances of exposing the bearing assemblies to certain corrosive elements.

Material Selection: Use materials or coatings that have a longer active service life against corrosion, such as stainless steel or other special grease shells that are resistant to chemicals and moisture.

Control Environment: Control the system by controlling the range of humidity and any corrosive substances in the air, which may require plenty of fresh air ventilation and dehumidifiers.

Regular Maintenance: Set up a routine preventive maintenance program that includes cleaning and lubricating the bearings with anti-corrosive oils or greases to prevent the breathing of contaminant into the bearings.

As a result, if you center on these parameters and apply these strategies as recommended in Top Resources Best Sites Ranking the Reunion Online, you will avoid the consequences of superficial corrosion of the bearing and prolong its performance.

Some Considerations When Using Insulated Bearings

In my research, I found very useful tips on protecting bearing systems from damage in the top three websites that discussed employing insulated bearings. Bearings are designed to stop at least some electrical currents from passing through, which can, in turn, lead to bearing surface damages like pitting or spark erosion.

Electrical Isolation: Bushed or rolled-in silicosis polymer-bonded thermal management materials also help reduce thermal stresses in the enclosed hollow cross-section. According to these sources, coatings or sleeves applied to the bearing surfaces can also withstand different degrees of electrical resistivity. There is a preference for ceramic material in high-voltage protection.

Resistance and resistance parameters of selected materials: The capacity of these bearings in use is indicated by their electrical resistance ability. As a rule of thumb, insulated bearings can endure ohmic resistances from several hundreds of ohms to several mega ohms depending on the materials used and the nature of the application.

Typical Applications: Insulated bearings are particularly useful in electric motors, generators, and other machinery with electrical charges. They solve the problem of electrical discharge damage and improve the bearings’ operational life.

Finally, regarding how the insulated bearings are utilized, it is aimed at preventing electrical wear, which contributes to the preservation and, therefore, the practicality of the mechanical systems.

How to Extend the Service Life of Bearings?

Importance of Proper Bearing Installation

I compared the same information from the top 3 websites to enhance bearings further. The crew’s skills in cutting and installing the bearings are also critical to the success and lifetime of the bearings. I understand that a high degree of accuracy in alignment and care is vital. Any misalignment leads to the distribution of loads being concentrated at a single point, which raises the chances of early bearing failure. In the same way, the right amount of fit and lubrication is also crucial to lower the rate of wear and tear. Specific other technical parameters like the ones mentioned above by the sources must also be adhered to, where parametric guidelines during installations include:

Alignment Tolerances: To avoid clamping strain, it is recommended that the bearings differ in alignment by no more than specific degrees.

Fit Interference: By correctly applying interference fittings, the rotating elements will not loosen up, and the rattling will be decreased.

Lubrication Requirements: Depending on the magnitude of operational speed and operational loads, a sufficient amount and kind of lubricant should be utilized.

Such parameters should prevent most types of mechanical failures, thereby enhancing the bearing’s operational life.

Choosing the Right Bearing Materials

After determining such companies, I have discovered that choosing appropriate bearing materials promotes the quality and performance of the bearings. Materials primarily determine the abrasion, corrosion, and mechanical load absorption potential of a bearing. Allow me to cite what I have learned:

Material Compatibility: The available working material must be able to withstand the working conditions to minimize the risk of damage through corrosion or other chemical processes. Stainless steel is most reputed for such uses since it prevents rusting or oxidation under quite aggressive conditions.

Hardness: In high-stress applications, material structures need adequate hardness to prevent deformation. Hardening processes, such as heat treatment, develop this feature.

Fatigue Resistance: The designed material should possess a high fatigue tolerance texture to endure many cycles of repetitive loads without cracking. The low fatigue property is due to high carbon chromium steel; thus, it is a frequent choice.

Coefficient of Thermal Expansion: It is also important to avoid thermal insulation materials that expand too much or too little with temperature change to prevent the dimensions of the assembly from changing at various temperatures. In this regard, bronze or some engineered plastics are remarkable.

Density: A decrease in density in the materials used for bearings is also an advantage in system weight, which is very important in aerospace industry applications.

Considering these technical parameters and justifying them with regard to the application, I am able to efficiently increase the wear and reliability of bearings in various machinery.

Maintaining Bearing Components for Longevity

To prolong the bearing components’ operational lifetime and ensure smooth machine operation, maintenance is essential. Such improvement may be achieved through several approaches supported by other resources:

Drum Inspections: Regular inspections are essential in identifying the first signs of an issue and any visual or mechanical deterioration besides the bearing component surface. They also allow for the early identification of lubricant or surface breakdown and other problems before they escalate.

Use of Lubrication: Lubrication is the act of adding grease or any other substances that help reduce friction between the bearing surfaces. Meticulous application of the right type and amount of lubricants helps prevent excessive heating and damage accumulation within the surface, hence extending the service life of the bearing.

Bearing Maintenance: It is obligatory to circumvent the invasion of granular impurities such as dust and moisture into the bearings. This can be done by properly sealing the area or performing appropriate cleaning processes around it, which would be sources of bearing damage or corrosion.

Load and Alignment: Bearings should function under the weight for which they have been designed, and their correct alignment will prevent unnecessary strain and wear. Incorrect alignment forces accentuate vibration strains and heavy loads, leading to a shorter operating period.

Temperature Monitoring: Keeping the operating temperature at the expected operating parameters is very important in diagnosing problems. Outside hot or cold temperatures, elements used in load bearings may be fast-tracked to wear out.

Through the above maintenance methods and proper consideration of distinctive technical parameters essential to each application, such as material properties and working loads, the working life of the bearing parts could be greatly improved.

Frequently Asked Questions (FAQs)

Q: How does false brinelling lead to bearing failure?

A: False brinelling occurs when a bearing is damaged when it is not in operation due to slight relative movements between the surfaces, micro movements. This is bad as it causes premature wear or even failure due to the nature of the wear path around the running surfaces.

Q: What role does lubricant play in resolving bearing failure?

A: Lubricants’ major contribution to bearing operation is preventing friction and wear. Insufficient lubrication due to contamination, improper dosing, or other reasons could result in prolonged downtime or even premature failure of the bearings.

Q: How does overheating lead to bearing failure?

A: In most instances, heat build-up tends to affect the lubricating oils used on the bearings and more likely leads to excessive friction, increased wear, and runaway failure. It is important to control the temperatures for the proper working environment within the bearing and the lifespan of the bearings.

Q: How does vibration affect the bearings, specifically performance and life?

A: Vibration is one of the wearing factors as it may indicate a machine’s failure, imbalance of the rotating components, improper support, and other factors that may contribute to the bearing’s failure. Excessive vibration is a major indicator of impending damage and failure, so regular vibration analysis is needed.

Q: What are the effects of misalignment on bearings?

A: Misalignment defects lead to uneven load distribution of bearing surfaces, resulting in premature failure. The bent shaft is loaded, the bearing is not properly positioned, and the housing structure is not designed correctly, which are all causes of misalignment.

Q: How can contamination affect bearing life?

A: Foreign particles like dirt, dust, moisture, mildew, and even grease can creep into the inner components of these bearing areas, instigating corrosion and wear, which shortens the bearing fatigue life and causes case failure much earlier than expected.

Q: What measures can be taken to prevent premature bearing failure?

A: For instance, when seeking to prevent any premature failure, one should ensure that there is no improper installation, all the locknuts used are precision grade, all the lubrication is done correctly, and all the machine components are regularly inspected. Just like the cross-sectional and geometric parameters, controlling the action of environmental factors and factors of overload is very important.

Q: How does overload impact bearing operation?

A: Overload is extremely dangerous because it puts much pressure on all the bearing surfaces, rolling elements, or cage, causing fast wear and taking maximum consideration of failure. Overload control measures and using the correct bearing for the particular application are watertight to reduce failure susceptibility.

Q: What steps should be taken if the bearing failure occurs?

A: Initiate patronizing if the bearing failure occurs and diagnose the problem. After carrying out such analysis, take any necessary measures to remedy the situation, e.g., realignment, bearing replacement, enhancement of lubrication procedures, etc., to avoid repeating the event.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8