How to Tell If Bearings Are Bad in Your Machine

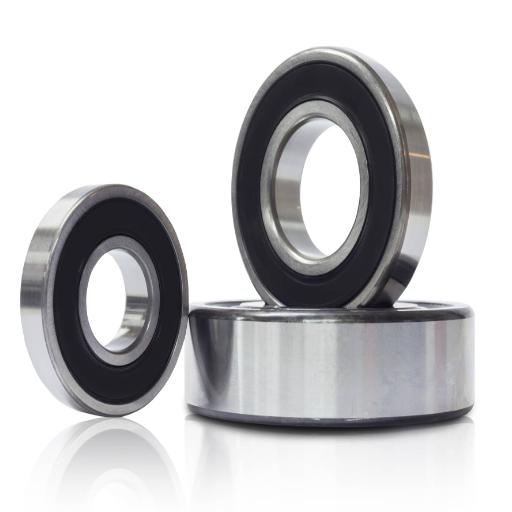

The wheel bearings allow the car’s wheels to turn while bearing the car’s weight. These parts may break down as they are used over time, resulting in inefficiency, weird sounds, and even potentially dangerous driving. A broken wheel bearing can also be diagnosed relatively quickly, and doing so can save minutes and costs and prevent future destruction. This article discusses the causes of a bad wheel bearing, how to reach a diagnosis, and how to treat this bad “condition” to prevent any further damage to the vehicle. Whether you are an experienced automotive technician or a car owner striving to gain knowledge, the details provided here will make your ride much easier and safer.

What Are the Common Symptoms of a Bad Bearing?

How to Identify Vibrations in the Steering Wheel

Steering wheel vibrations can worsen a vehicle’s ability to move, which is one of the first signs of wheel-bearing issues. Although the car seems to accelerate well while driving, the vibrations appear more aggressive the faster the vehicle travels. This phenomenon occurs when a faulty wheel bearing leads to uneven rotation, which results in friction and mildly disrupts the car’s functionality.

If dealing with vibrations due to the wheel bearing, consider checking for the following reasons to confirm your suspicion:

Speed-Dependent Feedback: Examine whether the vibrations increase with speed. The vibration related to the wheel bearings is often witnessed in the range of 40-50 mph (64-80 km/h), allowing the peaks to occur only during highway use.

Noise Accompaniment: Physical movement is not the only thing to watch out for. When vibrations occur, noise emitted from the wheel may be constant throughout the car’s rotation. It is not uncommon for this to accompany the car’s rotation, and if it does, consider it a sign of wear and tear or damage in the internal bearing.

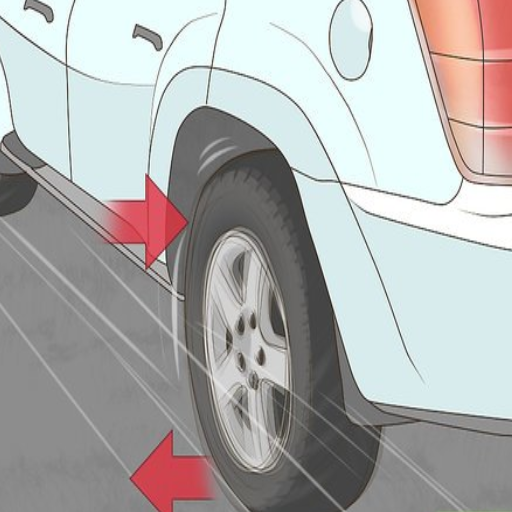

Lateral Play in the Wheels: Checking manually is also feasible, so you should grab the wheel and move it side by side. It is important to note that if there is more than the tolerable limit of 0.005 inches, internal mud buildup might occur, resulting in instability in the bearing and the mechanism.

Heat Buildup: An unusual amount of heat buildup can occur around the wheel due to wear and tear during driving. This is not a good sign, as friction will lead to heat generation, making the wheel warmer than usual.

N’hi ha per tant motius per la qual, escodrinats aquests símptomes i paràmetres, és possible detectar i posteriorment prendre acció per a garantir l’operativitat del vehicle en el cas de sentir vibracions en el volante que serien originades per un rodamientos deteriorat.

Recognizing Humming Noise and Growl

Noises like humming, tried-wheeling, or growling turning into noises tend to be associated with a defective wheel bearing. It is normal for these sounds to get louder with increasing speed. These greats may differ when there is a load change and the steering wheel’s direction. The measures to be taken into consideration are:

Noise Frequency and Fast Speed Coordination: As drives rotate at an increased speed, the bearing starts forming a load that grows as pitch increases. This can be mistaken for mechanical issues such as engine or tire noise.

Directionality Sensitive of Sound: The loud, irritating sound of burning off a tire tends to concentrate more when the car turns while driving. For example, a still-turning vehicle with a noisy right turning suggests the tire may be permanently damaged.

Some Key Measure:

- Decibels measurement: While boring conversations usually range between 70 and 90 dB, this noise also appears to be caused by a defective tire—or bearing, in this case.

- Using the right measuring tools: Who would have thought that shaking caused by a bearing defect could be measured using accelerometers? The best part is if they exceed 4.5 mm/s RMS, they are abnormal if they don’t on the standard drive.

Keeping a close eye on the last few lines, paired with using tools to assist with the measures taken, can help accelerate diagnosing and fixing the problem regarding the faulty wire bearing.

Detecting Loose Steering Wheel Issues

If the steering wheel is loose, the steering parts or even the steering system is damaged. This could affect the steering design and the vehicle’s overall safety. To pinpoint a diagnosis, include checking one of the following factors:

Excessive Lever Movement: Check the range of movement of the steering wheel; movement shouldn’t exceed 1 inch or 1.5 inches. Anything more extraordinary indicates that the steering mechanism might be loose.

Excessive Lever Components: Confirm that the column joints, universal joints, or other connections connecting the gear to the column are intact. Otherwise, the thinker pieces would encounter friction during steering action, causing the loosening to move along.

Ball Joints: Abnormal steering can also be pinpointed due to the ball joints. Usually, pin dimensions greater than 0.5mm interfere with the steering.

Power Steering: Aim to examine if the steering operates in low values, steering can be unresponsive without the right amount of psi which ranges from 800-1200.

Alginement: Check value for camber, caster and toe in case it was discovered that any abnormality existed, if none are found.

It is crucial to consider factors other than the above when making the above alterations. When those telescopic measures are redressed, steering struggles should ideally end.

How to Tell Which Wheel Bearing Is Bad?

Steps to Diagnose a Bad Wheel Bearing

If the steering wheel is loose, the steering parts or even the steering system is damaged. This could affect the steering design and the vehicle’s overall safety. To pinpoint diagnosis include checking one of the following factors:

Excessive Lever Movement: Ensure to check the range of movement of the steering wheel, movement shouldn’t outweigh 1 in or 1.5 inch, reason being anything more excellent signifies that steering mechanism might be loose.

Excessive Lever Components: Confirm that the column joints, universal joints, or other connections connecting the gear to the column are intact. Otherwise, the thinker pieces would encounter friction during steering action, causing the loosening to move along.

Ball Joints: steering abnormally can also be pinpoint due to the ball joints, usually pin dimensions greater than 0.5mm interfere with the steering.

Power Steering: Aim to examine if the steering operates in low values, steering can be unresponsive without the right amount of psi which ranges from 800-1200.

Alginement: Check value for camber, caster and toe in case it was discovered that any abnormality existed, if none are found.

Considering the above alterations, considering factors other than the above is crucial. When those telescopic measures are redressed, struggles with steering should ideally end.

Checking for Worn Bearings and Axle Problems

The first thing I do when checking for worn bearings and axle problems is evaluate systems and specific components’ condition. Specifically, I ascertain what other systems and components are out of the ordinary. I try to figure out if a bearing is failing in such cases. In my case, this would include noises while turning the vehicle, such as grinding or humming. Moreover, suppose I understand that some vibrations travel through the steering wheel or the truck’s body. In that case, I tend to move on to the inspection of the axle and its components, as it may imply that there is wear that may be excessive or may indicate that it has a misalignment.

I also check the wheel’s movement by raising the car and attempting to shake the wheel. Any noticeable play here would be out of the acceptable range, mostly less than 0.005 inches or 0.13 mm on most vehicles, so this would be abnormal. Besides, I use a torque wrench to avoid deviations regarding lug nut and axle nut tensions from the manufacturer’s instructions, as a side effect of incorrect torque will be a premature failure.

For cars with ABS that have warning signals, I get the specific codes that are useful in diagnosis and the computer-aided diagnostic scanning devices. The codes enable technicians to determine whether the problem is with the sensor or wheel bearing. In reporting the directions of the cut-outs, new tools, and old ones are put together, so axle and bearing mechanics deal with troubleshooting quite well.

Methods to Shake the Wheel for Detection

To efficiently identify any abnormal indications involving the axle or wheel bearing, I first take a jack, elevate the automobile, and then put it onto robust jack stands. When the wheel is off the ground, I grab it at the 12 o’clock and 6 o’clock positions and try to rock it about those two points. Too much clearance in this direction usually means the bearings are worn out or the axle assembly is loose.

Further, when I am grasping the wheel at the 9 o’clock and 3 o’clock positions, I also try to repeat the entire procedure, checking to see if there is any additional movement or yaw motion, jerks, and weird sounds that might suggest the possibility of a problem with the tie rod or other steering components. I allow slight movement during these tests, from 0.002 to 0.010 inches. Anything larger than this requires me to conduct more in-depth examinations.

Finally, I have confirmed what I have already suspected visually. A dial indicator can determine bearing play, as many manufacturers indicate that the face movement must not exceed a pre-determined value of 0.005 inches. This is to confirm the diagnosis conforms with the desired criteria to prevent misinterpretation of acceptable limits. Add all these together and get an efficient wheel and axle system inspection method.

When Is It Time to Replace a Bad Wheel Bearing?

Recognizing Signs of a Bad Wheel Bearing

Vehicle safety and performance need to discern details that could show a bad wheel bearing. From my experience, there are many signs, such as hearing the wheel region grinding, humming, or growling sounds, significantly when accelerating, decelerating, or turning, which I can attribute to increased friction in the troublesome bearing.

Other indicators include a shaky steering wheel, which causes slight vibrations that tend to worsen over speeds and indicate poor structural support, and the loss of heating in the wheel hub region, which is caused by reduced lubrication due to failed bearings. Another one to consider is tire wear, which could be linked to bad wheel bearings but can also result from suspension or alignment issues.

When viewed technically, the bearings that seem to wear down have a set tolerance by the manufacturer, which would allow for excess play of no more than 0.005 inches, and anything exceeding the limit would be grounds for replacement. This negligence can cause the wheel assembly components to sustain damage, such as the axle or suspension components, which could impinge on many safety aspects. Such parameters, combined with the physical observations, are the reason for accurate decisions and resolutions.

Evaluating Wheel Bearing Noise and Brake Performance

For noise evaluation of a wheel bearing, I assess for the presence of rhythmic grinding or hum that appears to be changing with the speed and direction of the vehicle, with special emphasis on the orbiting forces. Such is indeed the case of a deteriorating bearing. To ensure, I subsequently check whether there are differences in the stationary and rotating noise for straight pull and turning pull, considering a load stroke on one side may worsen the condition.

For the performance of brakes, I look at whether there is any jerk or kick felt during the application through the brake pedal, which may result from too much play in the wheel bearing. I apply pressure and measure the amount of bearing play, ensuring that it does not exceed a specific range provided by the manufacturers, and this usually does not exceed 0.005 inches. If the tolerances are more than this, there are possibilities of inconsistent contact of the rotors, thus meaning that braking will not be as effective as required or safe.

This, in turn, implies that the problem should be systematically approached, with strict parameters complying with the outlined symptoms, so that issues with wheel bearings can be identified without compromising the functionality of the brakes.

What Causes Wheel Bearings to Go Bad?

Understanding the Impact of Vibration and Hum

It’s worth mentioning that wheel bearing issues, be it vibration or humming noise, often result from a passing phase, such as neglect, wear, installation issues, or contamination. The moment there is an issue with a bearing, it will invariably cause damage to the components located internally, such as tools that roll or the raceway, which then has the bi-functional bearing to rugged damage, leading to overall variation amongst the wear patterns of the outer and the inner parts of the bearing. Additionally, the distorted parts will now vibrate and produce a humming sound that can be heard faintly but more noticeably in case of faster driving or making turns putting weight on a vehicle.

From a technical point of view, vibration measures run and radial play within the bearing assembly. Depending on the manufacturer’s design and specs, radial play ordinary standard tolerances lie between .0002 and .0010 inches. Correspondingly, the runout should be less than .001 inches since its values are higher than the ones mentioned. This tends to suggest awkward component fitting that results in deformation and still causes the humming sound.

Routine practices, such as proper installation to prevent contamination or lubrication, are worth considering to negate such issues. If ignored for an extended period, these issues can cause immense damage to a vehicle; for example, they can lead to an onslaught on a hub or spindle that eventually degrades a vehicle’s overall safety and performance.

Exploring the Role of Wheel Hub and Axle Wear

The vehicle’s wheels also help the carrot wrap around the weather-resilient tires. However, the wear of the wheel hub and axle is a major contributor to ensuring vehicle safety and performance. As the tires shred during rotation, wear is a common outcome caused by inadequate lubrication, contaminants, and mechanical stress caused by the vehicle’s operation. The axle and Wheel hub wear can be so extreme that it starts loosening the bolt or creating abnormal sounds.

A manufacturer focuses on creating a hub structure on its principle. The upper and lower limits of wear and tear must be defined when creating a hub. Any tolerances other than those described could lead to the bending or deformation of the hub, which is not desirable. For instance, If I tell you that the hub bore diameter exceeds 0.005 inches, allow a loose fit of the bearing assembly, which loosens the grip or causes vibration when rotating a vehicle with tires attached to its hub. Axles should also have a set upper and lower tolerance of runout, which generally is not more than 0.002 inches.

Not replacing the axle or wear and tear components in time causes a loss of structural integrity to the entire vehicle components. Also, proper maintenance procedures must be followed to increase the service life of the wheel hubs and vehicles. Ignoring the seals for contamination while ensuring that high-quality lubrication is added to the car also puts the driver’s vehicle’s life at risk, as the wheel and hub rotation may shred the entire structure of the vehicle while increasing the risk factor 10-fold. Not maintaining these parameters also comes with a price that may lead to loss of the steering performance and even operator safety, which is undesirable.

How Can You Prevent Bad Wheel Bearing Symptoms?

Maintenance Tips for Front Wheel Bearings

Regular inspection: Every once in a while, pay attention to the wheels to see if there is any audible noise or unusual vibration. If there are some sharpening or humming sounds at certain speeds, it suffices to say there is some form of bearing wear or damage. This identification permits swift and timely action.

Proper lubrication: Always use grease appropriate to the temperature and load conditions and is of good quality. Also, the bearings must be well-lubricated to reduce heat and friction. Use lubricants with an operating temperature of minus 40 F to 300 F or minus 40 C to 149 C for optimum performance.

Bearing tightening torque: The manufacturer’s recommended torque for the retaining nut must be used when installing or reassembling wheel bearings. A torque that is higher or lower than the optimal range will cause bearing and abnormal wear. Checking specific torque values in your vehicle’s service manual is a good idea.

Seal condition: Seals should be checked regularly to confirm that no balance contains grease leaking water or any other debris entering. Adequate seals are imperative to prevent bearing wear and tear or total damage.

Restrict your load limits: Also, keep in mind that your vehicle should not exceed the Rated Vehicle Weight (GVWR) as going beyond the limit will increase unnecessary stress on the bearings which will in turn speed up their degradation.

Replace Worn Bearings Promptly: Every piece of machinery has specific tolerances set by the manufacturer. Cross fingers! Life is complex and depends on a more extraordinary game. Imagine if accidental conditions destroyed everything. To put it another way, replacing parts is simple enough, so postpone it. Not replacing the item on time will cause damage to the hub or the axle assembly, thus making the routine maintenance rather pointless. If a specific radius is passed, barring an axial drift of less than 0.001 0.003 inches, replacement must be started immediately since bearing wear has exceeded the allowance.

These technical parameters contain a sizable amount of analysis, along with a set of maintenance practices that, if correctly followed, can substantially increase the service life of the front wheel, thus improving the vehicle’s reliability.

Professional Advice on Wheel Hub Assembly Care

I can suggest a few things that should help you maintain your wheel hub assembly properly and get the most out of it for a long time.

Greasing Standards: Correct greasing is essential. If I can select the grease, I will only use the one recommended for my vehicle based on its operating temperatures to avoid overheating. A typical NLGI 2 grease with a lithium complex base is perfect for most cars because it is thick enough and heat resistant.

Tightening Torque: I always use a torque wrench, even when refitting the wheel hub, to achieve the desired nut torque according to the manufacturer’s specifications. For instance, if the service manual says to torque the parts to 150 ft-lbs (203 Nm), I will do just that, not more or less. This is crucial as over- or under-tightening can cause problems for the entire assembly.

Check of Seal: Regular maintenance and inspection are crucial for checking for grease leaks and other external substances. Such parts also need to be changed if they are required to protect internal components from damage – in this case, I am referring to seal damage in my hub assembly as water and dirt getting through the seal will indicate its wear and problems.

Load Assistance: A key concern for me is load assistance under or at my GVWR; units supporting gear at max GVWR also get stressed, which increases wear and tear and leads to less-than-expected unit lifespans.

Wear Tolerance: During an inspection, if I notice any bearing play, I will settle for a measurement of such play using a dial indicator. Any tolerance greater than 0.001 – 0.003 inches will be the cause for concern. If any of it surpasses these prescribed limits, replacement wouldn’t be an option, as the bearings will have severe wear, resulting in malfunction of the axle assembly and causing safety concerns.

If I pay attention to these steps and the details outlined in the vehicle manual, I ensure my wheel hub assembly functions appropriately for a longer time. It’s all about maintenance and attention to detail!

Frequently Asked Questions (FAQs)

Q: What are some signs or indicators of a bad wheel bearing?

A: Wheel bearings perform several functions in a vehicle. Hence, standard indicators of a bad wheel bearing are unusual sounds such as rumbling, grinding, or squealing when the hub is rotating, especially while making turns or accelerating to higher speeds. Additionally, the driver will likely notice the ABS indicator light illuminating, vibrations on the steering wheel, or abnormal wear and tear patterns on the tires. These several symptoms suggest that the wheel hub’s steel balls or metallic rings part may no longer be functional or are about to fail.

Q: How do I go about diagnosing a bad wheel bearing?

A: The most straightforward way to examine an axle bearing is to jack the car up and shake the wheel from side to side. If the wheel moves, it can mean a wheel bearing is gone. You could also hear a grating sound by reaching for the wheel and rotating it. You should also listen to such noise while driving, for example, when the car turns left or right, or notice any strange noise that gets louder during a gradual speed increase.

Q: Are the tires on the car likely to be damaged if the wheel bearings are bad?

A: A failing wheel bearing can indeed (and often does) cause uneven tire wear and tear patterns. When a wheel bearing starts to wear out, it results in increased play in the wheel assembly, negatively impacting the vehicle’s alignment. This, in turn, creates an unequal distribution of force across the tire surface, resulting in uneven patterns of wear on a tire. This could eventually lead to an early retirement of the tire and harm the overall safety of the vehicle.

Q: What noise does a lousy wheel bearing make?

A: A malformed wheel bearing sometimes rattles like pieces rattling around inside the bearing. It can likewise produce a whining or grinding sound as the vehicle accelerates. The sound can also become louder when making a turn, which assists in determining how many bearings are at fail.

Q: Can hitting a pothole damage wheel bearings?

A: Yes, hitting a pothole can potentially damage wheel bearings. Potholes create sudden, higher loads on the wheel assembly, which can cause the bearing to become misaligned or damaged. Although bearings can withstand regular driving activities, severe conditions can lead to excessive unanticipated wear or collapse.

Q: How long can you drive with a bad wheel bearing?

A: The vehicle should not be operated for long distances with wheel bearings in an impoverished state. If the wheel bearing fails on you completely, you might be looking at some damage to the internal components of your car, which can be costly to repair. This is because while the vehicle is in operation, the failing wheel bearing can further damage suspension components and even increase the chances of an accident. Take it for inspection and get it rectified at the earliest possible.

Q: Do lousy wheel bearings affect the ABS?

A: Yes, a faulty wheel bearing could affect the ABS’s performance. The ABS sensor is housed in the wheel bearing assembly in most current vehicles. When the wheel bearing fails, the sensor may lose its ability to monitor the rotation of a wheel accurately. This might cause the ABS light on the dashboard to illuminate and reduce the effectiveness of the ABS.

Q: Is there a point at which one would say enough is enough with the wheel bearings and replace them?

A: There is no time guide for replacing wheel bearings within the set period because it is based on several influences, including driving conditions, type of vehicle, and bearing quality. However, the lifespan of most wheel bearings is between 85,000 and 100,000 miles. A WSS should be included in fixed maintenance to ensure the bearings are not damaged.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8