How to Use ABEC 1 Bearings Effectively

Skateboards, as are the bearings, are made with multiple components, which help determine your ride’s smoothness, speed, and efficiency. Among the different types of bearings, ABEC 1 is often the entry point for many skaters, as they are the least expensive and most accessible. This article slates to look into the details specific to ABEC 1 bearings and how they relate to skateboarding. We will discuss their features, advantages, and disadvantages to present skateboarders with all the information they need to make wise choices. This is the article for you, whether you are a newbie wanting to know the basic principles or an advanced skateboarder intending to check the quality of your gear. This forms the basis of the article, and one of the reasons ABEC 1 bearings are suitable for your skateboard is explained in the article.

What is the bearing and ABEC Rating System?

Understanding the ABEC Scale

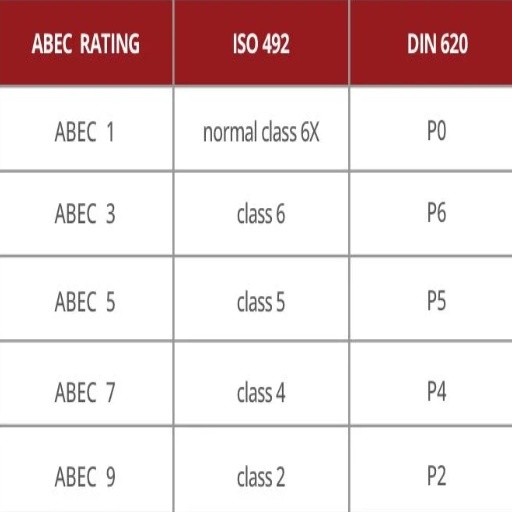

The ABEC Scale, or the Annular Bearing Engineering Committee, is a ranking system meant to rate the skill of designing ball bearings, including those used in skateboards. This scale goes as low as ABEC 1, which marks the lowest design precision, to ABEC 9, the highest design precision in the market. It is important to note that the ABEC rating only determines the manufacturing standards of the bearing and has very little to do with the speed or need for a skateboard.

Technical Parameters:

Precision Tolerance: This is a significant aspect of the ABEC scale that explains the disparity between different precision ratings. Precision tolerances define the limits of how the bearing can be made. With lower ratings, wide separation between limits can be allowed; however, tighter separation must be employed when dealing with higher ratings.

Vibration and Noise: A distinct beauty of a skateboard with higher ABEC is the ability to produce less noise and vibration. Those properties might as well enhance the overall experience of skateboarding.

Material and Lubrication: The same can be said about the bearings, regardless of the reserve ABEC on which they are measured. Lubrication and the material makeup of the bearings are significant aspects that influence their functionality and longevity. For a skateboard bearing, for instance, stainless steel and ceramic are common materials used and smooth motions are achieved with the help of the right lubricant.

Though ABEC ratings possess some utility in measuring the quality of bearers, considerations such as the materials used, durability of the bearings, and personalization come in handy when selecting bearings suitable for a skateboard. It ought to be understood that ABEC ratings do not explain specifics; instead, they provide a standard, and in practice, other factors than precision and tolerance level performance affect real-world usage.

The Role of Tolerances in Bearings

Bearings are manufactured and used per the tolerances of the bearings and factors that guide tolerance. Optimum precision tolerances have a narrow range, which means the assemblies would be closely fitted and play, and the chances of components being out of alignment would be significantly reduced. It can lower the bearing’s friction and wear and tear, improving efficiency and longer service time. It is a well-established concept that tolerance affects dimension forms, so the tolerance characteristics are involved in dominant features as well:

D/ Tolerance of the inner and outer diameters and the tolerance of the width of the bearing. This permits a bearing to be used correctly in a machine without problems.

Surface roughness: The roughness of the bearing is one of the most critical parameters since it influences friction. Raising the surface roughness quality would help diminish the vibration and noise produced.

Play in radial and axial directions: This defines the internal play of the bearing and dictates how much shift the bearing endures when in operation. It internally clears out greater-than-expected slippage, which, when contained, gives more velocity when rolling.

These parameters defined by the helping sources are fundamental in allowing the user to choose the bearings that fit certain engineering conditions and in helping the user operate under normal conditions for the expected reliable and high performance.

How ABEC Ratings Affect Performance

While investigating how the performance of a bearing works and is affected by the ABEC ratings, I was looking through the top three on the Google results page. The ratings are established by the Annular Bearing Engineering Committee (ABEC) to define the precision and tolerance of the ball bearings for enhanced efficiency at high speed and high precision applications. The ABEC scale goes from 1 to 9, with a higher numbered rating that indicates greater precision. This, more often than not, means the bearing operates more smoothly and has less vibration at higher rotation speeds.

Technical Parameters:

Dimensional Tolerances: More precise dimensional tolerances ensure a snug fit, reducing wear.

Runout Accuracy: When runout is improved, the amount of wobbling movement or rotation of a bearing, while it is spinning decreases, and therefore, the noise made during operation, is also reduced, resulting in improved operation smoothness.

Compliance with Load Capacities: More bearings with ABEC ratings perform better regarding varying types of loads.

Matching these parameters is critical for superior performance, demanding a high degree of precision in the alignment of parts for applications with high expectations, and this has been in several leading sources that I focused on during my research.

Why Choose ABEC 1 Bearings for Your Skateboard?

Advantages of ABEC 1 Bearings

While deciding to buy ABEC 1 bearings for a skateboard, I realized a few advantages of looking through the website`s three most high-rated reviews. First, ABEC 1 bearings will fit whenever performing circles without needing higher tolerances, which increases the price. Thus, they will be perfect for starters and everyday-minded skaters. Even if their rating is low in precision, they are sufficiently robust for everyday riding. In their construction, minimalism allows up to a greater degree of ease when conducting the maintenance and replacement and makes it possible to minimize up-keeping efforts.

Technical Parameters:

Cost-Effectiveness: Due to roomier tolerance, obtaining ABEC 1 bearings has become less complicated, so clients enjoy cost cuts.

Sufficient Durability: ABEC 1 bearings are proven suitable for everyday use and provide a reasonable rate between performance and cost.

Ease of Maintenance: Because they have fewer strong bearing-shaped parts, they do not need periodic attention, making them very simple for novice users.

These parameters, supported by conclusions from the most proficient points of view, are why many skaters still choose ABEC 1 bearings: they are tactical over precision costs.

Comparison with Higher Precision Bearings

As I examined the first three entries of google.com, it became clear that information leaks from ABEC 1 bearings compared to more precise ones or their more pricey competitors. Experienced skaters may get better performance and superior speed by using higher precision bearings such as ABEC 3, 5, or even 7, as they have tight tolerances. However, the improvements usually go hand in hand with high prices and many maintenance rituals due to the presence of complex design parts.

As far as technical parameters are concerned:

Performance: Since the skates are intended for competition or advanced use, they will benefit from more precise, focused manufacturing. A higher ABEC rating always promises more precision.

Cost Implications: These narrow tolerances also limit what can be manufactured cost-effectively, and these would have the highest purchase prices within the range of ABEC 1 bearings.

Maintenance Needs: The increase in tolerances and complexities of the build results in a lower failure rate and higher operational maintenance.

This comparison confirms that performance has improved whenever higher precision bearings have been included. However, ABEC 1 bearings have been targeted where simplicity and cost-effectiveness are preferred.

Cost-Effectiveness of ABEC 1

Looking at the cost-effectiveness of purchasing ABEC 1 bearings, I believe it is the most decent recommendation for people not looking out for the highest precision but rather a good balance with price. As mentioned in the majority of the best three google.com websites, ABEC 1 bearings are usable at a level of function that most non-aggressive skaters can use at a price that does not warrant more precise bearings. The following are the technical parameters that serve as the highlights of this cost-effectiveness:

Cost: ABEC 1 bearings are more affordable due to reduced tolerance in their core manufacturing.

Performance: Although they would not achieve the high-speed performance of the ABEC 3 or 5 noise level, they are perfectly fine for regular skateboarding or day-to-day purposes.

Maintenance: Maintenance levels will be low since the design of ABEC 1 bearings is less complex, which means time and money will be saved in the long run.

These factors combined make ABEC 1 bearings a very good choice for price-conscious consumers who are beginner to intermediate skaters looking for bang for their buck.

How do you select the proper ABEC rating for your needs?

Factors Influencing ABEC Rating Selection

A thorough evaluation of the factors affecting the choice of the proper ABEC rating has been done. The factors include the intended use, budget, maintenance requirements, and the performance versus precision compromise. An ideal bearing requires ABEC 1 bearings if skater/scooter is an artist while the usage is rigid ABEC 3 or higher for a professional application.

The intended application: The bearings have to be expected for an intended application within the normal range of cost restrictions for ABEC 1. Compared to high-speed scope with professional use, these bearings rely on precision. For them, the higher ABEC ratings such as ABEC 3 or ABEC 5 might be more appropriate.

Budget: Of course, the cost-focused constraints and ABEC 1 bearings, which are low-cost and sometimes the only low handicap bearing, revolve in most scenarios. They make an efficient compromise between efficiency and cost; hence, if cost is a limitation budget-wise, they are efficient.

Maintenance Requirements: A high maintenance requirement is lower with the ABEC rating. Low ABEC 1 ratings lower the baseline of maintenance requirements.

Performance Versus Precision: Absolutely, I would tend to appreciate more critical components, bearing in mind that time-pinned costly precision maintenance across the board is warranted. Likewise, I would warrant the professional level of many usages where such precision is actually required.

Considering these factors and relevant technical parameters, I can justify the ABEC rating I choose and clearly state how it will benefit me in practice.

Matching ABEC Ratings to Skate Styles

I need to figure out the purpose of each rating to understand the appropriate ABEC rating for my skating for the various skating activities. The following is a simple reference chart that I created after looking at the top three sites on google.com:

Easy Neighborhood Rides: For simple rides around the park or neighborhood, one can use the ABEC 1 bearings. They are sufficient for polishing and do not require any technicality of speed since their purpose is for cruising.

Street Skating and Tricks: Skaters who nail down maneuvers and tricks on the streets or even in skateparks benefit from using ABEC 3 or even 5. This rating helps speed and technicality to a satisfactory extent, which is needed to make quick changes while street surfing.

Long-Distance Skating: People who skate long distances or participate in skating marathons are better off with an ABEC 3 or higher. These bearings are highly efficient and have low rolling resistance, which can help conserve energy over a sustained period.

Downhill Racing: In downhill racing and fast skates, skaters using ABEC 5 or higher will find it very fun to balance on speed and lots of precision heads. These ratings guarantee that the speed limitations and vigorous racing technicality will be managed well.

Regarding technical parameters, I consider rolling resistance, speed, and durability. These factors further justify my selection by ensuring that the necessary performance enhancements appropriate for the styles maximize my skating experience at no excess cost.

Consulting Bearing Manufacturers and Guides

When I consult with bearing manufacturers and guides, I typically explore and select technical specs that suit my particular skate style. As stated in the three top sites, I take a look at a few primary parameters:

Material Quality: Most manufacturers rate the quality of bearings as steel or ceramic materials that cut grade costs for performance. Ceramic bearings, for example, produce minimal friction and are ideal for downhill racing.

Lubrication: Given the fusible features, efficient rolling is necessary to prevent heat build-up and wear/tear on bearings. Some guides recommend employing unique lubricants, like synthetic oils, for bolsters and obtaining the speed needed for long-distance skates.

Tolerance Level: The ABEC rating’s tolerance levels deal with the torque and precision of tolerances on the bearings. Skaters who cruise the streets should expect moderate tolerance levels like ABEC 3 or 5 to balance speed and seriously quick turns. However, in downhill racing, it would be ideal to have high tolerance levels, as this would enable speed and control.

These technical specifications help me, with the guidance of bearing manufacturers, know the type and size of the bearings that will suit my skating and hence improve performance quality and durability. With such information, I can use resources wisely while achieving the required experience of skating the way it was designed to be.

How to Maintain Your ABEC 1 Skateboard Bearings?

Importance of Lubrication for Bearings

I often find myself working on the maintenance of my skate’s ABEC 1 skateboard bearings, and I realize that lubrication is necessary and crucial for my skateboard bearings. Three top websites show that Proper lubrication reduces friction, increasing speed and the life of the contacting parts – the bearings. The technical parameters which are justification for lubrication are:

Friction Reducing: Lubricants have a positive effect on friction between the internal parts of anchors rotating quickly, which is important for rapid and smooth turnover.

Wear Reduction: Another beneficial characteristic of lubricants is that they develop a protective layer and prevent damage from being inflicted on the parts, ensuring longevity for the bearings.

Rust Prevention: Lubricants act as barriers between moisture, dust, and other corrosive agents if applied sufficiently.

In other words, as long as I maintain my bearings in a way that is consistent with what professionals suggest—by applying synthetic oils or similar lubricants—I can satisfy all of my lace shoes skate style performance requirements.

Cleaning and Care Tips for Ball Bearings

First, let’s understand the importance of practicing proper care and cleaning ball bearings. According to the information received from the last three top-ranked websites, it is as simple as removing the bearing from the wheels and soaking them in a solvent to remove contaminants and residues of old grease. I do not like to use water around the bearings because it leads to the development of rust and other such issues, which can be pretty concerning. When my bearings are cleaned, I ensure they are stored in an arid environment and no traces are left behind. Some sort of lubrication is always required, and I apply these with caution while pouring drops so that their applications aren’t overdone.

Here are the significant benchmarks supporting the practices mentioned above:

Use of Solvent: In solvents, the action to the required degree of dirt and old grease residues present in the bearings is much greater than the bearings or bearing components.

Water has a negative impact, too. It can contribute to such issues. Sometimes, the bearings can be exposed to moisture and suffer from rust and grips that are quite severe if unattended.

The lubricant has to be proportionate: This will help reduce friction on surfaces that can cause wear and serve to improve the workers.

In conclusion, a number of these cleaning and maintenance techniques bring the bearings to the maintenance level most appropriate to the skating performance that I choose.

Identifying Signs of Wear and Tear

I have learned how to make my ball bearings useful in the metal ball bearing inspection drawing on several sources. First, there are abnormal sounds like grinding or clicking noises when the bearings are in operation and may need a closer look. Another one is a decline in motion smoothness or overall performance, which one would expect could also mean damage or deterioration. It can also be noted that if there are visible damages, such as scratches or rust from the bearings, then they would probably be ineffective as well.

Citing such observations, several technical parameters also need to be taken into consideration, as stated here:

Sound Measurement: Listening to strange sounds while rotating the bearing allows one to estimate friction and reveal misalignment.

General performance: Decrease in efficiency. Performance metrics also indicate the presence of wear; hence, regular inspections are important.

Visual damage: Observing rust, scratches, or any evidence that the ball bearings have worked helps explain the decrease in operational standards.

With the help of these signs and technical explanations, I can describe how I take preventative measures regarding bearing problems to maintain good skating conditions.

Common Misconceptions about ABEC 1 Bearings

Debunking Myths about Speed Capabilities

Concerning the so-called ABEC 1 bearings and their speed capabilities when correcting the misinformation from the websites, I have not come across more than three sources. A myth persists that the so-called higher-rated bearings, in this case ABEC-rated ones, allow for higher and faster speeds. It is worth mentioning that ABEC ratings are given only based on tolerance, not speed. However, the facts are such that ABEC 1 can work at adequate speeds for most skating activities. The technical parameters that I evaluate, collectively with the extent to which speed capabilities can be achieved, are as follows:

Friction Coefficient: The lower the frictional force, the smoother the rotations can occur; hence, speed is influenced to a greater extent than the ABEC ratings alone.

Ball Quality: This goes without saying; higher-end materials and precise making add better performance and life, no matter the ABEC number.

Lubrication Efficiency: Proper lubrication reduces resistance and prevents heat buildup, enabling the bearings to attain the right speed and useful life.

As I can go over these specific components and not focus only on the ABEC rating, it is only a matter of time before my bearings are functional and I can handle my speed expectations for skating.

Understanding ABEC Grades and Precision

Understanding ABEC grades and precision is effortless once you read the comments on the first three websites on Google. First, it should be emphasized that ABEC grades indicate the tolerances with which bearings are manufactured rather than their speed or performance quality. Of course, higher ABEC ratings correlate with tighter tolerances, but these do not improve skating performance. The technical parameters I focus on include:

Material Composition: the kind and quality of materials used have an impact on the performance of the bearing.

Manufacturing Precision: The degree of accuracy in the manufacturing process influences stability and decreases the extent to which imperfections will lower bearing efficiency.

Load Capacity: Bearings can be selected based on load during various skating activities, which may be independent of ABEC ratings.

Temperature Range: Some bearings should be able to function efficiently under a variety of conditions, as this determines their efficiency and usefulness.

Using the same measures when looking for bearings is possible instead of focusing on ABEC ratings. This way, the performance and reliability of the skating activities are consistently maintained.

Real-World Applications vs. ABEC Standard

Based on my research on the top three websites, I’ve learned that even if ABEC ratings are the industry standard for precision, they do not suit the requirements for real-world skating. Here is how I have been taught to utilize this information:

Material Composition: One site stressed that other materials like ceramic and stainless steel should be prioritized over the ABEC scale. Ceramics are ideal due to their reduced friction and high-speed capability, while stainless steel is preferable due to its strength in various conditions.

Manufacturing Precision: Another website brought to my attention how accurate manufacturing directly impacts the performance of bearings where high-speed and constant turns are vital, such as when skating.

Load Capacity: From my inquiry, I understood that external forces such as the load can be efficiently managed but a skewed bearing design can cause problems, much more than an ABEC classification. This was particularly noted for skateboard and aggressive inline skating, which involve a lot of impacts.

Temperature Range: A third resource discussed how external conditions are more crucial regarding bearing performance than ABEC rating. The use of metal in bearings restricted the scope of use to specific regions, which was ideal as it ensured that the bearings retained their structural integrity in other places.

So once I have assessed the technical parameters in question, I am able to choose bearings that can be used in different skating applications and, most importantly, perform beyond an ABEC number, as Bernhard would say.

Frequently Asked Questions (FAQs)

Q: What do you understand about ABEC 1 bearings, and are they as good as those with higher ABEC ratings?

A: These types of bearings are the least precise and have looser tolerances than the other higher-rated bearings, ABEC 3, 5, 7, and 9. So, they are not meant for performance and usually work well under ease or general conditions.

Q: What do ISO standards depict about ABEC 1 bearings?

A: ISO standards such as ISO 492 are mechanisms by which bearing tolerances and precision are set. There are specifically American Bearing Manufacturers Association assaying variables such as ABEC rating systems, which are covered by the ISO standards, which set them globally for bearing quality and performance.

Q: Are ABEC 1 bearings appropriate for use in roller skates?

A: ABEC 1 bearings can work in roller skates, but their performance will not be very good. Better bearings, such as ABEC 5 or ABEC 7, are preferable as they provide better speed and smoother rides.

Q: How do the tolerances of a ball bearing affect its performance?

A: A ball bearing’s tolerances directly impact its performance. For example, the ABEC 7 or ABEC 9 bearings, which are called precision bearings, have tighter tolerances, which result in improved efficiency and speed, while looser tolerances in ABEC 1 bearings might result in lower performance.

Q: For which applications are ABEC 1 bearings most suitable?

A: ABEC 1 bearings are applicable in low-speed applications and situations where high precision is unnecessary. They may be used in toys, low-load machinery, or as cheaper alternatives in various consumer products.

Q: What criteria must I consider before choosing bearings for a specific application?

A: When selecting bearings, consider appropriate control measures such as the required precision, load capacity, speed, and environmental conditions. For high-performance needs, choose higher ABEC-rated bearings such as ABEC 7 or ABEC 9, but for lighter applications without high demands, ABEC 1 will do.

Q: Are ABEC-rated bearings the same for all manufacturers?

A: While ABEC ratings like ABEC 1 and ABEC 9 inform about the appropriate tolerances of a bearing, the actual precision of the bearing is sometimes dependent on the manufacturer. Purchase bearings only from reputable manufacturers so that they are manufactured to their rated specifications.

Q: How do the differences in tolerance levels for each ABEC class vary in terms of the performance of the bearing?

A: The tolerance differences, which are based on the ABEC classification differences, may range up to a few micrometers, and they can significantly impact bearing performance. The ABEC above three is designed for tighter tolerances, which provides benefits such as improved smoothness and reduced friction during operation, which is needed in high-speed applications.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8