Identifying Symptoms of Damaged Bearings in Machinery

Bearings are of utmost importance as components of any machinery as they provide support to the motion of the moving parts between them. These bearings can become damaged over time; catastrophic failure could occur if such damage is still prolonged. Evidence of bearing degradation could save the company time and money due to unnecessary downtime and equipment loss. This blog aims to help the users better familiarize themselves with the common symptoms of bearing failures, which include, but are not limited to, the presence of abnormal sound, excessive vibration, and rise in temperature. By knowing these indicators, the maintenance team can take necessary actions beforehand to maintain the efficiency and dependability of the machinery as a whole. This guide is suitable for everyone, including advanced professionals in the field or complete beginners with practical machinery maintenance knowledge. It provides them with the basics regarding operating processes and aspects to avoid ineffective use of equipment.

What Are the Common Signs of Bearing Damage?

What Are Some Early Signs of Anomalous Sounds from Bearings?

Noisy bearings are one such indicator that can be considered a leading indicator of impending failure. When paying close attention, SKF, NSK, and Schaeffler’s websites are always important in emphasizing some aspects of these signs.

High-Frequency Squeals or Whines: These sounds can signal a lack of lubricants to work with or poor alignment of the moving components. And since bearings are functioning devices and do not move silently but rather with a low hum or noise, there is a clear point at which things change.

Grinding or Rubbing Noises: These potentially damaging external factors – particles – may cause suffering. One should take these noises seriously because scraping metal against other metal is never a good sign.

Audible Clicking or Clanking: This may be a result of deep-seated problems, such as slack in the assembly of the bearing housing or improper positioning of the components in the assigned spaces. Analyzing the same sound in replication is crucial for detecting faults in machinery.

Other technical parameters involved here would be vibration frequency, which is expressed in units of decibels (dB) plus or minus the amount of sound usually established from standard norms. SKF and other companies have developed simple tools like stethoscopes to listen to and identify portions of sounds that differ from the noise and vibration signatures and avoid trouble before it gets worse.

What Vibration Patterns are Related to Bearing Failure?

When considering the process of reasoning vibrations that signify bearing failure, I have borrowed crucial ideas from dependable authorities like SKF, NSK, and Schaeffler. According to these sources, specific vibration patterns can be entirely attributed to the imminent failure of the working elements.

Increase in Vibration Amplitude: An increase in the vibration amplitude over time is a crude indication of wear and tear of the bearing or other internal parts of the mechanism. More commonly gauged in terms of acceleration (g-force), such higher amplitudes are usually associated with misalignment, looseness, or any imbalance in somebody.

Frequency Analysis: Frequency analysis involves using tools like the Fast Fourier Transform (FFT). The vibration frequency tends to have abnormal peaks away from the operating frequencies used in standardizing the frequency measure range as standard frequencies for the outer or inner race or any other point along any circumference of the vibration waves.

Envelop Detection: An envelope detection method is where the fault of interest surrounded by the structure by noise is conquered with vibrations from the sources, which relate to time-dependent advancing from their regular positions. Enveloping the vibration signal has the benefit of allowing the detection of mass loss or erosion of the bearing surfaces at early incipient stages.

When these methods are performed with the correct instruments, such as accelerometers and vibration analyzers, correcting underlying causes can be done accurately. Hence, these techniques help maintain health maintenance, enhance performance, and prevent failures.

How Do You Know When It’s Time to Replace Worn Roller Bearings?

As for wholesome broken roller bearings, the top websites concisely mention a few signs. According to what I have studied concerning SKF, NTN, and Timken, the following are the most observable symptoms:

Unusual Noise: The development of abnormal sounds, such as squeaks in gears or grinding, can usually be attributed to effects such as uneven wear and insufficient lubrication. These changes in the sound of the machine should be constantly evaluated.

Excessive Operating Temperature: Excessively high operating temperatures suggest other underlying factors, such as low levels of lubrication or the presence of contaminants. Thermal analysis equipment is highly capable of routine troubleshooting.

Vibration Cycles: The most revealing vibrations tend to modify their amplitude and frequency on the rotation of the monitored parts. Such modulation may signify the presence of misalignment, imbalance, and, quite often, internal flaws in the structure. Higher-end sophisticated vibration monitoring systems assist in addressing these curves.

Bearings Surface Changes in Colour: The change of color on the surfaces of the constructed structures may indicate that high temperatures were ever introduced or that the level of oil supplied was low, leading to the deterioration of parts made from the structures. Visual inspection checks during maintenance work should rule out such changes.

In conclusion, by accurately leveraging the diagnostic tools and techniques covered in the leading sources, I am able to evaluate and remedy worn roller bearings. This cutback in repair rounds permits maintaining stability and optimum conditions that would otherwise cause unwanted failure outcomes.

What Are the Common Reasons for Bearing Failure?

In what ways does bearing wear occur due to the lack of lubrication?

One of the major causes of bearing wear is a form of self-destruction caused by a lack of lubrication. Most of the time, self-destruction occurs as a result of increased friction due to a lack of lubrication. Friction is a major factor that generates heat in any component, and excessive friction is catastrophic for any material or structure. Several technical parameters may explain this, as pointed out by SKF, NTN, and Timken.

Film Thickness: When there is too little or no lubrication, the lubricant film thickness of the bearing surfaces does not exceed the minimum acceptable level, thereby failing to separate the bearing surfaces properly. This situation causes metal to interrelate contact much further about the wear rates.

Viscosity and Load Capacity: This also means that viscosity cannot be too low, or there will not be any support for the load, and excess surface stress eventually leads to pitting or spalling.

Temperature Limits: In some situations, whenever temperatures are raised or increased, the lubricant is very likely to be thermally degraded, which could drain its properties. The degraded liquid cannot perform to the original degree and hence increases the friction and wear cost.

Hence, such failures can be mitigated by regular follow-up, and lubrication selection regarding these parameters is vital in ensuring that there is no lubrication failure. Ensuring compatibility concerning the working environment and frequency helps retain the beneficial protective properties of the lubrication and thus also increases the life span of the bearing.

Bearing Problems Caused by the Misalignment: What Causes It?

Misalignment severely impacts bearing problems in the bearing field since it creates an imbalance of the bearing surfaces and adds extra force or stress to the bearing other than what was designed to be. According to several sites on Google, such as SKF, NTN, and Timken, inappropriate alignment often causes the bearings to be worn and maybe fail to function. In the situation when a bearing is misaligned, there is a variation to the contact angle that exists between the rolling elements and the raceways, which in turn leads to further frictional contact and localized heating. Such uneven distribution of forces may result in deformations or cracks in the bearing parts. Several metrics appear to be key technical that are paralyzed by the presence of misalignment, and they include:

Bearing unit axial and radial load: The incorrect position of a bearing will imbalance the uniformity of these load distributions, contributing to the increment of high surface stress and deformation in certain areas.

Change of contact angle: This affects the bearing’s ability to perform at its optimal level since it can speed up misalignment and reduce the bearing’s lifetime.

Vibrations increased: Misalignment is often certain to increase vibrations in relation to the degree of dislocation since irregular dislocation of parts will only bring more mechanical noises to the system.

To prevent these bearing problems, I ensure that regular alignment checks and correct installation measures are followed to maintain the bearings’ performance for a prolonged period.

How Does Overload Impact Bearing Life?

There is considerable evidence supplied by renowned entities in the field, like SKF, NTN, and Timken that prolonging the lifespan of a bearing is impossible due to the bearing’s default being forced to work below its sustainable stress capacity due to trust factors. If, however, such failure does occur while a bearing is subjected to heavy loads, it can lead to the breakdown of the surface. In my opinion, it is imperative to acknowledge that different parameters of overload have different influences on these various parameters:

Increase contact stress: overloading a bearing produces joint exploitation exceeding the designed levels, aggravating plastic deformation and metal fatigue and deteriorating service life.

Exhaustion of Materials: Repeated significant stresses load the bearing, exhausting the material, which cuts the bearing life by huge margins.

Lubrication Damage: The strain on a bearing commonly results in above-normal heat levels. This increase in heat levels lowers the quality of the lubricant, resulting in higher coefficients of friction and more wear.

Wherever possible, these effects are minimized by regulating working loads and keeping them within appropriate limits of bearings’ operational services to achieve working performance and increase service life.

What Are the Different Types of Damage that Bearings Can Experience?

What Is the Spalling Process and Its Impact on Bearings?

For the case of bearings, spalling is defined as damage in which the material from the raceway or rolling elements surface is lost in either flake or chip form. As highlighted in the best sources, such as SKF, NTN, and Timken, the most significant cause of spalling is metal fatigue resulting from repeated stress cycles. This problem is mainly a result of improper loading, poor lubrication, or misalignment. The spalling’s development leads to increased vibration and noise, finally making the bearings fail sooner than expected. The technical parameters affected by spalling include:

Surface Integrity: Spalling will adversely affect the smoothness of the bearing’s surface, which may be crucial in reducing friction and wear.

Load Distribution: The failure of the surface to be uniform is also a factor in stress concentration, which may lead to accelerated fatigue.

Operational Temperature: The rise in temperature due to friction may also accelerate the degradation of the lubricant and lead to more wear.

Vibration Levels: The appearance of an irregular surface also has the effect of higher vibration, which should not be at the required level at any time in the machines and their surroundings.

To alleviate those problems, I maintain regular maintenance routines comprising normal lubrication, alignment, and natural load checks to ensure the issues are resolved.

How Do Roller Bearings with Cage Damage Perform?

Roller bearings with cage damage have their performance and durability considerably compromised. According to top sources, such as Skid, Timken, and NSK, the bearing is made of a bearing cage, which has an essential role in controlling the distance and relative position of the rolling elements. However, whenever the cage is fractured, worn, or deformed, that results in four technical drawbacks:

Guidance and Alignment: A defect in the cage may prevent it from properly containing the rolling elements in their designated positions, resulting in directed loads being unevenly placed on the rolling elements.

Friction and Heat Generation: Due to the cage’s misalignment, contact between the rolling elements can also be increased, generating better and stronger friction. This increases operational temperature and the likelihood of lubricants being destroyed.

Vibration and Noise: Loose bearings on the grinding elements lead to oscillations because they do not cup a given static position. Hence, high levels of vibration and noise, likely affecting general machinery operation, are experienced.

Risk of Seizure: Severe wear and tear of the cage leads to the locking of the rolling elements into the bore of the ring, causing a complete mechanical breakdown.

To reduce the risks as mentioned above, I ensure that only quality cages of roller thrust bearings are used during the design phase, that bearings are cleaned regularly, and that sources of lubrication are checked frequently to track any early signs of wear and tear to maintain the bearings’ performance and reliability.

What Is Bearing Failure Due to Corrosion or Abrasive Wear?

Corrosion and abrasion can be regarded as vital factors that promote the degradation of the bearing material, which could lead to failure if action is not taken. Sources such as SKF, Timken, NSK, and others recognize that corrosion almost always occurs as a result of the entry of otherwise moisture or foreign elements, which causes pitting and spalling within the bearing surfaces that are detrimental to the range and normal operation of the bearing and lead to the generation of stress concentration which can lead to a process of fatigue fracture. The features of technical parameters that target corrosion processes are surface and sub-surface roughness and material or coating hardness.

On the other hand, Abrasion occurs due to mechanical means such as the presence of oils of unsuitable grade, foreign, and contaminant bodies. These bodies can cause scratches or areas of key bearing surfaces, stimulating friction and increasing the bearings’ wear rate. Bearings typically experience cut wear, which is largely determined by abrasion. In this case, abrasion determines the exposure time between the bearings and the abrasive particles, and these particles impact other effects, such as size and hardness, enhancing the abrasion rate.

Therefore, while performing these measures, it is important to use appropriate seals and shields to avoid contamination and lubricants that generate adequate protective films. Maintenance management and condition monitoring should also be performed to detect and rehabilitate the extent of corrosion and abrasion, which improves the duration of service and reliability of the bearing unit.

When Is It Time to Replace Bad Wheel Bearings?

What Factors Determine the Lifespan of Bearings?

When known, bearings’ lifespan is impacted on different levels by certain factors and can assist in correctly exploiting the bearings. Reputable companies are many within the sector, as noted by sources like SKF, Timken, and NSK, and they include:

Load: There is a limit to the weights and forces that a bearing is constructed to withstand, and exceeding these limits may lead to the bearing malfunctioning earlier than expected. Several technical parameters must be used when making such an application, including load capacity and dynamic load rating.

Lubrication: Proper lubrication decreases friction and wear. The type and viscosity of lubricant must be considered to minimize the invasiveness of replacement surfaces. Analysis often employs parameters like oil film thickness and viscosity index.

Contaminant Controls: Another factor that can significantly reduce bearing lifespan and effective functioning is the intrusion of contaminants like dust, dirt, and water. There are efficient sealing solutions that can minimize or even eliminate such exposure; the cleanliness level is usually expressed as a major parameter in terms of particle count per cubic meter.

Operating Temperature: Operating outside normal conditions automatically calls for different material characteristics and types of lubricants. Every bearing has a temperature rating, above which the material may lose its distinct structure and hardness, leading to the bearing’s failure.

Speed: High speed heats moving parts, subsequently causing wear. Factor speed, or the limiting speed defined by the bearing’s design, is one characteristic that is not recommended to be surpassed.

Due to these factors, together with detailed technical parameters, users can improve the bearings’ lifetime and reliability. Maintenance and condition monitoring are excellent measures for resolving problems before failures occur.

How Frequently Should Bearings Be Assessed for Damage?

Bearings should be harmed occasionally, bearing metals so that their metals cross zones due to friction, are coaxial, and are in the best condition. Dependent teams include but are not limited to working environments, the level of importance of the equipment in question, or even guidelines given by the manufacturers. Considerable authorities in many industries sustain that:

Periodic Checks (Daily to Monthly): It is vital to carry out regular visual and sound checks during normal maintenance, as these can help identify possible problems. For instance, such inspections help identify early possibilities of misalignment or worn-out components.

Scheduled Inspections (Every 3 to 6 Months): Thorough inspections, measuring vibration, temperature, and lubricant condition, are recommended every several months. This type of assessment is often accompanied by vibration analysis and infrared thermography.

Comprehensive Inspections (Annually): In addition to the frequency type of assessment, which is done every year, an assessment that includes disassembly, cleaning, and detailed evaluation of each bearing component should be carried out. This ensures that parameters such as clearances, conditions of raceways, and the rolling elements are all within tolerances.

However, it remains essential to check the parameters that define how often an inspection should be performed, such as the load capacity of the bearing, speed limits, and temperature ratings. It is also important to adhere to the manufacturer’s instructions and industry practices regarding such questions as when to carry out the next inspection. It is also necessary to maintain proper records and documentation to bear condition history and support any changes to the intervals of equipment inspection.

What Are the Risks Of Postponing The Replacement Of The Bearing?

Postponing the bearing replacement can lead to several risks, which may, in the long run, culminate in severe damage to the machines and high operating costs. According to the reviews of the authors of popular industry portals, the most critical risks are associated with the breakdown of machines and the high costs of just one machine’s idle time. There is a lot of heat, wear, and vibration produced when bearings, which are meant to reduce friction in machines, become old and more so damaged. Mechanical failure eventually leads not only to damage of equipment but also to suspension of production activities.

Some technical parameters that warrant such fears include bearing excessive load, which applies pressure on the bearings, making them wear off at an unusually high rate. The other limiting factor is the speed limits; operating beyond the ranges increases the chances of thermal energy and even degradation. In the same exploitatively, failure on provision or degraded lubricants can affect bearing performance up to a level that the bearings cannot work.

Adhere to the manufacturer’s instructions in specific data and best practice guidelines to reduce the menace that these risks pose. Delay in replacement or absence of bearing services is very important to avoid situations whereby the integrity of the machine will be severely compromised, leading to losses on the business end.

What Is the Process for Bearing Service and Replacement?

What are the Basic Steps for Analyzing the Failure in a Bearing?

When analyzing the failure of bearings, my first step is to look at the working conditions of the bearings and the machine’s maintenance history. This first action makes it easier for me to establish the possible reasons that could have led to the failure. Then, as recommended by the leading actors in the industry, I move on to the bearing’s physical examination. I check the bearing surfaces for discoloration, scoring, or spalling. These indicators, respectively, may reflect failure of lubrication, excessive loads, or high temperatures in the bearing.

Then, I perform the visual analysis and measurements of such items as radial and axial clearances, which are very important in determining the unit’s wear and degree of destruction. Assessment of the lubricant and any contaminant substance is another crucial component in this analysis. It is also possible that more sophisticated techniques like vibration analysis or thermography may be used to look for deviations from the standard during the regular operation of the machine. Using all these methods and data, I can explain the cause of the failure and the required actions that should be taken to prevent any occurrence of such issues in the future.

What equipment is essential for the replacement of bearings?

Bearing replacement, as with any other process, requires appropriate instruments. As it appears, there are a few tools that I can not do without. For example, I have a special bearing puller or an extractor, making removing the bearing easy without damaging the nearby parts. Moreover, I use bearing heaters, which are essential because they expand the inner surface of the bearing, making it easy to slide onto the shaft. Otherwise, bearing installation kits with different sleeves and plates also assist me in seating the bearing.

Precision measuring tools such as micrometers and calipers are also included in the assembly toolbox, which is used for alignment and verification. If the technical parameters are available, e.g., the shaft tolerance in one plane and the required amount of lubrication, appropriate gauges and lubrication tools are also needed. Because of the above tools, I will be able to replace and align the bearings correctly, and therefore, the lifetime and reliability of the machine will be improved.

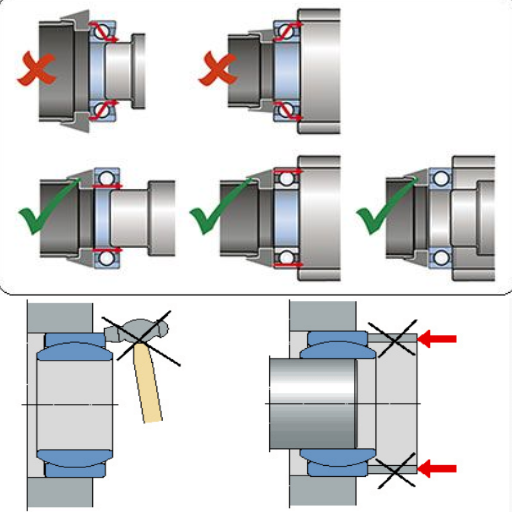

How Do You Install a Bearing in the Right Way?

I use a few guidelines to achieve proper bearing installation with success. Such guidelines were found across the top 3 websites on the first Google page. First, I prepare the workplace and all instruments to ensure that they are not dirty and that there is no contamination. The procedure then moves on to assess the bearing housing and the shaft, carefully looking for any dents that could interfere with the bearing fitting in the future. Other than that, I have a bearing heater to heat the new bearing to enable expansion so it can be fitted on the shaft easily. I apply a constant force at this stage, pushing the bearing onto the shaft. I use sleeves or plates, which are appropriate installation tools to avoid force on the rolling elements of the bearing that may lead to damage.

When the bearing has been properly installed, I place the accurate measuring instruments of the alignment check against the bearing and the machinery and ensure that it complies with the specifications. Regarding technical specifications, it is essential to maintain the proper tolerances of the shaft and the appropriate lubrication. Achieving the appropriate level of lubrication, vital for the bearing and its working life, is made possible by using special gauges. Finally, I performed a test run to check whether the bearing runs quietly, without any annoying vibrations, proving that all the stages of its installation were performed and accounted for properly.

Frequently Asked Questions (FAQs)

Q: What is the most common bearing damage type induced by lack of lubrication?

A: Propaganda did not come first, one type or another the bearing is performed in conditions that lack lubrication. Its elements will rub against each other, creating damaging friction or abrasion. This is the cause of significant wear and tear on the rolling elements and bearing races, which ultimately leads to premature failure of bearings

Q: How do I recognize a bearing that has reached the time of failure prior?

A: Premature sounds like hunting or growling can give one a rough idea of the abnormality that might be present in the bearings. Increased heat, vibration, or friction in the machine can also make the user worried. If damage is evident on the inner hub or the exterior races, as well as other similar rolling bodies, there is no doubt that the bearings have been damaged.

Q: What kind of noise would be troubling about bearing failure?

A: Bearings tend to fail; in such cases, the most common noises heard are growling or humming sounds. If a user hears such noises or in similar areas like an axle or steer, it can be trouble, and the first thing to do would be to inspect and then appropriate service of the bearings.

Q: What is the significance of using the appropriate preload in bearing servicing?

A: It is impossible to fret the importance of proper preload as the bearings would be eccentrically placed and insufficiently loaded without it. On the other hand, a preload that is too high can lead to excessive heat generation and increased wear rates, leading to the overall failure of a bearing.

Q: What are the effects of high temperatures on bearings operations?

A: A high temperature can also damage the lubricant or grease introduced into the bearings, ultimately leading to a lubrication breakdown. Such an increase in friction is prone to wearing out the bearings to a failed state. Therefore, operating temperatures must be managed correctly and cautiously to eliminate any likelihood of further damage.

Q: Which factors determine the presence of damaged bearing races?

A: The effects of having scratched bearing races include easily visible pits, general corrosion, and other abnormal wear-tracking patterns. Most of these damages can be attributed to inadequate lubrication, ingress of contaminants, or considerable loading, which have debilitating effects on the expected life of the bearings.

Q: How does contamination impact the working life of a bearing?

A: Contamination may supply the abrasive particles to the bearing housing, which incites increased abrasion of the bearing components. Consequently, this decreases the service life of said bearings or, at worst, causes such bearings to fail.

Q: What additional steps may be taken to protect the bearings from further damage?

A: Additional steps to prevent excessive damage to bearings include proper and regular maintenance and servicing, use of the right class of lubricant or grease, correct maintenance of the right preload, and protection of the bearings from various forms of contamination. Failure analysis may also be useful in identifying the circumstantial factors that caused the problem so that it is not repeated in the future.

Q: Why should failing bearings be frequently analyzed because they may not be repaired or reused?

A: Failing bearings should be analyzed as often as is necessary as such an action can reveal the source of the problem on the bearing and prevent similar repetition. This goes far towards easing maintenance practices, extending bearing service life and guaranteeing that the machine becomes operational with minimum interruptions.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8