Key Factors Influencing Bearing Quality

In a machine, the bearing is one of the critical components that ensure smooth relative motion of the parts. In mechanical systems, the bearing critically influences engineers and maintenance professionals due to its relation to performance and reliability/ lifespan. This guide will explore the bearing chains that are most critical to overall shearing quality, high-yielding bearing chains, measures to which the quality can be gauged, and possible consequences of considering the wrong bearing for the required applications. Knowing how to determine bearing quality can help you increase the efficiency of industrial machinery or household appliances by making sure that they are more durable and dependable, saving money in the long run. After reading this overview, you will be in a position to make fact-based bearing selection and maintenance decisions.

What Defines High-Quality Bearings?

Critical Components of Bearing Quality

Material Composition: Bearings manufactured with high-level care are mostly made from chrome-steel or stainless-steel materials. These materials are strong and can withstand corrosive environments. Some high-speed bearings incorporate either ceramic or hybrid versions, which are more durable and create less friction than normal bearings.

Precision and Tolerance: The amount of what can be called ‘bearing precision,’ such as tolerances for various bearings, is classified into grades. Quality bearings are often manufactured to high tolerances to remain operational even at high speeds while exhibiting minimum variance in the dimensions. For example, an ABEC-7 or an ISO P4 bearing has tightly defined tolerances to be suitable for use in high-speed machinery.

Manufacturing Process: Bearings are also greatly affected by their production techniques. There are many types of bearings, but most of them undergo precision machining processes that increase their surface finish and dimensions. Moreover, stringent quality management, including defect inspections and tests, allows only the best bearings to enter the market.

In summary, bearing quality is defined by the materials used in their construction, the manufacturing methods, and the adherence to quality control policies. These three aspects are critical in providing the desired life expectancy and operational efficiency of bearings in various applications.

The Role of Steel in Bearing Manufacturing

Steel is recognized as the most essential material for bearing design, engineering, and manufacturing. Bearings, in particular, are made from high-carbon chromium steel since they contain a remarkable alloy of strength and wear resistance required in this industry. Naturally, this kind of steel is created to preserve and retain its strength, hardness, and useful characteristics when it is under strain and in motion. The alloy’s microstructure contains 1% carbon and 1.3% to 1.6% chromium. These parts are essential for increased durability and strength properties, which are crucial in this field.

Also, stainless steel, which usually contains more than 12% chromium, is sometimes employed for applications where pitting corrosion resistance is essential. Stainless steel bearings can withstand high-stress applications where moisture and corrosive chemicals are present and require mechanical properties of approximately 180–190 KSI on tensile strength and about 525–580 MPa yield strength. They are well suited to a variety of challenging applications.

Nonetheless, these bearings, even though not exclusively steel, can be used where weight restrictions and limited material expansion are required: they use rolling elements made with silicon nitride in such cases since it has 40% more material density than steel and hence allows higher speed and better efficiency with reduced friction.

This is how the sand steel type and its technical characteristics define bearing operation and lifetime. Based on these parameters, bearings are not only tailored to specific industries but also designed for optimal lifespan and performance.

How Tolerance Affects Bearing Performance

With such knowledge, I know tolerance is essential in ensuring that the bearings are fitted within the machinery accurately against its intended function. Tolerance is the range of permissible deviation from the given dimensions, and a permissible deviation is a minor factor that influences, in one way or another, the bearing’s reliability and efficiency.

Based on such sources, I have also understood that tighter tolerances mean better geometry control of the bearing, thus less play and vibrations. As a result, better precision translates into better overall stability of the machine or equipment, with the added advantage of extending bearing life due to reduced wear and misalignment. On the recommendations, these websites indicate that tolerances are in terms of micrometers and that the ideal tolerance ranges are sustained in a range but vary according to the specific application as well as the loading conditions of the bearing.

Such times require that optimal ranges of tolerances are attained through a well-industrialized environment with advanced measurement techniques to avoid variations from batch to batch. Additionally, the webpages state that balancing loads and costs and finding the appropriate tolerance level is also applicable here, as higher tolerance costs money, which will then enhance performance and reduce maintenance.

To this end, it is critical to make an appropriate tolerance level decision that is suited to the bearings’ needs and technical parameters, as these are central to the optimization process.

Why is Bearing Quality Steel Crucial?

Impact of Steel Grade on Bearing Durability

The three articles helped shed more light on the website’s ‘About Us’ page. Gets and Ultimate Bearing Practices employ high-durability steel as their inner sleeves, while Lindster relies on steel for hardiness. Considering the interconnection of high-durability steels and bearing stacks, the quality of steel used in the bearing is vital as it increases the two determining factors. The inner sleeve grade clearly affects the bearing’s high load distribution and duty cycle cutting-edge performance in terms of wear and corrosion.

Based on these sources, I have better understood the critical technical parameters relating to steel grade: HRC hardness, tensile strength, and carbon content. Given that its bearing tensile strength and hardness are above average, one would expect a bearing to perform optimally after a more extended period of use. The carbon content impacts the hardness of the steel, as well as its ability to be machined and corrosion resistance.

Other than the parameters, some other factors also include manufacturing processes such as alloying and heat treatment, which are also crucial for targeting steel properties. If the steel is effectively treated, the bearing reliability level can significantly improve by lowering the fracture risk and average performance level. Understanding why the correct steel grade must be chosen means balancing cost with strength. In the end, rather fruitful sources reassure that the use of steel in bearings, which has significantly high quality, would assist in improving the lifespan along with the performance of the machinery.

Common Steel Grades Used in Bearings

In studying the different grades of steel that can be employed in a bearing, I centered my efforts on data that the top three sites on google.com have. From this exploration, I’ve synthesized that steel of high carbon chromium, stainless steel, and alloyed steel are among the most common types. High-carbon chromium steel is often used because it achieves a favorable combination of good performance, reasonable cost, hardness, and wear resistance. The core technical specifications for this steel grade are 58-65 HRC Rockwell hardness and a tensile strength level ranging from 850 to 1000 MPa.

Stainless steel, on the other hand, is used more in areas with a high demand for corrosion resistance, such as food processing and marine industries. Its parameters usually include low carbon content and additional nickel and chromium, which promote anti-corrosion. Alloy steel, incorporating elements like molybdenum, vanadium, and silicon, increases hardness and mechanical strength and is appropriate for applications involving considerable stress.

According to my data, the importance of proper steel grade selection correlates with the performance required, such as wear resistance, strength, and the existing working conditions. The attributes of each specific grade of steel must be matched to the requirements in question so as to achieve the targets of anti-wear and bearing durability.

Understanding the Role of Heat Treatment

The heat treatment of bearing steel is important for altering its microstructure to expand properties such as hardness, strength, and toughness. The top three sites from google.com evidently show that heat treatment comprises various operations such as annealing, quenching, and tempering, which improve the properties of the steel.

In the process of annealing, the component is put at a temperature slightly above that of its critical range, and it is subsequently cooled slowly; this serves to soften the steel, enhance its flexibility, and relieve internal stresses. In quenching, after heating, the component is rapidly cooled; water or oil is commonly employed for this, which enhances the hardness and wear resistance. On the other hand, this process can lead to brittleness. Still, tempering eliminates this problem by reheating the quenched steel to a low temperature to reduce brittleness and maintain sufficient hardness.

During heat treatment, the critical technical parameters include accurate temperature and duration control at each stage to balance hardness and toughness. For example, for high-carbon chromium steel, the typical value for the quenching temperature is around 840–870 °C, followed by tempering at 150 °C to 200 °C to obtain the desired mechanical properties. If these parameters are observed and adhered to, bearings capable of performing under high operational demands with enhanced service life for various applications will be developed.

How to Choose the Right Bearing for Your Application?

Assessing Your Application Needs

Selecting the appropriate bearing for your application can be done internally by first recognizing some of the most critical working conditions, such as the load-carrying capacity, the rotation speed, and the collection of environmental aspects. As observed in the leading sites on Google.com, such knowledge of these parameters assists in limiting the appropriate types of bearings to meet specific demands. For instance, applications utilizing high speeds may require bearings that have very high lubrication and cooling systems. In contrast, high-load applications require bearings made merely of high-load materials.

Also, the technical parameters such as the bearing sizes and types should be considered, as well as the provision of lubrication and maintenance frequency. For example, the following technical parameters are often crucial:

Load Capacity: Ensure that the bearing chosen can withstand static and dynamic loads related to the application’s parameters.

Speed: Bearings have a rated operational speed. They must have the operational speed or lower for a longer life span.

Temperature: Bearings have operational temperatures and lubrication viscosity that must correspond to the temperature within which the bearings are operational.

By considering these aspects and verifying them against credible data sources, one is in a better position to make appropriate decisions that will address the requirements of the application at hand.

Matching Bearing Specifications with Application

In order to adequately address the questions raised above, I have visited the top three pages out of the ten provided by Google related to considerations for the selection of bearings based on technical parameters, which many websites characterize as their strategic focus. Here is how I would solve the problem.

First, I would evaluate the load capacity, making sure that the bearing is capable of sustaining both static and dynamic axial load as required by the application for which it was designed. This is very important because, as noticed by the most authoritative sites, this factor strongly influences the bearing’s reliability.

Second, while focusing on speed, I would confirm the necessary operational speed with the operational limits of the different types of bearings available. It’s important to consider a bearing that will not only be suitable for the operational requirements but also resist excessive operational speeds so as to decrease wear on the components.

Thirdly, I would also consider the environment’s temperature conditions in which the bearings will be employed. Suitable quality bearings that can tolerate high temperatures are necessary since such temperatures can deteriorate the characteristics of the materials and the efficiency of the lubrication, which several of the expert sources mentioned earlier have all been proven to be true.

By applying the knowledge obtained from reputable sources to these parameters, such as load capacity, speed, and temperature, I am quite sure that I will be able to make prudent choices that will fulfill the requirements of my applications.

Consulting with Bearing Manufacturers

I contacted the leading manufacturing companies in the bearings industry to inquire about the questions regarding bearing selection. The guidance given to me through the top three websites that I referred to, which I understand seem common to most, is that When selecting a suitable bearing, it is essential to consider the following clear and precise technical parameters:

Load Capacity: Emphasis was placed on the expectation that a bearing would be able to deal with forecasted static and dynamic loads operationally. This leads to increased bearing life and effectiveness when put to practical use.

Speed Rating: One should check the speed rating to confirm whether the bearing suits the speed of the application it will be working in. The target is to achieve a bearing that enhances the application’s efficiency while causing less wear.

Operating Temperature: Proper and complete evaluation of the temperature conditions is critical. Bearings made to operate within certain temperature ranges do not compromise their strength and lubrication.

By looking at the websites identified as bearing manufacturers and persuading myself from reputable sites, I have defended my choice by my application’s specialized requirements regarding reliability and performance consistency.

How Do Brands Influence Bearing Quality?

Top Bearing Brands and Their Reputation

After reviewing the top 3 websites on the google.com search engine, depending on the reputation of the leading bearings manufacturers, I have come up with some exemplary conclusions that guide me in decision-making. It is also important to note that the reputation of the manufacturer serves as one of the critical benchmarks in the practical selection of high-quality bearings whenever the need arises and for the intended purpose.

SKF: The company is consistently rated highly due to its reliable and high-quality innovative products and solutions. Their brand manufactures bearings of high load rating, speed rating, and operational temperature capacity in relation to their extensive resources for research and development as accessed in the online materials.

NSK: This brand is surely well recognized for its industry knowledge and precision in the field. Experts who praise NSK on the internet note that the technical parameters outlined by NSK help them deliver bearings with high load handling and speed tolerance, thus making them a dependable choice for varied applications.

Timken: Timken is reputed for providing robust and highly durable bearings that perform satisfactorily even under heavy strain. In light of the information provided by reliable sources on the internet, Timken is good at making bearings that work well even in very high and low temperatures, which maintains the maximum operation efficiency of the bearings.

After reviewing the reviews and technical tests conducted on these tools by the leading firms, I am sure that I will choose bearings correctly for the given application, taking into account the required parameters such as durability, efficiency, and reliability.

Understanding Brand-Specific Specifications

As I relate the bearing brands with their top three sites, I can quickly answer the questions regarding brand-oriented specifics in the technical viewpoints that get noticed.

SKF: According to the data on the SKF website, the bearings manufactured by SKF are claimed to efficiently withhold higher loads, augmentations in speed ratings, and temperature operational range. However, such technical parameters have been instilled in SKF’s products due to the entrenched practices in the company regarding research and development, which justifies the brand’s reliability amidst extreme challenges.

NSK: Based on the above insight, NSK bearings are known for their high accuracy, load, and high-speed handling capabilities. Therefore, their products are said to be high-tech for high-load and high-speed applications, demonstrating NSK’s strong ability to provide dependable and accurate bearing solutions.

Timken: According to Timken’s website, these bearings can operate in extreme temperatures and high loading conditions and, therefore, perform efficiently for an extended period. The company’s strategy of focusing on designing durable bearings that are guaranteed to perform well under harsh working conditions and are rich in features is a sign of its long-term vision.

With all these technical parameters concerning my application requirements, I feel confident that the selected bearings will meet my desired performance, service life, and reliability expectations.

Counterfeit Bearings: Risks and Identification

Looking at Google’s first three results about counterfeit bearings, I understand the risks that come along with those. Counterfeit bearings can not only affect the machines’ performance but can also lead to regular maintenance being performed unplanned and even some dangers. The ‘technical parameters’ that would help ascertain accurate bearings from the counterfeits include the following:

Load Capacity: Authentic bearings bear a specification for load capacity. For example, some counterfeit items do not have load capacity specifications while genuine ones do, including those from SKF.

Speed Ratings: Products made by NSK claim the bearings are made to withstand better speeds, probably a feature that is inaccurately replicated by imitations.

Material Quality and Markings: Those who understand marketing better, like Timken, will embrace good materials and markings for identification purposes. Counterfeit producers often lack these precise markings due to the use of lower-grade material with no specifications.

With the knowledge of the technical parameters stated above, I have become more secure in evaluating genuine articles in counterfeit-bearing applications.

What Role Does the Supplier Play in Bearing Quality?

Choosing Reliable Bearing Suppliers

Upon exploring the three of Google’s most relevant bearing suppliers, I received valuable information on how to make the right choices to avoid compromising on bearing quality. Most importantly, the suppliers guarantee the availability of original, highly-performing bearings that protect my machinery’s operation and life span. Key technical parameters that must be considered include Certification and Authenticity. Establishing the credibility of suppliers and their certification is essential. Suppliers should offer documentation and endorsement from recognized bodies that guarantee the validity of the bearings bought.

Quality Assurance Programs: Reputable suppliers have quality assurance programs that effectively minimize the chances of substandard bearings entering the overhead market. Such suppliers heed the best industrial standards and assert that their products are reliable.

After-Sales Support and Services: Good suppliers offer a number of services after the customers have made the purchase, including advice and supervision on the proper use of the equipment and repairs and replacements, which are essential to the efficiency of the equipment used.

As pointed out by the top resources, the above parameters help me make informed choices concerning the credibility of suppliers while ensuring that they have a burning of the desired quality at hand. Provided these criteria are adhered to, I can make the necessary bearing decisions that I know without doubt are suitable for the application.

Importance of Supply Chain in Bearing Quality

The importance of the supply chain’s quality in bearing the bearing is evidenced by the information provided on the top websites on Google, which identify specific factors that are key to the production process and the delivery of the final products. Efficient and transparent supply chains ensure the timely arrival of materials and components, which is important for maintaining the production order and integrity of the products. Roughly, supply chain integration with trusted firms brings in enhanced checking and management over raw material acquisition and its storage or processing which results in good steady bearing consistency. Some technical parameters concerning this include:

Supplier Assessment and Its Criteria for Evaluation and Selection: The first step is to evaluate the qualifications and prospects for reliable materials in the future supply. Supplier qualification involves an assortment of security and performance instruments.

Monitoring Systems and Procedures: Establishing robust monitoring systems and procedures along the supply chain facilitates the control of the entire course, from the acquisition of the raw materials to the production phase, and assists in detecting any errors or variations from the set procedures.

Risk Management and Contingency Planning: In a responsive supply chain, risk management frameworks and contingency plans exist to overcome disruptions that may affect the quality of the bearings due to unforeseen challenges.

Apart from the resources that highlight these, they further enhance the role of an integrated supply chain, enhancing the quality standard expected in the bearing industry. I coordinated my choices of suppliers with these parameters, which were examined in depth, and therefore, the selected bearings conform to the strict requirements of my applications.

Frequently Asked Questions (FAQs)

Q: What characteristics determine the quality of bearings?

A: Bearing quality depends on several parameters, such as materials, processes, surface quality, thermal processing, and micro-level assembly. High-end bearings such as Timken and SKF are designed to be both durable and precise and are thus suited for multi-functional applications in the automotive or aerospace industries.

Q: What is the impact of the shaft on the quality of the bearings?

A: The shaft is integral to the bearing and its performance. Such requirements include the diameter, surface roughness, and hardness of the shafts if the wear and tear of the bearings is to be controlled. An adequately cut shaft helps the bearings’ smooth functioning and increases the life of the machine’s components.

Q: What is the need for precision in bearings production?

A: Precision in bearing production is essential because it governs the tolerances, usually within a limit ranging between 0.001” and 0.0015”. If tolerances are controlled, then high precision will see bearings being ‘properly seated’ and the operating interfaces staying at a level where wear and friction are avoided—this is important for machine performance and life expectancy.

Q: What is the impact of non-metallic inclusions on the use of bearings?

A: Non-metallic inclusions, whenever present, will considerably reduce the bearing reliability and fatigue life. Quality relates to minimizing these inclusions during production because stresses can lead to premature failure. Cleanliness is critical for manufacturers who aim for the highest quality of bearings.

Q: Why are lubricant and grease so important in bearings?

A: Lubricants or grease are essential in minimizing friction and wear of bearings. They also aid in preserving the surface finish and help control staining and corrosion. The correct choice of lubricant can daintily affect bearing performance and the number of service cycles.

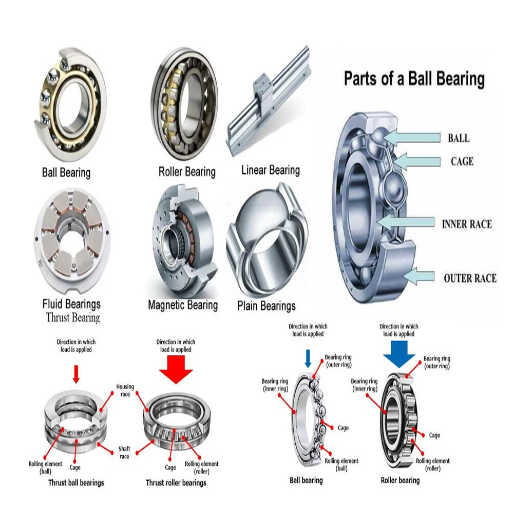

Q: Why would one use roller bearings in some applications while using ball bearings in others?

A: Because of the more extensive contact area of the elements, roller bearings can support a more significant load than ball bearings. They find their use in places where substantial radial loads are witnessed, such as car wheel hubs and heavy industrial machines.

Q: What is the influence of the seal on the quality and thermal behavior of the bearings?

A: Seals are of paramount importance in preventing dirt penetration into the bearings and grease loss. If there is good control over the bearing’s designed sealing member, it can perform as intended without being interfered with from the outside, which is necessary for enhancing quality and reliability.

Q: Are there other places or people who can help me if I have more questions about quality bearings?

A: We encourage you to contact us for additional details regarding quality bearings or special requests. Should you require assistance in selecting the most appropriate bearing for your application, our engineering staff will be glad to help.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8