Key Factors on What Causes Engine Bearing Failure

When it comes to automotive engineering, it is necessary to note that the condition and capabilities of the engine are influenced by the way its parts work. One such element is the rod bearing, which assists the connecting rods during combustion as they are put under high loading during this phase. However, rod bearing failure is one of the problems many engine builders face, and if it is not resolved quickly, it may lead to catastrophic engine failure. The focus of this article is to discuss the most prevalent reasons for the failure of rod bearings in detail and help the readers comprehend the reasons for such failures along with the ways out of them. By examining inadequate lubrication, contamination, improper installation, and excessive loads on engines, this blog serves to understand how to prevent any damage to an engine and prolong its usability. Whether you are an avid fan of cars or a car repair specialist, these basic concepts will help you provide preventive measures for engine bearing failure.

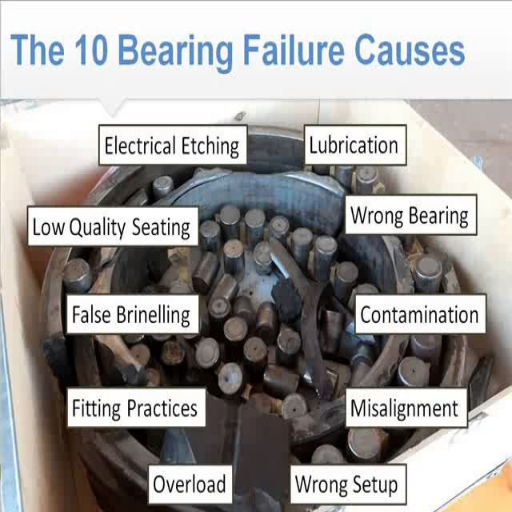

What Are the Common Causes of Bearing Failure?

What Can Happen in the Absence of Adequate Lubrication?

Inadequate lubrication is an essential element in premature rod-bearing failure mechanisms. Most engines incorporate oil-lubricated rod bearings instead of plain bearings, which, when they do not receive grease, would work less efficiently as a shock absorber between moving parts. This leads to higher heat, friction, and wear levels of the bearings. As time passes, these will likely lead to bearing failure, seizing the bearing and bringing it to a halt. Most authorities assert in their literature that proper lubrication reduces non-rotating portions’ motion only, thus removing most of the heat induced inside the engine during running conditions.

These technical parameters are frequently termed when correct lubrication is done:

Viscosity index (VI): This indicates the change in viscosity in the oil price about temperature. High VI oils can provide lubrication over a wide span of temperatures.

Oil pressure: Proper oil pressure is vital in ensuring that the lubricant enters even the most difficult-to-reach parts. Low oil pressure can result from some factors and directly serves the rod bearings, making them vulnerable to friction and wear.

Oil flow rate: This considers the volume of oil moving in a circulating system over time. Bearings depend on proper flow rates for lubrication, and there is no substitute when the flow rates are low.

To avoid rod bearing failure, which can occur from under lubrication, it is recommended that the vessel’s fluid levels and quality be regularly monitored, the recommended types of oils be used, and an oil pump be in good working order to circulate the fluid well.

Why Does Contamination Affect Bearing Surfaces?

Contaminated lubricants are the second reason for rod bearing failure, as they influence bearing quality and surface performance. Engine oil is polluted with heavy particles and dirt while working, which goes over the bearing surfaces, causing wear. This action causes scratches and grooves that cause bearings to wear, preventing the smooth running of the bearings. When contaminants are suspended in oil, the oil is known to become dirty, which leads to increased wear of the internal oil-wetted parts.

Technical Parameters

Any Damage on Bearings Due to Any Rubble or Particles: The damage on the bearing is partly related to the size, type, and nature of foreign material that has been introduced. Oil type: Particle Size and Type: The damage caused to bearings is partially determined by the size and type of contaminants. More extensive and harder particles tend to cause more significant wear.

Oil Viscosity: Oil with an inappropriate viscosity may fail to maintain an adequate oil film thickness, causing the consequences of contamination to increase dramatically.

Surface Roughness: Such high levels of contamination lead to increased bearing surfaces Ra, which in turn leads to poor bearing performance.

These findings stress the need for regular oil changes and careful replacement of damaged filters to prevent contaminated bearings from entering the engine, thus ensuring that the bearing’s performance is not compromised and the engine’s longevity is increased.

Why is bearing misalignment a contributor to bearing premature failure?

Bearing misalignment is one of the contributing factors to premature bearing failure since it leads to inappropriate load application across the bearing surfaces. Babbitt Metals, however, showed that some forces move the outer layer of the bearing warp when such sloping contact is present, which should be avoided, causing such forces to be too high. There are common reasons for misalignment, for example, careless alignment, shaft bending, or machine deformation.

Technical Parameters:

Angular Misalignment: Even a minor angular offset can exacerbate the stress concentration and the stress failure analysis of this misalignment.

Load Distribution: In some instances, the misalignment changes the entire bearing load’s size and rotation, with some forces acting on a smaller portion.

Vibration Levels: The mechanical axial vibrational displacement caused by the equipment’s geometral misalignment intensifies the wear of the machine surface, which may create damaging vibration modes in the machine components.

Great authorities on this subject agree that bearing alignment is essential. They further safeguard proper installation steps and routine examination and maintenance services to reduce such problems to the lowest reasonable level and ensure that the bearings are used effectively for the period they were designed for.

How Does Lubrication Failure Impact Engine Bearings?

What Are the Signs of Improper Lubrication?

As I gathered insights from the top resources online, I noticed that signs of improper lubrication are evident through several indicators. The factors that I have noted to be the most frequent are the presence of excessive friction and heat within the engine, which accelerates the wear inside the bearing surfaces. Another reminder of the pity of its users is that the engines may be making funny noises like grinding and knocking, for there is a lack of adequate lubrication. Quite a number of the bearing surfaces are subjected to periodic examinations, at times bearing discoloration or wear due to heat over the bearing, which is clear that there was not enough lubricant, may be observed. With these observations, some parameters do fall into place as follows:

Oil Viscosity: Either too low or too high a viscosity level leads to under or over-lubrication, which is fundamental in metal-to-metal contact avoidance.

Operating Temperature: The population of operational temperature may increase, but this is dangerous since it aggravates the chances of the lubricant failing, whose heat may help build hot spots inside the bearings.

Contamination Levels: There are also levels that are exceeded, such as water entry into lubrication or contaminates within it. This will only cause the lubricant to be ineffective and, therefore, damage it.

Oil Flow Rate: Decreased oil means that the wear surfaces have minimal or low coverage. Therefore, lubrication is minimal, and excessive frictional heat favors the wear and tear of the parts.

These signs need to be learned and tackled effectively to avoid marked deterioration of the bearing, which can influence engine efficiency and performance.

How to Prevent Lubrication Failure in Engines?

To prevent engine lubrication failure, aspects like maintenance schedules, choice of lubricant, and other operational parameters must be routinely done. First, safely keep every schedule in the engine maintenance program table so that there are no delays in serving the engine oil/engine filter change. To encourage this idea, regular oil changes are encouraged to provide proper performance of deodorizing oil, which degrades due to contaminants.

The right lubricant has to be selected; use your engine oil in accordance with its viscosity grade ability and the additional composition of the oil. These things are crucial in assuring that there is a lubricative layer between the metals, hence minimizing their wear and friction.

sumAzure Sumarma Key Technical Parameters assess the amount of hydraulic and mechanical penetrations. Another parameter for oil maintenance is levels of appropriate oil viscosity, assuring that there is a lubrication film to prevent metal-to-metal contact interaction. Remember to control operational temperatures to detect any abnormal temperature-ups as they can signify lubrication failure. In addition, oil degradation tests should also be regularly performed to avoid some similar contaminants like water/particles entering and affecting the oil. Finally, it is prudent to maintain the correct oil flow rate across all engine parts to ensure that each part will receive sufficient lubrication.

Upholding all these practices can retain engine reliability by blending the three activities of routine maintenance, appropriate lubricant choice, and technical parameters monitoring, which can improve the engine’s future performance and lifetime.

Why is the oil pressure lower than the average level?

By browsing the first three sites on google.com, I found a few possibilities for an oil pressure drop. First, an insufficient Oil person cannot have normal pressure because it can undergo lubricating oil. Low oil levels thus greatly impact pressure buoy. Also, many cite oil pump failure as a significant factor, especially when rolling over oil; there will be an appropriate decline in pressure. Another reason is insufficient oil pressure due to the increased clearance between the surfaces caused by worn bearings.

An oil pressure gauge is used under most working conditions, so oil viscosity is also a factor to watch out for in this case. This plays a vital role since oil may close up, blocking pressure. The oil pressure gauge with these mechanisms showed it had these aspects since oil is moved mechanically up and down with some.’s insights insight C D argue for more outstanding and active regular maintenance and vigilance. The above factors that prevent oil pressure problems need not be in high justification.

Why Do Bearings Fail Due to Excessive Loads?

How can Excessive Temperatures Lead to Bearing Failure?

As I researched the leading online sources on this topic, it was easy to see that internet search queries reveal that high temperature is a critical factor contributing to bearing failure. Let us consider how this happens with the operating temperatures of the bearings. High temperatures will result in degrading the lubricant that remains within the bearing, thereby reducing its efficiency in limiting friction between parts in motion. This degradation will, in turn, cause friction and more wear, which speeds up the wear and tear. Excessive heat may also cause thermal expansion of the gauged components so that the bearing components, such as the internal rings, backstops, and retaining rings, become improperly clearance or more undersized than required and cause crookedness, degrading, and de-operating the overall purpose of the bearing.

The critical technical parameters I noted include the following:

Lubricant Temperature: Keeping this within prescribed ranges is of utmost importance since high temperatures pose the risk of oxidation and emulsion breakdown of the grease/oil.

Surface Temperature: Excessive heat on the bearing surfaces increases the wear rates of the.. bearings and may cause deformation of the surfaces.

Ambient Temperature: It is necessary to monitor the outside heat, which influences the machinery’s operation. Extremely high ambient temperatures may increase the problem of internal temperature even more.

It is credentialed that excessive temperatures have negative effects on bearing performance and that output conditions should be controlled to the recommended level, as illustrated by these insights.

What Is the Role of Fatigue in Bearing Failure?

When researching the role of fatigue in bearing failure through the top websites on Google.com, I learned that fatigue is one factor contributing to the failures of bearings over time. Fatigue starts in the form of cracks which occur in the material as a result of repeated stress during the conversion process in the bearing, these cracks later develop as spalling on the surface of bearing. Such surface damage professionalism adversely affects the performance and reliability of bearings. The technical parameters having fatigue properties include Load cycles: The number of load cycles a bearing is subjected to is also significant in calculating the fatigue life. Regular assessment and control of bearing loading conditions will support usage in the optimal range for two failure modes and maximum fatigue resistance.

Material hardness: As a basic rule, the harder the material, the more resistant the bearing to fatigue failure in adverse cycles of loads.

Surface finish: An improved surface finish results in lower stresses when higher stress regions would lead to earlier fatigue failure than normal.

Such points stress the need to include fatigue as a parameter to consider while designing and maintaining bearing systems since stress and operational cycles should always be below the material’s endurance limit.

How Do High Speeds Affect Rod Bearings?

After researching how high speeds damage the top rod bearings on the top websites on Google.com, I found that the most significant damage to the N rod bearing occurs when it has high rotational speeds. The increasing speeds, in most cases, raise the working temperatures and may reduce the lubrication film in the bearing surfaces, leading to metal-to-metal-to-metal contact and wear. Also, at higher speeds, centrifugal actions can change the flow of the lubricant and thus its function in reducing frictional forces. Technical parameters related to the impacts of high speeds include the following:

Lubrication: Lubrication is one effective way to reduce the friction and heat produced during movement. At very high speeds, the amount of lubrication applied is insufficient, leading to excessive friction and wear that may cause a breakdown.

Material Composition: High-speed operations demand high-speed bailings made from materials that can withstand wear and excessive heat.

Clearance: There must be enough clearance between the two bearing surfaces to allow enough thermal expansion and proper lubrication at high speeds.

These conclusions underscore the need to consider aspects such as adequate lubrication, proper materials use, and avoiding incorrect clearance specifications in high-speed operations to increase the life and effectiveness of rod bearings.

What Is the Effect of Corrosion on Engine Bearings?

Where and How Does Corrosion Occur in Bearings?

In trying to figure out how corrosion takes place in the engine bearing, after consulting the first three websites of google.com, I discovered that most of the corrosion is caused by contact with moisture, acid, and other pollutants in the engine atmosphere. Moisture ingress may increase rust formation. On the other hand, acidic conditions may be caused by degraded any oils or fuels, which can also give rise to undesired reactions with bearing materials. Such reactions may create pitting or peeling/corroding damages to the component’s structures and surfaces, in this case, the bearings.

The aspects related to bearing corrosion due to the investigation of the technical parameters of the engine bearings include;

Environmental Exposure: Atmospheric moisture and contaminants within the engine area around the bearing may also promote corrosion of the bearing surfaces, as they may cause chemical reactions.

Lubrication Quality: Some oils contain anti-corrosive additives, which lower the rate of corrosion. However, when the lubricant oil is used, contaminated, or overheated, it prevents fundamental corrosive processes even though no apparent corrosion is observed.

Material Resistance: Circumventions made from components that are intrinsically less resistant to corrosion, such as corrosion-resistant alloys with protective coatings, are more effective in aggressive environments.

These things explain the importance of keeping the environment clean, proper operation of lubricating oils, and applying anti-corrosion materials to prevent corrosion of the engine bearings.

What Are the Consequences of Corrosion to Material of the Bearing?

I found this while considering the issue of corrosion on bearing material after reviewing the top three websites on Google.com. Corrosion can significantly damage the quality of engine-bearing performance over time. In some cases, corrosion may lead to loss of bearing surfaces, and consequently, more friction may occur. This can cause bearing failure and raise the cost required for maintenance and, in some cases, cause engine damage. Also, corroded bearings fail to operate correctly, which is signified by noise and vibration arising from the bearings.

The technical parameters that I found relevant with these constituents towards the end include:

Surface Wear: Surface wear and tear result from excess material loss in the bearing surface due to surface fatigue, which is also caused by wear and tear on other materials.

Strength Reduction: It is a shame that this vital mechanism becomes dammed by too many variables because it is revealed so early; thus, the complexity may increase and its efficacy reduced.

Lubricant Film Disruption: Corrosion or surface deterioration prevalent below the coating of the bearing shells may change the bearings’ physical appearance, reducing their lubrication potential by preventing the development of a constant lubricant film around them.

These results further confirm the necessity of mitigating corrosion and other weathering by implementing appropriate biomimetic interventions, such as privatizing propriety bolstering.

How Can Excessive Loads Lead to Rod Bearing Failure?

What Are The Reasons For Excessive Loads In Engines?

As a follow-up to this investigation, I analyzed the causes of excessive loads in engines, and based on the top three websites on Google.com, it appears that some reasons cause this situation. One of the primary reasons was the overloading of the engine, which can result from misuse or alterations that exceed that unit’s intended scope. There are also reasons related to maintenance activities where failure to perform the required services on the engine’s moving parts leads to dirt accumulation or inefficient oil supply, hence raising the heat and wear on the engine parts.

Another aspect is the incorrect relative positions of the elements. There are situations when crankshaft and connecting rod alignment don’t take place, which results in a malformed distribution of stresses, hence loading bearings axially and circumferentially more than the allowable axial loads. Also, poor quality fuels or an inadequate fuel-to-air ratio may create situations whereby combustion procedures are not effective, and this causes extra stress on bearings and other engine components.

The technical parameters involved include:

Load Rating: The Load Rating is the maximum load the engine can expect to operate satisfactorily without risk of mechanical failure from overloading.

Regularity Classification the Precision of Elements Assembly: The regularity consists of the following aspects of assembling different elements to achieve vertical alignment.

Lubrication Powers and Operating Conditions: Lubricants can reduce frictional force and protect parts from undue wear and tear.

Burning Quality of the Fuel Air Mixture: This refers to the extent to which the fuel-air mixture is consumed in combustion in an engine during its operation.

This calls for compliance with the guidelines provided by the manufacturers of these engines and necessary attention to the engines to avoid undue loads that may lead to damage.

How Can You Inspect for Excessive Loads?

Investigating whether an engine has excessive loads means that I first have to ensure that there is no engine overloading under consideration. This consists of verifying the specifications given by manufacturers regarding the permissible loading of their engines and the existing work on the engine in question. Another factor of concern includes components that may not be well aligned within the engine; in this regard, I look out for crankshaft and connecting rod alignment and wear and other similar attributes. The engine’s strength is also regularly checked through sampling the oil contents in the engine; stress levels are also managed by ensuring sufficient lubricants within the system to prevent overheating the moving parts. In addition, combustion should also be considered suitable, from its efficiency to the fuel quality and the fuel-air ratio, to limit the risks of partial fuel combustion. The technical parameters I think during the inspection include:

Load Capacity: Ensure the engine is not being put under pressures that are more than it can withstand.

Geometric Precision: Ensuring that different parts of the engine are geometrically straight to avoid straining of certain parts of the engine.

Lubrication Sufficiency: ensuring that lubricating materials are in sufficient quantity and effective in controlling heat through friction.

Combustion Efficiency: Determining the combustion of the fuel-air mixture to prevent undue burden on the engine parts.

In tackling these factors, I intend to identify and correct the deficiencies that can cause elevated loads on the engine, thus improving performance and durability.

Frequently Asked Questions (FAQs)

Q: What are the primary reasons for the failure of the engine bearing?

A: There are many causes of engine bearing failure, such as lack of lubrication, introduction of foreign material, improper bearing fit, overheating, etc. There is no such problem if the oil is regularly replaced and the fitting oil is used.

Q: How does such a condition of overheating lead to engine bearing failure?

A: System overheating may lead to degradation of the lubricant and increase the friction between two moving parts, causing early wear of the bearings and potentially culminating in catastrophic failure if not addressed in time.

Q: Low oil level is never a cause for engine bearing failure. True or false?

A: Yes, it is true that a low oil level can exaggerate the loss of lubricant. This may have adverse effects on bearings, causing them to be overheated and exposed to wear, and in some instances, failure. Making it a point to check the oil level regularly is very important to the health of the engine.

Q: In which way does the crankshaft contribute to the bearing failure?

A: The crankshaft is handled and supported by engine bearings, and therefore, wrong bearing alignment or worn bearings can lead to uneven bearing wear with vibrations, which in turn may cause bearing failure. It is necessary to position and support the crankshaft adequately.

Q: What role do contaminants play in the bearing interdisciplinary failure?

A: Dust, including dirt and particles of metals, are also sucked in through the oil system covering all the bearings in the engine, which increases their wear. Using high-quality oil filters goes a long way in ensuring that contaminants are captured.

Q: How does bearing clearance influence engine bearing failure?

A: If the bearing rotary clearance is not correct, it may hamper the flow of oil, leading to excessive friction. This friction will, in turn, overheat the system and cause wear at an early stage. It is necessary to guarantee that the bearing clearance does not exceed what is recommended; it might rather sit.

Q: Lubricants: Is repairing or changing used lubricants frequently necessary?

A: Frequent oil changes can clear built-up contaminants, replace bad lubricant, and lubricate moving parts of the engine with less risk of bearing failure, increasing the lifespan of the entire engine.

Q: How does the installation of the bearing affect engine bearing failure?

A: Any improper installation, like the bearings not being correctly aligned or the right bearing crush not being achieved, can cause tear and wear, overheating, and grievance defects. Generally, the manufacturer’s recommendations are to be adhered to during installation.

Q: Cause bearing failure due to malfunctioning liquid pump?

A: Yes, the liquid pump cannot adequately supply oil to properly lubricate the bearings, which can cause them to run hot and eventually fail due to a lack of proper lubrication. Therefore, the liquid pump should be serviced from time to time.

Q: What should I do if I hear a knocking sound in my engine?

A: In such cases, the knocking sound can be attributed to various problems, including engine bearing failure. The engine must be examined and diagnosed by professionals to make any necessary repairs and save other parts from further failure.