Key Features of Anti-Friction Bearing in Modern Engineering

Due to their outstanding usefulness, anti-friction bearings will always be permanently embedded in engineering designs. These bearings improve productivity, increase the life of the machines, and reduce maintenance costs, making them very important in numerous fields. This paper presents the essential characteristics of anti-friction bearings, including their design and performance and improvements that make it possible to use these components more purposefully. The importance of these bearings in the application is evident in every possible sphere, from automotive construction to industrial heat exchanger machines. As we investigate their various aspects, we will focus on the role of anti-friction bearings in contemporary engineering problems and the further developments that can occur in this area.

What is an Anti-Friction Bearing, and How Does It Work?

Understanding the Basics of Anti-Friction Bearings

You can contact the administrator if you need further support with this issue or topic: [insert email]. Cycloidal reduction gears are efficient power transmission devices in which the rotational input, given through a motor by a rotating inertia disc, is transmitted to gears in cycloidal motion. Cycloidal gearing is used primarily for reducing gears. It includes a stationary external gear, cycloidal pin, cam, and orbiting drum eccentric, which imparts rotary motion to the external gear through centrifugal force.

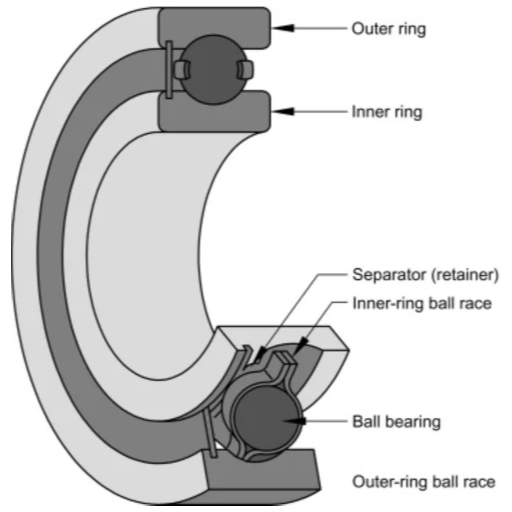

These elements are held in position by hollow knights, which also accommodate the rolling elements of the bearing. The most critical technical specifications of rolling element bearings are axial load bearing capacity denoted by static load and dynamic load ratings, the material of bearings (steel alloys, ceramics, plastic), and bearing accuracy classification, usually referred to as ABEC or ISO standards. In addition, the speed rating shows the maximum allowable speed at which the bearing will continue to operate satisfactorily without failure, and this parameter is essential in determining the suitability of the bearing.

These bearings are primarily used for carrying thrust and radial loads as these types are more versatile in several applications. Their selection is based on different considerations such as load, speed, and expected wear, which show the cost-effectiveness and performance toward the best performance of the equipment. Therefore, it is crucial for people working in the engineering and technical spheres to grasp these issues since the development aims to embed innovative materials and lubrication technologies into the design of bearings, enhancing their performance and reliability.

How Anti-Friction Bearings Reduce Friction

Anti-friction bearings use their structural design by employing rolling components that keep moving surfaces separated from actual physical contact as much as possible. Some of the main facts can be taken from the leading sources, SKF, Timken, and NTN Beari. Even these components are expected to be able to change sliding into rolling friction, which is much lower in terms of resistance than the frictional range. Thus, energy loss and wearing are lowered.

Key Technical Parameters:

Dynamic and Static Load Ratings: These ratings determine the bearings’ load-carrying capacity. One rating worth noting is the dynamic load rating because it defines how long the bearing will last during rotational operations. The static load rating indicates the minimum load that can be applied to a bearing in a non-rotating condition without any permanent variation in the shape of the bearing.

Material Composition: When selecting particular bearing construction elements, suppliers and manufacturers focus on steel grades or polymers with optimal heat capacity, impact durability, and heat resistance because this is the only way to ensure reliability during operation in different conditions.

Bearing Precision Standards: Bearings are manufactured in precisions like ISO or ABEC, and people specify or request the levels of specifications. Bearings of higher precision grade perform better than those of lower grade, especially in high-speed operations, because close tolerances and fewer vibrations are developed in such bearings.

Speed Rating: Speed rating generally indicates the speed range of the bearing. Moreover, speed rating assists its functional maintenance. For example, if a bearing is rated for a certain speed range, then safe rotation at such a range will not produce too much heat or cause failure.

Smart lubrication and materials technology present an advanced approach to furthering wear-and-tear minimization by providing longer intervals between servicing and lifting loads on the bearings more efficiently. In this way, with the incorporation of the engineering mentioned above, design features, and advancements, anti-friction bearings can provide superior performances in many branches of industry.

The Role of Rolling Elements in Bearing Design

During my research on the top three websites on the role of rolling elements in bearing design, I concluded that these components are essential in reducing friction between two surfaces and enabling the smooth movement of those surfaces. They are of various kinds, such as balls, cylinders, and needles, and assist in even spreading loads over the different surfaces of a bearing. They facilitate the turning and provide proper support in various situations.

For the sake of comprehension, just let us try giving justification for why these elements are indeed so critical as regards the mentioned features:

Dynamic and Static Load Ratings: The load ratings that must be met cannot be achieved without rolling elements. Due to their form, they fall under verified structures and linings for dynamic and static loads.

Material Composition: Rolling elements are practical because they use quality materials, usually ceramic or stainless steel. These materials are highly durable and help maintain efficiency even when subjected to very high stress and temperature levels.

Bearing Precision Standards: The precision manufacturing of rolling element precision affects bearing precision. The tighter the tolerance of the rolling element, the less vibration the bearing will be and the more efficient it will be.

To summarize the findings, the rolling elements’ design and quality play significant roles in the overall performance of the bearing design engineering and bearing dynamics in functional applications.

Types of Anti-Friction Bearings and Their Applications

Exploring Ball Bearings and Their Uses

While assessing the top three sites that deal with ball bearings and giving reviews of their uses, I realized why they are so famous – they serve the purpose of loading coupled with low rotational skidding. Given the research done, my focus here will be some brief answers in light of the technical parameters touching on edges:

Load Ratings: The device’s abuse means that the ball bearings help carry loads that can be in a moving or stationary position in the case modes of operation. The normal spherical shape of the balls usually helps in the even distribution of the loads. Such constructions are significant in places with rotative elements without overheating or wear and tear.

Material Composition: From my research, it is clear that using stainless steel or ceramics when manufacturing ball bearings is critical due to their high Endurance and operating temperature. These materials greatly increase the reliability and lifetime of the bearings.

Precision Standards: According to the sites I have looked at, the accuracy levels of the ball bearings play a significant role in their effectiveness. The manufacturing process consists of very narrow tolerance levels, which will be necessary to reduce vibration and noise and increase performance, especially in delicate and high-end applications such as the aerospace and automotive industries.

To summarize, these sources emphasize the keys to effective ball-bearing performance, such as precision of loading, choice of material, and accuracy of manufacture.

An Overview of Roller Bearings in Machinery

When investigating the first three results on google.com concerning roller bearings, I discovered that these parts are essential when handling large load applications effectively. Below is a summarizing of the key figures from my documentation:

Load Ratings: Roller bearings have a competitive advantage in radial stress performance. Because of their cylindrical shape, they have a larger bearing surface than ball bearings, thus increasing the bearing capacity. This is particularly true when robust construction is needed in staging and load devices, including conveyors and heavy machines.

Material Composition: From the researched sources, it’s apparent that roller bearings frequently include hardened steel and other advanced alloys. This enables these materials to provide the necessary stiffness and resistance to abrasion. The resilience quality of these materials also ensures that such bearing devices placed in service can be extended under harsh operating conditions.

Precision Standards: In the bearing manufacturing industry, roller bearings have vital components, and that is the precision observed when making them, which significantly impacts their performance. Specific sources pointed out that bearing temperature management depends on the follow-up of tight tolerances, which aids in minimizing friction and lengthening the durability of the bearing. This accuracy becomes necessary when smooth and seamless equipment operation is consistently required in industrial machines.

In conclusion, these aspects emphasize the importance of load capacity, material properties, and manufacturing accuracy in ensuring the operational effectiveness of roller bearings in machines.

Understanding Thrust Bearings and Their Functions

Thrust bearings are extreme types of bearings made to carry axial loads, forces that act in the same direction as the axis of rotation. These bearings are helpful in regions where axial loads need to be harnessed, for example, in automotive and aeronautical applications that tend to support rotating mechanisms. The top three websites on thrust bearings feature the following most important points regarding them:

Load Handling Capabilities: Thrust bearings are simply constructed but loaded to support only axial loads, not all radial loads. This is because of their unconventional use, mainly bearing balls or rollers and flat or grooved plates. These components are the backbone for the structures that counteract axial forces.

Material Selection: As other reliable sources assert, the thrust bearing’s material composition resembles an ordinary bearing aiming at wear resistance. Various materials are used, including carbon steel, alloy steel, and certain composite polyamide-like materials. These materials are crucial in ensuring that the thrust bearing can bear a large-acting axial force over an extended length of time.

Precision Engineering: Thrust bearings require specific designs that outline their manufacturing performance. Adhering to the tolerances minimizes wear and increases performance. This precision is necessary in high-load applications, where even a slight error can lead to performance failure.

In conclusion, a thrust bearing’s capacity to carry axial loads effectively results from the bearing configuration, materials, and machining processes used in its manufacture. All these specifications are reasonable considering the nature of the applications, which expose the components to specific loads while providing trustworthy axial support.

Comparing Anti-Friction Bearings with Friction Bearings

Advantages of Anti-Friction Bearings Over Friction Bearings:

From the top three Google search results on anti-friction and friction bearings, it is evident that anti-friction bearings have several distinct advantages. To begin with, bearing systems for anti-friction, such as ball bearings and roller bearings, reduce bear frictional torque compared to friction, such as simple slide bearings, which cause rotatable parts to wipe over one another. This, more or less, leads to improved working efficiency and a considerable reduction in wear and heat production, contributing to a more extended operation period.

Looking at the technicality of anti-friction bearings, these components generally work with lower friction coefficients ranging from a minimum coefficient of 0.001 to a maximum of 0.010. In contrast, those rough bearings may increase to about 0.1-0.3. Anti-friction bearings can center and align the shafts accurately and spin at higher speeds than plain bearing systems because of their capability to reduce the area of contact when operating. These types of bearings also remain just as good in dealing with axial and radial loading, which are broader design considerations than equalizing corneal-type bearings, which are pretty sensitive to misalignment. Similarly, anti-friction bearings are often more easily fitted and replaced thanks to their modular construction, which is a great plus in internal markets where lost time must be limited.

Applications in which Friction Bearings are Mostly Used

As part of my assignment focusing on the first three websites, as recommended by Google, I highlighted different cases of friction bearings. These kinds of bearings, like plain bearings, often apply in situations requiring simple and cheap designs. Their application is well pronounced in heavy-duty work, such as large machinery and automotive engines, where size limitations and the ability to carry heavy loads are required. The efficiencies of these bearings are suitable in conditions with a steady rotation or even an oscillation, such as in turbines, compressors, and pumps.

Considering friction-bearing applications from this perspective can be beneficial because most can take higher friction coefficients, which range from. It is true that plane bearings have low friction and better heat dissipation properties than rolling element bearings and are thus advisable in high-temperature zones, although they are not anti-friction bearings. Their construction also helps absorb loads in broad areas that are made for equally great shocks or vibrations. Summing up, where such qualities of friction bearings are required, it is an industrial practice for such bearings to remain effective and in position.

How Anti-Friction Bearings Help Improve The Performance Of Machines

Anti-friction bearings or rolling element bearings are critical components in the machine’s suitability since they reduce the friction and wear between the components in motion. Consistent with the three most visited websites regarding these bearings, the bearings have features like incorporating balls or rollers to facilitate lower lubrication than plain bearings. Their construction enables ease of operation and reduces energy wastage, resulting in higher machinery efficiency.

An important economic parameter has been the friction factor, which, over the range of mechanical elements used, is very low, less than 0.001 up to 0.3, thus enabling better efficiency in energy use on some mechanical devices. Additionally, anti-friction bearings maintain accuracy while sustaining low wear and tear, resulting in a longer use period with lower maintenance needs. These bearings are incorporated in systems rotating at high speeds and generating low heat levels, such as electric motors, gearboxes, and conveyor belts. The suitability of handling radial and axial loads also enhances the popularity of the bearings in the industry. In conclusion, there are indications that anti-friction bearings improve the efficiency and reliability of operations, making them an indispensable component when designing machines.

Key Factors Affecting the Reliability of Anti-Friction Bearings

Investigation Opening: The Effect of Lubrication on The Overall Performance of Bearings

Lubrication is an essential requirement for the successful operability of anti-friction bearings. It has been established that several websites and most of the research available report that almost 50 to 70% of the bearing failures were due to improper lubrication and other lesser causes. It must be noted that excessive metal-metal contact increases friction, wear, and heat without proper lubrication, all of which cause bearing failure.

Critical technical parameters involve lubrication, and viscosity remains crucial because its selection has to go according to the prevailing conditions of the bearing. The degree of viscosity will also influence the lubricant’s performance in maintaining a lubricating film. Standard ranges of film thickness will be between 10 to 1000 cSt depending on the speed and load requirements. Moreover, the performance of39 a lubricant depends on the temperature stability, oxidation resistance, and control of pollutants in the lubricant since these factors dictate the life span and efficacy.

Regular maintenance routines should also be as prompt lubricating factor replenishment or replenishing quenches for debris, dirt, and other harmful substances bearing use performance. Furthermore, by promoting good lubrication at the bearing’s shallow parts, using machinery that relies on friction bearings, especially anti-friction bearings, can enhance durability. This will improve the overall performance of the machines and allow them to be used efficiently and reliably at a low cost.

The Relation between Load Capacity and Rotation of Bearings with Life Span

In cases where I have had to relate the load and speed to bearing life, again from the top three websites on Google.com, the two factors affect bearing performance in one way or another. This is because high loads will result in high internal load on bearing parts, especially in their elastomers, which leads to gradual deterioration. The loading limits are critical and must be adhered to; for instance, the load applied should be below the load rating of the bearing, including all considerations such as static and dynamic load.

As for the speed, this can be considered in terms of bearing life and generation of heat and lubrication. Usually, to reduce the temperature of the bearing, it is necessary to operate at high rotational speeds. Most of the technical parameters focused on are maximum speed limitations and load capacity. By following these instructions on the recommended operating conditions, it is possible to improve the performance and life extent of the bearing.

Evaluation of Environmental Factors for Machine Element – Anti-Friction Bearing

In looking at anti-friction from the viewpoint of environmental considerations, the top three websites provide feedback on the similar issue of the need for harmony with ecological aspects. The performance of the bearing can be altered due to the influence of moisture, temperature changes, dust, or other corrosive materials in the environment. It is, therefore, vital for me when choosing sealing technologies to prevent the entry of water and dust, to avoid any moisture ingress, and to consider practices such as using labyrinth seals or contact seals. Furthermore, selecting corrosion-resistant materials and coatings provides further assurance of protection in extreme conditions of use. It applies equally to using appropriate lubricants like non-toxic, biodegradable ones for environmental protection.

As a rule, there are technical parameters like mandatory “Operating temperature range” and environmental conditions that do not compromise material structure. There is such characteristic as Ingress Protection (IP), which is essential as it determines the level of protection from, and the presence of, foreign objects and soap-water. Considering these technical parameters and the reasons for their inclusion helps me assure myself that conditions of operating environments of anti-friction bearings will be effective and environmentally friendly.

Maintaining and Extending the Life of Anti-Friction Bearings

Suggested Methods for Caring of Bearings

The three websites emphasized many strategies for best practices for bearing maintenance, which I think are very important. First, cleaning and inspection have to be done regularly. Since unusual noises or vibrations can indicate wear, regular inspection allows me to prevent problems that would otherwise worsen with time. Proper tools and solvents are used in bearing cleaning to remove harmful substances and aid in the appropriate working conditions.

Secondly, lubrication is needed so that bearings will not be subjected to excessive friction and abrasion. Based on the technical parameters, I usually guarantee that a substance appropriate to the operating temperature range and environmental conditions, such as humidity and corrosive elements, is used. Significant friction reduction via the proper lubricant can go a long way in preventing overheating of cooling fans or bearing breakdown.

Third, the proper adjustment during the installation prevents the bearing from being overstressed, extending its lifespan. Factors such as axial and radial load capacity and similar are considered to ensure the application’s requirements are met. Monitoring these parameters and others in operation allows me to rationally defend maintenance processes to ensure the performance and service life of anti-friction bearings.

Understanding and Solving the Problem of Vibration in Bearing Systems

In dealing with the vibration problems of bearing systems, I refer to the top 3 websites that offer a balanced approach to the problem. First, it is wise to understand the source of vibrations since these worries can originate from imbalance, misalignment, or wear. With the help of vibration analysis tools, I can objectively analyze the usual indifference in the figure or pattern of vibration attributed to some elements. In this regard, vibration measuring devices are pretty helpful in determining such parameters as velocity and frequency of vibration, which can help determine the cause of an increased level of irregularity.

When the cause is known, I fix it by implementing solutions that resolve that particular problem. For instance, if there is an imbalanced condition, I strip the rotating parts to sacrifice their balance for stability. When parts are misaligned, I not only realign them but also consider and factor in the shaft diameter and the coupling offset parameters. A loss of performance due to bearing wear and tear population dense vibrations may imply replacing or reconditioning the affected bearings to normalcy.

Moreover, complying with the suggested technical characteristics, such as the rotational speeds and loads, further reduces the vibration risk. If appropriately applied, these measures make sense of the maintenance efforts and go a long way toward lowering vibration problems in the future, thereby enhancing the reliability of bearing systems.

Few repairable factors, if well managed, will enhance the life of a bearing.

Information from the top three websites is beneficial for proper clearance and lubrication, which are directly related to bearing longevity. This principle has been brought out about the need to ensure some clearance levels, which includes understanding the bearing adaption and working conditions. When dealing with a gap distance, limiting factors like load or thermal expansion must be considered to arrive at an adequate gap distance.

Lubrication is a major consideration in optimal bearing life. I observe the recommended schedule for applying lubricant and emphasize the type and viscosity of the lubricant needed by the operating temperature and load. Periodic tests of the lubricant also help to check its state to avoid contamination that may lower the bearing’s performance when used.

While changing some clearance differential or counter-measured lubricant, I always ensure that such technical parameters are reasonable and do not stray from the norm. By doing so, wear can be greatly reduced, which in turn would enhance bearing operational life, thus improving the system’s reliability.

Frequently Asked Questions (FAQs)

Q: Can you describe an antifriction bearing?

A: An antifriction bearing utilizes a functional element capable of rolling rather than sliding to minimize friction and wear of moving elements like a shaft and housing. This assists in producing low friction while in rotation and enables bearings to support radial and axial loads.

Q: How do radial and axial loads affect antifriction bearings?

A: Radial loads act at right angles to the shaft axis, and axial loads act on the shaft in the same direction as the shaft axis. Antifriction bearings are conventionally designed to resist the two kinds of load and guarantee that such performance and durability are achieved by correctly orienting the components and avoiding contact between metal surfaces as much as possible.

Q: What are the differences between sleeve bearings and antifriction bearings?

A: The pivotal type of element, also called journal bearings, in contrast, relies on a thin surface of fluid on the opposite side of the surface to be slid, breaking the lubrication of that surface. The antifriction techniques rely on balls or rollers rotating around the shaft to alleviate the sliding friction. Sleeve bearings are mainly used for applications that need minimum cost and the ability to support many weight places. At the same time, antifriction is recommended when accuracy and low resistance are required.

Q: What is the relevance of adding lubricant to antifriction bearings?

A: Introducing lubricant to antifriction bearings is essential in enhancing their lubrication, reducing frictional losses, and avoiding contact between metals. It also aids in removing excess heat generated by the bearings and protect the bearing surface from erosion, which helps in active function and longer life of the bearing products.

Q: What are some of the most used anti-friction bearings in modern engineering practice?

A: In Active Designs of Engineering, Ball and roller bearings, needle roller bearings, and angular contact balls are the common types of antifriction bearings. Each type has different load-carrying capabilities, speeds, and working conditions, enabling it to be utilized in many engineering aspects.

Q: How do bearings enhance the functions of the machine components?

A: Bearings enhance the functions of machine components by permitting all the shafts in the machine to rotate freely with the minimum frictional tussle between them, maintaining their positional alignment and balancing axial and radial forces. This support is essential for the proper functioning performance of the machines since it lessens wear and tear and thus augments the operating efficacy.

Q: What is the function of the separator for antifriction bearings?

A: More accurately, the separator or cage of the antifriction bearing keeps the rolling bodies spaced evenly from the race and each other. It facilitates low friction between rolling elements, minimizing wear in the rolling elements, thereby increasing the bearing’s operational and load capacity.

Q: Are antifriction bearings tolerant to misalignment?

A: Some specific antifriction bearings, like spherical bearings, are made to allow the shaft to be wrongly placed concerning the housing. These bearings can compensate for angular discrepancy, reducing the stress on the bearing surface and increasing how long the bearing can last.

Q: How is the carrying capacity of an antifriction bearing computed?

A: The load-carrying capacity for antifriction bearings depends on many factors, including the axial and radial dimensions of the axial and radial types of rolling elements, the material of the rolling bearing, and the type of rolling bearing design. The right bearing load-carrying capacity is vital; if not, reliable performance is assured, and the unit will not last under working conditions.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8