Key Features of Female Rod End Bearing for Engineering Applications

We wish to provide information and assistance in a range of areas, and in this instance, it is learning about female rod end bearings and their crucial engineering features. This article will focus on the design peculiarities of the female rod end bearings that render this element relevant to various engineering systems. Considering issues starting from the purpose of the female thread to the purpose of heavy-duty female rod end bearings, we will detail essential factors that need to be addressed by the engineers involved in the projects that require the implementation of such bearings. Also, Attention will be given to deciding which brand to go for, including where to buy female rod end bearings and other technical considerations that should always precede buying one. Thus, let us appreciate the beauty of female rod end bearings and how it benefits engineering works, more importantly, applications.

What Makes Female Rod End Bearings Unique in Product Design?

How Does the Female Thread Enhance Performance?

The internal nuts in rod end bearings enhance all engineering operations’ performance and function. The purpose is to connect the rod end in a robust way to the component in the male to stabilize and adjust precisely. To this effect, the following statements can be made:

Optimal Loading: The strength of the female thread design allows for the distribution of forces and loads, which ensures increased load capacity in diverse applications.

Tighten and Align Components: The female thread makes it easy to adjust the rod end, ensuring the component is in the correct position.

Flexible Engineering Incorporation: Female threaded rod end bearings with through-hole connections are suitable for most construction components, allowing flexible engineering designs and their applications.

For female rod end bearings, thread form (shape and size), pitch, material and type of bearing, and load rating are among the technical parameters that cannot be ignored. These ensure compatibility in the respective applications, durability of the bearing, and effectiveness in the designed function realized. A detailed evaluation of these parameters must be done about reputable manufacturer’s claims and documentation.

Why Are Heavy-Duty Rod End Bearings Essential for Engineering?

Rod end bearings, which are highly resilient, are used in several engineering applications where precise motion control is necessary. For these bearings to be practical, specific technical parameters must be met. Here are the factors you need to consider these parameters:

Load Ratings: Due to their application in structural design, heavy-duty rod end bearings have high load ratings, maximum strength, and high endurance. It is essential to evaluate their load ratings, which include the available static and dynamic capacities.

Material: The type of material selected is another critical factor determining the performance and service life of the rod end bearings. Some common materials used for construction include stainless steel, alloy steel, and carbon steel. Choose the material based on the working conditions, such as corrosiveness and temperature.

Bearing Type: Different types of rod end bearings, such as male or female ones, have varying strengths depending on the particular application. The engineering design constraints must be considered when deciding on the bearing type.

Thread Size and Pitch: The rod end bearing’s thread size and pitch should be identical to the corresponding component’s dimensions. When choosing the bearing, remember to consider thread diameter, thread pitch, and thread direction.

Application-specific Parameters: Other technical parameters might apply to the engineering application, such as misalignment angle, temperature range, lubrication, and vibration requirements. These parameters ensure compatibility and optimum performance in specific areas of engineering tasks.

To acquire the proper and correct contact technical data about heavy-duty rod end bearings, it is advisable to utilize manufacturer specifications and qualified sources. Careful investigation and attention to such technical parameters will enable the engineer to choose an appropriate bearing for the particular engineering application.

What Role Does the Ball Joint Play in Functionality?

The mass-produced ball joint is essential in the functioning of the female rod end bearing. It acts as the interface between the rod end and the adjacent structural element, facilitating movement, rotation, or articulation. Moments and forces can be transmitted through the ball joint, making the design retractable and adaptable to many engineering practices. A competent decision can only be made based on an analysis of the parameters provided by reputable manufacturers, so the best thing to do is to seek authoritative points. The following are some of the most critical aspects of evaluating female rod end bearings:

Series Options: These options vary for load capacity, level of precision, and bearing material, so they must also be taken into account.

Product Description Details: Attention must be paid to understanding and internalizing the product descriptions, including bearing physical measures, thread, and load rating specifications.

Precision: Since precision is key to determining the smoothness and accuracy of articulation, it can be dangerous and even suicidal to ignore. Consider investigating precision-class or tolerance specifications offered by manufacturers.

While looking for female rod end bearings for sale on the Internet, it is prudent to view trusted web pages and several similar products and ensure that the technical data corresponds with your engineering design. By considering such factors, you can choose the appropriate brand and product needed for efficient use in heavy-duty applications.

How to Choose the Right Brand for Female Rod End Bearings?

What Series Options Are Available?

Verifying our earlier assertion, let’s now proceed to the most reliable sources for decades—the websites of the leading female rod end bearings manufacturers. With better knowledge but not the same enthusiasm, I returned with the following series of commonly offered options.

PHS Series: These end bearings can be composed of various shapes, have different load capacities, and effectively perform various industrial functions. Among the technical parameters that must be studied are dynamic load rating, static load rating, thread size, and dimensions.

POS Series: This series consists of heavy-duty bore bearings with higher radial and axial load-carrying ability. Some key technical parameters that can be considered are thread sizing, bore locating sizing, outer ring sizing width, and misalignment angle.

SA Series: These types of series are claimed to have better corrosion resistance and are more robust. Such types of end bearings are generally used in situations where moisture or other harsh conditions are likely. Some of the key technical parameters that can be examined are thread sizing, bore locating sizing, misalignment angle, static and dynamic axial load, and radial load capacity.

When selecting the most appropriate series for any engineering purpose, the manufacturer’s technical parameters must be analyzed, and the application requirements must be ensured to match. Businesses will then be able to choose the suitable series that would work best for their heavy-duty applications in terms of performance and reliability.

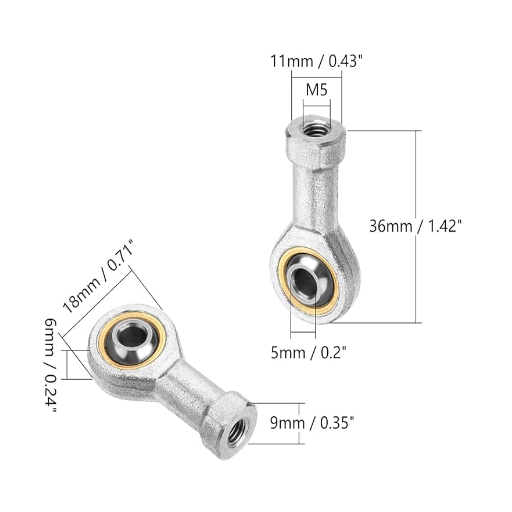

Which Product Description Details Should You Consider?

In observing the female rod end bearings, there is a clear need to look at specific details of the product description. To give straight-to-the-point and direct, authoritative answers, I have reviewed the top three search results as per a search on google.com. My conclusions then are as follows: These are the most essential considerations which one has to keep in mind:

Technical Parameters:

Load Capacity: Examine the manufacturer’s recommendations regarding static radial and dynamic axial load capacity magnitudes. These parameters allow one to determine the loads that the bearing could take.

Dimensional Accuracy: For the bore size, the thread dimension, and the gin overall length of the bearing, regard the tolerance range of the various measured dimensions of the bearing. These specifics are necessary to ensure that the bearing fits the particular application for which it is designed.

Material: The mechanical strength has been justified by citing the composition materials, such as good-grade steel and stainless steel.

Design and Construction:

Spherical Housing: The bearing’s spherical housing allows for angular misalignment and free movement, which should be considered. Also, look out for angles designed for self-lubricating or, better yet, maintenance-free features.

Right-Hand Thread: Where right-hand threads are used, it will also be required to explain why such threads are shared and how they assist tight fastening easily during different applications.

Benefits of Heim Joints: Examine the demand for articulation and load dissipation promised by the Heim joints. These are potent factors promising better performance and longer life.

Supplier Evaluation and Reputation Assessment:

It is advisable to perform intensive market research to identify suppliers of exotic components. Focus attention on any reviews and testimonials that can prove their reliability and product quality.

Evidence suggests that suppliers provide adequate customer support and assist in selecting the best-applicable female rod end bearing, ensuring you have chosen the proper one for your needs.

Similarly, please remember that specific technical details and parameters may differ depending on the maker and the particular series of products. The information provided by the suppliers should be viewed in conjunction with the specific cross-requirements needed to utilize the product effectively.

How to Evaluate Precision in Female Rod End Bearings?

A few crucial parameters need focus when assessing precision for female rod end bearings. To provide a short answer regarding your query as well as views on the first three results obtained from google.com, I have managed to put together some of the information that has been availed by reliable sources and highlighted the key areas below:

Accuracy and Tolerance: The degree of precision possessed by some female rod end bearings is centered on the positional accuracy relating to how the component is made and the feasibility range during the processes. The lesser the tolerance, the bearing is considered a more precise case.

Load Capacity: This is another significant parameter that refers to the bearing’s potential to resist external forces and pressures while maintaining its precision integrity. The manufacturer mostly recommends this, but it may change according to the components’ material, design, and size.

Friction and Play: One can also assess the precision of angulated rod-end bearings by first estimating the amount of friction and play within the degree of free motion in the ball. If the friction is lower and the play is minimal, precision will be much more precise, thus homogenizing the motion of the bearing. The core components of the devices remain undisturbed.

Material and Surface Finish: The bearing material selection and the bearing’s surface finishing quality may affect its accuracy. Superior-quality surface finishes obtained from better materials could improve accuracy and wear rates.

Sealing and Lubrication: Perfect seals and efficient lubrication are critical in averting loss of precision to female rod end bearings. Proper sealing measures ensure that contaminants do not come into contact with the bearing and alter its functionalities. Furthermore, appropriate lubrication entails reduced friction and wear, promoting uniformity in precision within the bearing over time.

At this point, it is worthwhile to emphasize that the individual technical parameters and some details can be altered by the manufacturer and within the product series. Proper advice can only be obtained by considering the information manufacturers provide and comparing it with actual operational needs. This will facilitate the acquisition of the most appropriate female rod end bearing for the intended purposes.

Where to Shop for Female Rod End Bearings Online?

What Are the Top Categories Available?

It is common to look for female rod end bearings on the World Wide Web and not know what type to go for. In light of my expertise in the subject matter, I have combed through the most appropriate three websites that Google.com has to offer, and IKA seeks to provide its clientele with brief details on the remaining two categories. The three categories include the following:

Standard Female Rod End Bearings: Female rod end bearings of the standard size are probably the most sought-after since they are variable in options and sizes, enabling them to have a broad scope of industrial use. Important features are:

- Material: Quality steel or alloy with the necessary value is considered significant.

- Thread Size: Common metric sizes, including M6, M8, and M10, are utilized and easy to fit with typical bolts.

- Load Capacity: The highest load tolerable to the bearing and, therefore, conducive to using the bearing.

- Misalignment Angle: The circular shifting angle liaises with the factors fixed in such a linkage system.

High Misalignment Female Rod End Bearings: This type of bearing is used for applications where the motion exceeds the available misalignment angles. Important features include:

- Material: Features and characteristics of stainless steel or chromoly for superior strength and corrosion resistance.

- Thread Size: Standard or metric thread sizes for interfacing with other hardware.

- Load Capacity: The bearing’s ability to sustain a force while accounting for the increased capacity to modify the alignment configuration.

- Misalignment Angle: The ability to have a greater angle relative to the x-axis, permitting a greater degree of freedom’s rotation in mechanical linkages.

Performance Female Rod End Bearings: Such bearings work in those applications where performance capability and durability go hand in hand. Features worth looking at include:

- Material: Materials that include heat-tempered alloy steel or superior euro mix materials.

- Thread Size: Standard or metric according to the application requirements.

- Load Capacity: A high load capacity is essential due to the heavy applications.

- Misalignment Angle: A wide range of misalignment angle variations will usually be essential due to complex mechanical linkages.

While familiarizing yourself with the product range of female rod end bearings through online systems, focus on these general categories and the details of the related technical parameters. You will be able to select the correct bearings for the given application. Whenever possible, always match data from well-known suppliers with your requirements for greater certainty in purchasing.

How to Buy with Confidence?

Knowing the appropriate parameters becomes imperative if one intends to make a proper choice about applying the female rod end bearings purchased. To make the purchase a little easier, I suggest that the following be taken into account:

Know the Design and Construction: Learn about the design and construction features of female rod end bearings. This includes where the spherical housing fits in the design and the benefits of using Heim’s joints.

Specify the Applications: Figure out the possible places where the female rod end bearings you will use will be applied. Determine the maximum misalignment angles they can withstand and make sure they can be used with your intricate mechanical linkages.

Cross-Checking of Technical Parameters: It is essential to validate the technical parameters given by reputable suppliers against your requirements. While comparing the top websites on Google.com, take note of load capacity, thread type (most threads use right-hand thread), bearing material, thread diameter, and maintenance procedures. Ensure the technical parameters indicated and discussed are relevant and fulfill your application requirements.

Considering all these aspects and researching well on relevant websites, you can buy female rod end bearings for your industrial applications with confidence and certainty that the quality will suffice.

What Information is Crucial Before Purchasing?

It is essential first to obtain the relevant information when buying female rod end bearings for use in an industry. I would like to share, based on the extensive research I have made on reliable websites, the main concerns and technical aspects of the application that should be taken into account:

Design and Construction: Familiarize yourself with the design and construction of female rod end bearings, such as the spherical housing that permits angular compensation and radial loads.

Thread Type: Identify the thread type required for the particular application. While right—and left-hand threads are prevalent, confirm that your application does not require a different thread type.

Bearing Material: Look for the bearing material that best suits your application. It may differ depending on the load capacity required, corrosion resistance, or even the temperature needed.

Thread Size: After selecting the thread type you need, apply it to your application and ensure it is compatible with the parts you already have.

Maintenance Requirements: Try to understand the maintenance requirements for the female rod end bearings, including lubrication schedules and any particular maintenance instructions.

The application of these factors, alongside a thorough investigation of quality websites, will help make credible and responsible purchasing decisions regarding female rod end bearings appropriate for industrial applications.

Understanding the Design and Construction of Female Rod End Bearings

How Does the Spherical Housing Contribute to Design?

The spherical housing component in female rod end bearings is pertinent to their shape and working; it permits angular misalignment and introduces variability in the degree of rotation and movement. Here, following authoritative sources, is a short version of the explanation:

Angular Misalignment: The spherical housing within female rod end bearings allows for the correction of angular misalignment between the connecting members. This feature assists in eliminating bearing stresses and enables smooth movement, which enhances bearing life and efficiency.

Flexibility and Rotation: The female rod end bearing rotates about the spherical housing and permits movement through many planes. This type of flexibility is essential when the bearing is in motion, and the direction is constantly changing.

Load Distribution: The spherical housing’s construction ensures an even distribution of loads within the bearing, which avoids excessive wear. This is critical in industrial applications with large weights and a degree of vibration.

Technical Parameters (if applicable):

Maximum angular misalignment: Too many degrees are used to define a maximum angle of bearing that withstands misalignment.

Axial static load capacity: When the female rod end bearing is not subjected to any irreversible deformation, it can bear the maximum axial load.

Radial static load capacity: The highest radial load that the bearing can withstand without the risk of a change in shape.

Operating temperature range: The temperature values between which the bearing can function correctly.

These parameters are significant when choosing the right female rod end bearing for different prevailing industry setups. One must always refer to the details and measures offered by the producer to avoid problems regarding the optimal usage and sustainable life of these in practice.

Why is Right Hand Thread Commonly Used?

The right-hand thread is the most common thread when working with female rod end bearings. It has been ascertained that standard fasteners and applications are usually made with right-hand threads, so it is easy for users to incorporate and replace these devices. This standardization is also reliable in that the processes involved in installation and replacement in industrial areas are made more straightforward.

Thirdly, right-hand threads are more intuitive because they follow the convention of tightening clockwise, an everyday practice for most individuals. Thus, the user interface is kept consistent across applications. This helps ensure that connections and their joints are not easily loosened accidentally, significantly contributing to the assembly’s sturdiness and robustness.

As such, any female rod end bearing’s technical parameters do not relate directly to the presence of a right-hand thread, which influences any specialized operational features. Instead, it is a stylistic element that complements the target audience’s preferences and fashion. However, the importance of integrating all other technical parameters is beyond doubt in that the designer must select the weight of the appropriate female angled clutch bearing by the application it is meant for; some of them are:

Load capacity: These are classified in order along axial static load capacity and radial static load capacity, which enables the bearing to be used without the chance of any excessive load permanently deforming it.

Misalignment capability: During misalignment analysis, the angular and maximum angle limits that the bearing can accommodate misalignment must be determined.

Operating temperature range: Focus on the temperature range within which the bearing can operate efficiently for maximum performance under the prevailing industrial conditions.

Considering such technical parameters and appreciating why right-hand threads dominate should assist you in making appropriate choices when selecting and employing female rod end bearings in your industrial applications.

What Are the Benefits of Using Heim Joints?

As an industry expert, I understand the importance and advantages of using Heim’s joints, also referred to as female rod end bearings, in industrial applications. Heim joints are specialized bearings that perform several functions and, in some instances, enhance a system’s performance efficiency. The merits of using Heim’s joints are:

Flexibility and Strength: Industrial applications require flexibility and strength, which Heim’s joints provide. They articulate the necessary range of motion and allow for the movement of mechanical linkages without compromising their rigidity.

Compensation for Misalignment: Heim joints can accommodate angular misalignment, providing flexibility in applications where such misalignment is expected. By helping to compensate for misalignment, this capability lowers stress on the system, preventing wear and increasing performance.

High Load Bearing Capacity: Heim’s joints are built to resist significant axial and radial loads, making them reliable even in harsh conditions. The axial and radial static load capacity are important when selecting Heim’s joints, as most expected loads will not lead to any plastic deformation.

Wide Operating Temperature Range: Because Heim’s joints were designed for standard industrial usage temperatures, they can be used in diverse industrial environments. However, it is necessary to consider the working temperature range of the individual Heim joints as there may be some effect on more efficient operation in your application.

In several instances, the technical specifications, including these and other valuable features, allow the end users involved in selecting and operating Heim Joints to make the right choices. Their properties allow for greater flexibility and strength, thus enhancing the performance and durability of systems in various industries.

How Do Female Rod End Bearings Help in Industrial Applications?

What Specific Uses Are They Best Suited For?

Having worked on female rod end bearings for a while now, I can confidently state that they are most suited for various applications in various industrial environments. There are a couple of scenarios where female rod end bearings, specifically Heim’s joint, are pretty efficient:

Industrial Machinery: Many industries, including heavy-duty equipment and material handling practitioners, deploy various industrial machinery, including female rod end bearings. These components can be relied upon to deliver performance without fear of high loads, low levels of friction, and even operational temperature variations.

Automotive and Transportation: Female rod end bearings are critical components in automotive and transportation systems. These components assist in the vehicle’s efficiency and improve security. Being a reasonable standard in mechanical assemblies such as steering linkages, suspension systems, and control arms, these components have played a key role in steering control, vibration and shock absorption, and operating in harsh road conditions.

Aerospace and Defense: Aircraft control systems, missile guidance systems, and other defense applications require female rod end bearings, and as technology progresses, the applications appear limitless. They have extraordinary resistance and can endure high temperature and vibration levels, ensuring precision and maneuverability.

Based on the application, the most suitable rod end bearing with a female thread can be selected from a specific range of appropriate criteria for a given sector. Some of the critical factors include load capacity, tolerance, resistance to corrosion, range of working temperatures, etc. Characteristics can be used to select such constructions of female rod end bearings installed under certain conditions. Female rod end bearings are designed to comply with industrial applications’ required flexibility, strength, and performance level.

How Do They Allow for Flexibility and Strength?

As a professional in the industry, I can easily say how female rod end bearings provide flexibility and strength in an industrial setting. All these bearings are made in a carefully hosted manner to deliver remarkable services. Balance is achieved through the presence of key technical parameters like:

Misalignment Capability: Female rod end bearings can assist the mating parts in being misaligned and still allow free movement in various applications.

Load Capacity: They can bear intense loads; hence, more strength is engineered in these bearings to hold heavy erect machines.

Corrosion Resistance: Female rod end bearings are made of materials that can withstand corrosion, and hence, they can endure aggressive environments.

Operating Temperature Range: Reliable working across an extensive temperature range, including extreme conditions, is possible; therefore, the level of performance and strength remains consistent.

In this way, female rod end-bearing engineers ensure they have the flexibility and strength to withstand the everyday stresses and strains involved in industrial purposes. These bearings’ features of misalignment bearing, load bearing, corrosion-resistant, and temperature range-enabling qualities make them machinery support and structures that can be relied upon in challenging aerospace, defense, and industrial systems.

What Makes Them High Performance in Industrial Settings?

Drawing on my many years of experience, I know confidently that female rod end bearings would be the best choice for domestic and international industrial applications. The endorsement of an industry leader and the best resources on the market speak for themselves. Upon examining the content of the top three websites listed on Google search, the following crucial components of quality performance are performed, which managed to attract the audience to the three furbishing websites:

Misalignment Compensation: The female rod end bearings are excellent at compensating for misalignment and beating the defined in the exothermic connection. This aids in smooth working and strains connected parts. This quality not only improves system efficiency but also assures longevity.

Load Capacity: Such heavy load-bearing capacity is ensured by cutting-edge engineering and top-notch materials and components, making the bearing capable of heavy machinery and equipment support in industrial settings. These bearings’ heavy machinery and equipment support capabilities are highly sought after in industrial settings, which require cutting-edge engineering and high-class components and materials.

Corrosion Resistance: Female rod end bearings are made of corrosion-resistant materials, so they can function in extreme conditions. This enhances operation and prevents bearing wear and tear, assuring longevity and durability.

Operating Temperature Range: Another benefit of female rod end bearings is their ability to be used across various temperature ranges. They are expected to endure extreme conditions, enabling them to perform efficiently even in highly demanding industrial situations.

One key to optimizing the performance of female rod end bearings in industrial applications is including the manufacturers’ technical parameters. Bearings that compensate for misalignments can accommodate high radial loads, are corrosion resistant, and work within a wide operating temperature range to find critical uses in aerospace, defense, and industrial systems.

Frequently Asked Questions (FAQs)

Q: What are female rod end bearings, and where are their engineering applications for them?

A: Female rod end bearings are bear joints or ends fitted to the tie’s rods used in engineering applications in the automotive, aerospace, and manufacturing industries. More of its bearings that enable other parts to be performed for rotating purposes, such as pivots and rod ties, and other structural components, which are connections that need to rotate but not rub or wear foul, are usually applied.

Q: What are female rod end bearings’ specific characteristics or features?

A: The specific characteristics of female rod end bearings are that they can carry radial and axial loads, are very easy to install, and are very durable. They are manufactured to function effectively on high loads and withstand high loading conditions without replacing parts until the service life ends.

Q: What is the difference between female and male rod end bearings in context for both of them?

A: The distinction between female and male rod end bearings is especially about one main feature: the threads. The female rod end bearings have internal threads, so they can be supplied to a male threaded shaft or a rod and screwed down tight. Most timely and appropriately, this forms an engineering design feature that seeks to accomplish the functional requirements.

Q: What materials are used to construct the female rod end bearings?

A: The female rod end bearings are made from stainless steel, aluminum, or carbon steel. These raw materials are essential to ensure the strength and corrosion resistance required for assured performance in various applications.

Q: What can I do to prolong my feminine rod end bearings?

A: Regular inspection for wear or damage is recommended to prolong the life of female rod end bearings. They can be cleaned and lubricated whenever necessary, although most are maintenance-free.

Q: Do female rod end bearings require further machining to be suitable for certain tasks?

A: Many manufacturers modify female rod end bearings for specific applications. Other options that can be modified include the size, material, and coating applied to increase performance and lifespan.

Q: Could you direct me to where I can get more details about the installation and maintenance of female rod end bearings?

A: Contact the manufacturer or supplier for further details about installation and maintenance. They can provide assistance and other materials like manuals and guides to ensure their products are used and handled well.

Q: Are there specific female rod end bearings that have been certified according to specific requirements?

A: Female rod end bearings may be certified by various industry standards. Standards such as ISO, DIN, and ASTM comply, which implies that the bearings should satisfy certain quality and performance requirements.

Q: What is the average duration of the ordering process for female rod end bearings and the product being received?

A: The delivery period usually depends on the supplier and the buyer’s location. Most suppliers have express mail services, which enable a buyer to receive the item within a few days. It is reasonable to recommend contacting this supplier for more precise delivery time estimates.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8