Maintenance Hacks to Prevent Worn Out Bearings

A wheel bearing is one of the most essential parts of any automobile, providing smoothness to the rotation of the wheels and helping the vehicle operate efficiently and optimally. These mechanical masterpieces ensure that the wheels can turn quickly with the least resistance needed to lift the vehicle’s weight and still be able to drive safely. But, as with any component that is underscored with a lot of use, wheel bearings also have an expiration. Understanding the danger signs of the wheel bearings’ failures can help avoid more severe damage to the vehicles and increase the safety of all road users. This article covers the average lifespan of wheel bearings, the various aspects that affect their lifespan, and the telltale signs that they will need repair or replacement. Understanding these areas will help vehicle drivers and proprietors take proper care of their vehicles and promote their safety and longevity.

How Can You Tell if a Wheel Bearing is Bad?

What are the symptoms of a bad wheel?

Unusual Noises: Most drivers will complain of noise from the wheel area that is higher than its permissible limits whenever the wheel bearing fails. This can take the form of a rough sound when turning or an increase in the pitch of the voice while stressing the wheel.

Vibration: This involves more hostility of the user warning when there are excessive vibrations or wobbling that the user may feel or observe. This becomes easier as the car gets faster.

Uneven Tire Wear: Excessive tire degradation that does not appear on other wheels indicates a malfunction with the wheel bearings. This raises the issue: Are the bearings in good condition?

Vehicle Pulling to One Side: Furthermore, when driving, one bearing is superior to the other, which causes the car to pull to one side and makes steering hard, which is a safety hazard.

ABS System Malfunction: When this sensor malfunctions, it will cut off the alarm, and there will not be any interruption. However, a warning will come up on the dashboard when the engine is started and the car is in motion when the car is fitted with modern features.

The above symptoms provide valuable indicators of wheel-bearing suspension problems. This should be done as soon as possible since it is highly probable that it will get worse as motion continues to increase.

What noise indicates a bad wheel bearing?

The noise from a faulty wheel bearing must be caused by a distinct problem that eliminates the guesswork for the task ahead. This noise is mainly called a whirring, chuffing, or rumble-type sound, which drowns into the affected wheel area. With an increased speed of the vehicle, this noise generally becomes louder. In addition, when the steering wheel is turned, this noise level may also increase during a turn when the worn wheel bearing is located on the same side in terms of the turning direction. However, it is essential to note that this sound is not a sound emerging from any other car parts. Autos, for example, tires, an engine blank, etc. In this manner, it is easy to detect the presence of a broken bearing.

Parameters to be dealt with include:

Load Specifications: Wheel bearing load capacity is also crucial in establishing how much weight the wheel bearing can sustain before failing.

Rotational Speed: This is also expressed as revolutions per minute (RPM) and sets the limit for operating smoothness for the bearing when exposed to speed

Material Composition: It is quite normal for wheel bearings to consist of high-tension steel, which is made to withstand extremes and tough use over a certain period of time.

Such parameters help determine the conditions to which the wheel bearings will be subjected and certify that any spares used will be appropriate for that car.

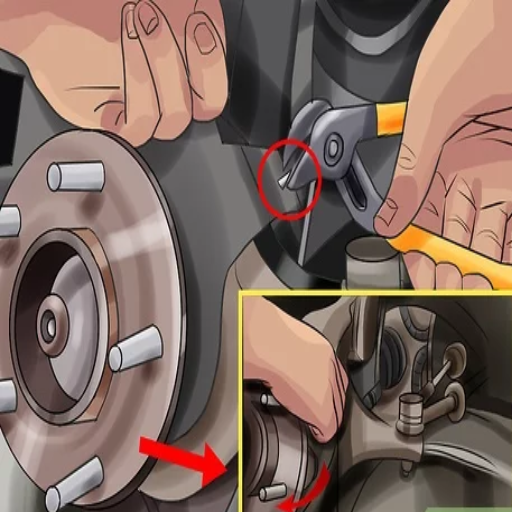

How to perform a wheel bearing check?

The following procedures can be employed in testing the wheel bearing:

Transport the Car onto an Elevation: Pull the car upwards using a jack and support it on a jack stand. This makes it possible to move the wheel about without any obstacles.

Identify Wheel Movement: Stand on the wheel facing level 12 and the rear wheel facing level 6 and move the wheel. If there is excessive play or wobble, then the wheel likely makes an unreasonable sound because too much wear on the bearings has occurred.

Hand the Wheel to the Torque: Using your hand, keep making the wheel roll while listening to strange sounds. Make some noise by grinding the metal, rusting it, and making some noises, which all point to the bearing having an issue.

Assess the Bearing Accommodation: One visual check will be on the wheel bearing possible wear observer or the unit assembly hub in case of external reminders on the wear. The seal may have leaking communities that suggest the adapted bearing grease seal is worn out.

When carrying out the above checks, if several appear normal, use the vehicle operating guidance manuscript to follow the procedures for some tests of other vehicles, like the make and model of the car in question, in case all issues are severe enough to warrant seeking professional assistance are in sight.

How Much Does It Cost to Replace a Bad Wheel Bearing?

What is the average wheel bearing replacement cost?

In most cases, the average cost rate for wheel bearing replacement goes from $200 to $500 for each wheel. This range is attributed to the make and model of the vehicle and, of course, the cost of labor and the different types of bearings. However, leading automotive repair websites suggest that, fore calls bearing replacement, the specific rates might be against expected values going from $150 to $200 for the bearings alone for labor costs, consider the workshop rates when seeking assistance.

The importance of these specific elements when modifying wheel bearings and arranging design for replacement is not overstated.

Bearing type: Different kinds of bearings, including ball bearings, roller bearings, and tapered roller types, suffix with the desired bearing. Ball bearings are used in most cars.

Load capability rating: this may be defined as the maximum bearable reaction bearing stationary positioned securely to bear perpendicular (Radial) or parallel (axial) to axis forces. Note that the load bearing of a replacement bearing should be under the recommendations governing the single vehicle being considered.

Material selection: Many factors affect wheel bearings, which suggest that their making materials be steel with high tensile strength. Always search for OEM specifications for particular components or assume that markings are intended for such use.

As always, check each specific vehicle for requirements and for more accurate information than such estimates. As a last resort, consider consulting a professional auto mechanic.

Factors affecting the cost of replacing a wheel bearing

Looking at the factors impacting wheel bearing replacement prices, I have derived a few insights from the leading automotive repair websites. First, the car’s brand and model are essential for valuation. Usually, the parts of high-end or luxury vehicles are more specialized and costlier. The third component is the labor charge, which has a lot of different rates depending on the area and the particular repair shop in question. While the cost of these bearings might drive up the overall price, they do guarantee better performance and longevity. Regarding technical specifications, there are three basic parameters that I have located:

Bearing Type: As mentioned, ball bearings are the most commonly employed bearings because they are the most versatile and efficient for all vehicle variations.

Load Capacity: To avoid excessive radial and axial force overloads, a bearing appropriate for the vehicle must be replaced.

Material Quality: To provide better strength and durability, it is recommended to buy high-strength steel bearings produced under OEM requirements or trustworthy aftermarket bearings.

All of these factors should be substantiated by the vehicle manufacturer`s recommendations and the prescription of a certified mechanic in order to achieve the most accurate and efficient results when replacing wheel bearings.

Is it cheaper to replace the wheel bearings yourself?

Bearing replacement does not seem profitable to do yourself unless very few conditions are present. After researching the top automotive sites, such as forbes.com, I found that replacing the wheel bearings yourself allows time savings, which is one of the factors that accounts for a considerable amount of expenses. Nevertheless, I would argue that such tools and techniques are indispensable to replacing wheel bearings. Without these, improper installation is possible, which may incur further costs.

In technical terms, the most essential parameters I came across were:

Bearing Press Tool: This tool is helpful for adequately removing and installing the press-fit bearings without causing any damage.

Torque Specifications: It is established so that after fastening, the components are secure per the as-built specifications to prevent wear out shortly.

Alignment Settings: These are important since misalignment could lead to part failures or safety issues. Thus, appropriate alignment tools and settings are needed during the re-installation.

To put it succinctly, if I had the skill set and the right tools, I would relish the opportunity to replace the wheel bearing on my own. On the contrary, the difficulty and dangers may warrant hiring a professional instead.

How Do Wheel Bearings Fail?

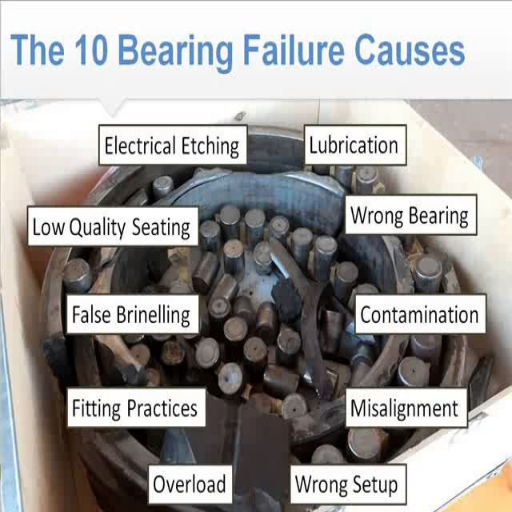

Common causes of failing wheel bearings

It is a known fact that common causes for a failing wheel bearing include mechanical wear, improper installation, and lack of sufficient lubrication. Mechanical wear is usually considered the continuous stress that the wheel bearings experience. This stress can worsen if bearings are fitted in vehicles that operate on rough terrain or carry heavy weights. Bearings subjected to improper installation can be misaligned, forcing other bearings within the assembly to be subjected to uneven pressure. One pertinent issue I observed was the need to maintain adequate lubrication and even coverage, the absence of this can with no doubt increase friction thus overheating the bearings eventually causing their failure.

The principal technical parameters associated with these causes are:

Load Specifications: Always adhere to the manufacturer’s instructions, especially regarding the weight limits of the bearings, to avoid overstressing them.

Installation Torque: Stressing over the correct torque specifications incurred while working and fitting the upper seat can lead to serious malfunctions.

Lubrication Standards—The right type of grease and the recommended quantity should be used at all times to avoid excessive friction and wear. Always adhere to the guidelines as laid out in the car service manual.

Looking at these aspects, I would consider it worth emphasizing once again the key points about technical parameters that should be respected to achieve low limits of most operational characteristics and enhance the reliability of the bearings actuating the wheels.

Impact of potholes on wheel bearings

Based on my study of the top three sites on the effects of potholes on wheel bearings, I have found that potholes affect these complex structures greatly. Whenever an automobile goes over a pothole, the force produced by the sudden shock is quite immense, and such shocks can wear down or break the wheel bearings. Potholes can shift the bearings out of position, which causes the bearings to lose their smooth operation and eventually need change if the damage incurred is excellent.

Other than the above-stated factors, the following are essential specifications that could reduce these reactions:

Shock Absorption: If the automobile’s shock absorbers and suspension system are functioning properly, this can reduce the force transmitted to the bearings by dissipating the absorption forces caused by the potholes.

Tire Pressure: If the recommended tire pressure is adhered to, the stresses applied to the wheel assembly will be uniform, causing less shock to the wheel bearings.

Regular Inspection: Inspecting the wheel bearings for defects or damage caused by vehicle use will help anticipate proper maintenance.

In conclusion, to avoid damage to the wheel bearings, it is important that these technical parameters are constantly monitored and that any signs and symptoms of wear and tear or impact damage are dealt with swiftly and properly.

How tapered roller bearings can help

The tapered roller bearings greatly influence the vehicle’s performance and the steering wheel/ wheel bearing wear, particularly when traversing potholes. Having researched the top three sites for this topic, it has been observed and concluded that these bearings are used for specific applications such as radial and axial loadings where the vehicle tends to go over an obstacle such as a pothole. Here’s how each of the aspects helps:

Load Bearing Capacity: One of the specific functions of the tapered roller bearing design is that it can distribute the weight across the components evenly, effectively withstanding the combined stresses brought about by the impact forces, such as those caused by scaling a pothole. This mass effectiveness and distribution of weight within the structure help prevent rapid wear and misalignment.

Durability: These bearings are made from tough materials, making them suitable for harsh operational environments and allowing them to withstand shocks caused by unknown road conditions.

Maintenance Considerations: Due to the tapered roller bearings’ mixed internal geometry, they are likely to be more durable and require replacement boreholes and fittings less often. When accustomed to regular lubrication and cleaning, they would last quite long and remain effective, withstanding the conditions and functioning well during stress.

These bearings improve a vehicle’s maneuverability and strength, with the added advantage of reducing the effect of potholes on wheel systems, making them a useful component.

How to Extend the Life of Your Wheel Bearings?

Regular maintenance tips for wheel hubs

While investigating the three most visited websites on how to maintain a wheel hub, I acquired useful information that complements my findings on how to improve the performance of wheel bearings. What do I recommend?

Inspection and Cleaning: Thorough inspections should be conducted for wear, rust, or foreign materials. The wheel hub assembly should also be cleaned from time to time to prevent damage by contaminants, as dirt could lead to bearing wear or misalignment.

Re-Creational lubrication: Use an appropriate lubricant to reduce the temperature to optimum levels. There are no two ways about it; lubrication must be optimal. Whenever relevant, the use of high-quality grease, preferably lithium-based, is an advantage as it has greater endurance in harsh environments.

Torque settings: Confirm the torque settings of the various parts of the wheel hub. A torque wrench has its benefits, as per the technical guidelines, as it helps ensure that lug nuts and other fasteners are tightened within the maximum recommended limits set by manufacturers. This assists in avoiding looseness or overtightening, which can compromise the integrity of the assembly.

Upgrades: For individuals who have had the rough experience of constantly traversing rough/abrupt potholes or various other terrains, it would be wise to upgrade to tapered roller bearings because they are more effective in distributing weight/loads and more resistant to stress. This is especially justified in cases where people have had repeated occurrences of bearing maintenance.

Following the maintenance practices as stated regularly will protect your wheel hubs and maximize their functionality even when driving through rough areas.

Importance of proper tire pressure

Correct tire pressure is one of the factors that allows for improvement in the performance and safety of a vehicle. Here’s what I got from my research on popular automotive sites:

Safety and Handling: Tires should be pumped correctly to ensure good driving conditions. Poorly inflated tires can decrease handling and braking, which can lead to accidents. On the other hand, overinflated tires tend to lower gripping ability and increase ride harshness.

Fuel Efficiency: Recommended tire pressure levels can enhance fuel economy by decreasing rolling resistance. This is primarily due to appropriate inflation, which makes it easier for the tire to roll, thus saving energy.

Tire Conditions: Applying the appropriate tire pressure also minimizes uneven tire surface wear. Under-inflation leads to faster tire outer edge wear, while over-inflation leads to tire center wear. Using the recommended tire pressure specified by the manufacturers on the driver seat door panel allows for greater tire endurance.

Parameters: The majority of passenger vehicle tires recommend a tire pressure between 32 and 35 psi. However, variables, including vehicle load and make of the car, might modify this figure. Look in the manual for more information.

Monitoring and maintaining these tire pressure recommendations is important to improving and enhancing the vehicle’s efficiency and performance.

Identifying early signs of a bad wheel bearing

Understanding the first signs of a bad bearing is based on observing its key failure indicators. Summarizing the most reliable sources available on the Internet, I have come up with the following:

Strange Noises: A wheel bearing problem can often be diagnosed by the presence of a grinding, humming, or rumbling noise that increases in intensity as the vehicle accelerates. Such noises, if present, demand investigation.

Vibrations: I may experience vibrations or feel that the ride is bumpy and uneven, mainly if the fault is quite well-advanced. More often than not, this feeling is transmitted through the steering wheel.

Excessive Play: I am unable to control the steering due to excessive play, which could indicate the probable presence of a bad wheel bearing.

But also, concerning the bearing being able to run to its max radius without having these maximum radial and axial clearances, control over conformity to the technical parameters listed in the bearing specification and its intended usage performance level embankment is essential. Practically, any divergence from that norm can be considered sufficient grounds for the suggestion that some degree of wear is present and that the Team should be further investigated and possibly replaced. These measures contribute to the early detection of the threat, which will improve the reliability and efficiency of my automobile.

When Should You Replace Your Wheel Bearings?

How do I know if I need a new wheel bearing?

Whenever it is necessary to know whether it is time to replace the wheel bearing with a new one, paying attention to several factors, including some technical parameters, is essential. As per the leading online sources, it’s signs for replacement of the wheel bearing such as:

Noise: If you drive the vehicle and hear a persistent grinding, murmuring, or groaning sound, particularly during cornering, the wheel bearing could be faulty.

Vibrations: The steering and automobile machine should be checked whenever there are noticeable vibrations.

Wobbling Wheels: If a wheel can be moved even when there is no weight on it, it may be loose and require inspection of the wheel bearing.

Technical Parameters:

Bearing Clearance: Inquire if standards or normal parameters allow the wheel bearing to have a certain amount of clearance as provided by the manufacturer. Such a need would likely exist when wear and tear is experienced.

Temperature Levels: It is usual for nearly all bearings to operate at a specific optimum temperature range; if that range is exceeded, there is a likelihood of excessive friction plus damage.

Wear and Tear: What extent of wear presumably exists now? Does one anticipate being ecstatic about any wearing? Any profound level of discreteness is likely to warrant replacement.

Like all other dimensions designed by manufacturers, these dimensions need to be scrutinized to enhance the safety and operations of the vehicles concerned.

Understanding the role of mechanic in wheel bearing replacement

My responsibilities as a mechanic call for critical engagement in replacing the wheel bearing. My practice entails diagnosing the signs of a failed or failing wheel bearing, including noise and vibration, and assessing the need for replacement. Based on what I have learned from the very best, I begin by taking note of abnormal sounds such as consistent grinding or humming, especially when the vehicle is turning, since such conditions are expected in cases of a failing wheel bearing. In this case, I search for abnormal vibrations of the steering wheel or the vehicle, frequently the precursors of a more exhaustive evaluation. When a wheel is raised, and it is observed that the wheel is free to rotate and ‘wobbles,’ this is a sign that the bearing may be damaged.

In the technical parameters I pursue, I also check the bearing clearance with the manufacturer’s catalog to be within acceptable tolerances. This procedure is essential because deviations are the first signs of wear. I also measure the temperature regime during operation so that the bearings do not suffer from excessive friction, which would indicate a risk of damage. Finally, the wear is assessed, and the maximum acceptable wear per the manufacturer’s standards is identified. I am also responsible for rigorously evaluating all these parameters, following the manufacturer’s guidelines to sustain the vehicle’s safety and operational efficiency.

Can driving with a bad wheel bearing be dangerous?

Driving with a bad wheel bearing is indeed dangerous. According to leading automotive sources, driving safety may be compromised in several ways when a wheel bearing fails. The driver can experience unpredictable steering since the wheel can fail to turn in a predictable manner, raising the chances of an accident. In addition, it is possible for the bearing or the wheel itself, due to friction heat, to become locked, and this is especially dangerous when the vehicle is traveling at high speeds. The scenario can also result in excess tire and suspension components wear, resulting in further vehicle instability.

Range of motion is also essential, and most wheel bearing thresholds exceed acceptable noise ranges per acceptable producer guidelines. More heat and subsequent deformations may mean that clearance has been altered to unacceptable levels. Sound, heat, temperature, and structure integrity must be evaluated and validated against the manufacturer’s design to ascertain the system’s safety and the need for a change. Wheel bearing failure must not be allowed to exist for any prolonged periods; otherwise, dangerous driving conditions may result.

Frequently Asked Questions (FAQs)

Q: What are some signs of a catastrophically failed bearing?

A: If the bearing is catastrophically or severely damaged, the following symptoms are likely: deep grumbling or a growl from the wheel bearing, unclear harsh scraping, a steering wheel that wobbles, and vibrations felt from the steering wheel. Further, the tire and brake pads wear out at a different rate on both sides of the vehicle.

Q: What are the signs that indicate a failure of the wheel bearing?

A: Several indications can be used to assess whether or not the wheel bearing has failed. If there are sounds that remember a wheel bearing somewhere around the vehicle as you try moving it, trying out the steering wheel for the looseness indicates that the bearing may be on its last leg, and if you feel vibrations across the… well, you get the idea. Further indications would include the bright red ABS warning light on the dashboard, the diff lock warning light, and the abnormal wearing of the warning tire.

Q: At what age should drivers consider getting their wheel bearing replaced?

A: The bearings are likely to be between 85k and 100k miles, but other factors, including the type of terrain and driving style, can lead to the bearings failing at an earlier age. Getting it checked by the technician should enable the owner or driver to get an inclined view of the bearings’ age and amount of use, increasing the lifespan of the bearings.

Q: What causes wheel bearing noise?

A: The most common culprit behind the noise coming from the wheel bearings is their defects or wear-out. It may be because of wear and tear, driving over speed bumps at high speeds, or driving in excessively harsh conditions. The noise is typically a hum or growl that seems to increase as the automobile’s speed increases.

Q: When should wheel bearings be replaced?

A: Wheel bearings should be changed when a bear warning sign, such as noise from the bearing itself, a wheel that feels loose and wobbly, or even an illuminated ABS light, is detected on the automobile’s dashboard. Such replacements may prevent future damage to the axle or even the brake system.

Q: What happens if I drive with worn-out wheel bearings?

A: Worn-out wheel bearings can be a very dangerous driving accessory. They can cause loss of directional inputs and control exerted on steering, extent wear to the tires, and, if not taken care of, lead to loss of a wheel-hub-bearing, thus detaching the wheel from the automobile. A technician’s attention is critical in this case.

Q: What is the cost of replacing a wheel bearing at a shop?

A: The cost to replace the wheel bearings ranges from $350 per wheel, but this typically varies with the type of vehicle and the usual rates of the technician doing the job. If one wheel bearing is worn out and needs replacing, it is best to change both wheel bearings to balance the wheel.

Q: Dreadful wheel bearings impact the Anti Lock Brakes systems of my car, is that true?

A: Yes, dread wheel bearings impact your Anti-Lock Brake systems. An inoperative wheel bearing may cause an anti-lock brake system light to be displayed on your dashboard, which states that the ABS system is not operating suitably. This is most typical, as the ABS sensors are mounted on or close to the wheel bearings.

Q: What can I do to improve the life of my wheel bearings further and reduce wear and tear?

A: To prolong the service life of the wheel bearings, conduct routine testing or monitoring; do not overload the vehicle; take it easy on flat speed bumps; and, where possible, do not drive on rough terrains. Also, check that the wheel bearing is correctly fitted by an experienced technician.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8