Maintenance Tips for Long-Lasting ABEC Bearing

In terms of enhancing the performance of a skateboard, attention must be given to the maintenance of ABEC bearings. Such little components, however, are vital as they determine how smooth a ride is and the speed of the ride, so it is essential to all types of skaters. Whether you are an advanced or a beginner, knowing how to handle and maintain the bearings properly will help increase their durability and improve your skating experience. In this manual, general guidelines concerning the servicing of the ABEC bearings are given, along with tips for preventing malfunctions and methods for sight diagnosis of the problems that hinder the smooth rotation of the wheels of a skateboard.

What is the ABEC scale, and why is it essential for skateboard bearings?

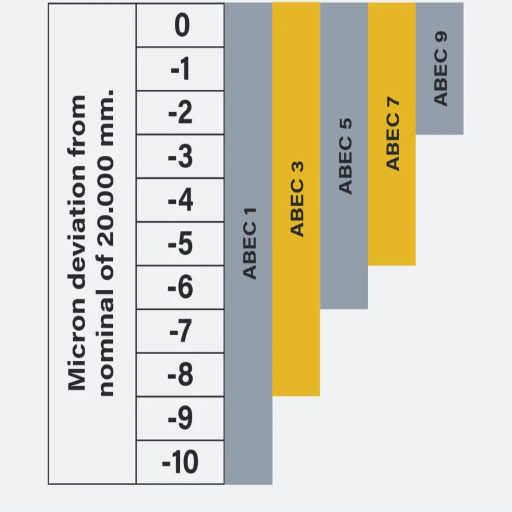

Understanding the ABEC rating system

The ABEC rating system is a standardized method of assessing the tolerance and the accuracy level of bearings about their rotation regarding smoothness and efficient usage. The term ABEC refers to the ’Annular Bearing Engineers’ Committee, and the countries give ratings from 1 to 9, in which nine is the most accurate.

ABEC-1: This is the lowest marked numbered for bearings. Achieving high tolerances is impossible, and all recommended is general use.

ABEC-3 is typical of many skateboard bearings. It allows skaters to cruise fairly well without exerting much effort.

ABEC-5: This bearing, also popular among skateboarders, allows for moderate speed and smoothness and applies in a casual to aggressive environment.

ABEC-7: Most suitable for competitive skaters as speed and smoothness are guaranteed, making it likable to an application with high speeds and minimal friction.

ABEC-9: This have been described as exceedingly accurate and strong allowing for swift skateboarding, however few companies endorse them due to the specificity they present when using them.

It is important to remember that skateboard bearings sacrifice accurate predictions of the use duration, lubrication methods, and materials used to achieve greater precision. The performance of a bearing on a skateboard will be different. ‘Skate ratings’ typically help with selecting the correct roller blades. Still, it has to be mentioned that they have to be adjusted for divergent skating needs and preferences.

How ABEC ratings affect skateboard performance

The effect of an ABEC rating on a skateboard’s functioning is based on its grade of smoothness and the level of precision it offers. In skateboarding, bearing primarily features a lower ABEC rating, for example, ABEC 3 or ABEC 5, because of their adequate smoothness and enough tolerance to absorb the force and oscillations created by tricks or rough surfaces. The need for higher ABEC ratings increases precision and smoothness (i.e., ABEC 7 or ABEC 9), but this is only true for cases that need downhill skating where speed accuracy is necessary.

Tolerance Levels: This relates to the relationship between an ABEC profile and bearing tolerance, which indicates the level of accuracy of a given bearing. For example, ABEC 5 has a tolerance of ±0.0035mm, and ABEC 7 features a tolerance of ±0.0025mm, which allows skates to have a wide range of applications. However, the difference in tolerance is not felt ( but may lead to a degree of difference in smoothness) in the average skating routine.

Speed Potential: It wouldn’t be an understatement to assert ABEC bearing 9 holds remarkable capacity. A claim that a bearing rated nine could withstand ~ 60000 does not sound unrealistic. Most skateboarders may never hit those numbers, but they offer the theoretical potential to go beyond.

Durability and Impact Resistance: Unlike other ratings, finding the relationship between ABEC and impact resistance or dirt is easy. The lower the rating, the greater the dirt, shock, or heavy impact tolerance. This makes the lower rating best for trick or street skating.

Overall, the applicability of comparing ABEC ratings relies on a compromise between the desired rotational speed and accuracy concerning the wear and tear needed for one’s skating style. This way, the rating is assigned to a specific need without unnecessary expenses.

Comparing ABEC 1, 3, 5, 7, and 9 bearings

It is critical to understand the specific features of the ABEC 1, 3, 5, 7, and 9 ratings and their practical applications to make the correct choice among these differences. The chart beneath shows the differences in the specifications of each of the classes and how they compare:

ABEC 1

Technical Parameters: It has the lowest degree of accuracy and efficiency of operation, the axial dimensions are the most slack in the bearing fits, and it has the most outstanding protection from contamination or shock.

Applications: It is ideal for beginners or skating, where the quality of construction and the ability to withstand abrasion are the primary goals, such as street or trick skating.

ABEC 3

Technical Parameters: Compared to other bearings, this one has less slack, increasing precision in responding to each attempt.

Applications: Appropriate for everyday skating since it offers a good compromise between roughness and smoothness.

ABEC 5

Technical Parameters: Consists of a standard degree of accuracy that can be rated as intermediate and recreational grade; the rolling efficiency is moderate after forming the bearing fits.

Applications: It has become a favorite use of most skaters. It is also cheap, durable, and relatively fast, although its best use allows the user to cruise and build speed with minimal effort and undertake stunts from time to time.

ABEC 7

Technical Parameters: Higher skipping and tolerances hold tighter together, allowing for better chances of high spinning and faster speeds.

Applications: Longboarding and downhill skating would be good choices for skaters who love speed and performance. However, they require more upkeep due to their lower tolerance for dirt and shocks.

ABEC 9

Technical Parameters: The highest percentage of precision with the least vent is made to have adequate speed and efficiency.

Applications: A primary application in pursuits characterized by speed, including racing.

Often excessive for urban boarding and more susceptible to the elements in extreme conditions.

Now that you understand these factors, you can select the appropriate ABEC rating for your skating style. Low ones are good for harsh environments and heavy impacts, while high ones are good for maximum speed and precision but lack toughness.

How do I choose the proper ABEC rating for my skateboard?

Factors to consider when selecting ABEC bearings

When determining the necessary ABEC rating for my skateboard, I pay particular attention to a few things:

Type of Skating: If the intention is just cruising or recreational skating, an ABEC rating of 3 or 5 is okay since it has some measure of speed and stability. However, when doing more demanding technical tricks or street skating, I would need bearings with lower ratings, which are more rugged. At the same time, this is the case when racing or downhill skating; another story for the support is an ABEC rating of 7 or 9, as they are simultaneously faster and more fabulous in precision.

Durability vs. Speed: Unlike the previous category, lower ABEC ratings are built to be stronger to cope with dirt, rocks, and tough grass. This is to say that a rating of ABEC 3 would work considerably well. In contrast, ABEC 7 would work well, but only in clean environments. However, that is also very rough, for they require more care.

Budget and Maintenance: If I’m not one to be skating at super high speeds or one that does not require advanced precision, then it would make no sense to get bearings with high resolve due to their steep pricing. So, I consider high-rating bearings because they need a lot of maintenance and are generally difficult to manage.

By coordinating my orientation, inclinations, and technical aspects like the local environment and performance exigencies, I can choose an ABEC rating that is suitable for my skateboarding aspirations while preserving the skateboard’s lifespan and performance.

Balancing precision and cost in bearing selection

In my experience, as long as I examine how I use my skateboard, the trade-off between precision and bearing cost makes perfect sense. For my particular style, for instance, a problematic rating for a specific bearing type is not worth it, nor does it offer significant advantages for ordinary use. This is how I think about it:

Precision (ABEC Rating): Bearings with an ABEC rating of ABEC-5 or ABEC-7 are standard in my assembly. Such bearings set a moderately good trade-off between smoothness, speed, and cost. There isn’t a massive shift in advantage for smooth street skating between ABEC high and low-end, so the high-end precision isn’t worth it.

Cost: Higher precision and advanced feature bearings come at a price. I always decide the price based on my needs. If I require these bearings only for competitive skating then I’ll invest into them, otherwise, bearing with basic specifications are sufficient for me.

Terrain and Performance Needs:

- These bearings add significant weight to the board, so I bear that in mind. I prefer bearings that withstand impacts during street and park skating while cutting through occasional debris.

- While cruising or skating on a flat surface, I focus entirely on speed and prefer more precise bearings. However, I will not compromise on cost.

- Maintenance: For my level of skating, I do not spare the cost of skateboards, but I also depend too much on maintenance. A sealed bearing has never let me down, while freely spinning requires regular cleaning.

Recommended ABEC ratings for different skating styles

According to what is best suited for my skating style, I look for the corresponding ABEC rating so I do not overly neglect the durability and maintenance of the bearing. This is how I go about it:

Casual or Recreational Skating: I find bearing ABEC 1 to 5 bearings more appropriate. These are easier to maintain and perfect for those leisurely rides. At such ratings, that perfect balance between speed and durability is achieved.

Fitness or Speed Skating: I like to stick with ABEC ratings between 5 and 7 for more extraordinary performance as they facilitate greater emphasis on speed while ensuring greater efficiency over extended periods. The low friction enables these bearings to move more smoothly and efficiently over longer distances.

Aggressive or Freestyle Skating: When causing impact on ramps and rails does not allow as much speed, I shift between an ABEC rating of 3 and 5, as they are durable enough to withstand those impacts. However, the onslaught of contacts generated from the tricks and jumps overbears the ABEC rating, so the speed is sometimes compromised.

Competitive Speed Skating: I usually prefer ratings of 7 or higher as they enable me to perform at my highest rate. Furthermore, in competitions and other events, these ratings promote a maximally controlled surface, which allows me to pursue without hesitation.

I ensure enhanced harmony in practices and performance by matching my bearing specifications and skating aims.

What are the best maintenance practices for ABEC skateboard bearings?

Cleaning and lubricating ABEC bearings

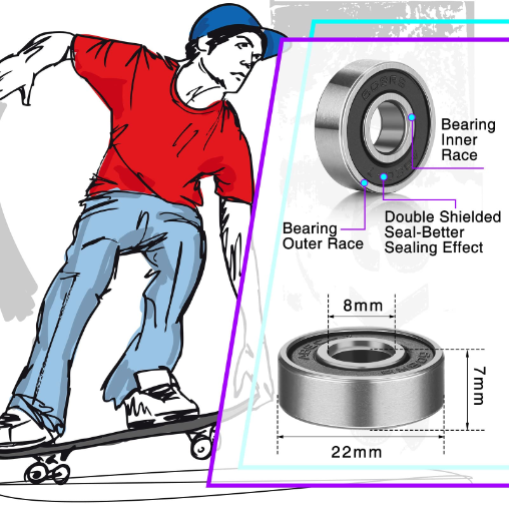

For the ABEC bearings to work efficiently for a longer time, cleaning and lubrication of the bearings is a prerequisite. To properly clean ABEC bearings, first remove them from the skateboard wheels and put them in an appropriate container, which can serve as a cleaner. This is effective because it uses high-quality isopropyl alcohol (not less than 90%), which can dissolve particles like old grease, dirt, and debris. Particles in the container are knocked off by shaking the container, and the bearings are left to dry.

After properly cleaning the bearings, the next most crucial step is lubrication. Use appropriate oils like lightweight bearings, which are specially required for high performance. Applying around 1-2 drops per bearing should reduce friction in the bearings and oil the smooth rotation. Causing over-lubrication is undesirable as it leads to extreme performance issues due to excessive dirt accumulation. Below are crucial specifications that must be complied with;

Lubricant viscosity: Low-viscosity oils must increase wheel speed as they tend to reduce drag.

Temperature resistance: All climatic conditions must be maintained and controlled to allow the consistent functioning of the lubricants.

Cleaning frequency: Depending on the environment, a cleaner must be used regularly: a dusty or wet area may need to be cleaned after every few sessions.

Depending on the materials used and practices followed, it is possible to maintain both the durability and accuracy of ABEC bearings.

Proper storage and handling of precision bearings

Due to the bearings’ long-term endurance and working performance, they usually unfazed themselves; proper handling and storage of the bearings is pivotal. A drastic rephrasing of these topics in a bullet point format can be provided through the following key measures:

Storage conditions:

Temperature: Ideally, their precision should not be interfered by expansion or contraction of bearings, therefore these should be stored with temperatures controlled to between 15°C and 25°C (59°F to 77°F).

Humidity: The relative humidity of the cube should never exceed 60%. This ensures that corrosion can never occur. For additional protection, use dehumidifiers or silica gel packets.

To ensure a contamination-free environment, ensure that bearings are stored in bags or boxes, sealed or as close to sealed as possible until they are ready for use.

Handling procedures:

Clean tools and hands: While changing bearings use clean and dry tools. Then, put on gloves and use lint-free gloves to avoid contact with skin.

Avoid shocks and impacts: Shock, Mechanical or otherwise, is sensitive to all bearings. It can simply ruin a perfectly positioned bearing. Cushioned materials like trays are used to transport the bearings safely.

Technical parameters:

Allowed storage time: In perfect conditions, bearings can be stored comfortably for 5 years. When storing rotor bearings, use armoring, and for longer periods, regularly check them for corrosion or fitting degradation.

Avoid spacing bearings close to chemicals, solvents, or materials that produce corrosive gases, as these deteriorate protective coatings.

Adhering to these measures will help preserve the bearing’s accuracy, efficiency, and durability, and smooth and steady operation will be guaranteed.

Signs that your ABEC bearings need replacement

Evaluating the indicators of ABEC bearing replacement so that the equipment does not get damaged and can work satisfactorily. The following indicators are essential to consider:

Unusual Noise or Vibration: Operating the bearings sometimes emits grinding, squealing, or other irregular sounds, which raise suspicion of wear on the internal parts or contamination. Such noise is also caused by increased vibration levels, which can be attributed to possible misalignment or surface damage.

Decreased Rotational Performance: One of the internal faults that can prevent smooth spinning and allow stiffness to bearings is pitting corrosion and lubricant deterioration. While at a low load, rotary resistance can be tested to confirm such suspicions.

Visible Damage or Corrosion: Loss of bearing function can be observed if there is a loose fit between the rolling elements and raceways, in addition to any cracks or marks of rust that can cause pitting or corrosion erosion on the components.

Exceeded Temperature Level: This is a common and obvious indicator of overheating due to a temperature rise and is typically used for housing to avoid high rotations or due to substantial temperature changes on the rolling elements. Operating high temperatures of a bearing upwards of 120 to 200°F depending on the bearing type, also means it requires an urgent replacement.

Leakage/Cross Contamination: Highly detrimental to function loss, over time, ABEC bearings can show signs of a precision rating that deteriorates quickly when dry or cross-contaminated; for this reason, avoiding dirt, debris, or lubricant waste is extremely important.

Addressing these problems according to their technical characteristics and carrying out a proper assessment allows timely replacement and maintains the efficiency and safety of your equipment.

How can I extend the lifespan of my ABEC bearings?

Regular maintenance routines for longevity

I prioritize a few primary maintenance routines to maximize my ABEC bearings’ lifespan and performance.

Regular Wash: The first thing that comes to mind is that I wash my ABEC bearings regularly as I clean them before use. However, periodically cleaning does not mean neglecting pre-use washing, as I also thoroughly check for wear or damage on the races and cages. I also warm the bearing before lubricating it to moisten the grease and assist with cleaning.

Lubrication: As I stated, cleaning is essential, so is lubricating. Applying the correct lubricant, quantity, and quality is crucial. It is not used carelessly towards the application as it quickly saturates or thickens even in austere conditions, nowhere attending application-specific grease that expands the working temperature. No thick grease goes untended in my setting, mainly because it has a high probability of leading to wear and corrosion due to its half-applied viscosity.

Structural Stress: Structural wear is also a significant concern; specific load to measure your product’s capacity does help alleviate that concern already. Critical failure to a product can occur when particular parameters are in excess, such as exceeding a dynamic load rating for my model.

Shielding: Water is one of the causes of worry related to ABEC’s bearings. Expanding on this, a seal or shield can help mitigate aspects of moisture or dust while occasionally checking these seals to help maintain maximum performance level.

Watching Operating Conditions: I monitor speed, temperature, and vibration levels concerning the bearing’s specification to avoid FMEA situations. For instance, I prevent rotational speeds from exceeding precision limits and maintain operating temperatures from exceeding 120 degrees (or the rated limit).

Working alongside these practices, I can optimize the performance of all my ABEC bearings and significantly increase their lifespan.

Protecting bearings from dirt and moisture

To begin with, the most crucial step is understanding the necessary concepts for efficient maintenance. This includes all the strategies one must implement to maintain the bearings. Steps that I ensure to maintain consist of:

Using Seals for Protection: Coming across seals or shields to protect components is very handy. However, one has to be careful as there are two types of shields available in the market: metal shields (that have low friction) and rubber seals (which offer better resistance).

Impact of Lubricants: Lubricants work as a fantastic barrier along with dirt and water. In certain situations, such as when it’s humid outside or during high temperatures, water-resistant grease is ideal to use, especially when there is high viscosity involved.

Protection in Hazardous Areas: Critical zones with risk factors present involve dirt and flammable chemicals. In such places, protection is necessary, and the bearings are alternatively placed inside the housing to protect them further. Water jets or sprays can damage seals, so avoiding them is essential.

Managing The Temperature: According to the desired temperature, never exceed the limit of 120°F as it can exceed minor characteristics of certain substances, directly interfering with the protection qualities of elements.

Once these principles are integrated into the routine maintenance checklist, it allows excellent bearings to stay operational and versatile as the conditions they can now withstand allow optimal chances of preventing damage.

Adjusting bearing tension for optimal performance

Bearing performance is a distinctive feature in that tensioning must be done carefully. Initially, I looked up what the bearing type I use specifies as the recommended preload or clearance. For example, angular contact sets of balls may call for some controlled preload for rigidity, whereas deep groove set balls may work under some alright preloading conditions.

In this context, I use a torque wrench and only go as far as the specifications go to avoid needless breaches of recommended tension strength. However, one has to remember that there is room for variance: tens of torque and 10 could be the lower baseline for other ranges of 10-30 Nm durant applications across numerous industrial iterations by these machines and machine loaders of different bearings. Many experts will argue that altering temperatures can add damage or shorten the lifespan in excess or tightening based on mechanical friction. To prevent this from happening, I will adjust the torque to the level where there is optimal rotation without resistance.

These adjustments are followed by a spin or load test, where I check for alignment and tension. Shifting loads, thermal fluctuations, and unusual vibrations followed by noise could be perfect pointers in determining whether torque was proper. In doing so, it is unsurprising that these steps’ precision elongates the bearing efficiency and lifetime.

Are high ABEC ratings always better for skateboards?

Debunking myths about ABEC 9 bearings

A typical misconception around ABEC rating is that the higher the rating, the more efficient skateboard performance is bound to be. While the ABEC scale is indeed a measure of the tolerances in manufactured parts, in most cases, speed and efficiency at high RPM matters more, for example, in tools and machinery, not skateboarding. On the other hand, skateboard bearings’ performance is affected much more by construction materials, the quality of lubricants, and the design as a whole than by being ABEC 9 rated.

Skateboards do not get to such high speeds enough for the difference that high ABEC ratings create to come into effect (up to or more than 30,000 RPM). Rather, using skateboards requires bearings that can withstand shocks, dirt, and unpaved surfaces. Bearings of a lower ABEC, say ABEC 5 or even ABEC 7 would work just as well if not better, as they have been rated or manufactured for tougher conditions. Some important factors include the following:

Load Tolerance: Why endure loads in the axial and radial range; bear the brunt of skateboarding with high velocity-based bearings.

RPM Relevance: The average skateboarding activity is relatively routine, and one does not wow us with speeds that are out of the ABEC rating zone, say around 200-300 RPM, depending on the wheels.

Materials and Lubrication: Ceramic or high-grade steel materials and reliable low-viscosity lubricants ensure the bearing lasts longer while providing a smooth ride.

In the end, it is often more reasonable to pursue strong and versatile bearings when it comes to skateboarding than those with the highest ABEC grade.

Balancing precision and durability in skateboarding

Regarding skateboarding, the primary focus is blending precision and high durability. Rather than isotopically seeking high ABEC ratings, my strategy revolves around function. Below are my approaches to core technical parameters:

Load Tolerance: I select bearings that can withstand axial and radial stress because such stresses are likely during landing tricks or making sharp turns. This ensures that bearings can take the beating and still provide stability.

RPM Relevance: Skateboarding operates at low RPMs in the region of 200-300. Hence my focus is not on how impressive an ABEC rating is, it is more how the bearings of the skateboard perform in real world situations, for example how smooth it is when riding on rough surfaces.

Materials and Lubrication: The bearings made of high-grade steel or ceramics with low-viscosity lubricants are long-lasting and improve the ride quality. These materials also enhance the reliability of the bearings over time by reducing friction.

With this range in mind, I find it easier to balance precision and the amount of abuse a skateboarder can put into it.

When to choose lower ABEC ratings for skating

In particular skating situations, slower bearings and a lower ABEC rating help, for instance, in cases where the resistance to impact and durability of the bearings are considered a priority. In most instances, lower-speed scenarios, including rough terrain, skate tricks, and low-speed rides, suffice and are appreciated more if outfitted with lower abec-rated bearings.

Load tolerance is hard to consider while bearing boundaries are being pushed, especially ABEC-rated variations. However, in instance studies revolving around trick skating or smoother surfaces, it was found that lower ABEC-rated bearings coped better in terms of damage alongside being more streamlined in format.

The majority of RPMs that skateboards operate on, which in case study studies lie between the 200-300 RPM range, form a basis for why low abec rated bearings do not perform poorly. Through case study scenarios, forcing a lower ABEC bearing rating doesn’t diminish the skateboarding experience alongside the robustness and smooth operation of the bearings.

Many use lubricants that allow the bearings to showcase desirable compact aspects, such as maintaining good shape while being durable despite relatively challenging situations. High-grade bearings alongside rigid components are enough.

Therefore, weighing these factors allows me to ensure a smooth balance by using bearings required in rough conditions and maintaining desired functional features.

Frequently Asked Questions (FAQs)

Q: What is the purpose of the ABEC Standard, and how does it relate to bearing accuracy?

A: Bearing tolerances are rated using the ABEC (Annular Bearing Engineering Committee) standard, which has now become accepted. This guide was created to assist consumers in making better decisions. Consumers have been guided and classified into four groups: ABEC 1, ABEC 3, ABEC 5, and ABEC 7. However, it’s worth mentioning that ratings such as ABEC alone do not define bearing functionality per se or their suitability for use in some designated purposes.

Q: How frequently should I clean my ABEC-rated bearings?

A: Usage and the surrounding conditions will determine the cleaning’s regularity. Cleaning’s aftermath is the role performed by the skate bearings or longboard bearings for cases where the conditions involve dirt and moisture as one area of application, and the recommendation is to clean them every three months. Cleaning may not be as frequent in less demanding environments, such as aircraft and surgical instruments. Proper washing and retaining methods assist the bearing in maintaining precision and longevity.

Q: What factors affect how often maintenance of ABEC 3 or ABEC 7 bearings would occur?

A: In terms of maintenance, ABEC 3 and ABEC 7 bearings are pretty much the same, but what STANDS OUT is the fact that the former has higher tolerances than the latter. Like ABEC 3 bearings, the ABEC 7 requires maintenance and regular lubrication. However, they will likely be more difficult because they have a high tolerance level and do not handle impurities and dirt well. Therefore, more cleaning and lubrication is required so as not to reduce their performance, which was initially very high.

Q: When lubricating ABEC bearings, what procedures should be followed?

A: Firstly, all ABEC bearings using a specific type of lubricant as part of the application should be cleaned well, the second step would be to apply a lubrication type that fits the operating conditions comprising of the bearings AS for elastomers sealed bearings should be used for high speed applications. The inner ring and ball bearings should be lubricated with a suitable amount of lubricant that surpasses the threshold. Applying too much lubricant can affect performance. Finally, when lubricating, avoid the use of thick oils as they are typically unsatisfactory

Q: Are ABEC-focused bearings interchangeable for different applications?

A: Yes, ABEC rated bearings with similar dimensions can be used interchangeably when required, however, that does not mean they can all be utilized for the same purpose. There are specific bearings for specific functions, and the AEC isn’t the only thing to consider; load capacities, speed, and weather resistance, for example. For instance, even if a bearing for skating machines has the same ABEC rating, it might still be interchangeable with bearings in other areas of application that involve specific machinations.

Q: Where does ISO 492 fit into the relative classification of ABEC ratings?

A: ISO 492 is, in effect, the standard ABEC tolerance because it deals with the tolerances of ball bearings. They don’t exactly match, but there is some correlation between the ABEC grades and the ISO tolerance classifications. In the International Organization for Standardization (ISO) Global Form Diffusion – Japan Standard for Industrial Specification (JIS) Normal Class, the International Standard for Bearing Categories is 1. In the ISO P5 class, the International Standard for Bearing Categories 5 class is equivalent. If both the standards are well understood, it will assist in choosing a bearing suitable for the measurement and lubrication best methods.

Q: What signs indicate that an ABEC bearing needs replacement?

A: Loss of spinning time, deterioration of parts of the bearing, improper movements, and noise of grinding, squealing, or clicking is invariably a sign of warning (gritter sounds), and in such cases, the wearable component, in this case, ABEC, bearing, has to be MMA’ed to Function in operation work optimally. BA testing is also crucial to determine the components’ wear so optimal performance can be maintained in operation.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8