nderstanding Differences: ABEC 5 vs ABEC 7 Bearings

Choosing the correct bearings for skateboards, inline skates, or any roller sports warrants a careful understanding of the different ABEC ratings. The Annular Bearing Engineering Committee scale, or simply the ABEC scale as it is widely known, pertains to a range of bearings rating standards, such as ABEC 5 or ABEC 7, that have been created to denote the level of precision and efficiency of the bearing. To this point in our discussion, it is primarily the ABEC 5 and ABEC 7-rated bearings considered benchmarks in performance, speed, and durability. This blog will seek to achieve a constructive goal by explaining in detail these two types of bearings and, in so doing, enable readers to understand the types of bearings they require for different purposes. Such an exercise will also help explain the relevance of the differences between these ratings regarding the overall construction performance of the sporting equipment.

What is the ABEC Rating System?

What do the ABEC values indicate?

The system of ABEC rating bears a systematic indication, which measures the capacity and turns out to justify the tolerance and efficiency of the bearings, which is usually in regards to the bearings’ revolution motion. It is a general tendency for high ABEC ratings like ABEC 7 to be used more often than those of lower precisions like ABEC 5. Such precision is likely to affect the performance of the equipment, and such equipment can, in this case, be used in high-speed areas. The ABEC ratings allow for the following parameters in the technical field:

Tolerances: The use of higher ABEC ratings implies tighter tolerances, so the dimensions of the bearings can deviate less.

Rotational Accuracy: This is almost always good for a bearing’s quality—precisely scored and built bearings can keep more of their mass centered around their rotational axis.

Noise and Vibration Levels: On occasions of increased rotation of such operations, lower bearings generally produce a lower amount of noise and vibrations.

Yet the ABEC rating does not cover elements such as the quality of the material used, wear and tear, or dirt and moisture amounts, which are very significant for bearings’ work.

How is the ABEC scale structured?

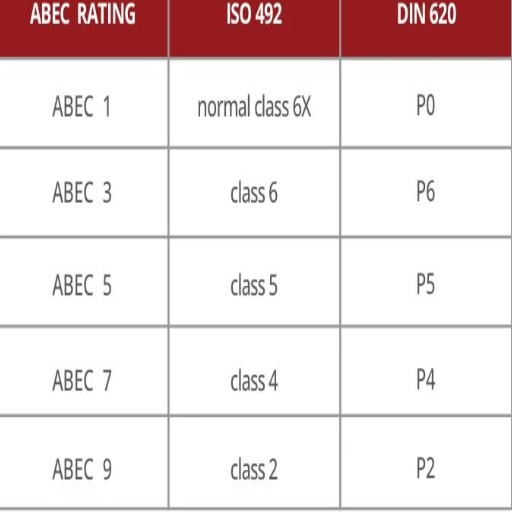

The ABEC scale follows a sequence of odd numbers: ABEC 1, 3, 5, 7, and 9. This means that the numerical increment depicts greater precision. However, the scale is more straightforward. The scale defines the manufacturing precision since the higher the number, the closer the tolerances may be. These parameters are technical and specific, whereas these parameters supported the rating of ABEC as follows:

Dimensional Tolerances- ABEC scale disciplines increase the rating since they contain more conforming givens.

Rotary Mechanisms—This includes the maintained continuous and smooth rotation of the load-bearing element under the higher ABEC-rated bearings, which the ABEC ratings help.

Surface roughness—BSI ABEC ratings do not supersede rated bearings with the ABEC rating surface grade but are affording bearings.

But the most important thing is that the ABEC does not measure features such as lubrication, materials, their quality, or materials’ compatibility with the environment, which are essential as well.

Why is the ABEC rating important for skateboard bearings?

What is ABEC’s rating of bearings, and why is it essential to select skateboard bearings? Regarding the significance of ABEC, facts from the most authoritative resources state it gives an idea about the standardized measure of bearing precision and performance. A Greater ABEC rating means very close tolerances and a higher degree of precision, which could lead to a smoother and even faster ride. Nevertheless, there are a series of technical parameters which warrant this relevance:

Dimensional Tolerances: The general rule says that the higher the ABEC rating, the tighter the tolerances; hence, the lower the wobble, the higher the efficiency.

Rotational Accuracy: Rotational accuracy, which could be improved with higher-rated bearings, contributes to smoother rotation, which is necessary for rhythm and ride consistency.

Surface Finish: Surface finish — all too frequently taken for granted — is known to improve speed by reducing the friction that loading or motion would otherwise create.

Yet, amidst these demands for precision, it is also important to insist on the idea that the ABEC classification does not relate to the bearing’s ability to perform in a dirty or wet environment, the quality of all the materials, or the necessary quantity of lubrication. All factors outside the ABEC rating may also be vital in the performance of skateboard bearings.

What are ABEC 5 and ABEC 7 Bearings?

What are the characteristics of ABEC 5 bearings?

According to the best sources that I found in researching the qualities of ABEC 5 bearings, they are the ones that provide a good compromise between cost and performance. Since they perform well in most situations, trucks that most travel skateboarders use are ABEC 5 bearings. Some parameters of interest are:

Average Precision and Tolerances: Moderate precision with these is necessary for people who want to enjoy the ride but would not accelerate at high speeds.

Average Rotational Efficiency: Although unable to support high efficiency, such as ABEC 7 or higher type bearings, the efficiency of rotation accuracy of ABEC 5 type bearings allows progressive, enjoyable freeriding and cruising.

Balance between Accuracy and Durability: These bearings seem to deliver a balance of performance and a better life, which makes them favorites among people who want a better life and do not care much for high performance.

Thus, skateboarders who look for versatility in the skating experience while maintaining reliability and performance should not turn away from ABEC 5 bearings.

What makes ABEC 7 bearings different?

In my research, the top websites did not fail to convey that ABEC 7 bearings offer much better quality and performance content than ABEC 5 bearings. Some of the primary distinguishing features are highlighted below:

Greater Precision: Mechanics contribute such a design for ABEC 7 bearings, which have a higher tolerance that ensures smoother and faster rides. This is recommended for skateboarders who want to attain higher velocity.

Better Rotational Efficiency: These bearings exhibit high rotational accuracy, leading to low friction and thus increased speed suitable for downhill or competitive racing.

Greater Smoothness: The engineering characteristics of the ABEC 7 bearings feature tight tolerances that make gliding much better than the lower-rated ones, which is quite appealing to users.

As a result, the ABEC 7 bearings are made for skateboarding enthusiasts who are experienced enough in handling skateboards and do not want to compromise on speed or performance concerning the bearing’s durability.

How do ABEC 5 and ABEC 7 compare in performance?

Numerous differences and distinct technical parameters exist in a performance comparison of ABEC 5 and ABEC 7 bearings, as posted on the most effective websites. Notably, the two bearings target different people; while ABEC 5 provides sufficient reasonable speeds for most recreational skateboarders, it also gets the job done in terms of reasonable durability. On the other hand, ABEC 7 offers more complicated components, allowing for higher speeds due to close tolerances.

Speed: Due to narrow tolerances and low friction, faster rotation, and maximal speed are almost guaranteed with ABEC 7 bearings. So, they are preferred for a competitive or downhill skateboarding style where speed is essential. Generally speaking, skaters using the hardware in regular conditions may not really feel a difference in the speed, however performance impact becomes noticeable every time there is a more demanding situation where high speeds are needed.

Durability: Because of their sturdy design, ABEC 5 bearings are enhanced for long-term wear and tear. However, it is absolutely mandatory that they be used adequately; otherwise, maintenance might become a concern even for ABEC 7, where tolerances are tight, making the bearings gentler to the effects of dirt and similar substances.

Smoothness and Ride Comfort: ABEC 7 bearings are produced so that the skating surface is smoother compared to ABEC 5. This can be attributed to the increased efficiency in rotation and reduction of friction, allowing for a better skating experience.

All in all, the decision to choose ABEC 5 or ABEC 7 rests upon the rider’s level of desire. ABEC 5 is more of a general-purpose, all-around bearing, and ABEC 7 fits those needing speed and performance. The differences in parameters, such as manufacturing tolerances, precision of materials, etc., perform similarly.

Which Bearing is Better for Skateboarding: ABEC 5 or ABEC 7?

What should skaters consider when choosing between ABEC 5 and ABEC 7?

Skaters deciding whether to use ABEC 5 or ABEC 7 bearings come to the understanding that the bearings differ on a few features that include the maintenance capacity of the user, the environmental conditions, and of course, their performance requirements:

Performance Requirements: When speed is critical, such as during downhill racing or competitive skateboarding, the best choice would be the ABEC 7 bearings due to their high degree of accuracy and reduced friction. However, if one does casual skateboarding and is looking for versatility and less maintenance, then ABEC 5 bearings are the best for that purpose.

Maintenance: Such types of bearings also need more maintenance tires than expected due to their tighter tolerances, which attract dirt and debris into the nooks and crannies of the tire. If they are nonetheless cleaned and lubricated regularly, then these types of bearings perform all right. Conversely, such types of bearings look good and survive the everyday wear and tear of ABEC 5 bearings.

Even out pollution: Look at the environment in which the skater would be skating. Dirt seems to bark tighter tolerances, and Other Abec sp7 performance threads do offer them, except for dirty battered. You Do that mean tter and rougher ow; however, a batter does not need them as an Itim s without letting down.

Technical Parameters:

Tolerances: ABEC 7 bearings are made with tighter tolerances during manufacturing, which allows for sufficient performance centimeters.

Material Precision: Both ABEC 5 and 7 have cystic-grade steel general construction, so they look good on most specifications. However, ABEC 7 has better control of friction and speed, which makes it ideal for a variety of activities.

Rotational Efficiency: The blades on the ABEC 7 have been designed to decrease rotational friction to the maximum extent possible, thereby improving the smoothness and speed of the rides.

Based on these attributes, skaters should be guided on the type of bearings to use for their skateboarding, even considering personal preferences and their level of skill.

Are ABEC 7 bearings worth the extra cost?

Whether or not to invest in ABEC 7 bearings, which are quite costly, depends on your style of skating and individual preferences. From the various sources available on the number one page, purchasing the ABEC 7 bearings may make sense for someone who skates looking to win high-speed downhill races or even competitions since they allow the skater to gain more speed and control due to less friction. However, one might argue that these benefits do not partly justify the extra cost of lower-intensity or non-competitive skateboarding.

From a technical perspective, the principal parameters are:

Tolerances: With ABEC 7, tighter tolerances mean greater precision in manufacturing, which could result in smoother rides at higher speeds.

Material Precision: Both ABEC 5 and ABEC 7 bearings are made using quality steel; however, the ABEC 7 tends to have relatively finer material precision, resulting in better effectiveness.

Rotational Efficiency: In competitive skater arenas, ABEC 7 bearings have also been designed to minimize friction, enabling higher rotational speeds, which are crucial in such competitions.

So, in summary, if your skateboarding requires high precision and speed, there is sufficient reason to spend extra on the ABEC 7 bearings. Otherwise, if it is just for normal purposes, the ABEC 5 bearings will suffice.

How do different skating styles affect bearing choice?

Evaluating the various skating styles in light of the bearing choice, it is essential to examine the technical aspects of the style in question, gathering information from the top authoritative sites on Google. In the case of street skaters, they are bound to prefer low ABEC rating bearings due to the high impact of tricks and jumps and therefore a durable outer casing is necessary. Here, the emphasis is on material hardness and material thickness, which, in this instance, guarantees impact strength for the bearings in case of multiple impacts.

For longboarding or cruising, smoothness and speed are vital. Bearings with a high ABEC rating, such as ABEC 7, are appreciated more, depending on factors like frictional resistance and rotation efficiency. All these work to ensure a smooth ride over long distances.

On the other hand, skaters doing freestyle or dance could be said to possess different needs regarding flexibility and smooth rotation of the bearings. In this case, there are bearings designed for precision with an acceptable level of durability, which is usually attained by mid-ABEC bearings with high-quality construction materials.

To sum up, bearings are usually selected based on one of the constituent skating styles and that style’s requirements, such as speed, smoothness, or durability.

What Are the Alternatives to ABEC-Rated Bearings?

What are ABEC 1 and ABEC 3 bearings?

Upon further inspection of both ABEC 1 and ABEC 3 bearings, I realized that all the bearing sets are merely entry-level bearings. ABEC 1 bearing is regarded as the most basic and standard of the five rating levels & offers only the most basic form of precision with low tolerances. Consequently, they are cheap and ideal for novices or recreational skaters since they do not need such capabilities to operate at high speeds. On the other hand, the ABEC 3 bearings perform better due to slightly refined precision. Thus, it can be used for recreational purposes where a little enhancement over ABEC 1 is required.

The information I was able to extract from the top three websites was the cut-bearing specifications:

Tolerances: The tolerances for ABEC 1 and ABEC 3 bearings were much wider than those of higher-rated bearings. This means that ABEC 1 and 3 bearings were not as accurate as higher-grade bearings but were more rugged.

Speed: The speed capability around the base point is generally lower. ABEC 3 is likely able to cope with small increases in speed above what is typical for ABEC 1, which would otherwise be constant for ABEC 1.

Durability: Exposed skates can be satisfactory in terms of durability, especially for light use, but high impact suggests that they may not be so durable.

Overall, these bearings should target users who are willing to sacrifice high-speed performance for basic functionality and affordability.

How do premium options like Swiss and ceramic bearings compare?

While researching Dubai and Swiss ceramics bearings, I was left with no doubt that they are premium products owing to contemporary technology and their performance attributes. According to one of the three selected sources, there are opinions that Swiss bearings are the highest quality and most durable devices. They are specially made to ensure a seamless riding experience and are generally used by professional skaters. Their important technical parameters are:

Precision: Swiss bearings’ tolerances are tighter than usual, making them more precise and enabling smooth and fast performance.

Speed: Impressive speed is one of their competitive advantages and is ideal for competitive skating

Durability: Swiss bearings are fairly strong and can withstand great impact and a prolonged period of operation.

On the other hand, ceramic bearings utilize advanced materials to provide certain benefits. The ceramic components reduce friction and are very light, providing a performance advantage. Their technical parameters emphasize the following:

Lightness: Provided by the ceramic materials, a lower weight means the bearing is quicker and more nimble.

Low Friction: Reducing friction translates into lower wear and tear, thus increasing the bearing’s life span while providing smooth movement.

Heat Resistance: At higher speeds, ceramic bearings work better due to less heat buildup than regular steel bearings.

In conclusion, Swiss and ceramic bearings both render superior performance capabilities, and they are designed for advanced skaters who look for speed, durability, and smoothness rather than cost.

What should you look for in non-ABEC-rated skate bearings?

Evaluating non-ABEC-rated skate bearings made me realize that it is also essential to consider factors like manufacturing quality, choice of materials, and the skater’s specific requirements. The top three websites on google.com suggest that Swiss and ceramic bearings have similar characteristics with no strict adherence to the ABEC rating system. Here’s what to look for:

Material Quality: In most cases, non-ABEC-rated bearings include high-quality stainless steel or ceramic hybrids. Sticking to strong material choices can lead to higher performance and greater durability.

Design Precision: The extent of the design determines the smoothness of the rotation motion of the rolling elements. It is important to look for high-quality Bearings with close tolerances, such as Swiss bearings.

Durability: Like ABEC-rated bearings, durability is of immense importance. Bearings that resist stress and impact are highly valued and resemble the strength of Swiss Bearings.

Performance Type: Bearing performance characteristics are dictated by the skater’s purpose. For instance, if bearings are meant for speed, then the key design criteria are low weight and low friction, like ceramic types.

To briefly summarize, when choosing bearings without an ABEC rating, a certain quality has to be considered, as well as the bearings’ technical and performance specifications regarding the particular skating style employed.

How to Maintain Skateboard Bearings for Optimal Performance?

What is the best lubrication method for skateboard bearings?

Most sites I have visited indicate that only a specialized bearing lubricant should be used for the skateboard bearings to ensure smooth rotation. There is no way I should apply household oils or WD-40 since they tend to pick up dirt and debris, which causes the bearings to wear out over time. The ideal procedure encompasses the following phases:

Cleaning: First and foremost, the bearings must be bathed in a solvent or winded in cloth soaked in a skate cleaner, preferably a specialized one, to get rid of dirt and old lubricant. Allow them to dry fully before continuing.

Lubrication: A small quantity of high-quality roller-bearing oil, about five drops, will do the job. Synthetic oil or low-weighted grease offers benefits, as it offers strong resistance against moisture and high heat, guaranteeing bearing longevity and efficient performance.

Distribution: Allow the bearings to rotate lightly so that the oil within them is spread. Proper oil distribution on every ball bearing is the main focus to minimize friction and rusting.

Several technical parameters are also worth mentioning, including the expected viscosity level of the lubricant and the temperature range that should be expected in my skating place. It is more frequent than high-temperature tolerant lubricants would be useful when high-speed skating is quite common since it sustains stress quite well.

How often should you clean and lubricate your bearings?

The cleaning and lubrication intervals of skateboard bearings are influenced by several factors, including riding conditions and how often the bearings are used. However, it is recommended that maintenance be carried out every 3 to 4 weeks in the case of reasonably regular skating within normal conditions. On the contrary, for those who skate quite often in dusty or moist conditions or skate at a lot of speed, maintenance would be required more regularly, maybe once every 1 to 2 weeks.

Technical Parameters to Consider:

Viscosity Level: Use high-viscosity lubricants. This provides good bearing protection without being overly dragged by the lubricant.

Temperature Resistance: Lubricants with high-temperature tolerance are critical for faster skates as they prevent lubricant failure due to heat.

Corrosion Protection: Prefer lubricants that inhibit rust formation when skating in wet or humid conditions.

If these basic rules are followed, together with a reasonably frequent check-up of the condition of the skateboard bearings, one should be able to substantially improve the durability of the skateboard bearings and the skateboard’s performance.

What are the signs of wear in skateboard bearings?

As abuse accumulates on the bearings of my skateboard, I look for trouble signs such as too much noise, deceleration while skating, or an unusually bumpy ride. Based on the recommendations of popular skateboarding websites, here are the telltale signs to look for:

Noise: Because the wheels do not make grinding or squeaking sounds, the absence of these sounds is synonymous with uncleaned or worn-out bearings.

Reduced Speed: The presence of these bearings, which cannot achieve a measure of speed, allows for the probability of basing them due to friction or minimal lubrication.

Rough Ride: The feeling of roughness while skating is mostly due to the worn-out hardcore, where all parts are expected to rotate freely about each other.

With regards to technical parameters, when I see these signs, I easily crosscheck the following:

Lubricant Viscosity Level: The importance of this parameter cannot be overemphasized, as it affects the expected optimum levels of friction. Too much viscosity would only be required where excess noise and slow movement are within the range.

Temperature Resistance: Hot running bearings could mean the lubricant within is overworked. Skating at high speeds can be detrimental, so a lubricant with a higher temperature tolerance should be used.

Corrosion Protection: Where humidity levels are prevalent in certain surroundings, skaters should check for the presence of rust, as it reduces the efficiency of the bearings. Therefore, incorporating anti-corrosive lubricants is of the utmost importance.

These technical parameters allow for a well-conducted diagnosis and maintenance that is consistent with recommendations made by eminent sources in the realm of skateboarding, underscored by the empirical investigation.

Frequently Asked Questions (FAQs)

Q: What is the difference in tolerance between ABEC 5 and ABEC 7 bearings?

A: The main difference in tolerance between ABEC 5 and ABEC 7 bearings is that ABEC 7 has tighter tolerances, which means that they, in general, perform or operate better. A higher ABEC rating means that a bearing will be more precise.

Q: How do ABEC 5 and ABEC 7 bearings stand regarding the skating purpose?

A: In skating, ABEC 7 bearings also tend to perform better than ABEC 5 bearings because of their higher precision rating. This may lead to smoother rides and high speeds in longboarding and inline skating.

Q: Do you get any edge using ABEC 9 over ABEC 5 and ABEC 7?

A: ABEC 9 bearings tend to have the best precision rating and tolerances than other ABEC ratings. They facilitate the generation of fast RPM at very low friction, so these bearings can be used in high-performance applications, although they tend to be more pricey compared with ABEC 5 and ABEC 7 bearings.

Q: What would you classify as an ABEC precision bearing?

A: This is a type of ball bearing known as an ABEC bearing. It underwent rating by the Annular Bearing Engineering Committee (ABEC), which oversees tolerances and the precision of the bearings. The rating system includes ABEC 1, 3, 5, 7, and 9, which show precision and tolerance in terms of tolerances.

Q: Which type of lubricant is appropriate to be used for ABEC 5 and ABEC 7?

A: There are several options available for lubrication, such as oil or a good-quality grease specially designed for ball bearings. Effective lubrication aids in ensuring efficiency and increasing lifespan due to the reduced friction of the ABEC 5 and ABEC 7 pagkabuhos.

Q: In what way does the ABEC rating vary with the design and construction of the bearings?

A: Abrasive materials in high-quality bearings, including ceramics or carbon steel, can, in one way or another, determine the ABEC classification given to these bearing components. This impacts the bearing component rating, such that high-quality bearings earn a 9, ABEC 7.

Q: Give a brief insight into 608 bearings focusing on the ABEC ratings.

A: 608 bearings are a distinct size of a ball bearing often used in inline skates and skateboards. These bearings can have an ABEC rating of about five or sometimes 7, where the higher rating reflects the inherent tolerance and precision in those bearings.

Q: Would you recommend that an individual use the ABEC 9s in place of the ABEC 7 or even the ABEC 5?

A: This can be particularly important for boosting performance in competition; hence, those investing in ABEC 9 bearings will likely reap such margins. The average user or skateboarder looking for a bearing may opt for an ABEC 5 or even a very affordable ABEC 7.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8