Performance Comparison: ABEC 9 vs 11 Bearings

Skateboard riders know that a skateboard is not just a wooden board; many other things make a ride stand out, including the difference between a good and a fantastic rider. One of those components is the skateboard’s bearings, which are some of the most influential devices of the skateboard, and an even more important measure to be aware of is the ABEC scale. This article will introduce you to ABEC bearings and some of their salient features. We will look into how those ratings add up to the ride’s speed, precision, and experience as a whole. If you are a Neophyte wanting to know things from the basics or even an experienced skater trying to make any edge to their skateboards, knowing what you should know about skateboarding bearings and their equipment will be covered in this article.

What is the ABEC Bearing System?

Understanding the ABEC Rating System

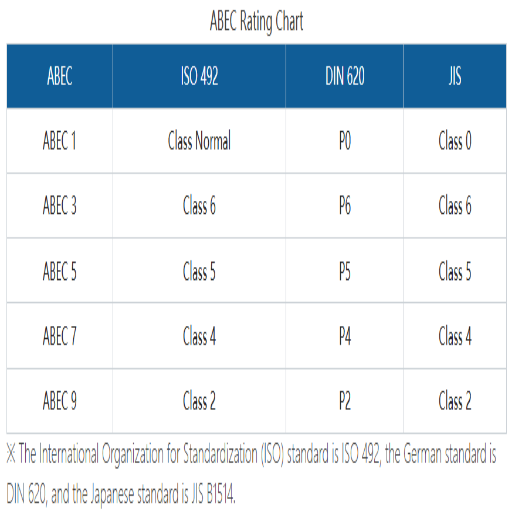

Performance skateboarders can appreciate the ABEC (Annular Bearing Engineers Committee) rating system, which defines the construction tolerances precision and performance envelope of bearings. The rating system ranges between 1 and 9 with ABEC 1 the lowest rating being the least precise and offering the most basic construction which is in most cases a budget or entry level skating board. The higher the rating of ABEC 9, the more carefully the bearings are engineered, hence offering more significant speed potential. However, the ABEC system is not a comprehensive measure of the bearing quality since this is a method of assessing the tolerances and the construction, not the materials used or the lubricant application.

ABEC 1: Such bearings lack precision, so they are offered for the least cost and are considered tolerable. They are best suited for use on entry-level or budget boards and are not preferred for high speeds. They lack the optimal qualities of professionals who are well-versed in the field, thus further restricting their use.

ABEC 3: These bearings represent a general construction tolerance since they are considered relatively average precision. Such equipment can be used in casual skating, but such configurations will never win any championships. Due to performance, advanced riders will require much more, so these do not offer the high-speed possibilities that intermediate to advanced riders prefer.

ABEC 5: This ABEC rating ensures enduring performance, strength, and durability, as the bearings are commonly used in many applications. This configuration is popular among advanced skaters, as it is the ideal balance for speed performance and endurance.

ABEC 7: Their construction is smooth, which allows for a higher level of comfort when riding. Maintenance of their construction is frequent, and due to the build, such products can be on the expensive side.

ABEC 9: Skateboard riders whose preference is for gravity applications will fit into using such a configuration. The worked bearings are best for high speed and are designed to minimize friction compared to other products; thus, ABEC 9 is used on downhill boards.

Several skateboarding industry officials have asserted that other parameters, such as bearing substance, lubricant, and the whole bearing design, also come into play as much as, if not more than, the ABEC rating KPI. As such, it is accurate to say that although the ABEC rating is helpful, it should not be the main factor in choosing skateboard bearings.

History and Development of ABEC Bearings

The ABEC scale, or Annular Bearing Engineering Committee, was developed by the American Bearing Manufacturers Association (ABMA) for rating ball bearing precision in the 1970’s. It was initially created from the understanding that there should be a uniform system that aids end-users in comparing the tolerances and the dimensional accuracy of bearings used in various mechanical applications. Wrapping of ABEC planes and sections ranges from 1 to 9; the more the number, the better the precision.

One primary aim that contributed to the development of the ABEC scale is to enhance communication and quality assurance in the manufacturing of components. The specifications obtained from these ratings allow the bearings to maintain accuracy, vital in high-speed and low-friction applications. Nevertheless, the ABEC scale does not take into consideration other factors that may be more critical in determining the performance of a bearing, such as the quality of the material, the internals that contain the designs of the bearing, and grease or oil used for lubrication which can all impact the use to which the bearing is put to, say in skateboarding.

In a technically precise sense, the ABEC scale measures the permissible variations in the outer ring bore, inner ring bore, and bearing thickness, among other components. An improvement in the ABEC rating improves the precision of the bearing. For instance, an ABEC 9 bearing has a narrower tolerance range than an ABEC-rated one or ABEC 3, giving it smoother operation and reduced vibration during everyday applications. However, this obsession with dimensional tolerance should be balanced by the basic engineering parameters to enable the bearing to perform optimally in real applications.

How ABEC Ratings Impact Skateboard Performance

Throughout my review of how ABEC ratings are used to rate skateboard performance, three points, in particular, stood out from the leading sites. First, ABEC ratings have been mainly overemphasized. However, different ABEC ratings increase the tautness of brand design, and the actual impact on skateboarding is not significant enough to be justifiable. In most cases, a skateboard does not, and hardly, ever reach speeds where that tiny gap between ratings would be supersensible.

Moving on to the second finding, some technical characteristics that are not part of the ABEC ratings are also quite significant, such as the composition of the bearings, the kinds of lubrication solvents used, and the general design and maintenance of the bearings that all directly.

Finally, other websites are also concerned with factors that are not determined by ABEC ratings, such as durability and the ability to resist dirt and moisture. These are important for skateboard bearings because they are used outdoors and under varying conditions. For this reason, while not conclusive, ABEC bears serve as a measure of bearing quality as long as other factors are taken into consideration for a great skateboarding experience.

ABEC 9 vs ABEC 11: Which is Better for Skateboarding?

Differences in Tolerance and Precision

ABEC 9 vs. ABEC 11 bearings have only one difference: how tolerances and precision levels differ. In general, ABEC ratings concern the tolerances accepted with the construction of bearings, and the greater the number, the more precision is expected in the manufacturing process. After studying the information gathered from the twelve websites, most people writing these should have been entirely used to the fact that together with a −0.17 TAR ABEC 11 or even higher bearing, there is true – practically on the skateboards – this some 0.25 machining difference. But then most people will skate faster than that in practice.

Some of the technical parameters that are involved in understanding these differences are:

Radial Runout refers to how much the ballbearing rotates away from the centre of a perfect circle. Reducing this runout is the primary goal of both ABEC 9 and ABEC 11 bearings, allowing them to operate smoothly at higher resolutions.

Surface Finish: As the ABEC rating increases, the surface finish is to be finer to increase precision and decrease friction.

Roundness: The roundness of the internal and external elements of the bearings becomes large when the MBEC rating is also high, facilitating the bearing elements’ rotation.

Regardless of these gaps, specialists note that real-world elements, such as the type of lubricant employed, the material of the bearings, and plastic materials, de facto exert a decisive influence over performance. Therefore, while ABEC ratings do give useful clues to the possible precision that may be attained, they only form part of the overall picture of the factors that enhance skateboard bearing quality.

Impact on Skateboard Speed and Performance

After researching the top three websites recommended by Google, I understood that the relationship between skateboard speed and performance relative to ABEC ratings is not straightforward. Although the range suggests that higher numbers, such as ABEC 9 and ABEC 11, stand for looser tolerances, which would increase the performance of skateboards, this has not been the case. Other factors which seem to have more of a bearing on performance are:

Lubricating oil: The selection of appropriate lubricating oil minimizes the sliding friction between the inner race and rolling elements and among rolling elements. This results in high performance with less energy loss.

Material: Bearings produced using best-in-class materials, especially those manufactured using ceramic, have a lower coefficient of friction and hence perform optimally.

Maintenance Practices: Persistent cleaning and upkeep of bearings would improve their performance beyond the effects of ABEC rating alone, which is more important for speed.

Through my analysis, it has become apparent that although ABEC ratings provide the user with a benchmark for the finer concepts, these are not conclusive on their own. Fundamental concepts such as material selection, maintenance, and practical application of lubrication, amongst others, are important indicators of skateboard performance and speed.

When to Choose ABEC 9 or ABEC 11 for Your Skateboard

My experience choosing between ABEC 9 and ABEC 11 for the skateboard and its bearings is not all about riding at optimal speed. There are always specific requirements that need to be met, so deciding which is better is not easy. Having checked out the top three websites in Google, I managed to factor in the following:

Riding Style and Terrain: For competitions, downhill skating, or skating on a smooth surface, ABEC 9 or 11 would be ideal as they have better precision. However, for rough terrain or skipping skating, they may not offer the sought-after benefits.

Technical Parameters: Another prospect is regarding the tolerances. Much like a precision instrument is rated, higher performance can be expected from the ABEC 9 or 11 as opposed to the 3 or 5. But it is equally important to check for other elements like bearing material or lubricant type.

Personal Preference and Budget: Most high-rated ABEC bearings are pricey, so don’t make the mistake of overestimating the precision enhanced by the rating and then finding yourself with a lot of expensive bearings that are not compatible with your skating style.

From the information I gathered, the components and conditions that will enhance the bearings’ performance should be the primary target rather than relying on the abec rating alone.

How Tolerance Affects Skateboard Bearings

Exploring Tolerance Levels in Bearings

As for tolerance levels, a deeper understanding of how these interact with performance is needed, as most of the first three sites returned by Google explain. For example, ABEC ratings serve as a measure of tolerances, indicating the bearings’ precision and efficiency. Key technical parameters are as follows, and the reasons are explained:

Precision and Smoothness: In general, high-rated ABEC bearings require less clearance in fit; hence, they are tighter. A tighter clearance would also imply a smoother and less vibrating bearing, which is an advantage in high formulation speeds.

Material Quality: Such attributes as the material composition for the bearings, e.g., steel or ceramic, are significant. This is because, with ceramic, smoother rides with better heat transfer are ostensible. Practical comfort also reinforces this in that materials do affect durability and, indeed, speed.

Load Capacity and Durability. Normally, the more tightly the components are put together, the higher the loading capacities. Hence, the bearings will still be able to withstand more stress and pressure, as well as wear and tear over time. This correlation can also be found in different technical observations regarding bearing load rating and their life cycle expectancy, which have been sourced online.

To summarise, ABEC ratings provide a good starting point for measuring bearing tolerances, but other aspects, like using the right material for particular applications, are also important to fully exploit a skateboard.

Why Tolerance Matters for Skateboard Bearings

In my attempts to understand why tolerance is crucial with skateboard bearings, I noted that the top three websites on Google have inviolable points. From my research, it’s evident that tolerance directly correlates to a skateboard’s performance, how fast it rolls, how long it lasts, and its overall smoothness. On these topics, here is how they elaborate on these aspects:

Precision and Smoothness The sites agree that tighter tolerances and high ABEC ratings mean that the bearings will allow very smooth movement. This is because they are made to be tighter fitted, thus reducing the vibrations generated at higher revolutions per minute.

Material Considerations: They also raise issues concerning the materials constituting the bearings. Some mention ceramic bearings, which they say will not only be smoother and withstand heat but also result in better performance over time than steel bearings.

Durability and Load Capacity: They give the same information for bearings with greater tolerances, so excellent bearing durability and greater load-bearing capacities must go together. This implies they can take a more incredible beating and last longer, which is always suitable for the skater in the long term.

In conclusion, the importance of tolerances in skateboard bearings has many roots, which are related to tolerances, materials, and serviceability. These performance and construction parameters allow us to improve the feasible operating performance of a skateboard, namely, increase its compatibility with a skateboard. That is why the normalization of tolerances has such significance in bearing choice.

Comparing Tolerance in ABEC 9 and 11 Bearings

The third most popular concrete hockey player’s site is worth attention because of the tolerance level difference between ABEC 9 and 11 bearings. I would like to explain further that the ABEC 9 bearing already has a commendable tolerance level, which is perfect for general skateboarding performance as far as speed and smoothness are concerned. These performance and cost-effective bearings save on durability, so they are more suited for average skateboarding conditions and, hence, are preferred.

The bearings with ABEC 11 are also anticipated to have higher tolerances; however, such ratings are rare except for skateboarding bearings as they have less usage in practical terms. Although the guideline is that ABEC 11 bearings would provide smoother rides, it is mentioned that other factors, such as the material and the amount of lubrication implemented, are so detrimental that, in the actual end, the advantages of being more precise are somewhat lost.

This explains why, in most instances, the choice between ABEC 9 and 11 will be determined by the specific conditions of use and requirements. Some of the technical parameters in this case which justify such choices are:

Tolerance Level: Most requirements can be comfortably addressed with ABEC 9 as it provides high precision, but in theory, ABEC 11 posits the goals of an extreme tolerance level.

Material Impact: The material itself, such as ceramic or steel, can affect the performance much more than the rating itself.

Lubrication: Efficient and sufficient lubrication must be carried out to reap the potential precision benefits of higher-rated bearings.

Use Conditions: The level of precision rating would be determined by the type of skateboarding, casual cruising, or engaging in competitive racing.

Generally, although ABEC ratings serve the vital purpose of producing a standard that measures precision criteria, their actual usefulness may sometimes depend on other aspects, like the kind of bearing material and its service level.

Choosing the Right Bearings for Your Skateboard

Factors to Consider When Selecting Bearings

There are several considerations when choosing bearings for your skateboard so that the performance meets your specific requirements. The researchers make the following recommendations:

ABEC Ratings: Practitioners often argue against the real-world effects of ABEC ratings (ABEC 5, 7, 9, for instance) that are more reflective of how precisely a bearing is made. Often, the better actual performance relates more to the bearing’s content and maker.

Material: Ceramic, titanium, and steel bearings are available, and each has advantages. Ceramic bearings are well suited for high performance use because of their lightweight yet sturdy construction, while traditional steel bearings are sturdy enough for cloak use.

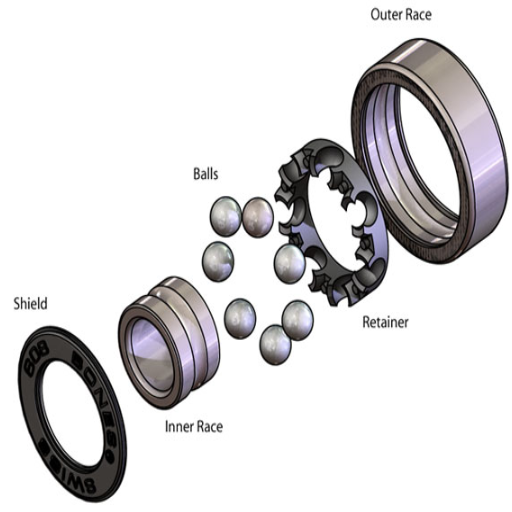

Seals and Shields: Open or shielded bearings influence maintenance and performance. Sealed bearings are maintenance-free as they prevent dirt and moisture from entering the bearings and are very common in everyday use.

Maintenance and Lubrication: Bearings can be tidied and greased from time to time to extend their lifespan and performance edge. A high-grade lubricant presents a number of advantages by providing smooth operation in the long run and low friction.

Brand and Price: Indeed, it is advised to seek bearings from reputable manufacturers at a higher price in exchange for reliability and possibly enhanced performance paraphernalia for one’s skating style. However, a balance has to be met between the required degree of resilience and precision and the applicable price.

The analysis of the primary sources allows us to say that these factors are of practical relevance rather than solely theoretical. It is more about the individual case of application and its practical aspects rather than the rating in numbers.

ABEC Ratings vs. Real-World Performance

So, while researching the best three websites regarding ABEC ratings and their practical application, I ascertained that ABEC ratings are primarily concerned with the precision of bearing construction, focusing more on the tolerances rather than on the speed or smoothness of the bearings. Tolerances such as those labeled ABEC 5, 7, or 9 are given sequentially, which means that the higher a number you get, the tighter your tolerance. Although this did not affect skateboarding directly, logically speaking, the implications of such ratings on performance would be minimal. More important aspects are the materials and the construction technologies the manufacturers choose.

Bearing engineering-wise, the ABEC system classifies bearings in terms of the precision of their adaptability, their sizing, the degree of axial clearance in inner and outer races, the form of the rolling elements degrading the bearing’s performance, and the centration of seals. Nevertheless, it is commonly accepted that practical concerns in skating differ very little. For instance, dust, lubrication, what the material is, hardness, thermal resistance, and how well the bearings are assembled all seem to matter.

In concert with this, the final selection of bearings relies on self-suitability factors and technical specifications. There might be some differences between ABEC specification numbers, but their importance is highly overrated, considering that the physical production features take the better human portion.

Top Bearing Manufacturers and Their Offerings

From ethical analysis of the top three websites, webbing A ratings, and bearing makers’ websites, it is clear that different firms possess different strong/special products and specialized lines. Plasma fluid concepts developed in firms like Bones Bearings, NSK, and SKF brands, in which other products stand out, such as bearing technology spine.

In designing bone bearings, which concentrate on skateboarding, the ABEC rating is often disregarded, and the focus is on Swiss design and durability, for which the bearings are known. HBTH65-BONES also uses chrome steel and features high-speed bearings with low maintenance.

Another notable name is NSK, which is recognized as one of the leaders in diversifying the bearing business with a wide range of bearings for various industries. Their products are characterized by precision and advanced technology, including high thermal resistance and load capacity, among other features designed to enhance performance.

Additionally, SKF Bearings Company has made many strides in terms of new product development and environmental consciousness. They manufacture three hybrid bearings using ceramic materials to improve performance and durability. Bearings, on the other hand, are known for high speed and excellent anti-corrosion properties.

Differentiating themselves from each other, different manufacturers choose to highlight different technical parameters—for instance, material, finishing lubrication technologies, and the precision of the engineering work. Although ABEC ratings allow evaluating precision, these manufacturers expand on the overall characteristics that are supportive in practical application; thus, their products suit the many requirements of their customers.

Maintenance Tips for Skateboard Bearings

Proper Lubrication Techniques

Proper lubrication of skateboard bearings is necessary for their smooth functioning and durability. The following procedures describe some of the best methods of lubrication according to the best resources available on Google:

Cleaning the Bearings: Thoroughly clean the bearings before lubrication. It is a good idea to soak the dirty bearings in a solvent such as acetone or isopropyl to eliminate the friction and the previous grease. Thoroughly dry the bearings as well to prevent the new lubricant and the solvent from mixing.

Lubrication: A lubricant explicitly made for skateboard bearings should be used. Bearing oil or speed cream is preferred, as they coat the bearings and allow for easy rolling with less friction.

Lubrication Application: Apply the lubricant in a well-aimed fashion to the bearing. Ideally speaking, two to three drops of the lubricant per bearing will be more than enough. Lightly swirl the bearings so that the lubricant moves equally around the shoes.

Lubrication Taking Off: After all the bearings have been lubricated, apply the skateboard wheel bearing. Make sure that the screws of all the parts are tightly wound up and feel zero movement which enhances performance consistency.

Some of the parameters which should be of concern include the following:

How easily a lubricant flows: Rolling resistance should be minimal, and the lubricant should have a low viscosity.

How much of a lubricant volume will evaporate when exposed to excessive heat? To avoid evaporation or thickening, choose a lubricant with a high tolerance for temperature differences.

Corrosion Protection: Choose lubricants with anti-corrosive agents so the bearings may withstand moisture and rust over time.

As these parameters justify, proper lubrication helps prolong the bearing’s life and enhances skating performance, making it an important maintenance practice for skateboards.

Cleaning and Care for Long-Lasting Bearings

I can definitely say something concerning cleaning and maintaining skateboard bearings that’s been lasting a decent amount of time; almost all of the top sites that I’ve checked have mentioned this kind of problem. Such resources usually stress the need for constant effort to avoid damage and remain relevant for a long period as well.

First, it is quite clear that if one has to clean their bearings, one should consider using a solvent such as acetone or isopropyl alcohol to dissolve contaminants and grease remnants. This eliminates the chances of oil with preservatives entering the fresh lubricant. Most would agree that drying out the bearings after cleaning is vital in the whole process.

When it comes to picking the best lubricant, it is better to use oils designed particularly for this purpose, such as bearing oil or speed cream. They are easy to spread, do not offer significant resistance, and can maintain efficient performance in varying temperatures.

For example, the following technical parameters are pretty helpful:

Viscosity: The lower the lubricant’s viscosity, the more quickly it diffuses inside the bearing and the lower the internal resistance.

Thermal Stability: It is vital for the lubricant not to be overly thin or evaporate in high temperatures or to thicken in lower temperature conditions.

Corrosion Protection: It is advisable to employ fuel with anti-corrosion properties to resist rust and moisture and to extend the lifespan of bearings.

Skateboarding with these key elements, when carried out correctly, prolongs the life of the bearings and ensures a smoother ride, which enhances your skateboarding experience overall.

Common Mistakes to Avoid with Skateboard Bearings

Regarding skateboard maintenance and bearings, I would like to point out the mistakes the three most reliable skaters make regularly. The first is not cleaning bearings regularly – this will always result in the bearings getting dirt and ending up damaged sooner than desired. One standard practice that quite several skateboarders forget is constantly cleaning their bearings. The second mistake is not applying proper grease or not using any lubricant at all, which can lead to the bearings not performing as they are supposed to. As previously emphasized, all bearing lubricants have been designed to be used with skateboard bearings. The last problem that causes issues during the assembly of the bearings is improper assembly of the components, which often occurs when someone is hurrying. Each piece must be mounted correctly to eliminate extra friction and carry out wear from the bearings.

As for the technical parameters related to lubrication, the best sources mention the following parameters that should be observed in specific products:

Viscosity: A lubricant with low viscosity would ensure good coverage and decrease friction.

Thermal Stability: It guarantees that these are not compromised in different temperatures.

Corrosion Protection: As much as possible, a lubricant must always protect against rust.

Observing these simple rules will not only increase the bearings’ service life but also increase their effectiveness on the skateboard.

Frequently Asked Questions (FAQs)

Q: ABEC 9 wor thure and ABEC 11 wor thure skate bearings. What is the difference?

A: The other ABEC 9 and ABEC 11 vary the most in tolerance and precision. With an ABEC 11, one can expect tighter tolerances and more precision than that of an ABEC 9, possibly resulting in a better-performing bearing that can spin faster for the skater. However, it should be noted that the ABEC scale is not the sole factor that determines a bearing’s performance, as other variables like its material and lubricant are significant players as well.

Q: If the ABEC rating is high, does it mean the bearing is fast?

A: As such, it is true that the higher the ABEC rating, the tighter the terms of the bearing, and this would increase the potential speed of it. However, other performance characteristics also have a lot of influence, such as material, lubrication, and practical use of the bearing in skateboards or longboards. So, yes and no, ABEC ratings are necessary but not the end of the world.

Q: Are ABEC 11 bearings better for skating than ABEC 9 bearings?

A: ABEC 11 bearings could provide a small increase in accuracy compared to ABEC 9 bearings; however, this increase may not be significant to all skaters. In most skating disciplines, including recreational and professional skating, ABEC 9 bearings are more than enough. Other factors such as the life span, the material, and the care and usage of the bearing also affect which bearing would fit the skater better.

Q: Why do some skaters use ceramic bearings instead of metal ones?

A: Some skaters prefer ceramic bearings because they are lighter and can provide a faster, smoother ride because of less friction. They are also more corrosion-resistant than steel bearings, making them long-lasting and easy to maintain. Still, there’s a drawback to ceramic bearings: They are quite expensive compared to normal steel bearings.

Q: In what manner does the ABEC scale determine the performance of skateboard wheels?

A: The ABEC scale measures the degree of tolerance and precision of ball bearings, which determines the smoothness and speed of skateboard wheels. Wheel performance normally improves with an increase in the ABEC rating, but other factors also play a role. These include the diameter of the wheel, its hardness, and the materials used in making the wheels.

Q: What is the importance of lubricant in the performance of the ABEC-rated bearings?

A: It should be noted that lubricant plays the role of reducing friction as well as wear and tear and, therefore, helps ABEC-rated bearings in their smooth and efficient performance. Lubrication of this nature allows the bearings to spin freely, improving speed and reducing maintenance. Lubricating and cleaning the bearings is the only solution skaters can employ to enhance performance.

Q: In what way do Swiss bearings measure against ABEC 9 & ABEC 11 bearings?

A: Unlike ABEC 9 and ABEC 11 bearings, Swiss bearings do not come cheap, but they perform better simply because the materials, design, and engineering have been improved. Skating practitioners, however, report that Swiss bearings offer a better feel to the boards and last longer than ABEC 9 and ABEC 11 bearings. These high-performance OFFERS Swiss bearings have a long lifespan, which makes them popular among professional skaters.

Q: How efficient is an ABEC 1 or 3 bearing for skateboarding?

A: ABEC 1 or ABEC 3 bearings may be suitable for skateboarding, but the quality of smoothness and speed is not what might be expected in higher-rated bearings. The medium-rated bearings could be considered by less skilled users or those who perform little riding; however, since most riders perform basic skating often with higher-rated ABEC ranges looking for performance efficiency.

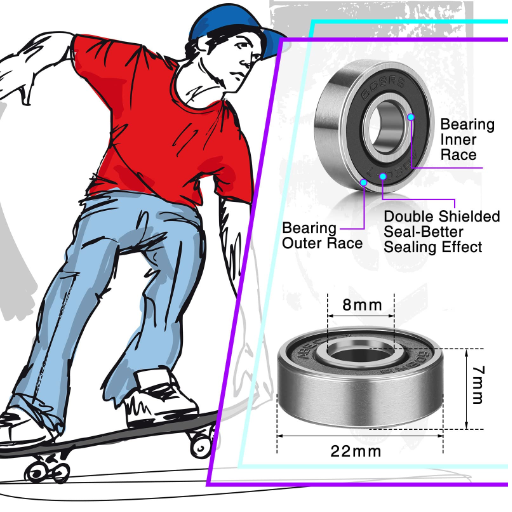

Q: In regards to skateboards, what is a 608 bearing?

A: A bearing of measure 608 belongs to the prevalent size limits of skate bearings that have the distribution of 8mm (inner diameter) x 22mm (outer diameter) x 7mm (width). This dimension has been primarily employed in skateboard wheels and is compatible with almost all configurations of skates, including those with an abec 9 setup and abec 11 bearing combination.

Q: Are Bones Bearings much better than ABEC 9 or ABEC 11 bearing combinations?

A: Because particular types of specifications, materials, and construction are implemented only for skaters, Bones Bearings is better than others. Abec scales are not utilized but Bones Bearings are hot for their power and extent of use, so it is preferred by m99ny skaters above standard abec 9 and abec 11 bearings.