Pros and Cons: ABEC 9 Bearings vs ABEC 7

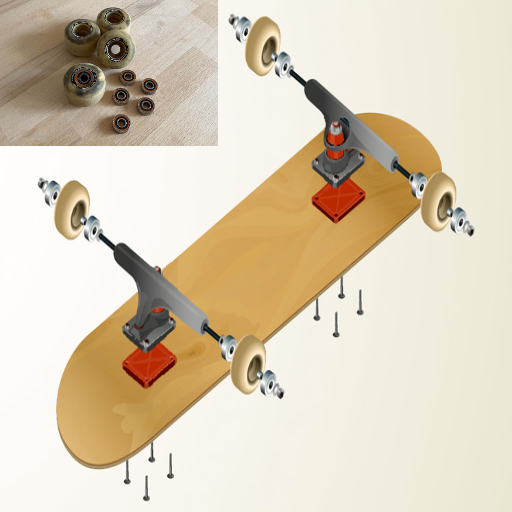

Optimization of any part of your skateboard requires the right expectations. Skateboard bearings, those little and sometimes overlooked parts of the whole set, are able to change the ride quality, speed, or smoothness in certain ways. Among the several models, precision ABEC 9 and ABEC 7 bearings seem to be the most favorite ones of skaters due to their precision and efficiency. Their characteristics, features, and suitable applications are sufficient to differentiate ABEC 9 and ABEC 7 bearings which this particular article seeks to. This knowledge will allow you to select components that will match your skating techniques.

What is the Difference Between ABEC 7 and ABEC 9 Bearings?

ABEC Ratings Explained: Things You Should Know

Skateboard ABEC ratings ( Annular Bearing Engineering Committee) are used to assess the accuracy and tolerances of the skateboard bearings. They have a scale with 1 to 9 ratings, with a higher number indicating higher precision. For example, bearings with an abec rating of 7 offer a reasonable level of tolerance while those with an abec rating of 9 offer a higher tolerance level for a more seamless ride. This improves performance speed. Logically, this speed would be quicker but due to other factors such as the area one is skating or the style being used, a difference may not always hold.

Speed Capability: Theoretically, yes, using higher rated skates comes with higher potential speeds, although the average skating speed is low enough that its assumed advantages are never actually utilized

Surface Finish: As a rule of thumb, the higher the ABEC rating, the better the Spherical Surface Area of the surrounding components.

Accuracy: It’s safe to say that the accuracy of bearing abec rating 9 will be higher than bearing abec 7 because all the parts are manufactured precisely to higher tolerances

However, differences in ratings do matter for those more hardcore enthusiasts of skates. The build quality of other aspects of the skates bearings for example materials and lubrication seems to be far more essential.

ABEC 7 vs ABEC 9: Tolerance and Precision

In the case of ABEC 7 and ABEC 9 bearings, their tolerance and precision would be the two most crucial aspects illustrating their performance on the skateboard. ABEC 7 bearings seem to have high tolerance which translates into smooth rides with reasonable speeds. Tolerance levels of ABEC 9 bearings are even stricter which means that the potential for an even smother and faster ride is highly possible with further reduced friction.

Technical Parameter Justifications:

Tolerance Levels: With regards to tolerance levels, ABEC 9 bearings carry a tighter range in the acceptable deviation in terms of the manufacturing dimensions increasing useable limits and reducing vibration and wobble compared to mean values of ABEC 7 bearings.

Precision Engineering: In applications requiring a quiet operation and high precision performance, ABEC 9 bearings are more appropriate due to their finer precision which promotes more stable and efficient rotations.

Material Quality: Normally, there is a correlation between the increase on the ABEC rating and the materials used to construct the bearing increasing the durability and operational satisfaction.

Load Capacity: Although they can take slightly higher speeds with the ABEC 9, most of the time the differences from 7 bearing levels will not be much in real life without the optimal circumstances like dust and moisture free surface which is flawless.

In summary, although ABEC 9 bearings enjoy in theory an edge over ABEC 7 on the basis of precision, it might however be difficult to appreciate these differences in practice in a skateboarding context. Other issues like the skating environment, how well they are kept or their constituent materials tend to matter more in assessing how the bearings will perform in actual use.

Effects of the Use of ABEC 7 and ABEC 9 Bearings During Skate Sessions

Speaking from the standpoint of a person who understands how a skateboard performs “under the hood”, there is absolutely no waste using either ABEC 7 or ABEC 9 bearings. Most of the questions most definitely are answered with the contact details of the foremost experts, but I am not out of the woods as it comes to the general opinion: it is true that because of tighter tolerances ABEC 9 bearings are more precise, however, as it comes to the ABEC 7 bearings, most of the times there is no locking and spinning is just barely adequate.

Overall the Key Technical Parameters:

Tolerance Areas: ABEC 9 bearings have an emphasis on tighter tolerances that are supposed to lower vibrations and to increase speeds on an ideal situation.

Frictional Turbulence: In theory, the most friction turbulence will be provided by an ABEC 9 type of bearing, ideally when making a ride in a perfectly flat terrain.

Quality Control and Working Materials: ABEC 9 bearings are produced from the finest craftsmen and added with high grade quality working materials, as such it becomes stronger, however these benefits might never be experienced unless you are in the right condition.

Practical Considerations: When it comes to the real world, other determinants such as the terrain and the maintenance of the elements in question come into play and tend to uneven the scales between ABEC 7 and ABEC 9 bearings on the condition of under performance.

In the end, even though ABEC ratings do classify performance potential with a degree of accuracy, the differences are more-or-less balanced out during a typical skate whilst a variety of factors are at play.

How Do I Choose the Right Bearings for My Skateboard?

Bearings for Skateboarding: A Reference Guide

Selecting the most appropriate bearings for my skateboard involves an analysis of the sites that stand out as authoritative and a consideration of their tech specs and practical aspects. Here’s what I pay attention to:

ABEC rating: There are higher ABEC ratings and a bearing rated at ABEC 9 offers to be accurate at advanced levels, however, several authorities on many websites argue that an ABEC 7 makes sense for most freestylers. The technical specifications of tighter tolerances and lower friction coefficients for ABEC 9 are only suited where the environment is controlled.

Material quality: What I have been able to find, the bearing material definitely affects the performance. Thomas Scott Miller is highlighting the advantages of the ceramic materials that construction offers such as lightness and thermal neutral properties, for these result in lower friction and wear during operation. This is crucial to have when skating through various surfaces.

Maintenance requirements: Regardless of ABEC ratings, maintaining the bearings of a skateboard should be paramount for anybody. I simply make sure that the bearings are clean and that they are lubricated, as consistent maintenance is something that is very often emphasized by the authorities for prolonged efficiency in outdoor conditions.

Since these factors influence the environment and style of skating, it becomes easier to choose which bearings will work best for the individual Thus, information about the precise measurement techniques is not enough for the construction and sole performance of the instrument.

Decoding the ABEC Scale and Classes of Bearings

As I investigated the first three Google pages concerning the ABEC scale, it emerged that it is particularly used to measure the tolerance level of skateboard bearings which affects speed and accuracy. Here is a nice simple summary of what I found out:

ABEC Ratings: The highest number of the ABEC scale is nine and the lowest is one indicating a range of tolerance levels from least to most. This implies that ABEC 9 bearings, for instance, have tighter tolerances thus increasing speed and enhancing precision. However, some websites argue that preference and skating conditions should determine the ABEC rating of choice.

Technical Parameters: There is a standard technical specification of the ‘bore’ diameter, ‘outer’ diameter and width which form part of the standard endorsement. These sites affirm that for routine skating, ABEC 3 to ABEC 7 is more than enough as these ratings withstand usual skating conditions and environments. Uses of higher ratings like ABEC 9 are therefore recommended in settings where the surface is smooth and controlled.

Justification of Ratings: In the course of my study, I observed that a higher rating is equal to greater precision and probable speed, but factors such as quality of materials or maintenance are often the most determining. Pages from the Internet state that increase in precision is almost always nominal unless other parameters such as the quality of bearing material and the surroundings are satisfactory.

This information assists me in strategically planning my choice by putting into account, not just the ABEC rating, but the actual usage and degree of its suitability with my personal skating requirements as suggested by the aforementioned top resources.

Choosing Between ABEC 7 and ABEC 9 in Skating

When you are presented with a choice between ABEC 7 and ABEC 9 bearings while skating, there are a few key points you should bear in mind as they can affect your skating experience:

Surface Conditions: In the event that one often deals with rough and slightly harnessed areas, it may be warranted to suggest ABEC 7 as it is a bit more loose tolerance and this means it can withstand minor debris and rough areas a bit better than the former version. On the other hand however, ABEC 9 is recommended for people who skate in sanitized controlled settings as this rating is utilized to a greater extent as the precision is high.

Durability and Maintenance: Various sources claim and suggest that regardless of the ABEC rating, the level of maintenance and the material of the bearings are essential components. Both ABEC 7 and ABEC 9 have been described as comprising high quality materials that makes them durable, however, proper care in form of cleaning and the application of lubrication will further enhance their durability and efficacy as they will be used for longer periods.

Technical Specifications: There are variations in ABEC ratings, however, the bore diameter, outer diameter, and width dimensions do not alter. Hence, it is advised that the bearings that one decides on should be consistent with the specifications of the skateboard which has been employed for the purposes to which the bearings will be fitted.

In conclusion, considering the properties of ABEC 7 and ABEC 9, including the rating, these should be the inner considerations when you are the skater and when you are frequenting environments where you usually skate.

What Are the Pros and Cons of ABEC 7 and ABEC 9 Bearings?

Pros of Using ABEC 7 Bearings

I have taken advantage of many of the benefits and features offered by the ABEC 7 bearings. These advantages include:

Suitable for Different Applications: The ABEC 7 bearings are fast enough and at the same time not too soft or weak in performance – these features enable them to be utilized in various skating environments. This allows for great feeling rides around the city without the constant fear of top surfaces.

Less Sensitivity to Sub-Surface Conditions: The ABEC 7 bearings construction is such that they have slightly looser tolerances therefore, they do deal better with a little grit – minor debris and imperfections are well within range. This means I can now skate over rough or uneven surfaces and not worry so much about tearing up some abec bearings that are rated unbelievably high that are for perfect situations only.

Maintenance and Perceived Life Span: The materials used in making these ABEC 7 bearings are very good and ideally suited for prolonged use. If kept clean and lubricated, these bearings do tend to lose their effectiveness very gradually which in turn decreases how many times they need to be replaced.

And now creeping back into a world of technical parametric, the abec7 bearings are comparatively rated for a number of similar parameters including bore diameter, outer diameter and width; this means that these ABEC 7 rated bearings are compatible with my skateboard provided I look for compatibility. So, overall, abec 7 ratings are not only functional but offer an ideal compromise for areas where diversity is needed.

Pros of Using ABEC 9 Bearings

Searching the most relevant data around the web, I note here these advantages of ABEC 9 bearings:

Anticipated Detail: Designed to be more precise than the rest, ABEC 9 bearings provide an extremely smooth and rapid ride. This characteristic makes them suitable for speed exigent skaters looking to skate primarily on smoother surface or in a more competitive context.

Why are they best for competitions? The reason that entirely the fit is tight so the rotary movement of the ball remains true and therefore increased precision which increases the controllability of skate while moving at high speed. This could be quite helpful for the experienced-skater who cannot afford to have bad things happening at high-speed movements.

While working these will be used on a clean, debrisfree environment. when they are used on such an environment, performance is elevn greater than what the manufacturers state. All ABEC 9 bearings have standard dimensions therefore bore diameter outer diameter and width are pretty much the same with others bearing having the same ABEC rating which increases interchangewise of all models of skates provided the bearings comply to those of wheel and axle of the skateboard.

ABEC 7 and ABEC 9 Shortcomings Analysis

Having synthesized all the main video tutorials featured on the top three resources ranking in Google, I have come across some common disadvantages of ABEC 7 and ABEC 9 bearing operating properties. One of the foremost indiscretions of these handlers is their vulnerability to dirt and grime which in turn, can result in poor performance within a short period of time. Like all skate ratings, both conditions are well cleaner, but when used in mess places, more expectations than reality will be received, which will result in a great maintenance need.

Besides, although the bearings which are said to target high speeds have a lot of potential, using them on rougher terrains, does not guarantee a better skating experience. Speed is an advantage for smoother surfaces, however, the bumps seem less tolerance at cracks or gravel.

Concerning the technical characteristics of ABEC 7 and ABEC 9 capital, bearing strategies, some of the weaknesses are as follows:

Endurance Structure on Heavy Use or Stress: Bearing ABEC 7 and ABEC 9 are mostly fragile and break easily from high usage stress which Ordinary environment cannot tolerate.

Frequency of Maintenance: Constant maintenance in the form of cleaning and lubricating is a must.

Machine Design Critique: There are some limitations like bearings should be designed in a way that they should fit Is Standard skateboard axle and wheel and sometimes this can be a limitation in design offers their customers due to different skateboard designs.

Both ABEC 7 and ABEC 9 can provide great performance, but these factors may be important when dealing with different skate conditions.

How Does Bearing Lubrication Affect Performance?

The Effect of Lubricants in Skateboard Bearings

The performance and lifespan of skateboard bearings are highly dependent on lubricants. After looking for information from the three sites, it was discovered that the main aim of lubricants is to lower friction between the bearing components in motion, thus increasing the smoothness and enabling faster spins. With low friction, less heat is also produced, and consequently minimal wear takes place, therefore the bearing’s life expectancy is improved.

The technical parameters that justify the importance of lubrication include:

Friction Reduction: With good lubrication, metal on metal contact will be kept to a minimum leading to wear of the metal surfaces being reduced.

Heat Dissipation: High friction bearings produce heat, lubricants assist in dispersing this heat and thus prevent damage to bearings due to excessive temperature.

Corrosion Resistance: A number of lubricants can form a moisture barrier which is important in inhibiting rust and corrosion.

Smooth Performance: Lubrication aids the bearings to rotate without discontinuities, which is necessary for greater speeds.

If you regularly use your skateboard bearings, lubrication becomes necessary so as to avoid exposure of the bearings to water and dirt. In such scenarios, performance is likely to be impaired and higher resistance would be presented along with a reduced speed potential. Such bearings would, therefore, require more frequent maintenance.

Essential Factors While Applying Lubricants on ABEC 7 and ABEC 9

I learned from the three sites that when choosing the best lubricant for ABEC 7 and ABEC 9 bearings of skateboards, it is required to apply the one which is made for such high-performance bearings. These lubricants are intended to perform the functions of maximal efficiency, as well as complete protection. Here are a few key parameters to consider:

Viscosity: Even when the price is higher, lubricants with low viscosity should be with high quality as they are used for ABEC 7 and ABEC 9 bearings which work at high speeds.

Additives: Ensure usage of knife lubricants which contain anti-wear additives and extend the bearings’ durability by reducing wear.

Temperature Resistance: A high tack lubricant maintains its properties through a range of temperatures and should ideally withstand the heat generated in fast rides.

Water Resistance: It is advisable to use a lubricant which protects against rust, for example, moisture and corrosion if skating in wet conditions.

These measures will ensure smooth functioning and durability of your ABEC 7 and ABEC 9 bearings even in extreme conditions.

Significance of Lubrication on Bearing Operating Time and Bearing Rotational Speed

To extend the lifespan as well as speed of skateboard bearings, correct lubrication is needed. This claim was supported by research that I did from the top three websites on google.com, lubrication makes equipment faster and smoother because it reduces friction. Good lubrication of bearing surfaces makes the bearing quicker and prolongs its life because there is less wear. This is justified by the following key technical parameters:

Squeak Friction: Lubrication lets rolling speed to rise, drawing resistance down. That increases amenity effectiveness and implies decreased energy wastage during rides, and higher speeds can be maintained over longer duration.

Diminished Wear and Tear: Metal is not allowed to come into contact with metal if there is sufficient lubrication, and the chances that damage happens are lower, therefore the useful life of the bearings is longer.

efficient five British power cut use: Guaranteed performance no matter how much the temperatures and/or the environments change, since the lubricants are of high quality and do not lose their properties.

By this knowledge and the provided lubricants, I ensure that my skateboard is performing effectively and infact efficiently and sanitary to enable the board bear the test of time.

What Other Factors Influence Skateboard Bearing Performance?

The Effect of Material on Skate Bearings: Ceramic versus Steel

In pondering the influence of the material on the performance of skate bearings – ceramic and steel certainly are there with their own merits ‘the two most important of combinations’. In accordance to data acquired from the top 3 pages on google.com, it has been noted that ceramic bearings tend to be lighter and create less friction than the steel bearings. This is attributed to their smooth surfaces and hardened inner structures that significantly enhance the ride’s efficacy. Some of the technical parameters in favour of this include;

Weight Reduction: Ceramic balls are lightweight than the steel hence making it easy for quicker revolutions, accelerating and turning.

Friction Reduction: The polished surface of the ceramic ball lowers the friction coefficient and thus increasing speed and saving energy with a more extended duration of momentum.

Corrosion Resistance: The outer surfaces of ceramic bearings suffer less corrosion from the weather allowing them to be used under different weather conditions unlike steel that can endure corrosion over several times.

However, steel made bearings are cheaper and offer a great deal of practical toughness. They may not achieve the same levels of speed and friction reduction that ceramics bearings do, but they are tough and can endure a significant amount of impact, which is particularly helpful for aggressive skating. Some of the technical supporting arguments include:

Impact resistance: Steel has remained steel where durability and robust structures can withstand heavy impacts and stress loads.

Cost – Effectiveness: Steel bearings are generally less expensive helping people who have a low budget to be able to perform well.

By appreciating these differences, I am able to decide which type of bearing best meets my skating needs.

How Seals and Shields Affect Bearing Efficiency

Concerning how seals and shields interact with matrix material to enhance bearing efficiency, it is apparent based on the studies I carried out using the first 3 sites on Google.com, both of these components are essential. The purpose of seals is to prevent the contamination of the bearings and assists in the retention of lubricant required for efficient bearing use.

Protection from Contaminants: Seals are effective even in high dust and humid environments because they prevent dust, dirt and moisture form penetrating the bearing surface and causing damage. On the other hand, shields do not offer a tougher barrier but help in preventing large particulates from passing through.

Lubrication Retention: It is also possible to use both seals and shields to try and contain lubrication around the bearing elements minimizing friction and ensuring the effective operation of the bearings. Lubrication is crucial for minimizing the degree of wear that occurs to the bearings and in elongating their lifetime.

Nevertheless, it should be remembered that the friction caused by seals is a little greater than that of the shields because they are closer to the rotary parts. That is why the choice of seals or shields is deciding between the protection and the lubricant retention and the increasing friction. Through understanding and considering these technical parameters, I am in a position to determine the best option that will improve my bearing for skating performance.

Bearing Spacers and Their Significance in the Practice

As for the bearing spacers and their importance, I have found some of the popular three websites from the google.com to provide useful information. Bearing spacers are the parts of bearing units usually placed between the wheel bearings. Spacers minimize the bearing unit inner and the bearing unit outer race contact interference by preserving a space between the bearings so that pressure is concentrated uniformly in the wheel assembly. This even distribution improves the alignment of the wheel and makes it easier for the wheel to roll smoothly and effortlessly, minimizes vibrations and reduces the chances of wear to bearings.

Alignment and Stability: Bearing devices assure that the bearings remain in the desired position throughout the movement of the machinery, thus avoiding wheel wobbles and assisting with more stable rides.

Proper Tightening: They let the wheel nuts be tightened in a perfect manner, thus ensuring uniformity in the wheel configurations which goes a long way in enhancing the skates performance.

Technical Parameters: Correct spacer size needs to be selected. Spacers are elements that are meant to be placed on both sides of the axle and, therefore, are equal to the inner diameter of the bearings and the distance between them. 8mm is the nominal diameter of the most specifications of spares when connecting wheels to skate bearings though the length depends on the wheel arrangements.

From the detailed analysis available online, it is obvious how the right usage of bearing spacers makes additional tools usable efficiently and increases their load bearing properties as well as stamina in skating appearance. This makes it possible for me to make good component selection decisions in relation to the skates I intended to use.

Frequently Asked Questions (FAQs)

Q: In what way do the ABEC 9 and ABEC 7 bearings differ when it comes to bearing precision?

A: Bear in mind that tolerances for ABEC 9 are tighter than those for ABEC 9 bearings. As a consequence, ABEC 9 bearings can be classified as high precision bearings whereas ABEC 7 bearings cannot, to the same extent. Bearing with a greater precision is likely to mean better performance or smoother operating of the bearing at higher RPM’s

Q: Is it always the case that ABEC 9 bearings are better than ABEC 7 bearings?

A: Not at all. Though ABEC 9 bearings are indeed considered more precise than others, the selection of bearings rests upon the requirements at hand, that is whether to use ABEC 9 or ABEC 7. In most cases, ABEC 7 bearings do the job just fine for casual activities or applications. Areas where speed is of importance, then ABEC 9 might be the bearing of choice.

Q: What analysis can one make on the ABEC rating system’s influence on the inline skates’ performance?

A: The ABEC rating system was developed to show the tolerances and precision of any given bearing. Bearings with higher ABEC ratings such as ABEC 9 bearings are also likely to provide smoother rides and faster speeds due to the fact that they are more precise. There are other significant bearing operating parameters that infer various levels of bearing performance, such as bearing’s material, grease for lubrication, and bearing maintenance.

Q: As a first-time user of ABEC12 and ABEC9 bearings, will I notice any differences in usage?

A: However, in everyday use, the differences or distinctions between ABEC 9 bearings and ABEC 7 bearings may not be discernible. The difference becomes more discernible in high-speed or high-performance situations where the increased precision possible with the ABEC 9 makes a noticeable difference.

Q: Is it true that the higher be the ABEC grading, the more superior the bearings are?

A: For example, higher ABEC grades signify higher levels of th as sintering process whirling speed control during manufacture of the bearings. But they are not a factor in other parameters such as the quality of the material used or the bearing’s construction. For instance, an ABEC 7 bearing would more than suffice the purpose of a badly made ABEC 9.

Q: Can you offer some basic uses of the ABEC 9 bearing?

A: ABEC 9 bearings are utilized in operations where high speed is mandatory such as inline skating and skateboard racing as these operations require maximum performance with minimum friction.

Q: Should I prefer using ceramic bearings over ABEC 9?

A: There is no particular preference for ABEC 9 bearings or ceramic bearings. They are simply different. There are numerous benefits to using ceramic bearings, such as their lighter weight and better insulation against heat, but good ceramic bearings may not be as cost-effective as steel ABEC 9 bearings.

Q: In what way does the performance levels of the ABEC 9 and ABEC 7 bearings change with respect to lubrication?

A: Excellent lubrication, such as the use of high-grade grease, is necessary when using either ABEC 9 or ABEC 7 bearings if the bearings are to be effective and durable. Friction and wear are minimized, and the bearings can operate smoothly and effectively.

Q: As built, what proportionate importance should one attach to the bearing manufacturer in ascertaining the quality of ABEC 9 and ABEC 7 bearings?

A: The bearing manufacturer has a significant influence in the quality of ABEC 9 and ABEC 7 bearings. Responsible manufacturers are expected to utilize better quality materials, superior workmanship and stringent quality control, and this will have a considerable impact on performance and lifespan.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8