Roller Bearings: The Ultimate Guide to Precision and Power in Motion

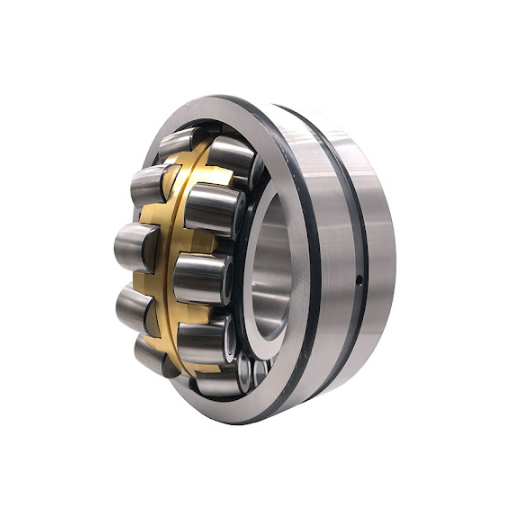

Roller bearings are an essential component in mechanical systems, enabling efficient, reliable, and precise motion across a wide range of applications. From heavy industrial machinery to everyday appliances, these critical elements reduce friction, support radial and axial loads, and ensure the smooth operation of rotating and moving parts. This guide aims to provide a comprehensive overview of roller bearings, detailing their design, functionality, types, and core applications. Additionally, it will elucidate the key factors to consider when selecting the appropriate bearing for specific use cases, highlighting advancements in technology that have enhanced their performance and durability.

What are the advantages of using roller bearings over ball bearings?

Comparing load capacity: roller bearings vs. ball bearings

In the conflict between roller-bearing load capacity and ball-bearing load capacity, it is clear that roller bearings are optimally suited for operational tasks that require high radial loads. Roller elements which can take the shape of cylinders, needles, or discs have an increased boundary area with the raceway. This leads to a fall in stress concentration and roller bearings can therefore carry heavy loads without any damage. Example:

- Radial Load Support: Under this category, roller bearings excel in carrying loads as they cover a large surface area, which makes them highly useful in strenuous equipment or machinery, unlike certain ball bearings that have load constraints.

- Axial Load Support: Other than the previously mentioned types, roller systems can also handle a combination of radial as well as axial loads, thereby making them multi-functional.

On the contrary, ball bearings possess a low load upper hand where the contact between the balls to the raceways makes faster and more efficient work possible but at an increased rate of friction. Because of this, roller bearings are the most sensible choice in almost any industrial application like gearboxes, conveyor belts, railways, etc. which are under great bearing loads.

Precision and stability in high-speed applications

To effectively assess precision and stability when it comes to high-speed applications, it is essential to keep in mind certain important technical aspects. In any machined element, a bearing providing High-speed operation must have a low level of vibration, low friction, and favorable accuracy of rotation. For instance, CNC machinery spindle bearings must be precise enough to maintain operational stability and accuracy during high-speed rotation.

- Rotational accuracy: Beatings have to meet minimum P4 or P2 tolerance classes (ISO standard 492) to be compatible with minimum deviation during operations.

- Friction coefficient: To achieve stability during high-speed working range, the friction coefficient should preferably be lower than 0.0015, to minimize heat and improve energy usage.

- Material composition: The use of components like ceramic (Si3N4) or hybrid bearings of high-grade material can result in lower rates of wear and higher speeds.

- Lubrication system: Correct lubrication like oil-air systems or low-viscosity grease enhances the chances of failure-free operation and accurate performance while preventing overheating.

- Limiting speed: For design rotation speeds bearings have to sustain; angular contact ball bearings, for instance, have a speed factor of over 1 million n·dm, and the bearings must be able to support that.

It is sufficient to set these factors to ensure acceptable precision requirements for the bearings, as well as stability, both of which are pivotal in the integrity and performance of supporting components in high-speed operations.

Roller bearings’ ability to handle radial and axial loads

According to their type and design, roller bearings are engineered to withstand radial as well as axial loads with huge efficiency. For instance:

- Radial Load Capacity: The cylindrical roller bearings are the best option for high radial force tasks owing to their increased line contact design. These bearings have exceptional ratings. Their load rating (often described in dynamic (C) and static (C₀) ) is calculated based on ISO standards and other credentials, like ISO 281.

- Axial Load Resistance: Tapered roller bearings are significantly strong in withstanding a combination of axial and radial force due to the oblique shape of the raceways and rollers. For example, single-direction tapered roller bearings have an axial load capacity of 20-30% of their radial load when optimally configured under ISO 355.

- Combined Radial and Axial Loads: Spherical roller bearings compensate for misalignment while enduring both radial and axial loads simultaneously. For example, Spherical roller bearings commonly authorize an axial load rating of between 10 and 15 percent of radial capacities, which is quite popular.

It is necessary to verify these technical requirements against application-specific requirements to select an appropriate roller bearing in a manner to enhance the mechanical reliability under load as well as ensure longevity.

How do you choose the right roller bearing for your application?

Factors to consider in roller bearing selection

Determining the proper type of roller bearing for my needs always begins with examining the load requirements. This encompasses both the axial and radial loads that the bearing is designed for. For example, the bearing’s load capacity that is allocated for axial forces – which is generally a rough estimate of 10–15% of the bearing’s radial load rating – is always checked for its adequacy, especially in cases where there is mixed loading.

The next thing I check is the system’s rotational speed because the bearings have a rated maximum limiting speed. This value cannot be exceeded, as it could lead to overheating or excessive wear. I also pay attention to the overall operating environment, which includes temperatures and the possibility of contamination or moisture. Appropriate materials and seals that can withstand these extremes are chosen.

Finally, I look at tolerances and compensation for misalignment. Spherical roller bearings are most suited for applications with a high degree of misalignment, while cylindrical bearings are suited for systems with high static radial load support and low axial minimum clearance.

In this way, I have found that the combination of all the technical requirements—load ratings, speed, materials, alignment capabilities, and other application-specific requirements—makes the bearing operate at the highest efficiency and provides the greatest reliability and lifespan.

Matching bearing type to specific load requirements

- Radial Load Capacity: In scenarios where the load is predominantly in the radial direction, rotating shafts, for instance, deep groove ball bearings or cylindrical roller bearings will be most suitable. These types of bearings support high radial forces while incurring low friction, which makes their efficiency high.

- Axial Load Handling: When the load is mainly axial, angular contact ball bearings or thrust bearings will be best suited because of their shape that is designed to cope with axial loads. For example, angular contact bearings have higher axial load capacity than radial load capacity in some applications.

- Combined Load Scenarios: In systems where there are simultaneous radial and axial loads, tapered roller bearings are a good fit. This is because of their conical geometry which enables them to combine loads with great accuracy and stable precision.

- Rotational Speed: Swift action processes require bearings with low rolling resistance, for example, ceramic ball bearings or hybrid bearings. They can endure great rotation speeds without extra generation of heat and reduced wear.

- Working circumstances: When dealing with extreme levels of contamination or elevated temperatures, there is the option of utilizing shielded or sealed bearings which are made from specialized materials such as ceramics or stainless steel for superior performance and durability.

By evaluating these factors in the specific context of the application, I make decisions that maximize performance, reliability, and service life. Each consideration is justified based on established engineering principles and the demands of the operating conditions.

Understanding dimensional and tolerance considerations

In terms of specifics, I ensure that each part and component is produced within the exact limits of specification. The established tolerances automatically regulate how much variation may occur in a system without degradation in performance. For example:

- Dimensional: I check a measurement of an assembly, which includes critical shaft diameters, bore dimensions, and individual component positions within the assembly. Oftentimes, these values do not correspond with the engineering rule of thumb or specifically designed parameters for the application. For example, a shaft tolerance of H7/h6 is acceptable on assemblies that have dynamic forces acting on them.

- Tolerance Classifications: Specific tolerances like clearance, transition, and interference fits are applied depending on the loads or thermal expansion or even when the assembly is going to take place. A good example is: considering a component that is expected to spin very quickly; and will need an interference fit to achieve the desired outcome.

- Surface Finish and Roundness: I check total roughness which is composed of a combination of various Ra values measured in micrometers that will cause minimal friction during work cycles, thus, minimizing wear and tear. Subsequently, to retain load evenly, roundness tolerances must also be kept within predetermined limits.

By complying with these factors, the strategies employed or other design choices made synergize with the stated performance objective. These factors, when utilized in conjunction with improperly aligned assemblies, reduce the threat of mechanical failure as well as wear and tear.

What are the maintenance requirements for roller bearings?

Proper lubrication techniques for roller bearings

To guarantee my roller bearings are always in optimal condition, I perform sanitization routines unique to each operational scenario. Proper lubrication decreases friction, dissipates heat, and prevents surface degradation from contaminants. The choice of grease or oil lubricant depends on the speed, load, and environmental conditions.

For grease application, I apply grease that is consistent with the bearing speed and load, NLGI 2 and 3 are common for general purposes. For oil application, the bearing operating speed and temperature help determine the oil viscosity, for example, ISO VG 68 to ISO VG 150 for moderate speeds and temperatures.

Combining factors like the size of the bearing, the speed at which it rotates, and the environment it operates in, helps provide intervals for relubrication. A common approach comes from relubrication intervals which are provided by manufacturers or ISO 281 standards. Grease is distributed to bearings through methods like central lubrication systems, grease guns, and manual greasing. Oil is distributed using oil baths or circulating systems where high heat dissipation is needed.

Following these steps assures me that roller bearings will function effectively without significant risks of wear and early failure.

Identifying and preventing common roller-bearing failures

To identify common failures of roller bearings, I address things like strange sounds, excessive vibration, heat, as well as wear and tear. I also check for pitting or spalling, in addition to discoloration on the rolling elements and raceways.

- Excess Noise: Suggests failure to lubricate and misalign the shaft with the bearings. I test whether all lubrication measures are satisfactory for non-thermic engines (specifically any needed viscosity) along with checking tolerances of the alignment with measuring tools.

- Vibration: Resulting from contamination, imbalance as well as structural resonance. I perform the maintenance of washing the components, installing accelerometers, and making sure the load is distributed evenly.

- Excess Heat: Suggests Overheating bearings may be caused by poor lubrication or overloading. I follow the recommendations regarding oils and greases and their temperatures, for example, I usually do not exceed the 70°C–90°C limits keeping in mind the bearing conditions under overloads.

Since bearing failure can have significant consequences, I have taken a systematic approach to addressing problem installation, along with the required pre-load and seal gated aforementioned shields to reduce the problem of contamination along with regular maintenance. Proactive hazard risk mitigation using vibration and thermal images allows me to keep bearing performance under stringent control and prolong their operational period.

Scheduled maintenance and inspection procedures

My approach involves implementing data-driven scheduled maintenance and inspection for bearings to enhance performance and reliability. To begin, I determine operating parameters and proceed to schedule lubrication checks at an interval of every 500 to 2000 hours of use depending upon the load and speed, and oil or grease with the appropriate viscosity is used. For example, ISO VG 68 is used for moderate-speed operations to ensure proper film thickness is maintained for lubrication.

Moreover, I check the temperature of the bearing components using thermal cameras and maintain an operational range of 80 degrees C (175 degrees F). Excess friction or contamination can be inferred if the temperature exceeds the specified range. Vibration analysis is conducted every fortnight to assess any early indicators of wear using acceleration (g- force) and frequency(Hz) to check for imbalance, misalignment, or surface defects.

While inspecting, the radial and axial clearances are measured with dial indicators and ensure that they do not exceed the tolerable limits set forth by the bearing manufacturer. A classic example is deep groove ball bearings which require clearances between 0.002 to 0.010 of an inch depending upon the size and application. I also take corrective measures such as re-lubrication, seal changes ,and preload adjustments to ensure I do not miss out on any anomalies.

In maintaining compliance with industry standards and best practices, I preserve system dependability and avoid expensive downtimes, which helps mitigate loss of productivity.

How do needle roller bearings differ from other roller bearings?

Design characteristics of needle roller bearings

The primary characteristic that distinguishes this type of needle rollers is their design. Their specific application involves compact size and great load-carrying capacity, especially in radial supports which is achieved by using long, thin cylinders that boast a 2:1 length-to-diameter ratio.

For instance, an INA needle roller bearing having a defined diameter of 2 roller mm and a 25 millimeters length achieves high radial load ratings due to the increased contact area. Radial space, such as in automotive transmissions or industrial machines, is, however, a restricting factor but needles are specifically made to adjust that with their minimal cross-section height.

To aid in minimum friction and optimal alignment of the rollers, bead cages are often made of steel and polymer. For superior durability and wear resistance under high load conditions, the rollers are made from hardened and ground high carbon chrome steel. In replacing some of the other rotating components, some needle roller bearings already have a reduced mass due to a built inner or outer ring, some replace raceways.

Through precise design features and careful construction tolerances, needle roller bearings offer effective load capacity while optimizing the available space. So they are crucial in settings with compact and effective design restraints.

Applications best suited for needle roller bearings

Needle roller bearings possess high effectiveness in compact designs without sacrificing capacity. They are widely used in vehicle transmission, particularly in the gearbox, where the cross-section, small, permits the palm girth to be shifted with great radial loading. Moreover, needle roller bearings are also components in aerospace systems, for example, helicopter rotors and actuation systems because these parts can operate dependably under severe vibration and dynamics.

- Radial Load Capacity: Up to 5,000 N within compact designs.

- Speed Range: Between 5,000 and 20,000 RPM depending on the lubrication and clearance.

- Temperature Resilience: Between -30 degrees Celsius and 140 degrees Celsius with appropriate seals and lubrication.

- Material Properties: High-carbon chromium steel for wear resistance in repetitive strenuous environments.

Needle roller bearings are crucial to various realms due to their advanced efficiency, small space, and robustness.

Advantages of needle rollers in compact assemblies

Due to its relatively small size and lightweight construction, the needle roller bearing has a high load-carrying volume which makes it ideal for many applications. Some advantages are:

- Spatial Constraints: It can be used in restricted areas due to its slim profile without affecting the structure’s performance.

- Radial Load: These bearings maintain a radial load of 5,000 N which means, despite their size, they can be placed in harsh conditions and still perform.

- Speed Performance: Speeds from 5,000 to 20,000 RPM are common, but can be restricted depending on the lubrication systems and clearance settings.

- Wear Resistance: Needle rollers made from high-carbon chromium steel are superior in terms of wear resistance even in cyclical high-stress conditions.

- Temperature Range: The bearings are designed to operate in conditions from -30°C to 140°C, assuming the necessary seals and lubricants are used.

These attributes make the needle roller bearing a must-have for compact assemblies where space constraints and high performance are essential.

What role do roller bearings play in industrial machinery?

Roller bearings in heavy-duty manufacturing equipment

Critical for the functioning of heavy machinery is roller bearings, which permit motion and action while bearing substantial weight. In my view, their primary role stems from enabling high-performance operations which enhances the dependability of the machine systems while mitigating wear.

- Load Bearing Capacity: Bearings have to withstand radial and axial loads simultaneously. Needle roller bearings are the perfect example for heavy-duty operations as they can withstand radial loads up to 5,000 N.

- Speed Operating Range: Many industrial applications require high speeds ranging from 5,000 to 20,000 RPM. Factors such as the lubrication systems and operational clearances will determine the exact speed.

- Material Strength: Construction from high-carbon chromium steel guarantees resistance to wear from continuous heavy-duty service and even under repetitive high-stress conditions.

- Temperature Limits: The bearings’ ability to operate within a range of -30°C to 140°C means that can withstand a wide variety of thermal conditions.

By adhering to these technical specifications, roller bearings ensure the seamless operation of machinery while minimizing downtime and maximizing productivity.

The importance of roller bearings in automotive applications

The automotive sector is increasingly turning to roller bearings as they provide exceptional transfer of loads and adept friction reduction between moving parts. The bearing’s capacity to sustain hefty loads while maintaining precision greatly influences the vehicle’s reliability and performance. An exemplary case is the tapered roller bearing that is widely employed in wheel covering assemblies because of its capability to endure both radial and axial forces which provide stability when cornering or under heavy loads.

- Load Capacity: For instance, rod bearings such as cylindrical open designs with a counterbore or tapered designs support radial loads of over 4000N as well as axial song whereby powerful D.C. electric motors are renowned for their high-quality radial and heavy-duty operating capabilities.

- Operating Speed: The designed roller bearings used in transmissions and in piston-type engines are capable of sustaining speeds of 10,000 up to 15,000 RPM with only a few nuances made with lubrication and alignment.

- Material Strength: These bearings are a combination of materials that include high carbon chromium steel which greatly increases fatigue resistance under over-rolling.

- Temperature Range: These bearings have a wide range of -30 to 140 degrees centigrade, making them helpful in all temperature ranges including freezing conditions and high engine temperatures.

This means that roller bearings have become a crucial component since with their unmatched unique attributes, they can influence overall automotive systems efficiency and performance optimization.

Roller bearings in high-precision machine tools

Roller bearings are essential for the accuracy, reliability, and effectiveness of high-precision machine tools. These tool bearings are built to sustain radial and axial loads while ensuring perfect alignment for machining operations.

- Load Capacity: High-precision machine tools rest on bearings that support heavier loads, sometimes exceeding 6,500 N on lower ends, and ensure operations with cumbersome components or high-resistance materials without shaking or disruptions occurring.

- Operating Speed: In regards to machine tools, the bearings have to rotate at over 20,000 RPM, depending on the spindle mechanism as well as the particular machining parameters. Lubrication quality must be strong enough to sustain such speeds without performance loss.

- Material Strength: Aerospace grade alloys or hybrid materials ceramic and steel masquerading as composites are selected with thermal stability and wear resistance in mind because the conditions often consist of repetitive stress.

- Temperature Range: In terms of wire application for thermal fluctuation, ranging from -20°C to above 150°C can be used. Special materials or coatings allow credibility to be attained within this range while achieving the desired thermally accurate shape.

Through these four technical requirements, roller bearings in high-performance tools should perform with minimal vibrational interference, reduced wear, and prolonging equipment lifespan.

Frequently Asked Questions (FAQs)

Q: What are the main types of roller bearings?

A: The main types of roller bearings include cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and linear roller bearings. Each type is designed for specific applications and can handle different loads and operating conditions.

Q: How do taper roller bearings differ from cylindrical roller bearings?

A: Taper roller bearings have tapered rollers and raceways, allowing them to support both radial and axial loads. Cylindrical roller bearings, on the other hand, primarily handle heavy radial loads and are better suited for applications with high-speed rotation.

Q: What are the advantages of using spherical roller bearings?

A: Spherical roller bearings can handle misalignment and shaft deflection better than other types. They have a high load-carrying capacity and can support both radial and axial loads. These bearings are particularly useful in applications that experience shock loads or where the shaft may become misaligned.

Q: How do roller bearings compare to ball bearings in terms of load capacity?

A: Roller bearings generally have a higher load capacity than ball bearings. They can handle heavy radial loads and, in some cases, significant axial loads. This makes roller bearings ideal for applications where ball bearings might not be sufficient, such as in heavy machinery or industrial equipment.

Q: What are linear guides, and how do they relate to roller bearings?

A: Linear guides are precision-engineered components that allow for smooth, low-friction linear motion. They often incorporate roller bearings to provide support and reduce friction. Linear roller bearings are specifically designed for use in linear guide systems, allowing for precise movement along a straight path either vertically or horizontally.

Q: How important is proper sealing for roller bearings?

A: Proper sealing is crucial for roller bearings to prevent contamination and extend their lifespan. A good seal helps keep lubricants in and contaminants out, reducing wear and tear on the bearing components. Different seal types are available depending on the operating environment and conditions.

Q: What factors should be considered when selecting roller bearings?

A: When selecting roller bearings, consider factors such as load type (radial or axial), load capacity, speed requirements, operating temperature, environmental conditions, and space constraints. It’s also important to consider the specific application, whether it’s for low-speed or high-speed operation and any potential for shock loads or misalignment.

Q: How can vibration be reduced in roller-bearing applications?

A: To reduce bearing vibration, ensure proper installation and alignment, use appropriate lubrication, and select the right bearing type for the application. Regular maintenance, including monitoring and balancing, can also help minimize vibration. In some cases, using specialized bearings or damping systems may be necessary for vibration-sensitive applications.

Q: How should roller bearings be lubricated?

A: Proper lubrication is essential for roller bearings. Most roller bearings require either grease or light oil lubrication. The choice depends on factors such as operating speed, temperature, and environmental conditions. It’s important to follow manufacturer recommendations for lubrication type, quantity, and frequency to ensure optimal bearing performance and longevity.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8