Roller Bearings: The Ultimate Guide to Rolling-Element Bearings

Roller bearings are indispensable components in modern engineering and machinery, widely utilized to reduce friction and support radial and axial loads efficiently. These rolling-element bearings are designed to handle high-performance demands across a broad range of industrial and automotive applications, offering reliability, durability, and precision. This guide aims to provide a comprehensive overview of roller bearings, including their fundamental mechanics, key types, material composition, and associated advantages. Whether you are an engineer, technician, or enthusiast, this resource will serve as a detailed framework to help you understand the critical role of roller bearings in technology and industry, shedding light on their design, use cases, and innovations.

What are the different types of roller bearings?

Cylindrical roller bearings: Features and applications

Cylindrical roller bearings are equipped with rollers in the form of cylinders which allows them to efficiently handle high radial loads while maintaining rotational accuracy. Their main strength lies in the small size of the contact area between the rolling elements and raceways, which minimizes the friction between them and enables high-speed operation. These bearings enable high durability coupled with precision usage and are typically used in electric motors, gearboxes, turbines, and industrial machinery.

- Dynamic load capacity (C): From 10 kN to over 1,000 kN, depending on the size and style of bearers.

- constructionISO 76, like all standard requirements, is acceptable.

- Speed rating: Bearers’ construction and lubrication usually cause maximum allowable speed to lie in the range of 3,000 RPM to 30,000 RPM.

- Bearers’The primary grade of construction steel makes these bearings wear-resistant and long-lasting.

These technical requirements allow cylindrical roller bearings to operate under specified operational conditions which assists them in withstanding challenging industrial tasks.

Tapered roller bearings: Advantages and uses

Tapered roller bearings have many benefits, especially in applications that combine radial and axial loads. Their construction comprises tapered inner and outer ring raceways and tapered rollers, which effectively manage load stresses throughout a wider surface area. This leads to enhanced strength and functionality during heavy operations. They are extensively used t in the automotive sector, for example in wheel hubs, as well as in industrial units where changing loads are being used.

- Rotate capacity: Tapered roller bearings have the best features in adjustable radial and axial load polarities. The efficiency of bearing an axial load depends on the angle of contact with the shaft; the bigger the angle the more efficiently the chair can bear an axial load.

- Material composition: They are best made from hardened alloy steel because it is durable, have high strength, and wear well in high-stress surroundings.

- Speed rating: In regards to rotational speed, these bearings can work efficiently within 500 RPM to more than 12,000 RPM, provided that lubrication and other factors are properly met.

- Design adaption: Changes in dimensions and taper angles are possible, and thus may be suitable for advanced operations.

As design adaption is essential to Tapered Roller Bearings to benefit and meet the needs of challenging and competitive industries.

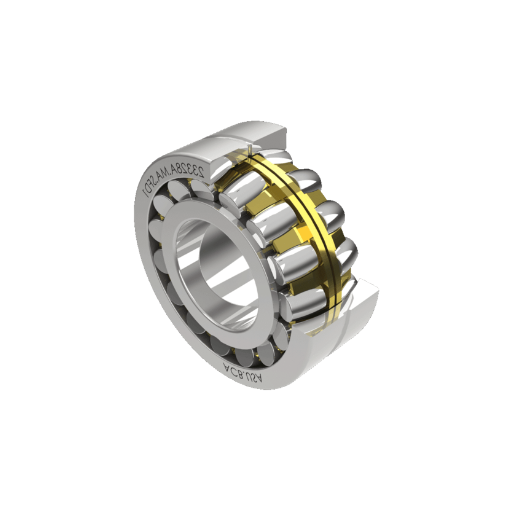

Spherical roller bearings: Handling misalignment and heavy loads

Spherical roller bearings are specially built to sustain high radial or thrust loads and are capable of withstanding significant axle misalignment.

- Tolerance to Misalignment: There is an element of self-alignment in these bearings owing to their outer ring raceway being spherical. The design allows for these bearings to tolerate angular misalignments ranging from 1.5 degrees or greater depending on the series of the bearing in use and the conditions of operation under which it is employed.

- Load Capacity: Spherical roller bearings can be subjected to higher magnitude radial loads as well as any amount of axial load. For example, their dynamic load rating C, generally varies from 150 kN to over 1000 kN, depending on load size and configuration. This is the reason why these bearings are widely used in heavy industries.

- Operating Conditions: The bearings can function properly in conditions that are considered extreme including high rates of vibration or shock loads. Several other variants are also available with special heat treatment or coating to endure working temperatures greater than 200 degrees Celsius.

These bearings are the ideal fit for a range of equipment from conveyors to crushers and industrial gearboxes, as they can easily tackle the intensity of load and misalignments that pose challenges in these machines.

How do roller bearings reduce friction and support loads?

Understanding radial and axial load capacity in roller bearings

The rolling elements incorporated in each bearing aid in sustaining and dispersing loads as roller bearings are specifically designed to do so. Now it is worth noting that each roller bearing has a set radial and axial load capacity. Radial load is defined as the load that gets applied perpendicularly to the shaft’s axis while axial is defined as the force that acts parallel to the axis. Various aspects factor into axial and radial bearings including internal geometry.

- Dynamic Load Rating: shows the range of loads a roller bearing can continuously endure while in motion. A good example of this is cylindrical roller bearings that typically have a C value that is higher than the rest, this is due to a greater area of contact by the rolling elements and raceway.

- Static Load Rating: this is the opposite of dynamic, C₀ indicates the maximum limit of the load that a roller bearing can carry when it is static. The best designs for static loads in this case are spherical roller bearings.

- Contact Angle: The greater the contact angle greater the axial loads supportable, this is particularly true for angular contact roller bearings which are efficient for axial load applications.

- Material Properties: these types of bearings are further enhanced in performance by using alloy steel as the source material because of the surface that is hardened which allows there to be more durability and bearing strength in stronger environments.

- Internal Clearance and Misalignment Compensation: these types of roller bearings such as self-aligning ones have inbuilt flexibility that allows for iconed misalignment without having to sacrifice load capability.

Understanding these key issues will help pick roller bearings correctly according to application and ensure better productivity, longevity, and dependability in varying load conditions.

Friction reduction mechanisms in rolling-element bearings

Bearings are essential components of any machinery that relies on rotation. The design’s rolling elements made of balls or cylindrical sleeves greatly reduce the friction between moving components, increasing efficiency while they function. First, unlike sliding contact bearings which use sliding motion, these bearings work on rolling motion which results in a significant reduction of the friction coefficients than in plain bearings. For rolling bearings, a thumb rule friction range of between 0.001 and 0.003 can generally be anticipated with some variance depending on the lubrication used and load applied.

Also, lubrication is one of the most important tools for friction reduction. Lubricants whether grease or oil are used in specific amounts providing a barrier between the surfaces that come in contact with each other. This action also reduces the chances of direct contact with the metals which causes wear and useful energy loss. In high-speed applications, oil lubrication does assist in cooling as well, thereby ensuring stability while functioning.

In addition, lower friction can be attributed to advanced material properties. The use of high-purity steel, or some ceramic hybrid design elements in bearings helps decrease the internal material friction due to fewer imperfections and better-finished surfaces. In hybrid bearings, ceramic balls present smoother surfaces and higher hardness than steel, ultimately minimizing energy dissipation.

Finally, features such as precision ground raceways and cage construction contours help to smoothen the rolling motions and mitigate the vibrations causing inconsistency in effectiveness. Incorporation of these mechanisms ensures the bearings rolling elements bear high efficiency and reliability throughout their lifespan even if used in severe industrial conditions.

What are the advantages of using roller bearings?

High load capacity and durability of roller bearings

Due to their greater surface area in rolling elements concerning raceways, roller bearings can support high radial and axial loads. Because of this advantage, you will find these working on heavy-duty industrial machinery, automotive systems, and aerospace equipment. High durability is due to the construction materials used, such as chrome steel, which has high hardness (approximately 58-65 HRC) and high endurance to fatigue.

- Dynamic Load Rating: The bearing capacity of variable loads as per the excuse is parameter bears no excess deformation or wear. For example, based on the bearing size, dynamic load ratings for cylindrical roller bearings typically range from 20 to 300 kN.

- Static Load Rating: The maximum static force the bearing can take without permanent deformation is called static load capacity. This rating is generally between 30 and 500 kN and guarantees stability under heavy stationary forces.

- Material Fatigue Life: Given as operating hours, L₁₀ life shows the expected time in which a batch of bearings (90%) is anticipated to work in the conditions delineated without impairment due to fatigue. Roler-bearing units utilize precision heat treatment technologies to achieve long L₁₀ life due to long time, fatigue changes.

The effectiveness and service life of roller bearings under severe working conditions are methodically assured using durable cage designs to keep the elements positioned and improved external finishes that lower friction.

Suitability for high-speed applications

Roller bearings are made to perform exceptionally well in high-speed applications, which is achieved through their design that reduces friction and heat generation.

- Dynamic Load Rating (C): This is the measure of the force a rotating bearing is capable of supporting without losing stability at high speeds. High-speed types of bearings tend to have a higher C rating to withstand more dynamic situations and maintain stability.

- Limiting Speed (nₗ): limiting speed is defined as the ratio of the number of revolutions of a bearing and the performance action in the system. For high-speed systems, specially designed bearings with optimized cage designs and high-quality lubricant should perform consistently at or near this limit.

- Thermal Stability: Bearings are subjected to certain heating processes during which the temperature rises while the bearing spins. The aim is to avoid excessive changes of shape or structure due to working at higher speeds for longer periods.

- Surface Finish: More sophisticated inhibiting surface treatments are employed to minimize micro-abrasion and friction to enhance operations at high speeds.

All of these factors mentioned above are balanced to achieve reliable performance to bear operational stresses in high-speed situations. These characteristics are what make roller bearings ideal for certain industries including aviation, automobiles, and precision machinery.

Ability to handle misalignment and shock loads

Shock-bearing roller designs are made to handle a given amount of misalignment and are also made to withstand shock loads. The self-aligning mechanisms or spherical raceways incorporated into the structure of these bearings assist in achieving a range of misalignments. In their design, these bearings have a high load-carrying capacity and robust structural strength which, in instances where there is a sudden heavy impact, ensures that there is reliable bearing performance.

- Dynamic Load Rating: Ensures the bearing can withstand varying loads and impacts during operation without failure.

- Spherical Geometry: Facilitates self-alignment to manage angular misalignments effectively.

- Material Strength: Provides better resistance to shock and fatigue owing to high-grade steel or alloys.

- Guarded Internal Clearances: Designed to prevent stress concentration during abrupt load changes.

These specifications ensure roller bearings maintain optimal performance even under demanding misalignment and shock load scenarios.

In which applications are roller bearings commonly used?

Industrial machinery and heavy equipment applications

Roller bearings are important parts of industrial machines and construction machinery because they can withstand significant loads with low friction to provide smooth rotational movement. Their construction makes them useful in turbine systems, conveyors, cranes, etc. For example:

- Conveyor systems: Large and heavy roller bearings are needed to continuously support large weights without stopping the system. As such dynamic load ratings (C) and fatigue limit loads are necessary for reliability when in constant use.

- Turbines: The bearings used in turbines are required to endure high speeds and turbine temperatures. The high mechanical heat resistance that the hose can manage is why high-grade steel alloys and precise dimensional tolerances are needed for these operating conditions.

- Cranes: Shock load bearings and bearings that support changes in direction in crane applications are important. The primary technical requirements are static load capacity while tolerating moments of misalignment.

These examples display how bearing properties are important for the technical needs of heavy load operations.

Automotive and transportation industry uses

Bearings are crucial for the automotive industry, and as such they are very high-tech with regards to their performance and safety. Some of these key uses are: engine, transmission, wheel steering, and hubs. These applications raise the following specific engineering requirements:

- Engine Bearings: Low friction and low wear are essential, along with the ability to operate at very high RPMs and temperatures. Key specifications include load bearing thermal resistanceers and anti-friction materials such as ceramic and coated steel etc.

- Transmission Bearings: Precise tight tolerances, low noise operation, and durability under cyclic loading come in very handy for effective torque transfer and efficiency.

- Wheel Hub Bearings: With the added ability to efficiently bear the static and dynamic loads that come from varying conditions, these have become indispensable. Key specifications include load rating, corrosion resistance, and long maintenance intervals.

- Steering Mechanism: These can be extremely useful if applied where low backlash operation and accuracy are essential. Most of the time, the sealing system design is advanced, ensuring that contamination is kept out and smooth operation is maintained.

Each of these categories highlights how the technical properties of bearings are optimized to ensure safety, efficiency, and longevity in automotive and transportation applications.

Aerospace and marine applications for roller bearings

Using roller bearings in aerospace and marine environments can achieve enhanced safety and security because of their ability to handle extreme conditions. They are manufactured to shield themselves from harsh temperates and variations in speed and endure exhaustion – a standard in above-the-surface aviation. Ships, propulsion, landing gear, and turbine engines are some examples of their application.

- Load Capacity: Roller bearings have both radial and thrust bearings which allow them to withstand heavy loads. These qualities enable bears to tackle various operatives including but not limited to aircraft landing systems and marine propellor shafts.

- Material Composition: The quality of these machines is exceptional, providing both protection against corrosion and high amounts of temperature. This is particularly beneficial when used in extremely saline marine areas or high-flying cold units.

- Operating Temperature Range: Aircraft engineering ensures that their screws and bolts can withstand -40oC to 150oC. A much wider range is useful as it enables bears to operate in extreme places including spaces that are sub-zero, and business aircraft engines.

- Sealing Technology: Specialist seals get rid of moisture, sand, and dust to make operations in marine and aerospace bear-powerful.

- Maintenance: Extended intervals aided by engineered lubrication methods alleviate system downtime making the bearing more reliable.

The reliability of these bearings along with their safety made them popular for high-end businesses.

How to choose the right type of roller bearing for your application?

Factors to consider when selecting roller bearings

Each application presents an opportunity to diverge from the common factors of focus which guarantee optimal performance when it comes to selecting roller bearings.

- Load Capacity: A key factor for consideration is load capacity. I determine if radial and axial loads are compatible with the application’s operational requirements. Furthermore, I assess the maximum dynamic load and static load ratings offered by the manufacturer.

- Speed Rating: I tend to consider the rotational speed minus the derogation of the bearing as an essential factor. This relies on the configuration of the bearing, the lubrication, and the requisite operating speeds while preventing overheating or excessive wear.

- Operating Environment: temperature, pressure, and the presence of certain impurities such as dirt, moisture, or chemicals have an impact on and shape my choice. For some bearings with extreme conditions, the presence of oxides plus specialized sealing and high-temperature lubricants often proves suitable.

- Material and Coatings: The material composition of stainless steel or ceramics ought to be matched so I ensure the application requires corrosion resistance, high strength or low thermal expansion.

- Dimension Tolerances and Fit: I check to ensure that the shaft and housing fits are accurate and specific so I check the dimensional tolerances and interference or clearance fits set by the ISO or ANSI standards that guarantee reliable operation.

- Lubrication Needs: Durability is enhanced through proper lubrication, so I assess if systems lubricated by grease or oil are more suited for maintenance periods and operating speeds.

Organizing these elements methodically makes it possible to choose practically according to particular operational conditions and environmental problems.

Matching bearing type to load requirements and operating conditions

To choose the type of bearing I must first consider the load which can either be radial, axial, or a mixture of both. Radial loads are best suited using deep groove ball bearings or cylindrical roller bearings, which have high radial load handling capacity. On the other hand, thrust bearings like thrust ball bearings or tapered roller bearings are efficient for axial loads.

While angular contact ball bearings or tapered roller bearings are ideal for handling combined loads with both radial and axial forces because they can withstand multidirectional forces.

- Radial Load Capacity: Make sure that C, the dynamic load rating of the bearing, is greater than the maximum amount of radial load expected in service.

- Axial Load Capacity: Check that the axial load rating of the bearing is sufficient for constant or maximum axial force.

- Speed Limits: Verify the operating speed against the maximum permissible speed (n_lim) for the selected bearing type.

- Misalignment Tolerance: Determine the extent of misalignment that is permissible in cases where the shaft and housing are not exactly aligned.

- Environmental Modifications: Consider the extremes in temperature and possible contamination when choosing the type of materials and seals for the bearings.

By ensuring these factors are in line with the operational scenario, the selected bearing is guaranteed to operate in an efficient manner and highly reliable while reducing wear and increasing service life.

Importance of proper sizing and mounting in roller bearing selection

To achieve excellent performance, reliability, and durability, it is equally critical to consider the proper sizing and the method of mounting roller bearings. In the first place, reasons related to the application such as load ratings, speed ratings, and dimensions induce correct sizing. More emphatically, I check the dynamic load rating (C) and the static load rating (C0) to make certain that they are greater than the forces acting during operations. Concerning mounting, I check the alignment accuracy and the degree of interference fit to eliminate the chances of uneven load that will increase wear and tear.

- Dynamic Load Rating (C): Selected bearings must accommodate dynamically produced forces during operation within permissible limits.

- Static Load Rating (C0): Ensure static loads over a primary period to be supported by the bearing remain below the bearing’s threshold to prevent rolling element deformation.

- Shaft and Housing Fit: Interference or clearance fits are calculated in a way that permits some degree of axial movement of the shaft, but prevents it in case of thermal expansion.

- Alignment Tolerance: Allowable misalignment of the bearings will be restricted to limits which do not result in excessive wear or vibration.

- Torque Requirements: Adjustable preload is enhanced without increasing friction or story above the required temperature.

By meticulously adhering to these factors during selection and ensuring precise installation techniques, I mitigate operational risks and optimize bearing performance.

Frequently Asked Questions (FAQs)

Q: What are roller-element bearings and how do they differ from ball bearings?

A: Roller-element bearings are a type of rolling bearings that use cylindrical or tapered rollers instead of balls. They are designed to withstand higher loads than ball bearings and are often used in heavy-duty applications. While both ball and roller bearings reduce friction between moving parts, roller bearings typically have a greater load-bearing capacity due to their larger contact area with the bearing races.

Q: What are the main types of roller bearings?

A: The main roller bearing types include cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and needle roller bearings. Each type has specific characteristics suited for different applications. For example, cylindrical roller bearings are excellent for radial loads, while tapered roller bearings can handle both radial and axial loads. Spherical roller bearings are self-aligning, making them ideal for applications where misalignment may occur.

Q: What is a needle roller bearing and where is it commonly used?

A: A needle roller bearing is a type of roller bearing that uses long, thin cylindrical rollers resembling needles. Needle roller bearings are ideal for applications where radial space is limited but high load capacity is required. They are commonly used in automotive transmissions, pumps, compressors, and small electric motors. Needle roller bearings can withstand heavy radial loads and operate at high speeds, making them versatile components in many mechanical systems.

Q: How can I identify signs of bearing failure in roller bearings?

A: Common signs of bearing failure include unusual noise or vibration, increased temperature, reduced performance, and visible damage to the bearing components. Specific indicators may include pitting or flaking on the inner ring or rollers, discoloration due to overheating, or the presence of contaminants within the bearing. Regular inspection and monitoring of bearing performance can help detect early signs of failure and prevent catastrophic breakdowns.

Q: What factors should be considered in the overall design of a roller bearing system?

A: When designing a roller bearing system, several factors must be considered, including load type and magnitude, rotational speed, operating temperature, environmental conditions, and space constraints. The choice between locating and non-locating bearings, the number of rows of rolling elements, and the selection of appropriate seals and lubrication methods are also crucial aspects of the overall design. Additionally, the material selection for both the bearing and the housing should be based on the specific application requirements.

Q: How do cylindrical roller thrust bearings differ from other roller bearing types?

A: Cylindrical roller thrust bearings are specifically designed to handle axial loads in one direction. Unlike radial roller bearings, which primarily support radial loads, these bearings have rollers arranged perpendicular to the shaft axis. Cylindrical roller thrust bearings are capable of carrying very high axial loads and are often used in applications such as gearboxes, machine tool spindles, and heavy industrial equipment where significant thrust forces are present.

Q: What advantages do angular contact roller bearings offer?

A: Angular contact roller bearings are designed to support combined radial and axial loads. They feature raceways in the inner and outer rings that are displaced relative to each other in the direction of the bearing axis. This design allows them to accommodate axial loads in one direction and radial loads simultaneously. Angular contact roller bearings are often used in pairs to handle axial loads in both directions and are common in applications such as automotive wheel hubs, machine tool spindles, and industrial gearboxes where precise positioning and high stiffness are required.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8