Electric motors

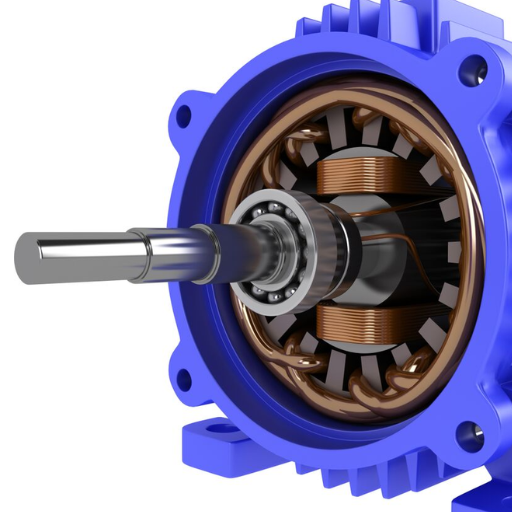

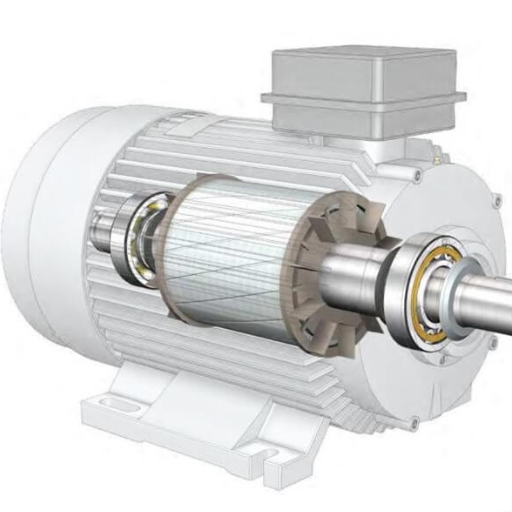

Electric motors are a critical component in many industrial and commercial applications. They are used to convert electrical energy into mechanical energy, making them an essential part of modern-day machinery.

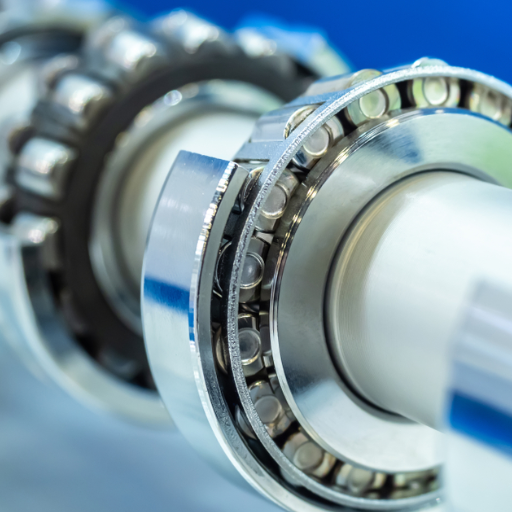

However, electric motors require bearings to function efficiently and reliably. Bearings are crucial in reducing friction between moving parts, supporting the motor’s load, and ensuring smooth rotation.

In this guide, we will dive deep into the world of electric motor bearings by Loyal. We will explore the different types of bearings used in electric motors, their functions, and maintenance tips to ensure optimum performance.

Overview of Electric Motor Bearings

Electric motor bearings serve as a pivotal component in the overall functionality of electric motors. They are designed to accommodate both radial and axial loads, thereby facilitating rotational movement. Commonly used bearings in electric motors include ball bearings, roller bearings, and sleeve bearings, each tailored to specific operational requirements and load capacities.

The selection of an appropriate bearing type is paramount for the efficiency and longevity of electric motors. Factors such as load conditions, speed, environment, and maintenance practices must be thoroughly evaluated to optimize performance. Proper lubrication is also critical; it reduces wear, mitigates friction, and expels contaminants, contributing to the overall lifespan of the bearings and, consequently, the electric motor.

Classification of Bearing Types

When discussing electric motors, it is essential to delineate the primary bearing types utilized in their design and operation. Each bearing type offers distinct advantages tailored to various applications and load requirements. The following are the main categories of bearings commonly employed in electric motor systems:

- Ball Bearings: These are among the most prevalent types of bearings in electric motors. They consist of a series of spherical balls encased in a ring, allowing for smooth rotation while supporting both radial and axial loads. Due to their versatility and ability to handle high speeds with low friction, ball bearings are widely used in small to medium-sized motors.

- Roller Bearings: Unlike ball bearings, roller bearings utilize cylindrical rollers to distribute load more evenly across a larger surface area. This design allows them to carry heavier loads compared to ball bearings of similar size. They are particularly effective in applications with high radial loads and lower speed requirements, making them suitable for larger electric motors.

- Sleeve Bearings: Also known as plain bearings, sleeve bearings are simpler in construction compared to ball and roller bearings. They consist of a cylindrical sleeve that allows a rotating shaft to glide over it, utilizing a lubricant to minimize friction. Sleeve bearings are often found in applications where low-speed operations are present, and they are advantageous in environments with high contamination levels due to their robust design.

- Magnetic Bearings: An emerging technology in electric motor design, magnetic bearings utilize magnetic fields to levitate the rotor, thus eliminating mechanical contact and associated wear. This advancement significantly enhances efficiency and prolongs the lifespan of motors by reducing the need for maintenance and lubrication.

- Thrust Bearings: Specifically designed to accommodate axial loads, thrust bearings maintain the position of rotating components under varying pressure. These bearings can be integrated into various motor configurations to facilitate axial movement while ensuring stability and alignment.

Each category of bearing plays a crucial role in the functionality and reliability of electric motors. The selection process should involve a comprehensive analysis of application requirements, operating conditions, and potential load scenarios to ensure optimal performance.

Interchangeability of Bearing Products Across Electric Motor Brands

The interchangeability of bearing products among different electric motor brands is a critical consideration, particularly when optimizing for performance and operational efficiency. For instance, the SKF 6200 Series bearings can serve as replacements for the NSK 6200 Series, provided the application parameters, such as load capacity and speed ratings, align closely. Furthermore, the Timken 32000 Series could potentially replace the NTN 32000 Series bearings in heavy-duty applications, given their comparable design specifications tailored for high-load scenarios typically encountered in industrial sectors.

Additionally, there are instances where cross-brand compatibility extends to precision motor applications. The NSK 62 Series bearings may be substituted with equivalent FAG 62 Series offerings, especially in sophisticated environments like aerospace, where precision and reliability are paramount. However, it is essential to note that while brand interchangeability allows for flexibility in maintenance and repair, careful consideration of dimensional accuracy and material suitability is vital to ensure optimal performance and longevity of the electric motors in question.

Different brands produce bearings with similar specifications, allowing for interchangeability between products. Below are selected bearings from NTN and NSK, showing their dimensions and links to detailed product pages.

| Type | Bore Diameter | Outside Diameter | Width | Brand |

|---|---|---|---|---|

| 7220CG/GLP4 | 100 mm | 180 mm | 34 mm | NTN |

| 7307CDB/GLP4 | 35 mm | 80 mm | 42 mm | NTN |

| 7218CG/GLP4 | 90 mm | 160 mm | 30 mm | NTN |

| 7217CGD2/GLP4 | 85 mm | 150 mm | 28 mm | NTN |

| 7214CG/GLP4 | 70 mm | 125 mm | 24 mm | NTN |

| NN3006ZTBKR | 30 mm | 55 mm | 19 mm | NSK |

| NN3006TBKR | 30 mm | 55 mm | 19 mm | NSK |

| NN3008TBKR | 40 mm | 68 mm | 21 mm | NSK |

| NN3007ZTBKR | 35 mm | 62 mm | 20 mm | NSK |

| NN3007TBKR | 35 mm | 62 mm | 20 mm | NSK |

Interchangeability and Compatibility

For electric motors, it is crucial to ensure that the bearings used are compatible and interchangeable to maintain the motor’s efficiency and lifespan. Brands like NTN and NSK offer bearings that meet similar specifications, allowing for easy replacement and maintenance. The table above provides a quick reference to some of the available options, ensuring that you can find the right bearing for your needs.

For more detailed information and to make inquiries, please visit the product links provided in the table.

Considerations for Electric Motor Bearing Installation

- Alignment: Proper alignment of the bearings is essential to minimize misalignment-induced wear. Misaligned bearings can lead to increased friction, eccentric motion, and premature failure. Utilizing precision alignment tools and techniques prior to installation is crucial.

- Lubrication: Adequate lubrication must be ensured prior to operation, as inadequate lubrication can lead to excessive wear and overheating. Selection of the appropriate lubricant, based on the operational environment and bearing type, is vital for ensuring optimal performance and longevity.

- Environmental Conditions: Consider the operating temperature, humidity, and potential exposure to contaminants. Bearings designed for harsh environments may require protective seals or specialized coatings to maintain operational integrity in such conditions.

- Load Specifications: Understanding the radial and axial load requirements is necessary for selecting the right bearings and ensuring that they are installed correctly. Overloading bearings beyond their specified limits can result in catastrophic failure.

- Installation Technique: Employing proper installation techniques, such as using appropriate tools and avoiding excessive force during insertion, is vital to prevent damage to the bearings or the motor components.

By meticulously considering these factors, the integrity of the electric motor’s operational functionality can be significantly enhanced, thereby ensuring a reliable and long-lasting performance.

Common Issues During Operation

Electric motor bearings are critical components that ensure smooth and efficient operation. However, they can encounter several issues during use, which can affect performance and longevity. Here are some common problems to watch out for:

- Overheating: A prevalent problem in electric motor operation is overheating, often resulting from inadequate lubrication or excessive load. Monitoring temperature is essential, as sustained high temperatures can lead to bearing failure and decreased efficiency. Implementing temperature sensors can aid in real-time monitoring of thermal conditions.

- Vibration: Excessive vibration during operation may indicate misalignment, imbalance, or wear in the bearings. Regular vibration analysis should be conducted to identify abnormalities and determine the necessary corrective actions.

- Contamination: Environmental contaminants such as dust, dirt, and moisture can enter the bearing housing, leading to accelerated wear and potential failure. Regular inspection and maintenance of seals and protective enclosures are necessary to mitigate this risk.

- Noise: Unusual noises emanating from electric motors typically signal internal issues, such as wear or damage to the bearings. Conducting auditory inspections can help in diagnosing problems early and warrant timely maintenance.

Addressing these common issues proactively and systematically can preserve electric motors’ operational reliability, ultimately enhancing machinery’s performance and endurance.

Clearance Requirements for Electric Motor Bearings

Understanding and adhering to the clearance requirements for electric motor bearings is crucial for optimal performance and longevity. The recommended clearances can vary based on several factors, including bearing type, application, and operating conditions. Below are key considerations regarding clearance specifications:

- Radial Clearance: For rolling element bearings, the radial clearance typically ranges from 0.01 mm to 0.1 mm, depending on the bearing’s size and load conditions. Adequate radial clearance allows for thermal expansion and operational flexibility, reducing the risk of bearing seizure during operation.

- Axial Clearance: Axial or thrust clearance specifications can vary significantly, often between 0.05 mm and 0.5 mm, according to bearing design and operational load. This clearance is critical in applications subjected to axial loads to prevent excessive movement which can lead to premature wear.

- Temperature Variations: The bearing clearance requirements should be adjusted based on significant temperature fluctuations in operating environments. Increased temperatures can expand the bearing components, thereby necessitating larger clearance tolerances to maintain functionality.

- Lubrication Impact: The type of lubrication employed can influence the required clearances. For instance, grease-lubricated bearings may necessitate slightly higher clearances compared to oil-lubricated counterparts due to differences in thermal properties and lubrication film strength.

- Load Conditions: The bearing clearance must be tailored to the specific load conditions the bearing will face. Heavier loads may require tighter clearances to ensure stability, while lighter loads might allow for more flexibility to accommodate thermal expansion.

- Installation Considerations: The method of installation can also affect clearance requirements. Proper alignment and fit during installation are crucial, as misalignment can lead to uneven wear and increased clearance needs over time.

- Bearing Material: The material of the bearing can impact the required clearance. Different materials may expand at different rates when heated, necessitating adjustments in clearance to maintain proper function and longevity.

- Speed of Operation: Bearings operating at higher speeds may require specific clearances to reduce the risk of overheating and ensure optimal performance. Higher speeds can generate more heat, making appropriate clearance critical for maintaining lubrication film integrity.

- Endurance Testing: Conducting endurance tests can help determine the appropriate clearance for specific applications. Manufacturers can refine clearance specifications by assessing performance under various conditions to enhance reliability and lifespan.

Sealing Requirements for Electric Motor Bearings

The sealing requirements for electric motor bearings are critical to ensure optimal performance and longevity. Effective sealing serves to prevent the ingress of contaminants such as dust, moisture, and abrasive particles, which can significantly decrease the operational efficiency and lifespan of the bearings.

- Type of Seal: Electric motor bearings typically employ different types of seals, including lip seals, contact seals, and non-contact seals. Lip seals provide a direct seal against contaminants while retaining lubricant, whereas contact seals offer a tighter fit, albeit with increased friction. Non-contact seals, while less effective at containing grease, can minimize drag and heat generation.

- Operating Environment: The specific operating environment dictates the sealing requirements. Motors exposed to harsh conditions—such as extreme temperatures, humidity, or corrosive environments—may necessitate advanced sealing solutions to withstand these external factors and maintain internal integrity.

- Lubrication Compatibility: Seal materials must be compatible with the lubrication method employed in the bearings. For example, seals used with grease-lubricated bearings must withstand the chemical properties of the grease, while those in oil-lubricated applications must accommodate the flow dynamics of the lubricant used.

- Pressure Considerations: Bearings in electric motors may encounter varying pressure conditions. Seals must be designed to withstand the differential pressure created during operation, ensuring that lubrication remains contained and contaminants are effectively excluded.

- Maintenance and Replacement: Regular maintenance assessments should include inspection of seals for wear or damage, as compromised seals can lead to lubrication loss and contamination ingress. Timely replacement of seals is vital to prolong the service life of electric motor bearings and maintain operational efficiency.

Environmental Requirements

- Temperature Range: Bearings must be rated for the temperature extremes they will encounter. High temperatures can lead to lubricant breakdown, while low temperatures may cause increased viscosity, affecting lubrication efficiency.

- Humidity Levels: In humid environments, moisture ingress must be mitigated to prevent corrosion and premature wear of bearings. Seals should provide adequate barrier protection against moisture while facilitating proper lubrication.

- Vibration and Shock: Bearings are subject to varying degrees of vibration and shock loading. The design must accommodate these mechanical stresses without compromising structural integrity, potentially requiring special materials or shock-resistant features.

- Contaminant Exposure: Electric motors may operate in environments laden with dust, dirt, or chemicals. Hence, bearings should incorporate robust sealing solutions that prevent contaminants from entering while retaining necessary lubricants to ensure smooth operation.

- Altitude Effects: Higher altitudes can affect the atmospheric pressure and temperature, necessitating adaptations in bearing selection to ensure reliable performance under reduced pressure conditions.

Temperature Requirements

Bearings must be selected based on their ability to withstand both operational and environmental temperatures. The operating temperature of electric motor bearings typically ranges from -40°F to 250°F (-40°C to 120°C), depending on the specific application and lubrication methods employed.

When temperatures exceed the upper limits, lubricants may degrade, leading to increased friction, wear, and potential bearing failure. Therefore, it is essential to monitor operating conditions, ensuring that bearings are adequately cooled and lubricated. Conversely, at lower temperatures, lubricants can thicken, increasing resistance and impeding efficient movement, which may result in thermal stress over time.

Manufacturers provide temperature ratings for bearings, which should guide selection based on the application requirements. Additionally, utilizing synthetic lubricants can improve temperature resistance, facilitating performance stability across a broader temperature spectrum. Proper thermal management, including the incorporation of thermal insulation and effective heat dispersion solutions, is paramount in prolonging the functionality of electric motor bearings.

Selection of Lubricants for Bearings

First, the lubricant’s viscosity grade is paramount, as it must align with the bearing’s operational speed and load conditions. Typically, higher speeds require lower viscosity lubricants to minimize drag, while higher loads may necessitate increased viscosity for adequate film strength.

Additionally, it is essential to evaluate the temperature stability of the lubricant, specifically its ability to maintain performance over the anticipated temperature range of the application. This is particularly vital in environments with extreme temperatures where conventional lubricants may fail. The lubricant should also possess good oxidation stability, preventing degradation over time, as well as excellent water resistance to keep contaminants at bay and maintain performance.

Another aspect involves the additive package incorporated in the lubricant. Anti-wear additives, extreme pressure additives, and rust inhibitors can enhance the lubricant’s properties, providing protection against wear and corrosion. Furthermore, selecting a lubricant compatible with the bearing and seal materials is crucial to prevent adverse chemical reactions.

Lastly, regular lubrication intervals and monitoring should guide the selection process. A lubricant that can withstand longer intervals without degradation can significantly reduce maintenance costs and downtime. In summary, the choice of lubricant for bearings hinges on a detailed assessment of operational conditions, environmental factors, and the specific requirements of the application.

Selection of Bearing Type

When selecting the appropriate bearing type for electric motors, several critical factors must be considered to ensure optimal performance and longevity.

- Load Capacity: Evaluate the radial and axial loads that the electric motor will experience during operation. Bearings must be chosen not only for their capacity to handle these loads but also for their ability to withstand shock loads, which are common in electric motors.

- Speed Rating: The motor’s maximum operating speed significantly influences bearing selection. High-speed applications typically demand bearings that can operate efficiently without generating excessive heat, which can lead to premature failure.

- Lubrication Method: The lubrication technique must be considered. For instance, some bearings may be designed for grease lubrication, whereas others may be optimized for oil lubrication or sealed for life. The choice of lubricant will directly affect the bearing’s performance and durability.

- Environmental Conditions: The operating environment of the electric motor can greatly impact bearing selection. Factors such as exposure to moisture, dust, and chemicals necessitate the use of bearings with enhanced protection features, such as seals or shields.

- Material Compatibility: Bearings are available in various materials, including steel, ceramic, and polymer composites. The selection should align with the motor’s application requirements, considering factors like corrosion resistance and thermal stability.

- Mounting Configuration: The physical configuration and mounting of the bearing within the motor should also be taken into account. Ensure that the bearing fits well with the motor’s design and provides adequate alignment capabilities.

- Noise and Vibration Characteristics: For applications where noise reduction is paramount, selecting bearings with low noise and vibration characteristics can enhance overall system performance, contributing to a more efficient and quieter motor operation.

Bearing Life

Several critical factors influence the lifespan of bearings in electric motors, each necessitating specific mitigation strategies to enhance reliability and prolong service life.

- Load Conditions: Bearings subjected to excessive loads may experience increased wear and premature failure. Implementing proper load distribution techniques and selecting bearings rated for the specific load conditions can significantly extend their lifespan.

- Operating Speed: High-speed applications can elevate operational temperatures and stress, adversely affecting bearing life. Employing bearings specifically designed for high-speed operations, along with appropriate cooling mechanisms, can mitigate these effects.

- Lubrication Quality: Inadequate or contaminated lubrication can lead to increased friction and wear. Utilizing high-quality lubricants suited to the operating environment, along with regular maintenance schedules to replace or replenish lubricant, can enhance bearing performance.

- Alignment and Installation: Misalignment during installation can lead to uneven load distribution and increased failure rates. Adopting precise alignment methods and ensuring proper installation practices are crucial for optimal bearing life.

- Environmental Factors: Bearings exposed to extreme temperatures, moisture, or contaminants are at risk of degradation. Utilizing bearings with protective seals or shields designed for specific environmental conditions can help safeguard against these factors.

- Operating Conditions: Frequent start-stop cycles and heavy shock loads can impact bearing longevity. Implementing soft start techniques and shock absorbers can reduce the impact on bearings, thereby enhancing their operational lifespan.

- Material Selection: The choice of bearing materials plays a vital role in durability. Selecting advanced materials with superior fatigue resistance can significantly improve resistance to wear and corrosion, ultimately extending bearing life.

Basic Dynamic Load Rating and Fatigue Life

The Basic Dynamic Load Rating (C) is a crucial parameter in bearing selection, representing the maximum load that a bearing can sustain while operating under normal conditions without excessive wear or failure. It is quantified based on a standardized test, where a specific axial load is applied to a rotating bearing until a defined amount of wear occurs. The dynamic load rating allows engineers to ensure that the selected bearing can withstand the operational loads expected during its service life.

Closely related to the basic dynamic load rating is the concept of fatigue life, typically expressed in terms of L10 life. The L10 life indicates the number of revolutions at which 90% of a group of identical bearings will still be operational without failure due to material fatigue. The relationship between dynamic load rating and fatigue life is mathematically described by the formulation:

L10 = (C / P)³

In this equation, L10 represents the expected life in millions of revolutions, C is the dynamic load rating, and P is the applied equivalent dynamic load. Understanding these metrics is crucial for predictive maintenance and optimizing mechanical system design, as it helps in selecting the appropriate bearing configuration to ensure reliability and longevity in diverse operating conditions.

Dynamic Equivalent Load

The Dynamic Equivalent Load (P) is a critical concept in bearing analysis and selection, representing the load that, if applied steadily, would produce the same effect on the bearing life as the actual load conditions during operation. This parameter accounts for various factors, including load direction, magnitude, and rotation, offering a more accurate understanding of the operational stresses that bearings endure.

To determine the dynamic equivalent load, one must consider the radial, axial, and occasionally moment loads acting on the bearing. The calculation can vary based on the bearing type; for instance, different formulas are applicable for ball bearings compared to roller bearings. Generally, the equivalent load is computed using the following equation:

P = X * Fr + Y * Fa

In this equation, Fr is the radial load, Fa is the axial load, and the factors X and Y correspond to specific ratio values dictated by the bearing’s design features and loading conditions. Understanding the dynamic equivalent load is essential for ensuring that the selected bearing can reliably sustain the operational demands placed upon it, ultimately influencing maintenance schedules and overall system efficiency.

Basic Static Load Ratings and Static Equivalent Loads

The Basic Static Load Rating (C0) is another fundamental parameter in bearing selection, quantifying the load at which a bearing will have a 90% probability of not experiencing permanent deformation under static conditions. This rating is crucial when considering applications where the bearing may be subjected to immovable loads. The ability to accurately assess the static load rating is essential for ensuring the longevity and performance of the bearing in its intended application.

The concept of Static Equivalent Load (P0) relates closely to the basic static load rating. It represents the equivalent static load that results in the same level of stress in the bearing as encountered in actual operational conditions. The determination of this static equivalent load involves evaluating the bearing’s loads, including radial and axial components, as well as understanding the static load rating provided by the manufacturer. The calculation can often be expressed as:

P0 = (X0 * Fr) + (Y0 * Fa)

In this formula, Fr represents the static radial load, and Fa stands for the static axial load. The coefficients X0 and Y0 should be chosen according to the specific conditions that influence the bearing’s operational envelope. A solid understanding of static load ratings and static equivalent loads is essential for properly specifying bearings to meet their intended loads, optimizing performance, and reducing the risk of premature failure.

Bearing Tolerances

Bearing tolerances refer to the permissible limits of variation in the physical dimensions of a bearing. These tolerances are crucial as they dictate how well the bearing fits within its housing and around its shaft, ensuring the desired operational efficiency.

The importance of bearing tolerances cannot be overstated. Firstly, they ensure a precision fit, minimizing any unwanted movement between parts, which is vital for maintaining the bearing’s performance and longevity. Secondly, tight tolerances prevent excessive wear and tear on the bearing and associated components, enhancing durability. Lastly, accurate tolerances help in reducing friction and heat generation, thereby improving the overall efficiency of the machine.

In electric motors, bearing tolerances play a significant role in various operational aspects. Loose tolerances can lead to increased noise and vibration levels. Incorrect tolerances can affect the torque, efficiency, and electromagnetic parameters of electric motors. Inaccurate tolerances may result in uneven heat distribution, causing overheating and potential failure. Manufacturing tolerances affecting the motor shaft can introduce run-outs on the bearing journal, leading to imbalance during operation.

In conclusion, bearing tolerances are critical to the optimal functioning of electric motors. Ensuring precise tolerances can significantly improve the motor’s lifespan, efficiency, and overall performance, making it a fundamental aspect of motor design and maintenance.

Fit and Internal Clearances

Fitting and internal clearances are vital considerations in ensuring the efficient operation of bearings in electric motors and other machinery. The fit refers to the relationship between the bearing and its respective shaft or housing. A proper fit can be classified as either a tight, loose, or interference fit. An interference fit is often employed to enhance stability, critical in high-speed applications, while a loose fit may be used to allow for thermal expansions and facilitate easier assembly.

Internal clearances, on the other hand, denote the amount of space between the rolling elements and the raceway within the bearing. These clearances, typically measured in micrometres, are essential for accommodating lubricant film thickness and thermal growth. Insufficient internal clearance can lead to excessive friction, heat generation, and even premature bearing failure, while excessive clearance may result in reduced load-carrying capability and increased vibration. Therefore, careful consideration of fits and internal clearances plays a crucial role in the design and functionality of bearing systems, ultimately contributing to the reliability and efficiency of electric motors.

Lubrication

Lubrication is a critical aspect of bearing performance in electric motors, impacting both the longevity and efficiency of the system. Adequate lubrication reduces friction between the rolling elements and the raceways, preventing wear and overheating that could lead to premature failure. There are various types of lubricants available, including oils and greases, each with specific properties suited for different operating conditions.

Oil lubrication offers benefits such as better heat dissipation and the ability to flow freely, which is ideal for high-speed applications. In contrast, grease provides a protective barrier against contaminants and is advantageous in applications with lower speeds or when the bearing is not easily accessible for regular maintenance.

It is essential to select the appropriate lubricant based on the bearing design, operating environment, and expected load conditions. Regular maintenance and monitoring of the lubrication system play a key role in ensuring optimal performance and reliability of bearings in electric motors.

Materials for Bearing Rings and Rolling Elements

The selection of materials for bearing rings and rolling elements is paramount in ensuring optimal performance, durability, and reliability of bearing systems in electric motors. Commonly utilized materials include high-carbon chromium steel, stainless steel, and ceramics, each exhibiting distinct properties suited for specific applications.

High-carbon chromium steel is widely preferred due to its excellent hardness, wear resistance, and ability to withstand high loads. It undergoes heat treatment to achieve the desired microstructure, enhancing its performance under mechanical stress. Stainless steel, notable for its corrosion resistance, is suitable for environments exposed to humidity and corrosive substances, although it may sacrifice some load-carrying capacity compared to high-carbon steels.

Ceramics, such as silicon nitride, offer outstanding hardness and low density, making them ideal for high-speed applications. Their inherent resistance to corrosion and thermal degradation further enhances their suitability in extreme environments. However, the brittleness of ceramic materials necessitates careful consideration in design to mitigate potential fracture under heavy loads.

Ultimately, the choice of material for bearing rings and rolling elements should be guided by the specific operating conditions, including temperature, load, and environmental challenges, to maximize the lifespan and efficiency of the bearing system.

Electric motors bearing brands

| Brand | Main Bearing Models | Main Characteristics |

| SKF | 6200, 6300, 7000 Series | Offers high load capacity, low friction, and exceptional durability, making them ideal for high-speed applications. |

| Timken | 32000, 34000 Series | Engineered for heavy-duty use, these bearings provide superior strength and wear resistance through advanced manufacturing. |

| NSK | 60 Series, 62 Series | Designed for precision and low noise, suitable for high-performance electric motors with reduced operational vibration. |

| NTN | 60 Series, 72 Series | Focused on increasing energy efficiency, these bearings utilize enhanced lubrication and vibration-reducing technologies. |

| Schaeffler (INA/FAG) | X-life, E1 Series | Features innovative materials and design for superior performance and longevity in harsh operating conditions. |

This table outlines key models from leading electric motor bearing brands, detailing their prominent features which enhance the efficiency and reliability of bearing systems across various applications.

Applications of Bearing Brands in Electric Motors

The aforementioned bearing brands are integral to the operation of various electric motor types across different industries. For instance, SKF bearings, such as the 6200 and 6300 Series, are often employed in high-speed electric motors utilized in automotive applications, where efficiency and durability under dynamic loads are crucial. Timken’s 32000 and 34000 Series bearings are commonly found in heavy-duty industrial motors, particularly in sectors like mining and construction, where they endure significant mechanical stress and harsh environments.

In contrast, NSK bearings, including the 60 and 62 Series, are ideally suited for precision electric motors used in robotics and aerospace applications, where low noise and minimal vibration are essential for operational effectiveness. NTN bearings, particularly the 60 and 72 Series, enhance energy efficiency in servo motors, widely used in conveyor systems and automated production lines. Lastly, Schaeffler (INA/FAG)’s X-life and E1 Series bearings are frequently implemented in specialty electric motors designed for renewable energy applications, such as wind turbines, due to their advanced materials and design that ensure longevity in demanding conditions. The careful selection and use of these bearings significantly contribute to the performance and reliability of electric motors across varied applications.

Conclusion

In summary, the selection and maintenance of bearings in electric motors are paramount to ensuring high performance and reliability across various applications. At Loyal, we emphasize the importance of utilizing high-quality bearings designed for specific operational parameters. Our commitment to providing exceptional bearing solutions enables customers to enhance the efficiency and lifespan of their electric motors. By focusing on precision engineering and robust materials, Loyal stands at the forefront of bearing technology, ensuring that our clients receive the best in durability and operational excellence.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8