Exploring Split Pillow Blocks: Enhancing Machinery Support

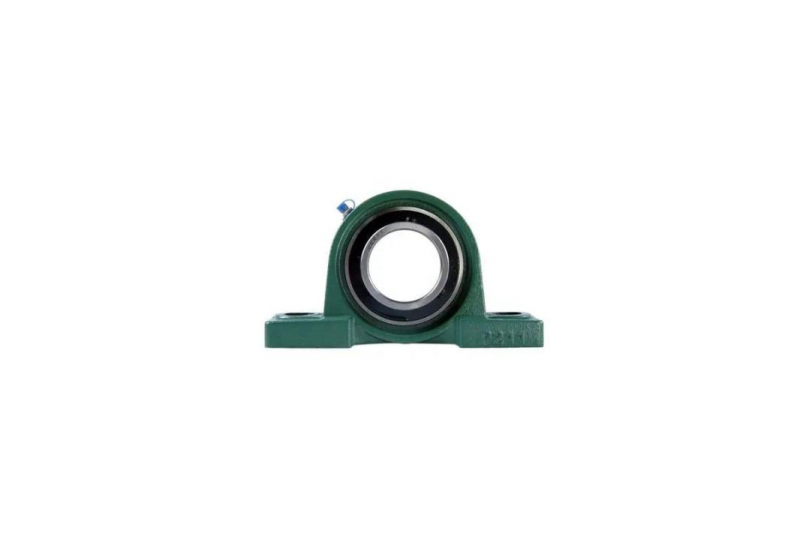

In the world of machinery and industrial equipment, there exists a critical component that often goes unnoticed but plays a pivotal role in ensuring smooth operation and longevity – split pillow blocks. These unassuming support structures are the unsung heroes that maintain the stability and alignment of machinery, ultimately enhancing machinery support. In this exploration, we will delve into the various facets and advantages of split pillow blocks, shedding light on their significance in the industrial landscape.

The Foundation of Stability

Split pillow blocks serve as the foundation of stability for a wide range of machinery and equipment. They are specifically designed to provide support and house bearings, which are responsible for carrying the axial and radial loads generated during operation. The unique split design of these blocks allows for easy installation and maintenance, making them a preferred choice in many industrial applications.

Precision in Alignment

One of the key functions of split pillow blocks is to ensure the precise alignment of machinery components. Misalignment can lead to increased wear and tear, reduced efficiency, and even catastrophic failure. Split pillow blocks are engineered with precision to minimize misalignment issues, thereby contributing to the overall efficiency and reliability of the equipment they support.

The Journey Ahead

As we embark on this journey of exploration, we will uncover the intricacies of split pillow blocks, from their design and construction to their diverse applications across various industries. We will also delve into the installation and maintenance practices that maximize their longevity. Additionally, we will examine the advantages and limitations of split pillow blocks, offering a comprehensive view of their role in machinery support.

Design and Construction: The Heart of Split Pillow Blocks

In our journey to explore split pillow blocks and how they enhance machinery support, it’s crucial to delve into the very heart of these essential components – their design and construction. Understanding the intricacies of their design principles and the various components that comprise a split pillow block is fundamental to appreciating their significance in machinery support.

The Design Principles

At the core of every split pillow block lies a set of well-thought-out design principles that govern its functionality. These principles are the foundation upon which split pillow blocks are built to provide support and stability to machinery. By comprehending these principles, we can gain insights into how split pillow blocks excel in their role.

Components of a Split Pillow Block

A split pillow block consists of several key components, each with a specific purpose in ensuring the effective support of machinery. These components include:

| Housing | The housing is the outer shell of the split pillow block and serves as the main structure that supports the bearing and provides a mounting point for the equipment. It is designed to withstand the loads and stresses encountered during operation. |

| Bearing | The bearing within the split pillow block is responsible for carrying the axial and radial loads generated by the machinery. It plays a critical role in ensuring smooth rotation and minimizing friction. Different types of bearings can be used in split pillow blocks, depending on the application’s requirements. |

| Seals | Seals are essential components that prevent contaminants from entering the split pillow block, ensuring the longevity of the bearing and the equipment it supports. Proper sealing is crucial for maintaining optimal performance. |

| Lubrication | Effective lubrication is vital for reducing friction and wear within the bearing. Lubricants ensure smooth and efficient operation while dissipating heat generated during the process. Understanding the lubrication requirements of split pillow blocks is essential for their proper maintenance. |

Types of Split Pillow Blocks

Not all split pillow blocks are created equal, and the market offers various types to cater to different industrial needs. Exploring these different types and their specific applications is essential to making informed decisions when selecting split pillow blocks for machinery support.

As we continue our journey into the world of split pillow blocks, we will further unravel the significance of their design and construction. By gaining a deeper understanding of these principles and components, we can appreciate how split pillow blocks excel in enhancing machinery support and contributing to the efficiency and reliability of industrial equipment.

Applications Across Industries: The Versatility of Split Pillow Blocks

As we delve deeper into our exploration of split pillow blocks and their role in enhancing machinery support, it becomes evident that these versatile components have found their way into a wide array of industries. Their adaptability and reliability make them indispensable in various applications, each with its unique set of demands. we will uncover the diverse range of industries that rely on split pillow blocks and shed light on specific examples of their usage.

Industries That Rely on Split Pillow Blocks

Conveyor Systems

Conveyor systems are the backbone of many industries, facilitating the smooth movement of materials and products. Split pillow blocks find extensive use in conveyor belt applications, where they provide the necessary support and alignment for efficient material handling. Their robust construction ensures reliable performance in demanding environments.

Pumps and Compressors

In the realm of fluid handling, pumps and compressors play a pivotal role. Split pillow blocks are utilized to support the rotating shafts of pumps and compressors, ensuring stable operation and minimizing vibrations. This application is crucial in industries such as manufacturing, water treatment, and oil and gas.

Fans and Blowers

Fans and blowers are prevalent in various settings, from HVAC systems to industrial processes. Split pillow blocks are employed to support the fan and blower shafts, allowing for smooth and efficient air movement. Their ability to maintain alignment under varying loads contributes to the longevity of these systems.

Benefits of Split Pillow Blocks in Enhancing Equipment Reliability

The reliance on split pillow blocks across industries can be attributed to the numerous advantages they offer:

– Easy Installation and Maintenance

The split design of these pillow blocks simplifies installation and maintenance procedures. It allows for quick access to the bearing and shaft, reducing downtime during repairs or replacements.

– Load-Carrying Capacity

Split pillow blocks are engineered to handle substantial axial and radial loads, making them suitable for heavy-duty applications. Their load-carrying capacity ensures the stability and longevity of equipment.

– Alignment Precision

Maintaining precise shaft alignment is critical for machinery efficiency and reliability. Split pillow blocks excel in this regard, as they provide the necessary support and alignment, minimizing wear and extending equipment life.

– Contaminant Protection

Sealed designs and effective sealing options protect the bearing from contaminants, ensuring a clean and well-lubricated environment. This protection enhances the durability of both the bearing and the machinery it supports.

In conclusion, split pillow blocks have carved a niche for themselves in various industries by providing dependable machinery support. Whether in conveyor systems, pumps, compressors, or fans, these components play a pivotal role in enhancing equipment reliability and overall operational efficiency. Their adaptability and performance make them a valuable asset across diverse industrial applications.

Installation and Maintenance: Ensuring Longevity and Performance

In the world of machinery support, split pillow blocks are revered for their reliability and ease of maintenance. Proper installation and regular upkeep are crucial in maximizing the lifespan and performance of these components. we will provide a step-by-step guide on how to install split pillow blocks, offer best practices for maintenance and lubrication, and explore strategies for monitoring and addressing wear and tear in industrial environments.

Step-by-Step Installation Guide

Inspection

Before installation, thoroughly inspect the split pillow block and all its components, including the housing, bearing, seals, and any associated hardware. Ensure that they are free from any damage or defects.

Cleanliness

Maintain a clean and dust-free workspace during installation. Ensure that the shaft and the mounting surface are free from dirt, debris, or any contaminants that may affect the bearing’s performance.

Alignment

Proper shaft alignment is crucial for the longevity of the split pillow block and the equipment it supports. Use precision tools to align the shaft with the bearing, minimizing misalignment issues.

Lubrication

Apply the recommended lubricant to the bearing. Ensure that the lubrication is evenly distributed, and do not over-grease, as it can lead to overheating. Follow the manufacturer’s guidelines for lubrication intervals.

Secure Fasteners

Tighten all fasteners according to the specified torque values. Ensure that the split pillow block is securely attached to its mounting surface to prevent any movement or misalignment during operation.

Maintenance and Lubrication Best Practices

– Regular Inspections

Implement a routine inspection schedule to check for any signs of wear, corrosion, or damage. Early detection of issues can prevent costly repairs down the line.

– Lubrication Management

Monitor the lubrication of the bearing and reapply grease as needed. Over time, the grease may degrade or become contaminated, affecting the bearing’s performance.

– Temperature Monitoring

Keep an eye on the operating temperature of the split pillow block. Elevated temperatures can be indicative of issues like overloading, misalignment, or inadequate lubrication.

Addressing Wear and Tear

– Bearing Replacement

If the split pillow block exhibits signs of significant wear or damage that cannot be rectified through maintenance, consider replacing the bearing. Select a suitable replacement bearing based on the equipment’s load and requirements.

– Vibration Analysis

Regularly perform vibration analysis to identify any abnormal vibrations in the machinery. Excessive vibration can be a sign of misalignment or bearing wear, and addressing it promptly can prevent further damage.

In conclusion, proper installation and maintenance are paramount in ensuring the longevity and reliable performance of split pillow blocks. Following a meticulous installation process, adhering to best practices for lubrication, and implementing effective monitoring strategies will contribute to the enhanced support provided by these essential components. By taking these steps, industries can optimize machinery support, minimize downtime, and maximize operational efficiency.

Advantages and Limitations: Weighing the Pros and Cons

Advantages of Split Pillow Blocks

Ease of Installation

One of the primary advantages of split pillow blocks is their user-friendly installation process. Unlike solid pillow blocks that require shaft disassembly, split pillow blocks can be easily mounted and dismounted without the need to remove other components. This feature significantly reduces downtime during maintenance or replacements.

Accessibility for Maintenance

Maintenance tasks become more straightforward with split pillow blocks. Their split design allows easy access to the bearing and other internal components. This accessibility streamlines lubrication, inspection, and any necessary repairs, contributing to prolonged bearing life and efficient machinery support.

Adaptability to Shaft Misalignment

Split pillow blocks are designed to accommodate certain degrees of shaft misalignment. This adaptability helps minimize wear and tear on both the bearing and the machinery, promoting longer equipment lifespan and reduced maintenance costs.

Wide Range of Sizes and Designs

Manufacturers offer a wide variety of split pillow block sizes and designs to cater to diverse industrial needs. This versatility ensures that there’s a suitable split pillow block solution for various applications, from light-duty to heavy-duty machinery.

Cost-Efficiency

The ease of maintenance, reduced downtime, and adaptability of split pillow blocks contribute to cost-efficiency in the long run. While the initial investment might be slightly higher than traditional solid pillow blocks, the savings in maintenance and operational costs make them a cost-effective choice.

Limitations and Challenges

Limited Misalignment Tolerance

While split pillow blocks can accommodate some degree of shaft misalignment, excessive misalignment can still lead to premature wear and reduced bearing lifespan. Users must ensure that shafts are adequately aligned during installation to prevent this issue.

Higher Initial Cost

Compared to standard solid pillow blocks, split pillow blocks may have a slightly higher upfront cost. However, as mentioned earlier, the long-term savings due to reduced maintenance and downtime often offset this initial investment.

Reduced Rigidity

In certain heavy-duty applications, where rigidity is crucial, solid pillow blocks might outperform split pillow blocks. Industries with such specific requirements may need to evaluate whether the flexibility of split pillow blocks aligns with their machinery support needs.

Comparison with Alternative Bearing Support Systems

To provide a holistic perspective, it’s essential to compare split pillow blocks with alternative bearing support systems such as solid pillow blocks and flange units. The choice between these options depends on factors like application, load, shaft size, and budget. Engineers and maintenance teams should carefully consider their specific requirements and consult with manufacturers or industry experts when making these decisions.

In conclusion, split pillow blocks offer numerous advantages, including ease of installation, accessibility for maintenance, adaptability to shaft misalignment, versatility in size and design, and long-term cost-efficiency. However, they do come with certain limitations related to misalignment tolerance, initial cost, and reduced rigidity in specific applications. By weighing these pros and cons and considering their unique needs, industries can make informed choices when selecting split pillow blocks for enhancing machinery support.

Innovations and Future Trends: Paving the Way Forward

As we explore the realm of split pillow blocks and their pivotal role in machinery support, it’s equally important to look ahead and anticipate the innovations and trends that will shape the future of this technology. we will delve into the evolving landscape of split pillow block advancements, materials, design, and manufacturing techniques, and their profound implications for sustainability and efficiency across diverse industries.

Evolving Trends in Split Pillow Block Technology

Advanced Materials

One of the key trends in split pillow block technology is the continuous development of materials used in their construction. Engineers and manufacturers are actively researching materials with enhanced properties such as higher load-bearing capacities, improved corrosion resistance, and reduced friction. The adoption of advanced materials ensures split pillow blocks can withstand even harsher industrial environments.

Precision Engineering

Precision engineering techniques are becoming increasingly prevalent in split pillow block manufacturing. This trend is driven by the need for greater accuracy and reliability in machinery support systems. Components are now designed and machined with exceptional precision to minimize wear and maximize efficiency.

Sealing Innovations

Seals play a crucial role in protecting split pillow block components from contaminants and maintaining proper lubrication. Recent innovations in sealing technology have led to the development of highly effective and long-lasting seals that require minimal maintenance. These advancements contribute to extended bearing life and reduced downtime.

Future Advancements

Smart Pillow Blocks

The advent of Industry 4.0 and the Internet of Things (IoT) has opened up opportunities for smart split pillow blocks. These intelligent components can monitor their own performance, report data in real-time, and even predict maintenance needs. Smart pillow blocks can significantly enhance predictive maintenance strategies, reducing unexpected breakdowns and associated costs.

Sustainability Focus

Sustainability is a growing concern in the industrial sector, and split pillow block technology is no exception. Future innovations are expected to prioritize eco-friendly materials and manufacturing processes. This shift towards sustainability not only benefits the environment but also aligns with the goals of many industries to reduce their carbon footprint.

Customization and 3D Printing

Advancements in 3D printing technology are opening doors to highly customized split pillow blocks. Manufacturers can produce components tailored to specific machinery requirements, resulting in improved performance and efficiency. Customization also allows for quicker prototyping and product development.

Industry Implications

The innovations and trends in split pillow block technology discussed above have significant implications for various industries. These advancements lead to:

– Enhanced Reliability: The use of advanced materials, precision engineering, and smart technology contribute to machinery support systems’ increased reliability, reducing downtime and maintenance costs.

– Improved Efficiency: Sealing innovations and custom designs lead to smoother operation and lower energy consumption, improving overall machinery efficiency.

– Sustainability: As industries embrace eco-friendly materials and processes, split pillow block technology plays a part in reducing environmental impact, aligning with global sustainability goals.

In conclusion, the world of split pillow blocks is undergoing rapid evolution, driven by advancements in materials, precision engineering, smart technology, and a growing focus on sustainability. These innovations are poised to revolutionize machinery support systems, offering industries enhanced reliability, improved efficiency, and a more sustainable future. As engineers and manufacturers continue to push the boundaries of what’s possible, the future of split pillow block technology looks promising and transformative.

Conclusion: Unveiling the Pillars of Machinery Support

In this comprehensive exploration of split pillow blocks and their invaluable role in enhancing machinery support, we have uncovered the essential components and advantages of these versatile elements. As we conclude our journey through the world of split pillow blocks, it is imperative to recap their central role and highlight the encouragement for industries to embrace the benefits they offer in terms of improved machinery reliability and performance.

Recap of the Central Role

Throughout this article, we have delved into the intricacies of split pillow blocks, shedding light on their design, construction, applications, installation, maintenance, advantages, limitations, and the exciting trends and innovations that lie ahead. These components serve as the bedrock of machinery support systems, providing stability, alignment, and reliability to a diverse range of industrial equipment.

Split pillow blocks play a pivotal role in maintaining the integrity and functionality of machinery, ensuring it operates at optimal levels. By effectively supporting the rotating shafts and bearings within machinery, they minimize wear and tear, reduce downtime, and contribute to enhanced overall performance.

Embracing the Benefits

As we conclude, it is essential to encourage industries and manufacturers to explore the benefits offered by split pillow blocks fully. These components are not merely passive elements within machinery; they are the unsung heroes that bolster reliability, efficiency, and sustainability.

Industries that embrace split pillow blocks stand to gain from:

| Enhanced Reliability | Machinery equipped with split pillow blocks experiences reduced wear and tear, leading to fewer breakdowns and increased reliability. This translates to lower maintenance costs and less downtime. |

| Improved Efficiency | Split pillow blocks contribute to smoother machinery operation, translating into improved energy efficiency and overall equipment effectiveness (OEE). |

| Sustainability | The use of split pillow blocks aligns with sustainability goals by extending the service life of machinery, reducing the need for frequent replacements, and minimizing environmental impact. |

In conclusion, split pillow blocks are the unsung champions of machinery support, silently ensuring the reliability and performance of industrial equipment across various sectors. As industries evolve and seek ways to enhance machinery support systems, split pillow blocks emerge as a critical solution. We encourage businesses to explore and embrace the numerous benefits these components offer, as they hold the potential to revolutionize the way machinery is supported, ultimately paving the way for a more reliable, efficient, and sustainable future in the industrial landscape.

FAQs: Common Questions about Split Pillow Blocks

we will address some of the most frequently asked questions about split pillow blocks. Split pillow blocks play a vital role in machinery support, and it’s essential to clarify any doubts or queries that may arise regarding their design, installation, and maintenance. Let’s explore these common questions and provide clear answers.

What Are Split Pillow Blocks, and How Do They Work?

Split pillow blocks are bearing housings that can be easily separated into two halves, allowing for convenient installation and maintenance of bearings. They work by providing support and alignment to rotating shafts, reducing friction, and preventing premature wear.

What Types of Bearings Are Suitable for Split Pillow Blocks?

Split pillow blocks are compatible with a wide range of bearings, including ball bearings, roller bearings, spherical roller bearings, and more. The choice of bearing depends on the specific machinery requirements and load capacities.

Are Split Pillow Blocks Easy to Install?

Yes, split pillow blocks are designed for easy installation. Their split design allows users to mount or dismount bearings without the need to disassemble other machine components fully. Proper alignment during installation is essential for optimal performance.

How Can I Ensure Proper Lubrication for Split Pillow Blocks?

Proper lubrication is crucial for the longevity of split pillow blocks. Lubrication methods may vary depending on the application, but it’s essential to follow manufacturer recommendations for the type and amount of lubricant. Regular lubrication maintenance is also necessary to prevent premature wear.

Can Split Pillow Blocks Be Used in Harsh Industrial Environments?

Yes, split pillow blocks are known for their durability and are suitable for use in harsh industrial environments. The choice of materials, such as cast iron or stainless steel, can enhance their resistance to corrosion and wear, making them ideal for demanding applications.

What Are Some Common Signs of Wear or Damage in Split Pillow Blocks?

Common signs of wear or damage in split pillow blocks include increased noise during operation, excessive vibration, and temperature fluctuations. Regular monitoring and maintenance can help detect these issues early and prevent further damage.

Can Split Pillow Blocks Be Customized for Specific Applications?

Yes, many manufacturers offer customization options for split pillow blocks. This allows users to tailor the design, materials, and dimensions to meet the specific requirements of their machinery and applications.

Conclusion

These FAQs provide essential insights into the world of split pillow blocks, addressing common questions about their design, installation, maintenance, and customization. Understanding the key aspects of split pillow blocks is crucial for ensuring machinery operates smoothly and efficiently. If you have more questions or need specific guidance, it’s advisable to consult with a knowledgeable bearing specialist or manufacturer.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8