Automotive Production

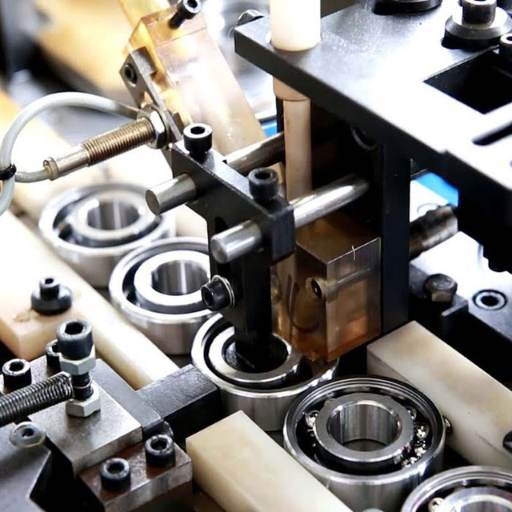

In the world of automotive manufacturing, bearings play a crucial role in ensuring the smooth operation and longevity of various vehicle components. Bearings are essential for reducing friction, supporting loads, and enabling precise motion control in engines, transmissions, wheels, and other critical systems. Loyal, a trusted name in bearing solutions, is dedicated to providing high-quality, reliable bearings specifically designed for the demanding conditions of automotive production. This article delves into the types of bearings used in the automotive industry, their applications, and the benefits of choosing Loyal bearings for your automotive needs.

Main Bearing Product Classification Types

In the automotive manufacturing industry, various types of bearings are utilized to ensure the efficient and reliable operation of vehicle components. Each bearing type has unique characteristics and applications. Below are the main types of bearings used in automotive equipment:

1.Deep Groove Ball Bearings

Characteristics:

Simple structure

Long service life

Easy maintenance

Applications:

Deep groove ball bearings are the most common type of bearing and are extensively used in automotive engines, transmissions, and wheels. They can handle both radial and slight axial loads and are suitable for high-speed operations. These bearings are favored for their versatility and durability in a variety of automotive applications.

2.Tapered Roller Bearings

Characteristics:

High load-carrying capacity

Excellent wear resistance

Capable of handling large axial and radial loads

Applications:

Tapered roller bearings are primarily used in automotive wheel hubs, transmissions, and differentials. These bearings are designed to manage significant loads and impacts, providing stability and safety for vehicles during operation. Their ability to support combined loads makes them essential in heavy-duty automotive applications.

3.Cylindrical Roller Bearings

Characteristics:

High rigidity

Suitable for high load applications

Good thermal stability

Applications:

Cylindrical roller bearings are commonly found in automotive transmissions, generators, and electric motors. These bearings are capable of supporting high radial loads and moderate axial loads, making them ideal for high-temperature environments. Their robust construction ensures reliability in demanding automotive applications.

4.Needle Roller Bearings

Characteristics:

Compact design

High load-carrying capacity

Low friction

Things to Note When Installing Bearings in Automotive Equipment

Proper installation of bearings is crucial to ensure their optimal performance and longevity. Here are some important points to consider during the installation process:

- Cleanliness

Keep the Environment Clean: Ensure the installation area is clean and free of dust, dirt, and other contaminants. Even small particles can cause significant damage to the bearing surfaces.

Clean Components: Clean the bearing, housing, and all related components thoroughly before installation. Use lint-free cloths and appropriate cleaning agents.

- Handling

Handle with Care: Bearings are precision components and should be handled carefully to avoid damage. Use gloves to prevent direct contact with the bearings.

Avoid Dropping: Dropping a bearing can cause brinelling or other internal damage that may not be visible but will affect performance.

- Proper Tools

Use Correct Tools: Utilize the appropriate tools for bearing installation. Improper tools can cause misalignment, damage, and excessive wear.

Press Fit Installation: Use a press fit method for installing bearings into housings and shafts. Never apply force directly to the rolling elements or the cage.

- Alignment

Ensure Proper Alignment: Misalignment during installation can lead to premature bearing failure. Make sure the bearing is aligned correctly with the shaft and housing.

Check Shaft and Housing Tolerances: Verify that the shaft and housing are within the specified tolerances. Improper fits can cause bearing distortion or uneven load distribution.

- Lubrication

Apply Proper Lubrication: Use the recommended type and amount of lubricant. Over-lubrication or under-lubrication can both cause issues.

Lubrication Points: Ensure that all lubrication points are adequately serviced to maintain optimal bearing performance.

- Temperature Considerations

Control Installation Temperature: If the bearing or the surrounding components need to be heated or cooled for installation, ensure the temperature is within the manufacturer’s recommended range to prevent damage.

Thermal Expansion: Be aware of thermal expansion differences between the bearing and the surrounding components.

- Sealing and Protection

Use Proper Seals: Ensure that appropriate seals are used to protect the bearing from contaminants. Seals help in retaining lubrication and excluding dirt and moisture.

Shield from Environmental Factors: Protect the bearing from harsh environmental factors during and after installation.

- Testing and Adjustment

Perform Initial Tests: After installation, rotate the shaft by hand to check for smooth operation and correct positioning.

Adjust as Necessary: Make any necessary adjustments to ensure the bearing is operating correctly within its housing and shaft assembly.

By paying attention to these factors, you can ensure a successful bearing installation, leading to reliable performance and extended bearing life in automotive equipment.

Common Problems That May Occur During Bearing Use in Automotive Equipment

Despite careful selection and installation, bearings can encounter various issues during use. Understanding these problems and their potential causes can help in diagnosing and addressing them effectively.

- Premature Wear

Causes:

Inadequate Lubrication: Insufficient or incorrect lubrication can lead to excessive friction and wear.

Contamination: Dirt, dust, and other particles entering the bearing can cause abrasion and accelerated wear.

Solutions:

Ensure proper lubrication practices, using the recommended type and quantity of lubricant.

Install appropriate seals and maintain a clean environment to prevent contamination.

- Overheating

Causes:

Excessive Load: Bearings subjected to loads beyond their capacity can overheat.

Poor Lubrication: Inadequate lubrication can result in increased friction and heat generation.

High-Speed Operation: Bearings operating at speeds higher than their rated capacity can overheat.

Solutions:

Ensure the bearing is suitable for the load and speed requirements of the application.

Regularly monitor and maintain the lubrication system.

- Noise and Vibration

Causes:

Misalignment: Improper alignment of the bearing with the shaft or housing can cause noise and vibration.

Damaged Components: Dents, scratches, or other damage to the bearing or surrounding parts can lead to abnormal noise.

Solutions:

Check and correct alignment issues during installation and maintenance.

Inspect bearings and components for damage and replace if necessary.

- Brinelling

Causes:

Impact Loads: Sudden shocks or impacts can cause indentations in the bearing raceways.

Improper Handling: Dropping or mishandling bearings during installation can lead to brinelling.

Solutions:

Avoid subjecting bearings to impact loads.

Handle bearings with care during installation and transport.

- Corrosion

Causes:

Moisture Ingress: Exposure to moisture can cause rust and corrosion in bearings.

Chemical Exposure: Contact with corrosive substances can degrade bearing materials.

Solutions:

Use proper sealing techniques to prevent moisture ingress.

Choose bearings with appropriate corrosion-resistant coatings for environments with chemical exposure.

- Fatigue Failure

Causes:

Cyclic Stresses: Repeated loading and unloading cycles can cause material fatigue and lead to failure.

Overloading: Operating beyond the bearing’s load capacity accelerates fatigue failure.

Solutions:

Select bearings designed to withstand the operational load cycles.

Ensure the bearing load does not exceed the manufacturer’s specifications.

- Cage Damage

Causes:

Excessive Speed: Operating at speeds higher than the bearing’s rating can cause cage deformation or breakage.

Improper Lubrication: Lack of lubrication can increase friction, leading to cage wear.

Solutions:

Adhere to the recommended speed limits for the bearing.

Maintain proper lubrication to reduce friction.

- Creep

Causes:

Loose Fit: A bearing that is not fitted tightly in the housing or on the shaft can move or rotate, causing creep.

Insufficient Clamping: Inadequate clamping force can result in relative motion between the bearing and the shaft/housing.

Solutions:

Ensure a proper interference fit during installation.

Apply appropriate clamping forces to secure the bearing.

- False Brinelling

Causes:

Vibration During Standstill: Bearings exposed to vibration while stationary can develop wear marks resembling brinelling.

Transportation Vibrations: Bearings can experience false brinelling during transport if not properly secured.

Solutions:

Isolate or dampen vibrations when the machinery is not in operation.

Secure bearings adequately during transport.

Regular maintenance, monitoring, and adherence to proper installation and operational practices can help mitigate these problems, ensuring the longevity and reliable performance of automotive bearings.

Summary of Product Clearance Requirements for Bearings

Proper clearance is essential for the optimal performance and longevity of bearings in automotive equipment. There are two main types of clearance: radial and axial.

Radial Clearance

- Definition: Distance one bearing ring can move relative to the other in the radial direction.

- Importance: Ensures smooth rotation, accommodates thermal expansion, and compensates for misalignment.

- Factors: Affected by operating temperature, fit and mounting, and load.

- Recommendations: Follow manufacturer specifications and check clearance before and after installation.

Axial Clearance

- Definition: Distance one bearing ring can move relative to the other in the axial direction.

- Importance: Allows for thermal expansion, prevents axial preloading, and ensures proper load distribution.

- Factors: Influenced by shaft and housing design, thermal effects, and mounting conditions.

- Recommendations: Consult manufacturer guidelines and measure axial clearance during installation.

Measurement and Adjustment

- Tools: Feeler gauges, dial indicators, and specialized tools.

- Methods: Shimming, temperature control, and proper fitting techniques.

Operating Conditions

- High-Speed Applications: Require appropriate initial clearance to handle thermal expansion.

- Heavy Load Applications: Need larger clearances to prevent excessive contact and friction.

- Variable Temperatures: Bearings must adapt to thermal expansion and contraction.

Properly managing bearing clearance ensures smooth operation, minimizes wear, and prevents premature failure. Always adhere to the manufacturer’s guidelines for specific clearance requirements.

Product Sealing Requirements for Bearings

Proper sealing is crucial for ensuring the performance and longevity of bearings in automotive equipment. Effective seals prevent contamination, retain lubricants, and protect against environmental factors. Here are the key sealing requirements:

Purpose of Sealing

- Prevent Contamination: Seals block dust, dirt, and moisture from entering the bearing, which can cause damage and reduce lifespan.

- Retain Lubricant: Seals help to keep lubricants inside the bearing, ensuring smooth operation and reducing friction.

- Environmental Protection: Seals protect bearings from harsh environmental factors such as chemicals, water, and extreme temperatures.

Types of Seals

- Contact Seals: These seals provide excellent protection against contaminants but increase friction. They are suitable for environments with high levels of dirt and dust.

- Non-Contact Seals: These seals have lower friction and are ideal for applications where minimal resistance is crucial, although they offer less protection against contaminants.

Material Considerations

- Rubber Seals: Offer good flexibility and sealing capabilities, making them versatile for various applications.

- Metal Seals: Known for their durability and resistance to harsh conditions, suitable for heavy-duty environments.

- Composite Seals: Combine different materials to provide specific advantages, balancing flexibility and durability for specialized applications.

Sealing Configuration

- Single Seals: Used for general applications where standard protection is adequate.

- Double Seals: Provide enhanced protection, ideal for demanding conditions with high contamination levels or where additional lubricant retention is necessary.

Installation

- Alignment and Fit: Ensuring correct alignment and fit during installation is critical to seal effectiveness.

- Avoid Damage: Care must be taken to avoid damaging the seal during installation.

- Proper Seating: Verifying that the seal is properly seated and making necessary contact with bearing surfaces is essential.

Maintenance

- Regular Inspection: Regular checks for wear and damage to the seals are necessary to maintain their protective functions.

- Timely Replacement: Worn or damaged seals should be replaced promptly to prevent bearing damage.

- Lubricant Compatibility: Ensuring seals are compatible with the lubricants used is important to prevent degradation.

Operating Conditions

- Temperature Tolerance: Seals must be capable of withstanding the operating temperature range of the application.

- Speed Handling: Seals should handle the bearing’s operating speed without excessive wear.

- Environmental Suitability: Seals must be chosen based on exposure to contaminants, chemicals, and other environmental factors.

By adhering to these sealing requirements, bearings in automotive equipment can achieve optimal performance, reliability, and longevity. Proper sealing is a key factor in preventing bearing failure and maintaining smooth operation.

Usage Environment Requirements for Bearings

To ensure the optimal performance and longevity of bearings in automotive equipment, it is crucial to consider the following environmental requirements:

Temperature

- Operating Range: Bearings must be capable of withstanding the specific operating temperature ranges of the application.

- Thermal Expansion: Consider the effects of thermal expansion and contraction on both the bearing and surrounding components.

Contamination

- Protection: Bearings need protection from dust, dirt, and moisture.

- Sealing Solutions: Implement appropriate sealing solutions to prevent the ingress of contaminants that can cause damage and reduce bearing life.

Chemical Exposure

- Resistance: Bearings must be resistant to chemicals and corrosive substances encountered in the operating environment.

- Materials and Coatings: Use corrosion-resistant materials or apply protective coatings to enhance durability.

Load Conditions

- Load Handling: Bearings should be capable of handling the expected variations in load, including both radial and axial loads.

- Dynamic and Static Loads: Consider both dynamic (operational) and static (resting) loads when selecting bearings.

Vibration and Shock

- Absorption: Bearings should be able to absorb and withstand vibrations and shock loads typical in automotive applications.

- Mounting: Ensure proper mounting to minimize the effects of vibration and shock on bearing performance.

Installation Environment

- Cleanliness: The installation environment should be clean to prevent contamination of the bearings.

- Proper Tools: Use the correct tools and techniques during installation to avoid damaging the bearings.

Maintenance Access

- Accessibility: Ensure that bearings are accessible for regular inspection and maintenance.

- Ease of Replacement: Bearings and their seals and lubricants should be easy to replace as needed to maintain optimal performance.

By adhering to these usage environment requirements, you can enhance the reliability, performance, and lifespan of bearings in automotive equipment. Proper consideration of these factors helps in preventing premature failures and ensuring smooth operation.

Temperature Requirements for Bearings

|

Aspect |

Description |

| Operating Temperature Range | Bearings must operate efficiently within the specific temperature range of their application. High-temperature bearings withstand elevated temperatures without degrading, while low-temperature bearings maintain performance and structural integrity in extremely cold conditions. |

| Thermal Expansion and Contraction | Materials of bearings and housings should be compatible to minimize effects of thermal expansion and contraction. Bearing clearances must be appropriate for the expected temperature range to prevent binding or excessive play. |

| Lubrication | High-temperature lubricants maintain viscosity and lubrication properties at elevated temperatures. Low-temperature lubricants should not thicken excessively, which can impede bearing movement and increase friction. |

| Thermal Conductivity | Bearings should dissipate heat effectively to avoid overheating. Use materials with good thermal conductivity and ensure proper ventilation. Additional cooling systems may be necessary in some applications. |

| Temperature Fluctuations | Bearings must handle rapid temperature changes without losing performance or integrity. They should also be resistant to thermal fatigue from repeated heating and cooling cycles. |

| Monitoring and Maintenance | Temperature monitoring systems track bearing temperatures during operation, identifying potential overheating issues early. Regular inspections check for signs of temperature-related wear and tear, such as discoloration or changes in lubrication condition. |

Lubricant Selection for Bearings

Selecting the appropriate lubricant for bearings is essential to ensure optimal performance and longevity. Here are the key considerations for lubricant selection:

Lubricants with high viscosity are suitable for slow-moving bearings or those under heavy loads, while low-viscosity lubricants are ideal for high-speed applications to reduce friction and heat generation. For operating temperature considerations, high-temperature lubricants maintain stability and lubrication properties at elevated temperatures, whereas low-temperature lubricants remain fluid and effective at very low temperatures without thickening excessively.

Load carrying capacity is another crucial aspect. Lubricants with EP (Extreme Pressure) additives are necessary for bearings subjected to high loads or shock loads to prevent wear and damage, while those with anti-wear additives protect bearing surfaces under moderate loads and conditions. Corrosion protection is vital, so lubricants should contain corrosion inhibitors to prevent rust and corrosion, especially for bearings exposed to moisture, chemicals, or corrosive environments.

Material compatibility ensures that the lubricant is compatible with bearing materials, seals, and other components to avoid degradation or chemical reactions. The choice between grease and oil depends on application requirements, with grease providing better sealing and protection, and oil offering cooling and cleaning properties.

For the application method, manual application is suitable for bearings with easy access and low maintenance intervals, while automatic lubrication systems are ideal for bearings in hard-to-reach locations or requiring continuous lubrication. Environmental considerations include the use of biodegradable lubricants in environmentally sensitive areas to minimize ecological impact and non-toxic formulations for applications in food processing or other sensitive industries.

Performance enhancements can be achieved with lubricants containing friction modifiers to reduce friction and improve efficiency in high-speed applications, and oxidation stabilizers to extend lubricant life by preventing oxidation and degradation over time.

By carefully considering these factors, the most suitable lubricant can be selected to ensure the optimal performance and longevity of bearings in various applications, minimizing friction, wear, and potential failures, and contributing to the overall reliability and efficiency of the equipment.

Selection of Bearing Type

Selecting the appropriate bearing type is essential for ensuring the optimal performance and longevity of automotive equipment. The choice of bearing type depends on various application-specific requirements, such as load type and capacity, speed, alignment, space constraints, environmental conditions, temperature, and lubrication needs.

Different bearing types are designed to handle specific conditions and demands. For instance, deep groove ball bearings and cylindrical roller bearings are ideal for applications primarily experiencing radial loads, while thrust ball bearings and tapered roller bearings are suitable for handling significant axial loads. In cases where the application involves combined radial and axial loads, angular contact ball bearings and spherical roller bearings provide excellent support.

High-speed applications benefit from bearings designed to operate efficiently at elevated speeds, such as deep groove ball bearings and angular contact ball bearings. On the other hand, low-speed or oscillating applications may require cylindrical roller bearings and needle roller bearings for their robustness and durability.

For applications prone to misalignment, self-aligning ball bearings and spherical roller bearings are recommended as they can accommodate angular misalignments, reducing stress on the bearing. In contrast, applications with precise alignment can utilize rigid bearings like deep groove ball bearings and cylindrical roller bearings.

Space constraints also play a role in bearing selection. Needle roller bearings and miniature ball bearings offer compact designs suitable for tight spaces, whereas standard-sized bearings are used where space is less of a concern.

Environmental conditions such as contamination and temperature extremes impact bearing choice. Sealed or shielded bearings are ideal for contaminated environments, while open bearings are suitable for clean environments. High-temperature applications require bearings with heat-resistant materials, whereas low-temperature bearings are necessary for cold conditions.

Lubrication needs vary based on maintenance capabilities. Pre-lubricated bearings are convenient for applications with limited maintenance, while bearings with re-lubrication provisions are suitable for regular maintenance schedules.

By understanding the specific requirements of your application, you can select the most suitable bearing type to ensure reliable performance, extended service life, and efficient operation of your automotive equipment.

Bearing Life

Bearing life refers to the expected operational lifespan of a bearing before it exhibits signs of fatigue or failure. It is a critical factor in ensuring the reliability and efficiency of machinery and automotive equipment. The life of a bearing is influenced by various factors including load, speed, lubrication, installation, and environmental conditions.

Key Concepts in Bearing Life

- Rated Life (L10 Life): The number of revolutions or hours at a given constant speed that 90% of a group of identical bearings will complete or exceed before showing signs of fatigue.

- Dynamic Load Rating (C): A calculated value indicating the load that a bearing can endure for one million revolutions.

- Fatigue Life: The point at which a bearing begins to show signs of surface fatigue, such as spalling, due to repeated stress cycles.

Proper selection, installation, and maintenance practices, along with the right lubrication, can significantly extend bearing life, enhancing the performance and longevity of automotive equipment. Regular monitoring and timely interventions are essential to maximize the operational life of bearings.

Basic Dynamic Load Rating and Fatigue Life

Basic Dynamic Load Rating (C)

The Basic Dynamic Load Rating (C) is a key parameter in bearing selection and design, representing the load that a bearing can endure for one million revolutions under ideal conditions without experiencing fatigue. It is a measure of the bearing’s capacity to withstand dynamic (changing) loads during operation.

- Definition: The Basic Dynamic Load Rating is the constant load which a bearing can theoretically endure for a basic rating life of one million revolutions.

- Importance: This rating helps in determining the suitability of a bearing for a particular application based on the expected loads and operational conditions.

- Calculation: The rating is provided by bearing manufacturers and is derived from empirical testing and theoretical calculations based on the bearing’s design, materials, and manufacturing processes.

Fatigue Life

Fatigue life is the duration or number of revolutions a bearing can operate before showing signs of fatigue, such as spalling or cracking. It is a critical factor in determining the reliability and maintenance intervals of machinery.

- Definition: Fatigue life is the time or number of cycles a bearing can operate under specific conditions before surface fatigue occurs.

- L10 Life: Often expressed as L10 life, which indicates the lifespan where 90% of a group of identical bearings will not exhibit fatigue failure.

- Factors Influencing Fatigue Life:

- Load: Higher loads generally reduce fatigue life, while lighter loads extend it.

- Speed: Higher operating speeds can increase wear and reduce fatigue life.

- Lubrication: Proper lubrication reduces friction and wear, extending fatigue life.

- Environment: Contaminants, temperature extremes, and moisture can negatively impact fatigue life.

- Installation and Alignment: Proper installation and alignment prevent additional stress on the bearing, enhancing its fatigue life.

Understanding and optimizing both the Basic Dynamic Load Rating and fatigue life are essential for selecting the right bearing for an application, ensuring reliable performance, and minimizing downtime and maintenance costs. Regular monitoring and maintenance are crucial to achieving the expected bearing life in real-world conditions.

Summary of Dynamic Equivalent Load

The Dynamic Equivalent Load is a calculated value that represents the hypothetical load under which a bearing would experience the same fatigue life as it does under the actual combination of radial and axial loads in a given application. This concept simplifies complex loading conditions into a single equivalent load, facilitating the evaluation of bearing performance and life.

Key aspects include:

- Calculation: For radial ball bearings, the formula is P=X⋅Fr+Y⋅FaP = X \cdot F_r + Y \cdot F_aP=X⋅Fr+Y⋅Fa, and for tapered roller bearings, it is P=Fr+Y⋅FaP = F_r + Y \cdot F_aP=Fr+Y⋅Fa, where FrF_rFr is the radial load, FaF_aFa is the axial load, and XXX and YYY are load factors provided by manufacturers.

- Factors: The calculation considers the direction and magnitude of loads, load factors specific to the bearing type, and application conditions.

- Importance: Accurate determination of the Dynamic Equivalent Load is crucial for proper bearing selection, performance prediction, and design optimization, ensuring the chosen bearing can handle the actual operating conditions and loads effectively.

By understanding and utilizing the Dynamic Equivalent Load, engineers can enhance the performance, reliability, and longevity of bearings in various applications.

Summary of Basic Static Load Ratings and Static Equivalent Loads

Basic Static Load Rating (C0)

The Basic Static Load Rating (C0) represents the maximum load a bearing can withstand without permanent deformation of its rolling elements or raceways. It is crucial for ensuring the longevity and reliability of the bearing under stationary or slow-moving conditions. Manufacturers provide this rating based on standardized tests.

Static Equivalent Load (P0)

The Static Equivalent Load (P0) simplifies actual loading conditions into a single hypothetical load, representing the same stress and potential deformation as the real-world combination of radial and axial loads.

- For radial ball bearings, the formula is P0=X0⋅Fr+Y0⋅FaP_0 = X_0 \cdot F_r + Y_0 \cdot F_aP0=X0⋅Fr+Y0⋅Fa.

- For tapered roller bearings, it is P0=Fr+Y0⋅FaP_0 = F_r + Y_0 \cdot F_aP0=Fr+Y0⋅Fa.

Understanding and using these ratings helps in selecting bearings that can handle specific static loads, preventing permanent damage and ensuring safe, reliable operation.

Bearing Tolerances

Bearing tolerances are the permissible variations in the dimensions and forms of bearing components, ensuring precision, performance, and reliability. These tolerances are essential for the proper fitting and functioning of bearings in various applications.

Key Aspects of Bearing Tolerances

- Dimensional Tolerances: Allowable variations in the bearing’s inner and outer diameters and width to ensure correct fitting on shafts and housings.

- Form Tolerances: Include roundness, cylindricity, and runout, which ensure the bearing’s raceways and rolling elements are within precise geometric limits.

- Radial and Axial Play: Internal clearance levels that affect the bearing’s ability to accommodate thermal expansion, misalignment, and load distribution.

- ISO and ABEC Standards: Classification systems that define tolerance grades, with ISO standards ranging from normal to precision grades (e.g., P6, P5, P4, P2) and ABEC grades from 1 to 9.

Maintaining proper bearing tolerances is crucial for achieving smooth operation, reducing vibration and noise, preventing premature wear, and ensuring the longevity and reliability of the bearings in their applications.

Fits and Internal Clearances

Fits

Fits refer to the relationship between the dimensions of a bearing and its mating components (shaft and housing). They determine how tightly or loosely the bearing is installed, impacting its performance and longevity.

Types of Fits:

-

- Interference Fit: The bearing is slightly larger than the mating component, ensuring a tight fit. Used for high-load applications to prevent movement between the bearing and its seat.

- Transition Fit: A compromise between interference and clearance fits, allowing for slight movement under load.

- Clearance Fit: The bearing is slightly smaller than the mating component, allowing for easy installation and removal. Suitable for applications where frequent assembly and disassembly are required.

Fit Classes: Standardized by ISO and other organizations, fit classes (e.g., j6, k6, m6 for shafts; J7, K7 for housings) specify the degree of tightness or looseness in the fit.

Internal Clearances

Internal clearances refer to the amount of internal free space within a bearing, specifically the distance between the rolling elements and the raceways. Internal clearances are critical for accommodating thermal expansion, load distribution, and ensuring smooth operation.

Types of Internal Clearances:

-

- Radial Clearance: The total distance the rolling elements can move in a radial direction. It impacts the bearing’s ability to handle radial loads and thermal expansion.

- Axial Clearance: The total distance the rolling elements can move in an axial direction. It affects the bearing’s ability to accommodate axial loads and misalignment.

Clearance Classes: Bearings are available in different clearance classes (e.g., C2, C0/Normal, C3, C4) to suit various operational conditions and requirements.

Maintaining the correct fits and internal clearances is essential for optimizing bearing performance, reducing wear, preventing premature failure, and ensuring the reliability and longevity of the bearing in its application.

Key Aspects of Lubrication

Types of Lubricants:

- Grease: Commonly used for its ease of application and good sealing properties, making it suitable for various applications.

- Oil: Provides effective cooling and cleaning but requires a more complex lubrication system, ideal for high-speed and high-temperature applications.

Functions of Lubrication:

- Friction Reduction: Minimizes direct contact between bearing surfaces, reducing friction and wear.

- Heat Dissipation: Helps in dispersing heat generated during operation, preventing overheating.

- Corrosion Protection: Forms a protective layer on bearing surfaces to prevent rust and corrosion.

- Contaminant Removal: Carries away contaminants and debris from the bearing surfaces, maintaining cleanliness.

Application Methods:

- Manual Application: Suitable for low-maintenance bearings, involving periodic relubrication.

- Automatic Lubrication Systems: Provide continuous lubrication for high-maintenance or hard-to-reach bearings, ensuring consistent performance.

Selection Criteria:

- Viscosity: Must match the bearing’s operating speed and load conditions.

- Temperature Range: Lubricant should remain effective within the bearing’s operating temperature range.

- Load Capacity: Should include additives to handle the bearing’s load conditions, such as extreme pressure (EP) additives for high-load applications.

Proper lubrication is crucial for preventing bearing failure, ensuring reliability, and extending the service life of bearings in various applications. Regular monitoring and maintenance of lubrication systems are essential to maintain optimal bearing performance.

Materials for Bearing Rings and Rolling Elements

The selection of materials for bearing rings and rolling elements is crucial for ensuring optimal performance, durability, and reliability in various applications. Different materials offer distinct advantages based on their properties, including hardness, wear resistance, corrosion resistance, and suitability for specific operating conditions.

Common Materials for Bearing Rings

High Carbon Chromium Steel (52100 Steel)

Properties: High hardness, excellent wear resistance, and good fatigue strength.

Applications: Widely used in most rolling bearings due to its durability and cost-effectiveness.

Stainless Steel (440C, 304, 316)

Properties: Corrosion resistance, moderate hardness, and good wear resistance.

Applications: Used in environments where corrosion resistance is critical, such as food processing, marine, and medical applications.

Through-Hardened Carbon Steel

Properties: High hardness throughout the material, providing uniform strength.

Applications: Suitable for heavy-duty applications where high load capacity and wear resistance are required.

Case-Hardened Steel

Properties: A tough core with a hard, wear-resistant surface layer.

Applications: Used in applications requiring both high wear resistance and toughness, such as automotive and heavy machinery bearings.

Ceramics (Silicon Nitride, Zirconia)

Properties: High hardness, low density, excellent corrosion resistance, and high temperature stability.

Applications: Used in high-speed and high-temperature applications, as well as in environments with harsh chemicals.

Common Materials for Rolling Elements

High Carbon Chromium Steel (52100 Steel)

Properties: High hardness and excellent wear resistance.

Applications: Standard material for most rolling elements in bearings due to its balance of performance and cost.

Stainless Steel (440C)

Properties: Good corrosion resistance and moderate hardness.

Applications: Suitable for applications requiring corrosion resistance, such as in food processing and medical equipment.

Ceramics (Silicon Nitride, Zirconia)

Properties: Very high hardness, low density, excellent corrosion resistance, and superior high-temperature performance.

Applications: Ideal for high-speed, high-precision, and high-temperature applications. Often used in hybrid bearings (ceramic balls with steel rings).

Carbon Steel

Properties: Lower cost with moderate hardness and wear resistance.

Applications: Used in less demanding applications where cost is a significant factor.

Polymers (PTFE, PEEK)

Properties: Lightweight, good chemical resistance, and low friction.

Applications: Used in applications where weight reduction and chemical resistance are important, such as in aerospace and chemical processing.

Considerations for Material Selection

- Load and Speed Requirements: Higher loads and speeds typically require materials with higher hardness and wear resistance.

- Environmental Conditions: Corrosive environments require materials with excellent corrosion resistance, like stainless steel or ceramics.

- Temperature: High-temperature applications benefit from materials like ceramics that can maintain performance under extreme heat.

- Cost and Availability: Balancing performance requirements with cost considerations is crucial for selecting the most suitable material.

By carefully selecting the appropriate materials for bearing rings and rolling elements, manufacturers can ensure that bearings meet the specific demands of their applications, providing reliable and long-lasting performance.

Introduction to Major Bearing Brands

The bearing industry features several well-known brands, each offering unique strengths and specializations. Understanding the differences between these brands can help in selecting the best bearing for specific applications based on factors like quality, performance, availability, and price.

1. SKF

- Origin: Sweden

- Strengths: SKF is known for its high-quality bearings and extensive research and development capabilities. They offer a wide range of bearings and related products, including seals, lubrication systems, and maintenance services.

- Applications: SKF bearings are used in various industries, including automotive, aerospace, industrial machinery, and renewable energy.

- Differentiators: Emphasis on innovation and technology, strong global presence, and comprehensive after-sales support.

2. NSK

- Origin: Japan

- Strengths: NSK is recognized for its precision bearings and high-performance products. They focus on automotive and industrial applications, providing solutions for efficiency and reliability.

- Applications: Automotive, industrial machinery, precision machinery, and medical equipment.

- Differentiators: Advanced technology in precision and miniaturization, strong focus on customer-specific solutions, and extensive technical support.

3. FAG (Schaeffler Group)

- Origin: Germany

- Strengths: FAG, part of the Schaeffler Group, is known for its high-quality rolling bearings and advanced manufacturing processes. They offer a comprehensive range of bearings and integrated solutions.

- Applications: Automotive, industrial, aerospace, and rail industries.

- Differentiators: Strong emphasis on innovation, high reliability, and integration of bearing solutions with other components like housings and seals.

4. TIMKEN

- Origin: USA

- Strengths: Timken is renowned for its tapered roller bearings and high-performance industrial products. They provide bearings, power transmission components, and related services.

- Applications: Industrial machinery, automotive, aerospace, rail, and heavy-duty applications.

- Differentiators: Expertise in tapered roller bearings, focus on heavy-duty and high-load applications, and extensive service and support network.

5. NTN

- Origin: Japan

- Strengths: NTN offers a broad range of bearings and precision machinery products. They are known for their innovation and high-quality standards, particularly in automotive and industrial applications.

- Applications: Automotive, industrial machinery, construction equipment, and agricultural machinery.

- Differentiators: Strong R&D capabilities, focus on reducing friction and improving efficiency, and extensive product range.

6. INA (Schaeffler Group)

- Origin: Germany

- Strengths: INA, also part of the Schaeffler Group, specializes in needle roller bearings, linear guides, and other precision components. They are known for high-precision products and innovative solutions.

- Applications: Automotive, industrial machinery, and linear motion systems.

- Differentiators: Specialization in needle roller bearings and linear motion products, high precision, and integration with FAG products for comprehensive solutions.

Each bearing brand brings its own strengths and areas of expertise, allowing customers to choose the most suitable products based on their specific needs and applications. Whether prioritizing innovation, precision, heavy-duty performance, or specialized applications, these major brands offer a wide range of options to meet diverse requirements.

Application of Major Bearing Brands in Automobile Production

In the automotive industry, bearings play a crucial role in ensuring the smooth and efficient operation of various vehicle components. Below is an overview of how major bearing brands are applied in automobile production:

1. SKF

- Applications: SKF bearings are used in numerous automotive components including wheel hubs, transmissions, engines, and suspension systems.

- Specific Use Cases:

- Wheel Bearings: Ensuring smooth rotation and supporting the vehicle’s weight.

- Engine Bearings: Reducing friction in the crankshaft and camshaft.

- Transmission Bearings: Enhancing efficiency and durability of gear systems.

2. NSK

- Applications: NSK bearings are widely utilized in powertrain, chassis, and engine applications.

- Specific Use Cases:

- Powertrain Bearings: Improving efficiency and reducing noise in drivetrains.

- Suspension Bearings: Providing smooth movement and durability under load.

- Electric Vehicle Bearings: Specialized bearings for electric motors and hybrid systems.

3. FAG (Schaeffler Group)

- Applications: FAG bearings are integral in engine, transmission, and chassis components.

- Specific Use Cases:

- Transmission Bearings: Ensuring smooth gear shifting and durability.

- Clutch Release Bearings: Providing reliable engagement and disengagement of the clutch.

- Differential Bearings: Reducing friction and wear in differential gears.

4. TIMKEN

- Applications: Timken bearings are known for their use in heavy-duty automotive applications such as trucks and off-road vehicles.

- Specific Use Cases:

- Tapered Roller Bearings: Used in wheel hubs and axles to handle high radial and axial loads.

- Pinion Bearings: Supporting high loads in the differential and drivetrain components.

- Wheel End Bearings: Enhancing reliability and performance in commercial vehicles.

5. NTN

- Applications: NTN bearings are applied in automotive engines, transmissions, and suspension systems.

- Specific Use Cases:

- Engine Bearings: Reducing friction in moving parts like the crankshaft.

- Transmission Bearings: Improving efficiency and performance of automatic and manual transmissions.

- Wheel Bearings: Ensuring longevity and smooth rotation of wheels.

6. INA (Schaeffler Group)

- Applications: INA bearings are used in precision applications such as engine components and linear motion systems.

- Specific Use Cases:

- Needle Roller Bearings: Applied in gearboxes and engine components for high load capacity and compact design.

- Timing Belt Tensioners: Ensuring proper tension and operation of the timing belt.

- Valve Train Components: Enhancing precision and reliability in valve operations.

These major bearing brands are integral to various critical automotive components, each offering specific advantages tailored to different applications within automobile production. By selecting the appropriate bearing type and brand, automotive manufacturers can ensure their vehicles’ reliability, efficiency, and performance.

Interchangeability of Bearings Between Different Brands or Models

Interchangeability of bearings between different brands is a critical consideration in automotive production and maintenance. It allows for flexibility in sourcing, reduces downtime, and ensures continuous operation. Here are key aspects of interchangeability between major bearing brands:

Standards and Specifications

International Standards:

ISO: The International Organization for Standardization (ISO) sets global standards for bearing dimensions, tolerances, and performance. Bearings conforming to ISO standards are generally interchangeable.

ABEC: The Annular Bearing Engineers’ Committee (ABEC) sets precision grades for ball bearings. ABEC-rated bearings are interchangeable if they meet the same ABEC grade.

DIN: The German Institute for Standardization (DIN) provides standards for bearings commonly used in Europe.

Manufacturer-Specific Standards:

Each manufacturer may have specific standards or proprietary designs for certain bearings, which could affect interchangeability.

Bearing Series and Types

Common Bearing Series:

Standard bearing series such as 6000, 6200, and 6300 series deep groove ball bearings are produced by all major brands (SKF, NSK, FAG, etc.) and are typically interchangeable if they meet the same dimensional and performance standards.

Specialized Bearings:

Bearings with unique designs or specialized applications (e.g., ceramic bearings, high-precision angular contact bearings) may not be directly interchangeable between brands due to proprietary specifications.

Dimensional Compatibility

Inner and Outer Diameter:

Bearings with the same inner and outer diameters are generally interchangeable, provided the width and tolerance class match.

Width and Tolerance:

Differences in width or tolerance class (e.g., P6, P5) can affect interchangeability. Always verify that the replacement bearing meets the original specifications.

Load and Speed Ratings

Dynamic and Static Load Ratings:

Ensure that the replacement bearing has equal or higher dynamic and static load ratings compared to the original bearing.

Speed Ratings:

The replacement bearing should match or exceed the speed rating of the original bearing to ensure proper performance.

Material and Lubrication

Material Compatibility:

Bearings made from different materials (e.g., stainless steel vs. high carbon chromium steel) may not be interchangeable if specific material properties are required for the application.

Lubrication Requirements:

Ensure that the lubrication type (grease or oil) and specifications (e.g., high-temperature, low-friction) are compatible between the original and replacement bearings.

Application-Specific Considerations

Environmental Conditions:

Bearings exposed to harsh environments (e.g., high temperature, corrosive conditions) may require specific material or coating specifications.

Performance Requirements:

High-performance applications, such as those in racing or aerospace, may require bearings with specific performance characteristics that are not universally interchangeable.

Examples of Interchangeability

Deep Groove Ball Bearings:

Common models like the 6204 bearing are typically interchangeable between brands like SKF, NSK, FAG, and Timken, provided they meet the same ISO standards.

Tapered Roller Bearings:

Bearings such as Timken’s LM11949/LM11910 are interchangeable with equivalents from other brands like NSK, NTN, and SKF, if they meet the same specifications.

Needle Roller Bearings:

INA needle roller bearings can often be interchanged with equivalents from NTN or Koyo, as long as they conform to the same dimensional standards.

Summarize

In automotive production, the selection, application, interchangeability, load rating, tolerance, fit and lubrication of bearings are key factors to ensure their performance and reliability. Correctly selecting bearing types and their applications, ensuring that they meet international standards, are interchangeable, and meet load and speed requirements, can significantly improve the efficiency and life of automotive components. The service life and load capacity of bearings depend on their basic dynamic and static load ratings, while appropriate tolerances and fits ensure accurate installation and smooth operation. Proper lubrication can reduce friction, prevent wear, dissipate heat and protect bearings from corrosion, ensuring their long-term reliable operation. Therefore, understanding and correctly applying these bearing technologies are essential to improving the quality and reliability of automotive production.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8