Exploring Precision: Applications of Double Row Angular Contact Ball Bearings

1 Introduction

In the realm of industrial machinery, precision is a cornerstone of efficient operation and optimal performance. The pursuit of precision has led to the development and utilization of specialized components, among which double row angular contact ball bearings shine as key contributors. In this article, we delve into the world of double row angular contact ball bearings, exploring their crucial role in achieving precision in various applications.

Precision engineering has become a defining factor in many industries, from aerospace to manufacturing, where even the slightest deviation can lead to significant consequences. Double row angular contact ball bearings offer a solution that has garnered attention for their exceptional precision and reliability.

2 Understanding Double Row Angular Contact Ball Bearings

To explore the precision and applications of double row angular contact ball bearings, it’s crucial to begin with a comprehensive understanding of what these bearings are, how they are designed, and how they function within various industrial settings.

What Are Double Row Angular Contact Ball Bearings?

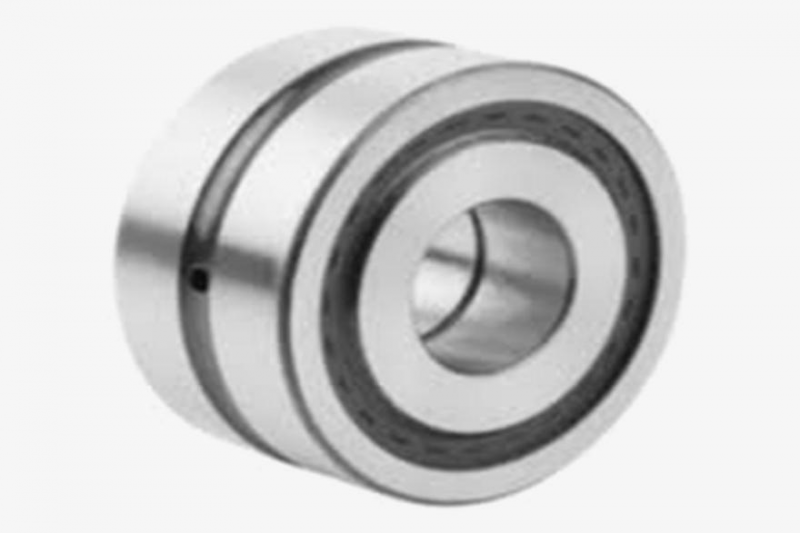

Double row angular contact ball bearings, often abbreviated as DRA bearings, are specialized components used in machinery and equipment where precise rotational performance is critical. They belong to the family of angular contact ball bearings but stand out due to their unique configuration.

Design and Structure

These bearings consist of two rows of balls with an inner ring, outer ring, and ball cage. What sets them apart is their contact angle, which allows them to simultaneously carry axial and radial loads. This design feature is crucial for achieving precision and load-bearing capacity.

The Inner Workings

Double row angular contact ball bearings are engineered to accommodate high radial loads, thrust loads, or combined loads. The internal ball arrangement is designed for minimal friction and optimal load distribution, ensuring smoother and more precise motion.

Comparing with Other Bearings

In comparison to other types of bearings, such as deep groove ball bearings or cylindrical roller bearings, double row angular contact ball bearings excel when it comes to handling both radial and axial loads. Their ability to do so makes them highly sought-after components in precision engineering.

3 Advantages in Precision Engineering

When it comes to precision engineering, the applications of double row angular contact ball bearings are both diverse and indispensable. These bearings offer a range of advantages that make them a preferred choice in various industries where precision is paramount. In this section, we’ll explore the advantages of using double row angular contact ball bearings in precision engineering.

Crucial in Numerous Industries

Double row angular contact ball bearings find their applications in a multitude of industries that demand high precision and reliability. Some of these industries include:

| Machine Tools | In precision machining and milling operations, the accurate movement of cutting tools and workpieces is essential. Double row angular contact ball bearings provide the necessary support and precision for such equipment. |

| Aerospace | The aerospace industry relies on precision components for aircraft navigation, control surfaces, and landing gear systems. Double row angular contact ball bearings play a vital role in ensuring the accuracy of these critical systems. |

| Medical Devices | The medical sector requires high precision in equipment such as surgical robots, diagnostic devices, and imaging machines. These bearings contribute to the accuracy and reliability of medical technologies. |

| Robotics | Robots used in manufacturing, logistics, and healthcare require precise motion control. Double row angular contact ball bearings are a key component for achieving smooth and accurate robotic movements. |

Real-World Precision Enhancement

Let’s dive into a few real-world examples to illustrate how these bearings enhance precision in various applications:

Aerospace Navigation Systems: In the aerospace industry, navigation systems depend on highly accurate angular movements. Double row angular contact ball bearings enable the precise control of aeronautical instruments, contributing to safer flights.

Medical Robotic Surgery: In robotic-assisted surgeries, every millimeter counts. These bearings facilitate the exact positioning of surgical instruments, reducing the margin of error during procedures.

High-Precision Manufacturing: Industries like microelectronics manufacturing demand extreme precision in production processes. Double row angular contact ball bearings ensure the reliable operation of machinery used in these delicate processes.

The Role of Precision

Precision engineering is not just a luxury; it’s often a necessity. Achieving desired outcomes in precision-critical applications hinges on the components used. Double row angular contact ball bearings provide the level of precision required to meet the stringent demands of these industries.

5 Maintenance and Longevity

Maintenance is a critical aspect of ensuring the long-term performance and precision of double row angular contact ball bearings. In this section, we will explore essential tips and best practices for the maintenance of these bearings, highlighting how proper care can extend their lifespan and guarantee continued precision.

Maintenance Tips

1. Regular Lubrication: Adequate lubrication is fundamental to reduce friction and wear in double row angular contact ball bearings. It’s essential to follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricants for the specific application. Regularly check and replenish lubrication as needed.

2. Monitoring Temperature: Keeping an eye on the operating temperature of the bearings can provide valuable insights into their condition. Unusually high temperatures may indicate problems such as overloading or inadequate lubrication. Regular temperature monitoring can help detect issues early.

3. Sealing and Shielding: Ensure that the sealing or shielding of the bearings remains intact. Damaged seals or shields can allow contaminants to enter and damage the bearing surfaces. Regularly inspect and replace seals or shields as necessary.

4. Alignment and Mounting: Proper alignment and mounting of double row angular contact ball bearings are crucial for their performance. Misalignment can lead to uneven load distribution and premature wear. Use alignment tools and follow mounting guidelines to achieve the correct fit.

5. Cleanliness: Maintain a clean environment around the bearings to prevent the ingress of dust, dirt, or other contaminants. Clean the surrounding area regularly and use appropriate protective measures such as covers or enclosures.

Benefits of Maintenance

Proper maintenance practices offer several benefits:

– Extended Lifespan: Regular maintenance can significantly extend the lifespan of double row angular contact ball bearings. Bearings that are well-maintained are less prone to wear and failure, reducing the need for frequent replacements.

– Consistent Precision: Well-maintained bearings continue to provide consistent precision in motion control systems. This ensures that machinery operates at optimal levels of accuracy, contributing to high-quality production.

– Cost Savings: Effective maintenance practices reduce the overall cost of ownership. By avoiding unexpected breakdowns and replacements, businesses can save on repair and downtime expenses.

Real-Life Case Studies

Let’s take a look at some real-life examples that illustrate the impact of maintenance on the longevity and precision of double row angular contact ball bearings:

1. Aerospace Manufacturing: In the aerospace industry, precision is paramount. Regular maintenance of bearings used in critical aircraft components ensures that they perform flawlessly. This level of precision not only enhances safety but also reduces operational costs.

2. Medical Equipment: Medical devices rely on precision for accurate diagnostics and treatments. Maintaining the bearings in medical equipment guarantees that these devices consistently meet the stringent requirements of the healthcare industry.

3. Industrial Robotics: Bearings play a vital role in industrial robotics, where precision and reliability are essential. Proper maintenance not only prolongs the lifespan of these bearings but also enhances the efficiency and accuracy of robotic systems.

In conclusion, maintaining double row angular contact ball bearings is crucial for achieving longevity and precision in various industries. By following best practices and regularly monitoring their condition, businesses can ensure the continued performance of these precision components.

6 Conclusion

6 Conclusion

In the journey of exploring precision and the applications of double row angular contact ball bearings, we’ve delved into the critical role these bearings play in various industries. As we conclude this article, let’s recap the importance of precision in industrial machinery, emphasize how double row angular contact ball bearings contribute to achieving this precision, and reflect on their significance in modern engineering.

Precision in Industrial Machinery

Precision is the cornerstone of efficient and reliable industrial machinery. Whether it’s in manufacturing, aerospace, medical equipment, or robotics, achieving precision in motion control is a top priority. Precision ensures that components fit together seamlessly, that measurements are accurate, and that processes run smoothly. This not only enhances productivity but also minimizes waste and reduces operational costs.

The Role of Double Row Angular Contact Ball Bearings

Throughout this article, we’ve seen how double row angular contact ball bearings stand out as precision components. Their unique design and ability to accommodate both radial and axial loads make them versatile and well-suited for demanding applications. These bearings excel in situations where precision, load capacity, and speed are paramount.

Double row angular contact ball bearings contribute to precision by ensuring that rotational movements are smooth and consistent. They help maintain the integrity of complex machinery, ensuring that it operates as intended. Their ability to handle both radial and axial loads makes them an ideal choice for applications where multidirectional forces are at play.

Significance in Modern Engineering

In the fast-paced world of modern engineering, innovation and efficiency are key drivers. Double row angular contact ball bearings align perfectly with these goals. They enable engineers to push the boundaries of what’s possible in terms of machinery performance. Whether it’s in the aerospace sector, where safety and precision are non-negotiable, or in the medical industry, where accuracy is a matter of life and death, these bearings play a pivotal role.

Their significance extends beyond precision; they also offer durability and reliability, reducing maintenance requirements and downtime. This, in turn, contributes to cost savings and operational excellence.

In conclusion, double row angular contact ball bearings are not just components; they are enablers of precision, efficiency, and innovation in modern engineering. Their applications span across a wide range of industries, touching our lives in more ways than we may realize. As we continue to explore new frontiers in technology and industry, these bearings will undoubtedly remain at the forefront, ensuring that precision in motion is never compromised.

7 FAQs: Common Questions about Double Row Angular Contact Ball Bearings

In this section, we’ll address some common questions that often arise regarding double row angular contact ball bearings. These FAQs aim to provide clarity and insight into the characteristics, applications, and selection of these precision components.

1. What distinguishes double row angular contact ball bearings from other bearings?

Double row angular contact ball bearings are unique due to their design, which includes two rows of balls arranged at specific angles to each other. This configuration allows them to handle both radial and axial loads simultaneously. This distinguishes them from single row angular contact ball bearings and other bearing types.

2. What are the advantages of using double row angular contact ball bearings?

The advantages are multifaceted. These bearings offer higher load capacity, increased stiffness, and improved axial load-carrying capacity compared to single row angular contact ball bearings. They are also capable of accommodating high-speed applications, making them suitable for various industries, including automotive, machine tools, and robotics.

3. How do I choose the right double row angular contact ball bearings for my application?

Selecting the right bearings involves considering several factors. These include the type of loads (radial, axial, or combined), operating speed, temperature conditions, and the level of precision required. Consulting with a bearing expert or manufacturer is often recommended to ensure the optimal choice.

4. Can double row angular contact ball bearings handle heavy radial loads?

Yes, they can. One of the key features of these bearings is their ability to handle both radial and axial loads. However, the load capacity may vary depending on the specific bearing design and size. It’s essential to refer to bearing catalogs and technical specifications to determine the load-carrying capacity for your application.

5. What maintenance is required for double row angular contact ball bearings?

Proper maintenance is crucial for extending the lifespan and ensuring continued precision. Maintenance typically includes lubrication, monitoring for wear and tear, and periodic inspections. The frequency and type of maintenance depend on factors such as operating conditions and the manufacturer’s recommendations.

6. Are double row angular contact ball bearings suitable for high-speed applications?

Yes, they are well-suited for high-speed applications, thanks to their design and precision. These bearings offer reduced friction and heat generation, making them capable of handling rapid rotational speeds. However, it’s important to select the appropriate bearing size and lubrication to ensure optimal performance at high speeds.

In conclusion, double row angular contact ball bearings are versatile and precision-engineered components that find applications in various industries. Understanding their characteristics, advantages, and proper selection is essential to harness their full potential in precision engineering and machinery. If you have more questions or need specific guidance for your application, consulting with bearing experts or manufacturers is recommended.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8