Elevating Performance: Tapered Roller Thrust Bearings in Action

1 Introduction

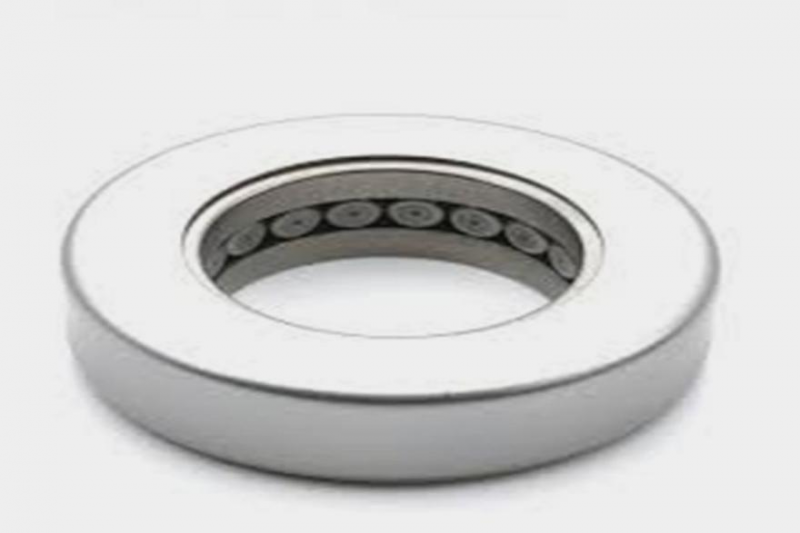

Tapered roller thrust bearings are a critical component in various industrial applications, playing a pivotal role in enhancing overall performance.

These specialized bearings are engineered to manage axial loads, making them indispensable in machinery and equipment where thrust loads are involved. From automotive transmissions to heavy-duty machinery, the versatility of tapered roller thrust bearings is undeniable.

2 Mechanics and Design

Tapered roller thrust bearings are remarkable in their design and mechanics, making them a preferred choice for applications where axial loads need to be managed effectively. In this section, we will delve into the intricate details of their mechanics and design principles, shedding light on what sets them apart in the world of bearings.

Mechanics of Tapered Roller Thrust Bearings

Tapered roller thrust bearings are engineered to accommodate axial loads in a single direction. Their unique tapered design enables them to handle both heavy thrust loads and moment loads simultaneously. The tapered rollers themselves are angled to match the cone and cup races, ensuring efficient load distribution.

One of the key features that distinguishes tapered roller thrust bearings is their ability to handle both thrust and radial loads. This versatility is crucial in applications where varying load types are encountered. Additionally, their design minimizes friction, resulting in reduced heat generation and increased efficiency.

Design Principles

The design of tapered roller thrust bearings is a testament to engineering ingenuity. These bearings typically consist of two races, known as the cone and cup, which house the tapered rollers. The cone race is mounted onto the shaft, while the cup race is secured in the housing.

The tapered rollers themselves are precision-crafted to match the angles of the cone and cup races perfectly. This precision engineering ensures uniform load distribution, reducing stress on individual rollers and prolonging bearing life.

The arrangement of the rollers also allows for a larger contact area, which translates to higher load-carrying capacity. This design characteristic is particularly advantageous in applications where heavy axial loads need to be managed consistently.

Versatility for Different Industries

Tapered roller thrust bearings find their utility in a wide range of industries, thanks to their robust design and exceptional mechanics. From automotive transmissions to heavy machinery in construction and mining, these bearings are adaptable and capable of withstanding the rigors of demanding applications.

Their ability to handle heavy thrust loads while maintaining efficiency makes them indispensable in scenarios where performance and reliability are paramount. Industries that rely on precise axial load management turn to tapered roller thrust bearings to ensure smooth operation and extended bearing life.

In conclusion, understanding the mechanics and design principles of tapered roller thrust bearings is essential to appreciate their role in elevating performance across various industrial applications. The next section will delve into real-world applications and showcase how these bearings make a tangible difference in enhancing performance and efficiency.

3 Applications Across Industries

Tapered roller thrust bearings are versatile components that play a pivotal role in elevating performance across a multitude of industries. In this section, we will embark on a journey through various sectors and discover how these bearings are effectively employed to enhance machinery and equipment performance.

| Automotive Industry | The automotive industry relies heavily on the precision and reliability offered by tapered roller thrust bearings. They are prominently used in vehicle transmissions to manage the axial loads generated by gears and other rotating components. These bearings ensure smooth gear engagement, reduce friction, and contribute to improved fuel efficiency and overall vehicle performance. |

| Aerospace Sector | In the aerospace sector, where safety and precision are paramount, tapered roller thrust bearings are preferred for their ability to handle high axial loads. They are commonly employed in aircraft landing gear systems, ensuring smooth and controlled landing operations even under immense stress. These bearings contribute significantly to passenger safety and aircraft reliability. |

| Construction and Heavy Machinery | Construction and heavy machinery, such as excavators, bulldozers, and cranes, rely on the ruggedness of tapered roller thrust bearings. These machines often operate in demanding environments with substantial axial loads. Tapered roller thrust bearings excel in such conditions, offering durability, longevity, and consistent performance. |

| Industrial Manufacturing | In the realm of industrial manufacturing, where precision and efficiency are imperative, these bearings are indispensable. They are used in a wide array of equipment, including conveyor systems, machine tools, and industrial robots. Tapered roller thrust bearings enable smooth and reliable operation, contributing to increased production efficiency. |

| Energy and Power Generation | The energy sector, encompassing power plants and wind turbines, depends on the reliability of tapered roller thrust bearings to manage the axial loads generated by rotating turbines and generators. These bearings ensure uninterrupted power generation and contribute to the overall efficiency of the energy industry. |

Real-World Impact

Tapered roller thrust bearings have a profound impact on the performance and reliability of machinery and equipment across these diverse industries. They enable efficient load management, reduce friction, and extend the service life of critical components. The real-world examples and case studies mentioned above highlight how these bearings are instrumental in elevating performance standards.

In conclusion, the applications of tapered roller thrust bearings extend far and wide, touching various facets of modern life. Their versatility, durability, and exceptional performance make them a cornerstone of machinery and equipment design, ultimately contributing to the elevation of performance across industries. The following section will delve into best practices for maintaining and maximizing the lifespan of these crucial components.

4 Maintenance and Best Practices

Maintaining the optimal performance of tapered roller thrust bearings is essential to ensure the longevity and reliability of machinery and equipment. In this section, we will delve into the best practices for maintaining these crucial components and maximizing their lifespan.

Proper Lubrication

Proper lubrication is paramount to the smooth operation of tapered roller thrust bearings. Insufficient or incorrect lubrication can lead to premature wear and reduced performance. It is essential to follow manufacturer recommendations regarding the type and quantity of lubricant. Regularly inspect the lubrication system and ensure it is functioning correctly. Lubrication intervals should be adhered to diligently, and any signs of contamination or degradation should be addressed promptly.

Regular Inspections

Scheduled inspections are crucial to detect early signs of wear, misalignment, or damage in tapered roller thrust bearings. Visual inspections should include checking for any unusual noise, vibrations, or temperature changes during operation. Additionally, measuring axial play and bearing temperature can provide valuable insights into the bearing’s condition. Any abnormalities should trigger a comprehensive inspection and, if necessary, corrective measures.

Proper Handling and Installation

Improper handling and installation can lead to bearing damage and reduced performance. When handling tapered roller thrust bearings, ensure they are kept clean and free from contaminants. It is advisable to store them in their original packaging until installation. During installation, use the correct tools and follow the manufacturer’s instructions carefully. Proper alignment and preload adjustment are critical factors in achieving optimal performance.

Replacement When Necessary

Tapered roller thrust bearings have a finite lifespan, even with proper maintenance. Recognizing when to replace these bearings is essential to prevent costly breakdowns. Bearings that have exceeded their recommended service life, exhibit signs of heavy wear, or have sustained damage should be replaced promptly. Delaying replacement can lead to further damage and compromise the performance of the entire system.

Expert Guidance

In complex industrial settings, it is often beneficial to seek expert guidance for maintenance and replacement of tapered roller thrust bearings. Collaborating with qualified technicians or engineers can help identify potential issues, develop effective maintenance schedules, and ensure the correct selection of replacement bearings. Their expertise can significantly contribute to the longevity and performance of your equipment.

In conclusion, proper maintenance practices are crucial to maintaining the high-level performance of tapered roller thrust bearings. Regular inspections, correct lubrication, careful handling during installation, and timely replacement when necessary are key aspects of ensuring these bearings continue to elevate performance across various industries. By following these best practices, you can maximize the lifespan of your bearings and optimize the efficiency of your machinery and equipment.

5 Performance Comparison

In the world of thrust bearings, various types are available to serve distinct purposes. However, when it comes to elevating performance, tapered roller thrust bearings stand out as exceptional components. In this section, we will delve into a performance comparison between tapered roller thrust bearings and other types of thrust bearings. By understanding the advantages and potential limitations of these bearings, you can make informed decisions for your machinery and equipment.

Tapered Roller Thrust Bearings

Tapered roller thrust bearings are renowned for their exceptional load-carrying capacity and ability to handle both axial and radial loads. They are designed with tapered raceways on the bearing rings, enabling them to support heavy axial loads while maintaining precise axial alignment. The tapered design also distributes loads more evenly, reducing the risk of premature wear and increasing bearing lifespan.

Advantages:

| – High load-carrying capacity | Tapered roller thrust bearings can handle significantly higher axial loads compared to other types of thrust bearings. |

| – Precise axial alignment | Their design ensures accurate axial positioning, crucial for maintaining machinery performance. |

| – Reduced friction | Tapered rollers distribute loads evenly, minimizing friction and heat generation. |

Ball Thrust Bearings

Ball thrust bearings, also known as thrust ball bearings, are well-suited for applications with moderate axial loads. They feature ball-shaped rolling elements that allow for smooth and precise axial movement. However, their load-carrying capacity is generally lower than that of tapered roller thrust bearings.

Advantages:

– Low friction: Ball thrust bearings offer low friction and minimal heat generation.

– Suitable for high-speed applications: Their design allows for quick and precise axial movement.

Limitations:

– Lower load capacity: Ball thrust bearings are not ideal for heavy-duty applications with extremely high axial loads.

Cylindrical Roller Thrust Bearings

Cylindrical roller thrust bearings feature cylindrical rolling elements and are designed for applications with moderate to heavy axial loads. They offer good load-carrying capacity but may not match the performance of tapered roller thrust bearings in certain scenarios.

Advantages:

– High load capacity: Cylindrical roller thrust bearings can handle significant axial loads.

– Precise axial alignment: They provide accurate axial positioning.

Limitations:

– Higher friction: Compared to tapered roller thrust bearings, cylindrical roller thrust bearings may experience higher friction and heat generation.

– Limited suitability for combined radial and axial loads: While they excel in axial loads, they may not perform as well in combined radial and axial load applications.

In conclusion, when it comes to elevating performance in heavy-duty applications with substantial axial loads, tapered roller thrust bearings are the preferred choice. Their unique design, high load-carrying capacity, and precise axial alignment set them apart from other thrust bearing types. However, it is essential to consider the specific requirements of your machinery and equipment to determine the most suitable thrust bearing type. By understanding the performance characteristics and limitations of each option, you can make informed decisions to optimize your systems for efficiency and reliability.

5 Conclusion

In conclusion, the versatile and high-performance nature of tapered roller thrust bearings makes them indispensable components in various industries and applications. Through this comprehensive exploration, we have gained insights into their mechanics, design principles, applications, maintenance, and performance comparison with other types of thrust bearings.

Tapered roller thrust bearings, with their unique design featuring tapered raceways and rollers, excel in handling substantial axial and radial loads while maintaining precise axial alignment. Their load-carrying capacity, precision, and reduced friction make them the preferred choice for elevating performance in heavy-duty machinery and equipment.

In today’s competitive industrial landscape, where efficiency and reliability are paramount, the adoption of tapered roller thrust bearings can significantly impact overall performance. Their role in enhancing machinery operation, minimizing downtime, and optimizing energy efficiency cannot be overstated.

As we look ahead, it is crucial for industries to recognize the potential of tapered roller thrust bearings in elevating their performance standards. Whether in the aerospace sector, automotive manufacturing, or heavy machinery applications, these bearings can play a pivotal role in achieving operational excellence.

In conclusion, consider integrating tapered roller thrust bearings into your machinery and equipment to experience the benefits firsthand. Embracing these high-quality components can lead to smoother operations, longer equipment lifespan, and improved productivity. Make the choice that elevates your performance—choose tapered roller thrust bearings.

7 FAQs: Common Questions about Tapered Roller Thrust Bearings

In this section, we will address some common questions and concerns regarding tapered roller thrust bearings to provide you with a comprehensive understanding of these essential components.

Q1: What are tapered roller thrust bearings, and how do they work?

A1: Tapered roller thrust bearings are a type of thrust bearing designed to handle both axial and radial loads simultaneously. They consist of two tapered races and rollers placed at an angle, allowing them to carry high axial loads while maintaining axial alignment. The tapered design reduces friction, making them ideal for applications where precision and high load-carrying capacity are crucial.

Q2: Where are tapered roller thrust bearings commonly used?

A2: These bearings find applications in various industries, including automotive manufacturing, aerospace, construction machinery, and more. They are typically employed in scenarios where heavy axial loads need to be managed efficiently while maintaining precision, such as in gearboxes, steering systems, and heavy machinery.

Q3: What sets tapered roller thrust bearings apart from other thrust bearings?

A3: Tapered roller thrust bearings have several advantages. Their tapered design allows them to handle both axial and radial loads, while other thrust bearings primarily focus on axial loads. Additionally, the tapered rollers distribute loads evenly, reducing friction and enhancing efficiency. These features make them superior in applications that demand high load capacity, precision, and durability.

Q4: How can I ensure the proper maintenance of tapered roller thrust bearings?

A4: Proper maintenance is crucial for ensuring the longevity and performance of tapered roller thrust bearings. Regular inspections, lubrication with suitable lubricants, and timely replacement of worn-out components are essential. It’s advisable to follow manufacturer guidelines and recommendations for maintenance procedures.

Q5: Are there any limitations or scenarios where other thrust bearings may be preferable?

A5: While tapered roller thrust bearings excel in various applications, there may be scenarios where other thrust bearings, such as ball thrust or cylindrical thrust bearings, are more suitable. For instance, ball thrust bearings offer higher speed capabilities, and cylindrical thrust bearings may be preferred in situations where space constraints exist. The choice depends on specific application requirements.

By addressing these common questions, we hope to provide valuable insights into the world of tapered roller thrust bearings and help you make informed decisions when selecting and maintaining these essential components for your machinery and equipment.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8