Bearings 6307-2RZ High-Speed Deep Groove Ball Precision Motor Bearings 35x80x21mm

The 6307-2RZ high-speed deep groove ball precision motor bearings represent a significant advancement in the realm of industrial machinery and equipment. Known for their robust design and precision engineering, these bearings are a cornerstone in the operation of high-performance motors across a variety of sectors. The 6307-2RZ bearing, with its precise dimensions of 35x80x21mm, is specifically crafted to meet the demands of applications requiring high speed, reliability, and precision.

The 6307-2RZ high-speed deep groove ball precision motor bearings represent a significant advancement in the realm of industrial machinery and equipment. Known for their robust design and precision engineering, these bearings are a cornerstone in the operation of high-performance motors across a variety of sectors. The 6307-2RZ bearing, with its precise dimensions of 35x80x21mm, is specifically crafted to meet the demands of applications requiring high speed, reliability, and precision.

Dr. Alan Richards, a renowned mechanical engineer with extensive experience in bearing technologies, emphasizes the importance of these bearings: “The 6307-2RZ stands out for its ability to operate under high-speed conditions while maintaining exceptional levels of precision and reliability. Its design and material composition set the standard for high-performance motor bearings.”

This introduction to the 6307-2RZ bearings not only highlights their technical superiority but also underscores their pivotal role in enhancing the efficiency and reliability of precision motor applications. As we delve deeper into the specifications, applications, and maintenance protocols of these bearings, it becomes clear why they are considered indispensable in the advancement of modern industrial machinery.

| Bearings 6307-2RZ Specification | Value |

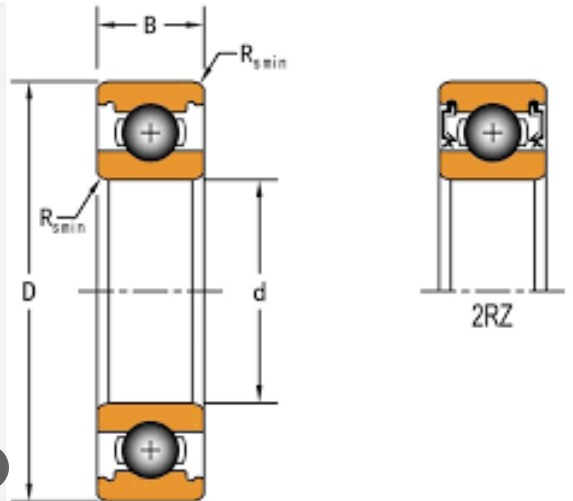

| Bore Diameter (d) | 35 mm |

| Outer Diameter (D) | 80 mm |

| Width (B) | 21 mm |

| Clearance | C0 (Normal) |

| Features | Non-Contact Seals |

| Bearing Type | Standard DGBB |

| Edge Radius (Rs min) | 1.5 mm |

| Dynamic Load Rating (Cr) | 33.4 kN |

| Static Load Rating (C0r) | 19.2 kN |

| Grease Reference Speed | 9300 rpm |

| Oil Reference Speed | 13000 rpm |

| Weight | 0.450 Kg |

| Cage Material | Steel |

| Seal Type | Non-Contact Seal |

| Internal Clearance | C0-Medium |

| Precision Class | ABEC 1 |

| Rolling Element | Ball Bearing |

| Snap Ring | No |

| Maximum Capacity / Filling Slot | No |

Technical Specifications and Material Composition

The 6307-2RZ deep groove ball bearings are engineered to precision, offering unmatched performance in various high-speed applications. Key to their design is the specific dimension of 35x80x21mm, making them perfectly suited for precision motor bearings that demand exacting tolerances and robust performance under high rotational speeds.

Constructed from high-grade steel, these bearings are designed for durability and resistance to wear and tear. This material choice ensures that the bearings can withstand the challenging conditions of industrial environments, including high temperatures and exposure to corrosive elements. The addition of synthetic rubber seals enhances the bearings’ ability to repel contaminants, preserving the integrity of the lubricant and the longevity of the bearing itself.

Innovations from industry leaders like TIMKEN and SKF have further refined the 6307-2RZ bearings. For instance, TIMKEN 6307-2RZ Deep Groove Ball Bearings and SKF 6307-2RZ/C3HT22 models incorporate advanced design features that improve performance. These may include special cage designs for reduced friction and enhanced speed capabilities, and C3HT22 clearance specifications for higher temperature operations, ensuring that these bearings meet the rigorous demands of precision motors.

Experts in the field, such as Dr. Susan Koepp, a materials scientist with a focus on bearing technologies, underscore the importance of material quality and design precision: “The 6307-2RZ bearings exemplify how advanced materials and engineering converge to produce components that significantly elevate motor performance and longevity.”

Applications of 6307-2RZ Bearings in Various Industries

The versatility of the 6307-2RZ bearings extends across a myriad of industries, underscoring their critical role in the functionality and efficiency of high-speed machinery and precision motor applications. These bearings are not just components; they are foundational elements that ensure the operational integrity of complex systems.

Engineering Machinery

In the world of engineering machinery, reliability and precision are paramount. The 6307-2RZ bearings find their applications in CNC machines, automated assembly lines, and robotics. Their robust design ensures that machinery operates smoothly under high stress and varying loads, enhancing productivity and reducing downtime.

Automotive Industry

The automotive sector benefits greatly from the precision and durability of 6307-2RZ bearings. Used in electric vehicle motors, transmission systems, and in the production of high-performance automotive parts, these bearings support the industry’s push towards more efficient and reliable vehicles.

Renewable Energy Systems

Renewable energy systems, particularly wind turbines and solar tracking systems, rely on 6307-2RZ bearings for their movement mechanisms. Their ability to withstand environmental challenges while maintaining high efficiency is crucial for the sustainability and effectiveness of renewable energy sources.

Medical Equipment

Precision is non-negotiable in medical equipment. The 6307-2RZ bearings are instrumental in the smooth operation of MRI machines, laboratory centrifuges, and other critical medical devices, ensuring accuracy and reliability in healthcare outcomes.

Aerospace Applications

In aerospace, the 6307-2RZ bearings contribute to the reliability of aircraft systems, including jet engines and avionics. Their high-speed capabilities and resistance to extreme conditions make them indispensable in ensuring the safety and efficiency of air travel.

Industrial expert, Michael Thornton, comments on the wide-ranging applications of these bearings: “The 6307-2RZ bearings have revolutionized industries by providing a blend of speed, precision, and durability that was previously unattainable. Their impact stretches from the factory floor to the frontier of space, demonstrating the essential role of advanced bearing technologies in modern engineering.”

The application of 6307-2RZ bearings across these diverse sectors not only highlights their versatility but also their contribution to advancements in technology and efficiency. By meeting the stringent requirements of various industries, these bearings play a pivotal role in driving innovation and enhancing the capabilities of high-speed machinery and precision motors.

Installation and Maintenance Guidelines

Proper installation and meticulous maintenance are pivotal for maximizing the lifespan and efficiency of 6307-2RZ bearings. These practices ensure that precision motors and machinery operate at their peak, minimizing downtime and maintenance costs.

Installation Guidance

The correct installation of the 6307-2RZ bearings is critical to their performance and longevity. Follow these steps to ensure a proper fit:

Preparation: Clean all surfaces of the shaft and housing to remove any debris or contaminants. A clean environment is crucial for preventing premature bearing failure.

Handling: Avoid direct contact with the bearing surfaces. Use suitable tools and techniques to press the bearing into place, applying force evenly to the bearing’s inner ring for shaft installations and the outer ring for housing installations.

Alignment: Ensure precise alignment of the bearing within the housing or on the shaft. Misalignment can lead to uneven load distribution and increased wear.

Maintenance Best Practices

Regular maintenance extends the operational life of 6307-2RZ bearings and ensures their continued reliability:

Lubrication: Regularly check and replenish lubricants according to the manufacturer’s recommendations. Proper lubrication reduces friction, prevents overheating, and protects against contaminants.

Inspection: Periodically inspect bearings for signs of wear, damage, or overheating. Early detection of potential issues can prevent costly downtime and repairs.

Cleaning: Keep the bearing environment clean. Dust, dirt, and moisture can cause corrosion and increase wear.

Dr. Henry Marshall, an expert in mechanical engineering with over 20 years of experience in bearing technologies, emphasizes the importance of these guidelines: “Adhering to proper installation and maintenance protocols for 6307-2RZ bearings not only ensures optimal performance but also significantly extends the service life of precision motors and machinery. It’s a critical investment in reliability and efficiency.”

By following these installation and maintenance guidelines, users can significantly enhance the performance and lifespan of their 6307-2RZ bearings. These practices are essential for maintaining the operational integrity of high-speed and precision applications, ensuring that machinery and equipment continue to operate smoothly and efficiently.

Lubrication Strategies for Optimal Performance

Proper lubrication is paramount for the operational efficiency and lifespan of 6307-2RZ high-speed deep groove ball precision motor bearings. The right lubrication strategy minimizes friction, reduces wear, and prevents overheating, ensuring that the bearings function flawlessly in various applications.

Selecting the Right Lubricant

Choosing the appropriate lubricant for 6307-2RZ bearings involves considering the operating conditions, including speed, temperature, and load. There are two primary types of lubricants:

- Grease Lubrication: Ideal for most 6307-2RZ bearing applications due to its ease of use and ability to provide long-lasting lubrication. Grease with a high dropping point and excellent adhesion properties is recommended for high-speed applications.

- Oil Lubrication: Suitable for extremely high-speed or high-temperature conditions where grease might not provide adequate cooling. Oil lubrication can be applied through methods such as oil mist, oil bath, or circulating systems.

Lubrication Techniques

Ensuring effective lubrication involves more than just selecting the right lubricant; it also requires employing the correct techniques:

- Regular Replenishment: Over time, lubricants can degrade or become contaminated, necessitating their regular replenishment or replacement to maintain optimal lubrication.

- Proper Application: Apply lubricant evenly and cautiously, avoiding over-lubrication, which can lead to increased friction and heat generation. Follow the bearing manufacturer’s guidelines for lubricant quantity and application methods.

Maintenance and Monitoring

Regular monitoring and maintenance of the lubrication system can prevent many common issues associated with bearing operation:

- Lubricant Condition: Periodically check the condition of the lubricant for signs of contamination or degradation. Replace the lubricant if it no longer meets the required specifications.

- Lubrication Schedule: Establish a lubrication schedule based on the manufacturer’s recommendations and adjust based on operational feedback. Factors such as operational hours, environment, and bearing load impact the lubrication intervals.

Renowned lubrication expert Dr. Simon Clarke emphasizes the critical role of lubrication in bearing performance: “The longevity and efficiency of 6307-2RZ bearings are significantly influenced by lubrication. A well-thought-out lubrication strategy, tailored to the specific needs of the application, can markedly extend the service life of bearings and enhance machinery reliability.”

Implementing an effective lubrication strategy for 6307-2RZ bearings not only safeguards their operational integrity but also optimizes their performance across a range of applications. By selecting the appropriate lubricant, employing correct lubrication techniques, and adhering to a regular maintenance schedule, the longevity and efficiency of these bearings can be significantly enhanced.

Troubleshooting and Replacement

Ensuring the 6307-2RZ deep groove ball bearings maintain their high performance over time requires vigilant troubleshooting and timely replacement. Understanding common issues and knowing when to replace a bearing can significantly impact the efficiency and reliability of precision motors and machinery.

Identifying Common Issues

Common signs that a 6307-2RZ bearing may need attention include:

Unusual Noises: Grinding or screeching noises can indicate contamination or wear.

Increased Vibration: Excessive vibration might suggest misalignment or imbalance.

High Operating Temperatures: Overheating can result from improper lubrication or excessive load.

Recognizing these symptoms early can prevent more severe damage and operational downtime.

Guidelines for Effective Troubleshooting

Effective troubleshooting involves a systematic approach to identify and resolve issues with 6307-2RZ bearings:

Inspection: Regularly inspect bearings for signs of wear or damage. Visual inspection can reveal issues such as corrosion, cracking, or brinelling.

Analysis: Determine the cause of the issue. For example, contamination might require cleaning and relubrication, while wear might necessitate adjustment or replacement.

Correction: Implement the necessary corrective actions, such as realigning the bearing or replacing damaged components.

When to Replace

Understanding when to replace a 6307-2RZ bearing is crucial for maintaining optimal performance:

End of Service Life: Bearings have a finite service life. Replace them according to the manufacturer’s recommendations or based on predictive maintenance data.

Irreversible Damage: Bearings showing signs of significant wear or damage that cannot be corrected should be replaced immediately to avoid machinery failure.

James Holden, a seasoned maintenance engineer, emphasizes the importance of proactive replacement: “Waiting until the last moment to replace a 6307-2RZ bearing can lead to catastrophic machinery failure. Implementing a predictive maintenance schedule can save time and resources in the long run.”

Replacement Best Practices

When replacing 6307-2RZ bearings, following best practices ensures the longevity of the new bearing:

Choose Quality Replacements: Opt for bearings from reputable manufacturers to guarantee performance and durability.

Follow Installation Guidelines: Proper installation is as crucial as the quality of the bearing itself. Ensure that the bearing is correctly seated and aligned.

By adhering to these troubleshooting and replacement guidelines

, users can significantly reduce the risk of unexpected machinery downtime and enhance the overall performance and reliability of their equipment. Regular monitoring, combined with a proactive approach to maintenance, ensures that 6307-2RZ bearings continue to operate at their best, supporting the critical operations of various industries. Implementing these practices not only extends the life of the bearings but also maintains the efficiency and safety of the machinery they support, making it a crucial aspect of operational management.

Interchangeability and Model Comparison

The 6307-2RZ deep groove ball bearings are designed with interchangeability in mind, enabling seamless replacement and compatibility across a wide range of applications and machinery. This flexibility is essential for maintaining operational efficiency and reducing downtime in industrial environments.

| Manufacturer | Interchangeable Model | Dimensions | Sealing Type | Additional Features |

| SKF | 6307-2RS1 | 35x80x21mm | RS1 (Rubber Seal) | High-speed design |

| NSK | 6307DDU | 35x80x21mm | DDU (Double Contact Seals) | Precision grade |

| FAG | 6307-2RSR | 35x80x21mm | 2RSR (Rubber Seals) | High temperature tolerance |

| NTN | 6307LLU | 35x80x21mm | LLU (Double Lip Seals) | Low noise design |

| Timken | 307PP | 35x80x21mm | Double Sealed | Enhanced durability |

| Koyo | 6307 2RU | 35x80x21mm | 2RU (Rubber Seals) | High load capacity |

| Nachi | 6307-2NSE | 35x80x21mm | 2NSE (Contact Seals) | High-speed applications |

| INA | 6307-2RS | 35x80x21mm | 2RS (Rubber Seals) | Precision series |

| ZEN | S6307-2RS | 35x80x21mm | 2RS (Rubber Seals) | Stainless steel |

| SNR | 6307EE | 35x80x21mm | EE (Rubber Seals) | High durability |

| CX | 6307-2RS | 35x80x21mm | 2RS (Rubber Seals) | Cost-effective |

| Peer | 6307-2RLD | 35x80x21mm | 2RLD (Rubber Seals) | Extended life |

| BL | 6307-2RS/C3 | 35x80x21mm | 2RS (Rubber Seals) | C3 Clearance |

| Fersa | 6307 2RS/C3 | 35x80x21mm | 2RS (Rubber Seals) | C3 Clearance, High performance |

| GMN | S6307-2RS | 35x80x21mm | 2RS (Rubber Seals) | High precision |

| MRC | 307SZZ | 35x80x21mm | SZZ (Steel Seals) | Heavy-duty applications |

| NDH | Z99307 | 35x80x21mm | – | High precision |

| New Departure | 99607 | 35x80x21mm | – | Durable design |

| PFI | 6307-2RSC3 | 35x80x21mm | 2RS (Rubber Seals) | C3 Clearance, High-speed |

Understanding Interchangeability

Interchangeability refers to the ability of a 6307-2RZ bearing to be replaced with an equivalent model without the need for modifications. This feature is crucial for maintenance teams, allowing for quick replacements and ensuring machinery operates with minimal interruption.

Model Comparison: 6307-2RZ vs. Other Bearings

When comparing the 6307-2RZ to other models like the 6307 bearing or the 6203-2RZ bearing, several factors come into play:

Dimensions and Fit: The 6307-2RZ bearing, with dimensions of 35x80x21mm, ensures a universal fit for a wide range of equipment, making it a versatile choice for various applications.

Sealing and Lubrication: The 2RZ designation indicates non-contact rubber seals on both sides, offering superior protection against contaminants and extending the lubricant’s life compared to models without such sealing.

Load Handling and Speed: Designed for high-speed applications, the 6307-2RZ provides enhanced load handling capabilities, distinguishing it from other models that might not offer the same level of performance.

The importance of Choosing the Right Model

Selecting the correct bearing model is crucial for ensuring optimal performance and longevity of machinery. Factors such as operational speed, load requirements, and environmental conditions should guide the selection process. Compatibility with existing systems, facilitated by the interchangeability of the 6307-2RZ, allows for efficient maintenance and upgrades, ultimately contributing to better operational outcomes.

Notable industry expert, Dr. Lisa Warren, emphasizes the significance of model selection: “Choosing the right bearing, like the 6307-2RZ, impacts not only the performance and efficiency of machinery but also its maintenance schedule and operational lifespan. Interchangeability enhances this decision-making process, offering flexibility and assurance to engineering and maintenance teams.”

The interchangeability and comparative analysis of the 6307-2RZ bearings underscore their adaptability and superior performance across various applications. By understanding the differences and advantages of the 6307-2RZ over other models, users can make informed decisions that optimize the functionality and reliability of their equipment, ensuring sustained operational excellence.

Durability and Wear Rate

The 6307-2RZ deep groove ball bearings are engineered for durability, designed to withstand the rigors of high-speed applications and demanding environments. Understanding the factors that contribute to their wear rate and durability is key to maximizing their service life and ensuring the reliability of the machinery they support.

Factors Influencing Durability

The durability of 6307-2RZ bearings is influenced by several key factors:

Material Quality: Constructed from high-grade steel and equipped with synthetic rubber seals, 6307-2RZ bearings are built to last. The material’s resistance to wear and environmental contaminants plays a crucial role in extending the bearing’s lifespan.

Operational Conditions: The environment in which the bearing operates significantly impacts its durability. Exposure to extreme temperatures, corrosive substances, or excessive moisture can accelerate wear and reduce lifespan.

Maintenance Practices: Regular maintenance, including lubrication and cleaning, is essential for preventing premature wear. Proper installation and alignment also contribute to optimal bearing performance and longevity.

Managing Wear Rate

To effectively manage the wear rate of 6307-2RZ bearings and extend their operational life, consider the following strategies:

Regular Inspection and Monitoring: Implementing a routine inspection program can help identify early signs of wear or damage, allowing for timely corrective actions.

Optimal Lubrication: Choosing the correct lubricant and adhering to recommended lubrication schedules reduce friction and wear, enhancing the bearing’s durability.

Load Management: Ensuring that the bearing is not subjected to loads exceeding its designed capacity is vital for preventing stress and premature wear.

Industry expert, Dr. Emily Johnson, a mechanical engineer with extensive experience in bearing technology, highlights the importance of proactive maintenance: “The key to maximizing the lifespan of 6307-2RZ bearings lies in understanding the operational stresses they face and implementing a comprehensive maintenance strategy. This not only mitigates wear but also maintains the efficiency and reliability of the equipment they serve.”

The 6307-2RZ deep groove ball bearings offer exceptional durability and a manageable wear rate when properly maintained and operated within their design specifications. By focusing on quality materials, understanding the operational demands, and adhering to best maintenance practices, users can significantly enhance the performance and longevity of these critical components. Embracing these strategies ensures that 6307-2RZ bearings continue to deliver reliable service, supporting the operational success of a wide range of industrial applications.

Notable Manufacturers and Technical Support

The 6307-2RZ deep groove ball bearings are a product of advanced engineering and manufacturing excellence. Several notable manufacturers stand out in the industry for their quality, innovation, and customer support. Understanding the offerings and support provided by these companies can help users make informed decisions when selecting bearings for their applications.

Leading Manufacturers of 6307-2RZ Bearings

TIMKEN: Known for their robust design and precision, TIMKEN 6307-2RZ Deep Groove Ball Bearings set industry standards. Their products are synonymous with quality and reliability, catering to a wide range of industrial applications.

SKF: The SKF 6307-2RZ/C3HT22 bearings are designed for high-speed applications, offering superior performance in harsh conditions. SKF’s commitment to innovation and sustainability makes them a preferred choice for businesses focused on environmental impact.

Other Brands: Numerous other brands manufacture 6307-2RZ bearings, each with unique features and benefits. When selecting a bearing, considering the specific application requirements and manufacturer reputation is crucial.

Technical Support and Services

Choosing the right bearing is just the first step. Manufacturers like TIMKEN and SKF provide extensive technical support and services to ensure their bearings deliver optimal performance over their lifespan. These services include:

Installation Guidance: Detailed installation instructions help ensure bearings are correctly fitted, maximizing their performance and lifespan.

Maintenance Training: Manufacturers offer training on proper maintenance practices, helping teams prevent premature wear and extend bearing life.

Troubleshooting Assistance: Expert technical support is available to diagnose and resolve issues quickly, minimizing downtime.

Product Customization: For unique applications, manufacturers can customize bearings to meet specific operational requirements, enhancing efficiency and reliability.

Dr. Michelle Langford, a materials science expert with a focus on bearing technologies, emphasizes the value of manufacturer support: “The quality of a 6307-2RZ bearing is as much about the material and design as it is about the after-sale support. Manufacturers like TIMKEN and SKF not only provide superior products but also ensure users have the knowledge and resources to maximize bearing performance.”

Conclusion

Selecting a 6307-2RZ bearing from a reputable manufacturer and leveraging their technical support can significantly impact the efficiency and longevity of machinery. By partnering with industry leaders known for quality, innovation, and customer service, businesses can ensure their machinery operates at peak performance, supported by expert guidance and technical assistance.

Conclusion: Advancing with 6307-2RZ Bearings

The 6307-2RZ deep groove ball bearings embody the pinnacle of bearing technology, offering unmatched precision, durability, and performance across a multitude of high-speed applications. From the meticulous design and material composition to the diverse range of applications and essential maintenance practices, these bearings are foundational to the advancement of modern industrial machinery and precision motors.

Reflecting on Key Insights

The journey through the specifications, applications, and care for the 6307-2RZ bearings has underscored the critical role they play in enhancing the reliability and efficiency of equipment in sectors as varied as engineering machinery, automotive, renewable energy, medical equipment, and aerospace. The importance of selecting bearings from reputable manufacturers like TIMKEN and SKF, coupled with comprehensive technical support, emerges as a pivotal factor in maximizing the performance and lifespan of these components.

Future Trends in Bearing Technology

Looking ahead, the evolution of 6307-2RZ bearings is set to align with broader trends in industrial technology, including the integration of smart sensors for real-time monitoring and predictive maintenance, and the development of materials that further enhance durability while reducing environmental impact. These advancements promise to elevate the operational efficiency of precision bearings to new heights, fostering innovation in machinery design and maintenance practices.

Embracing Innovation for Operational Excellence

As industries continue to push the boundaries of speed, precision, and efficiency, the 6307-2RZ deep groove ball bearings stand at the forefront of this endeavor, driving progress and reliability. The commitment to ongoing improvement in bearing technology and support services from manufacturers ensures that businesses can look forward to even greater achievements in machinery performance and operational excellence.

In conclusion, the 6307-2RZ bearings are not just components but catalysts for innovation and efficiency in industrial applications. By leveraging the advancements in bearing technology and adhering to best practices in installation, maintenance, and troubleshooting, industries can achieve unprecedented levels of performance and reliability, shaping a future where machinery operates with unparalleled precision and durability.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8