Brand duplex bearing DB. DF. DT. DBD matched pairs interchange catalog

SUPER PRECISION BEARINGS FOR MACHINE TOOL APPLICATIONS

| Brand Bearing | NACHI | NSK | NTN | LOYAL | KOYO | SKF | FAG | RHP | |

|

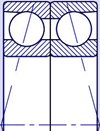

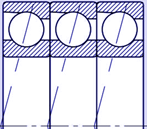

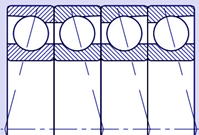

Back to back arrangement |

DB | DB | DB | DB | DB | DB | DB | DB |

|

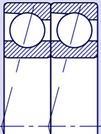

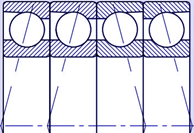

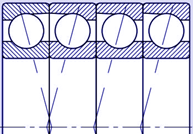

Face to face arrangement |

DF | DF | DF | DF | DF | DF | DF | DF |

|

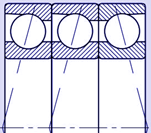

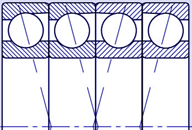

Tandem arrangement |

DT | DT | DT | DT | DT | DT | DT | DT |

|

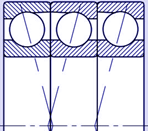

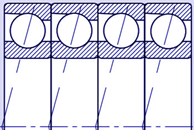

Combination of tandem and back to back arrangement |

FFB | DBD | DBT | DBD | DBD | TBT | TBT | 2TB |

| (FBB) | |||||||||

|

Combination of tandem and face to face arrangement |

BFF | DFD | DFT | DFD | DFD | TFT | TFT | 2TF |

| (BBF) | |||||||||

|

Tandem arrangement |

FFF | DTD | DTT | DTD | DTD | TT | TT | 3T |

| (BBB) | |||||||||

|

Back to back arrangement |

FFBB | DBB | DTBT | DBB | DBB | QBC | QBC | 2TB2T |

|

Face to face arrangement |

BBFF | DFF | DTFT | DFF | DFF | QFC | QFC | 2TF2T |

|

Tandem arrangement |

FFFF | DTT | DTTT | DTT | QT | QT | 4T | |

|

Combination of tandem and back to back arrangement |

FFFB | DBT | DBTT | DBT | DBT | QBT | QBT | 3TB |

| (FBBB) | |||||||||

|

Combination of tandem and face to face arrangement |

BFFF | DFT | DFTT | DFT | DFT | QFT | QFT | 3TF |

| (BBBF) |

face-to-face (DF) plans are objectionable since they supply the least. when the operating speeds are relatively high, such mountings might accumulation bearing preload exceedingly since of the temperature level gradient in between the real estates, bearings and shafts.

As this gradient increases, the bearing preload develops, beginning a damaging cycle that might cause early spindle damage. In spindle mountings, the shaft temperature level normally alters at a much faster rate than the real estate, producing temperature level differentials in between the 2 members. These are because of their distinction in mass and their particular capabilities to function as heat sinks.

The shaft and the inner-ring spacer expand at a much faster rate than the real estate and the outer-ring spacer. As the shaft broadens longitudinally and the inner-ring spacer extends, an axial load develops on each bearing and continues to increase till the stability temperature level is reached. This takes place when the temperature level at the real estate levels off and the heat moved from the bearings stabilizes the heat created within the system.

If the real estate obtains an exceedingly heat, the preliminary bearing temperature level is developed substantially. In an in person , the shaft broadens radially and longitudinally and the inner-ring spacer extends, however at a quicker rate than the outer-ring spacer. This thermal growth triggers an extra axial load to be troubled both inner rings, increasing the preload of the bearings.

back-to-back installing: The longitudinal growth of the inner-ring spacer tends to alleviate, instead of develop, the bearing preload. The 2 back-to-back sets, are installed so that the 2 middle bearings are in person. As formerly observed, temperature level differentials trigger the preload of these inner bearings to increase throughout operation. This installing operation is not recommended.

In bearing mountings of the system seen, excessive axial loads are placed on the 2 external bearings as the temperature level along the shaft ends up being greater than at the real estate. The 2 inner bearings discharge, beginning a vicious circle of increasing temperature level, preload accumulation and lube breakdown. This likewise is an inappropriate installing plan and is not recommended. The exact same bearings are revealed properly installed in tandem and set up back-to-back. Lateral growth of the shaft and inner-ring spacer of such mountings increases neither axial loading nor bearing preload.

To avoid boosts in preload due to the thermal growth, back-to-back mountings are chosen for bearings on device tool spindles. When 2 sets are utilized, each set must be installed in tandem, however the mix needs to be set up back-to-back.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8