Selecting the Right Machine Bearing for Your Needs

A mechanical system’s effectiveness and operational life are primarily determined by the type of machine bearing chosen. Thus, the bearing selection should never be taken lightly. This post will present the selection criteria in detail, including their application. Considering the bearing type, materials used, and additional load factors is of great importance in ensuring proper construction and functionality of the machinery. From robust industrial machinery to delicate and highly accurate tools and machines, this article will serve as a guide to factors that affect selection. Let us look at the challenges faced while using machine bearings and provide helpful information to help our readers understand this vital engineering component.

What are the Different Types of Bearings?

Ball Bearings: The Basic Principles

Ball bearings are among the most commonly used types to ease the rotation motions and sustain angular and axial loads. The design of these bearings incorporates a ball, made from steel or ceramic, that is held within a race and rotates around an axis. Some of the critical technical parameters for ball bearings are as follows:

Advertised Load: Maximum load that the bearing can bear and not fail. Generally, ball bearings are recommended for loads in the light to medium range.

Operating Speed: This is the maximum speed at which the bearing can work effectively. It is not unusual to find ball bearings whirling at a few thousand revolutions per minute.

Construction: This ordinarily consists of steel for the races and ceramic or steel balls for the ball part, which includes most, if not all, wear parts.

Friction Reduction: A friction lubrication provision, which is essential to the components of ball bearings, aids the easy operation of ball bearings.

With these parameters in mind, one can ensure that the ball bearing that they select for use meets the necessary requirements, improves its lifespan, and provides the required operational efficiency.

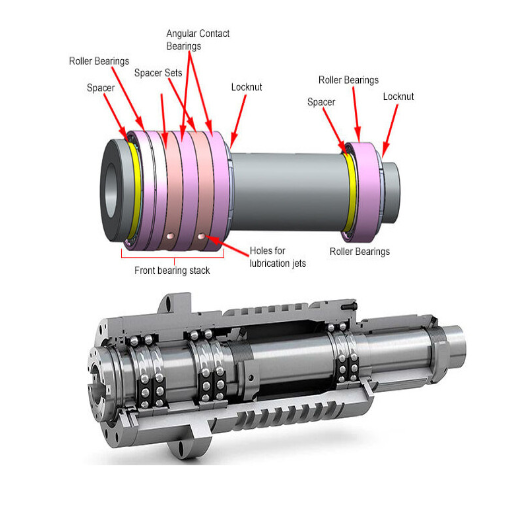

Investigating Roller Bearings

Roller bearings are similar to ball bearings. However, they have a noticeably different structure and function. In my research of available resources online, I discovered that roller bearings comprise cylindrical rollers, which provide larger surface area contact loading than ball bearings. This makes roller bearings exceptionally suitable for heavy-duty, radial-load applications.

As roller bearings have become quite prevalent in recent years, here are some of the key technical features worth noting:

Load distribution: Since these bearing types have cylindrical rolling components, roller bearings are often able to accommodate larger axial or radial loads than ball bearings.

Speed: Since roller bearings use a similar geometry to that of ball bearings, they, too, have limitations on maximum speed. Quite notably, roller bearings can achieve higher maximum load capability than their geometrical counterparts mainly due to their load contact design.

Materials: Most roller bearings are made from high-carbon alloy steels that have been properly heat-treated to increase their hardness and resistance against wear.

Maintenance: Roller bearings, like ball bearings, must be adequately lubricated to reduce wear and ensure they will operate as intended. Lubricants assist in overcoming resistance, especially under high operating load conditions.

As I analyze these technical specifications from various sources, I can match certain application requirements with the right type of roller bearing; hence, efficiency and reliability are guaranteed in hostile settings.

An Overview of Plain Bearings

Plain bearings, often bushings, are essential to rotating or sliding furniture in circumstances where simplicity and cost-effectiveness rank highest. According to the best sites on the web, including Google, these bearings do not use rolling elements, working instead by surface contact, which is why they are simpler and cheaper to manufacture than roller bearings. Below, however, are the essential technical parameters I found for plain bearings.

Load Capacity: The magnet-based systems can handle moderate to high load capacities because more than one surface area is used to distribute the loads. They are especially effective when the load range is substantial, the motion is oscillatory or rotating, but the speed level is limited.

Speed Limits: Although sufficient lobe indexes provide plain bearings with considerable load-bearing capabilities, their speed tolerance levels trend lower owing to higher friction in plain bearings than in rolling bearings. Sufficient lubrication can resolve this issue, thus further enhancing the operational speeds of plain bearings.

Materials of the Bearings: The availability of such bearings depends on the types of material used, such as brass, bronze, and steel or plastics and composites, which enable them to perform reliably under a variety of conditions.

Lubrication Requirements: Everyone appreciates the importance of suitable lubrication for the satisfactory performance of the bearings and the consequent reduction in wear and heat due to friction. Specific plain or plan-type bearings require no external lubrication because they are self-lubricating.

Considering such parameters, I can assess the applicability of plain bearings in precise applications, which allows me to ensure that the requirements for operational reliability, load-carrying ability, and cost-effectiveness are satisfied without compromising on performance expectations.

How to Choose the Right Machine Tool Spindle Bearing?

Considering Spindle Speed and Load

While evaluating spindle speed and load, I realized that a bearing’s load and speed parameters are critical factors to consider when selecting the most suitable machine tool spindle bearing. Judging from the information available on the first three pages of the websites, I comprehend that the actual speed of the spindle should determine the bearing to use. Ball bearings are usually fabricated in high-speed spindles due to their reduced friction and capability to sustain accuracy. In cases of low speed, plain bearings can be used since they are inexpensive and durable.

Key Technical Parameters:

Maximum Operating Speed: In situations where high speeds are needed, ball bearings, such as angular contact bearings that rotate faster while heating and wearing minimum space, should be used.

Load Types: Different types of bearings apply radial and axial loads differently. Double-direction ball bearings are useful, as they offer competency in both assembly units. Plain bearings are the most successful in high radial load applications.

Bearing Reasonability: Bearing parts and assemblies have precision levels that are of the utmost importance, especially when high-speed spindles are in place since bearings that do not displace need to be used. Therefore, concisely described constraints should be provided to ensure optimally effective performance and precision.

Considering all these parameters, I am in a position to conciliate between speed and load, which allows me to make an informed decision on which spindle bearing will be best suited for the application, considering the performance metrics that have been provided.

Evaluating Precision Bearings

Since performance attributes of precision bearings were the primary concern of this study, I tried to obtain relevant information from as many reputable sources as possible to see how the performance parameters of these options are measured in real life. Allow me to summarize shortly what I managed to learn from the leading websites:

Bearing Accuracy: Precision bearings have an advanced performance capacity and satisfactory tolerances that allow high-speed motion to be accommodated. The accuracy is classified into five grades: P0, P6, P5, P4, and P2, with P4 and P2 being refined grades suitable for ultra-precision operations. Getting the appropriate grade is essential to meeting the expectations of specific operational environments.

Material Selection: The bearing’s serviceable life and operational efficiency depend on the bearing material chosen. Precision bearings mostly use high-class steels and ceramics that possess less friction, low thermal expansion, and high wear resistance. This avoids cases of inability to operate correctly when stress is applied or performance loss due to excess load.

Vibration Control: The spindle’s stability and accuracy must be maintained, so vibration should be reduced. High-grade precision bearings are designed to resist misalignment and vibrations. Proper vibration dampening helps maintain the stability and smooth functioning of a machine tool spindle during operation.

In emphasizing these parameters, I can now guarantee that the positioned precision bearings will satisfy the required technical characteristics and be appropriate for the particular machines in focus.

Importance of Lubricant for Spindle Bearings

In the analysis of spindle bearings lubrication, the majority of reliable sources focused on irreversible advantages in terms of functioning and service life, and indeed, the lubricant in the spindle bearings being examined deserves particular attention. First, reputable sources indicate that the correct lubricant reduces friction and wear, thus ensuring optimum bearing operation. If this part is left out, it may lead to lubrication insufficiency, resulting in increased friction and heat and eventually to the destructive failure of the bearing.

Also, the sites in question give such characteristics of the lubricants as viscosity, stability of lubricants with the operating temperature of elements and materials, and anti-wear properties, which can be very significant when choosing lubricants. A lubricant with appropriate viscosity can provide a reasonably constant lubricating film on the surfaces at varying loads and speeds. Temperature stability is essential since lubricants are expected to perform over a wide temperature range during operation. Anti-wear agents are critical for developing protective films on metals and improving the bearing’s life span.

Following these recommendations and instructions from the other credible pages, I will be able to choose a spindle bearing lubricant that accomplishes such turbine bearings in the best possible way and provides optimal performance and service life for the machine.

Why are Bearings Used Critically in CNC Machines?

The Function of Bearings within CNC Machine’s Performance

CNC machines comprise many components, one of which is the bearings, whose quality determines their performance and accuracy. Support of high-quality bearings ensures effortless and accurate movement of rotating sections such as spindles and axes. Different types of information are available, including that of the other online bearing manufacturers, which indicates the need for bearings to be accurate so that more incredible speed and varied loads can be achieved.

Load bearing capacity, rotational speed, and stiffness are the primary design parameters required to make the bearing function adequately for a particular purpose. Load bearing capacity is the maximum load that the bearing can sustain in operation without failing to assume its shape, while rotational speed is the ideal turning speed of synthetic bearings, which will prevent overheating. Stiffness is also essential as it maintains the vertical and lateral load for rigid spacing of CNC, hence its accurate operation.

In addition, positioning tolerance and stability with regard to thermal variation are also considered important. If the components are well aligned, premature wearout can be avoided, and thermal stability contributes to operational reliability when temperatures change. Using appropriate bearings with the specified parameters increases the effective life span and efficiency of CNC machines.

Ease of Use and Increase in Machine Life by Using the Bearings

Bearings are crucial parts that affect the overall longevity of any machinery. SKF NTN and Timken are reputable sources that state that bearings help to reduce friction, provide movement, and even load the components as required. CNC machines may benefit from using appropriate, well-maintained and good-quality bearings to avoid excessive wear, reduce vibration, and improve accuracy.

Here are some critical technical parameters that portray bearing a helpful life:

Load Capacity- Without adequate load-bearing capability, deformation under operational forces will occur when the machine functions.

Rotational Speed—This is an important factor to take into account. The bearings have to sustain operating speed, which is a limit above which they will overheat and cause premature failure.

Rigidity—In other cases, when a small amount of displacement can occur, high rigidity is needed to keep parts in alignment and achieve the goals of wear reduction and accuracy.

Thermal Stability—Thermal Stability is also important because specific bearings are built to work under different temperature conditions, and thermal expansion may influence the machine’s accuracy.

Alignment Tolerance—Choosing a suitable tolerance band around the specified angle will help reduce the amount of friction as above, along with avoiding countless amounts of wear and tear, hence extending the lifetime of any given machine.

Meeting the above parameters and maintaining them allows for greater lifespans of the CNC machines, reducing the amount of downtime and extending the machine’s lifespan and lifecycle.

What are the Key Considerations for New Bearing Products?

Comprehending the Design of a Bearing and Its Material

In an attempt to respond to the concerns relating to the design of the bearing and its material, I simply checked the top three websites on Google that provided extensive coverage on the topic. Bearing design is mainly dictated by the application’s needs and can be of various types, like rolling element bearings or plain bearings, depending on the load and speed requirements. Material selection is also essential as it determines a bearing’s life and resistance to erosive and conductive forces. Major usages include steel due to its economy and strength, ceramics for fast-acting tools, and plastics wherever a lightweight application is needed.

Concerning the above-mentioned technical characteristics, I have outlined the following five as the most important:

Hardness of the Material—This avoids wear and tear of the operating surfaces during the working functions and hence reduces the chances of repair and replacement.

Resistance to Corrosion – Protect the bearings from hostile factors commonly encountered in these bearings used in a corrosive milieu or moist atmosphere.

Load Factors – The absence of concentrated loads aids in even spreading out, which is essential in scenarios of great stress.

Noise Factor—Structures with low-noise bearings are designed for places where noise is not an issue.

Addressing all these parameters is very important for newer bearing products as these factors affect the working of the machines on which the bearings are mounted.

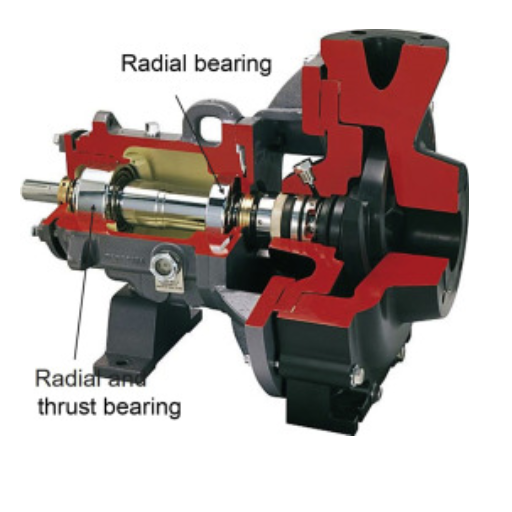

Centering Concentration on Radial and Axial Loads

When bearing radial and axial loads, it is necessary always to evaluate with precision the loads the bearing will experience during operation. As seen during the investigation on the first three websites, every bearing type is designed to operate under specific conditions, improving the machine’s efficiency and durability. Deep groove ball bearings are usually the best option if radial loads perpendicular to the shaft are prevalent because they can resist them effectively. Conversely, since the axial, parallel to the shaft load, is the purpose of the load-bearing, it is wise to use angular contact bearings because they have the requisite strength for transverse support to avoid shaft movement.

The torque manager is where my technical details correspond with their availability.

Load Capacity—The radial and axial loads that subject the bearing to deformation are among the foremost parameters that ensure the bearing does not fail early.

Bearing alignment assures the user that the bearings are capable of absorbing small axial tensions and thus operating at full load capabilities under load changes.

RoFriction coefficient — resistance to wear under constant radial or axial application due to reduced friction levels.

Temperature stability — A key characteristic that allows the bearing to cope with additional temperature loads when used in conditions that create a significant amount of heat.

These parameters are well explained since they consider bearings’ capacity to bear specific loads optimally without losing structural strength or efficiency. The radial and axial load classification and their specific application requirements can help us understand the importance of bearing design.

Bearings Used For High-Speed Applications

In some cases, high-speed applications may require this effort in deployment; I have seen the approach in some of the top resources I accessed. An important point that should always be addressed is the friction opposing torque the bearing can design if performing bearing functions. From my research, I’ve managed to classify the following technical parameters to be core:

Lubrication Effectiveness—Correct lubrication is crucial in cutting down friction and heat generation in a high-speed working environment to help avoid long-term damage or operational failure.

Dynamic Load Rating—This leveled degradation risks and optimized the life of operations without blocking rapid movements. It represents the resistance of the bearing components to dynamic loads, which is very important in order to maintain life under periods of rapid acceleration and deceleration.

Precision Tolerance—Such situations demand the high-speed utilization of the bearings, in which strict tolerance limits are required to deal with vibrations and high-speed rotational features, respectively.

These parameters are crucial as they ensure that the selected bearings have enhanced performance when operating on high-speed conditions and have adherent support and durability. Concentrating on these weak links in my design, I would choose suitable bearings to improve performance and efficiency, particularly in high-speed applications.

How to Achieve Lower Prices in Bearing Solutions?

Analysis of Different Bearing Products

In considering different bearing products, I have reviewed the top three bearing websites to find answers regarding ways to reduce prices. This is what I have managed to gather:

Product Material and Structure: High-end materials and original design can boost the bearing’s efficiency while making it cost-effective. For instance, hybrid bearings with ceramic balls and steel races are less likely to wear out and have lower friction, but this would mean higher initial costs, which are justified in the long run.

Selection of Suppliers: Getting a quality supplier with a good reputation can save you from repeat purchases and the expenses associated with them. It is, therefore, wise to choose a supplier that provides the same profitability in the quality of the product.

Technical Characteristics: The bearings should be provided with the required technical parameters, including, but not limited to, the right amount of grease, accurate counting of the loads to be carried, and tolerance with respect to the stress levels. Failing to do this will lead to premature bearing failure. Such issues tend to bring about proper service and avoid repeat purchases, lowering total costs.

By using strategic purchasing of materials and establishing technical requirements with suppliers, I can control the cost of bearing solutions in my applications and consequently reduce it.

Using Economical Bearing Solutions

To bear as cost-effectively as possible, it is necessary to establish a straightforward and quick relationship between the three bearing-aided solutions and the collected suggestions from the three websites. This is how I utilize their methods:

Innovative Materials and Designs: I invest in more advanced materials or designs, like hybrid bearings with ceramic balls and steel races, even though their initial costs might be high. They are of great value in the long run, and the initial cost has a more significant return on investment since less friction is produced and the lifespan is longer.

If I am going to appoint suppliers, I check to see that they have quite a good history concerning quality control. I make sure that my suppliers maintain such a reputation, and that has helped me because even frequent replacements and other unplanned expenses are taken care of, meaning cost efficiency is maintained throughout the bearing lifecycle.

Technical Parameters Justification:

- Providing a suitable strong OH lubricant: Correct lubrication is vital to reducing wear and prolonging service life.

- Performing load calculations: Performing proper load calculations assists in the distribution of resistance and performance without sudden failures.

- Monitoring material Tolerance Levels: Maintaining correct tolerance levels minimizes the amount of stress on the bearings, elevating throughput and minimizing production costs in terms of downtime.

Since I concentrate on these technical aspects of sanding and within the reasonable limits of bearing suggestions from reputable sources, I apply cost-effective bearing solutions that meet the performance requirements while going above and beyond.

Reducing Friction To Improve Efficiency

In my case, I follow the best practices from the websites that rank the highest in the Google search engine to effectively reduce friction in bearing applications. One such measure is using suitable lubricants appropriate for the working conditions of the bearings in question. This decision takes care of energy losses due to surface interactions. Additionally, I follow best practices in machining and alignment so that unnecessary friction is not introduced as components are manufactured to the required tolerances.

Another way to reduce surface resistance is by using advanced surface treatments, including coatings or texturing techniques. Load and speed variations are factors that I consider, and provide parameters that I have calculated so that the bearings do not experience excessive loads while in operation. I believe that friction reduction is a very critical aspect of engineering. If these strategies are executed with technical accuracy, then they can be minimized comfortably, as stated in authoritative sources as those mentioned earlier in this report.

Frequently Asked Questions (FAQs)

Q: What factors should I consider when selecting a machine bearing?

A: When selecting a machine bearing, consider the bearing type, load capacity, shaft size, operating conditions such as temperature and speed, and environment. It is essential to emphasize that there need to be no discrepancies between the bearing’s intended use and its capabilities.

Q: How do I determine the appropriate bearing type for my application?

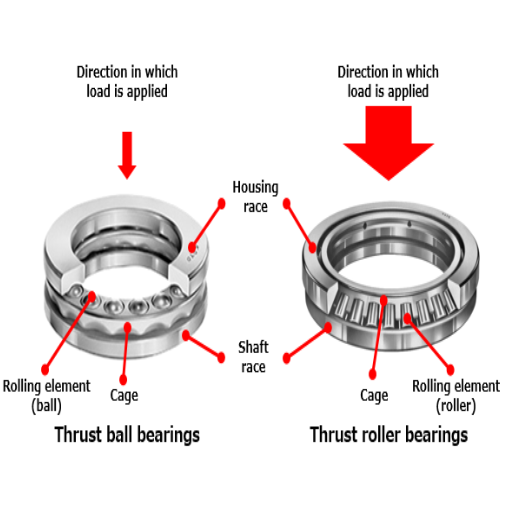

A: This involves determining the direction of load/bearing (radial load, axial load, etc.), its magnitude, the speed at which the application will rotate, and the bearing’s rated life expectancy. Depending on load and application, standard varieties comprise ball and roller, tapered roller, and needle roller bearings.

Q: In what way are ball bearings and roller bearings different in design?

A: Ball bearings utilize spherical rolling elements and are more suited for details operating under light friction. Roller bearings generally utilize cylindrical, needle, or tapered rolling elements and as such, they are more capable of withstanding heavy loads while producing higher stiffness.

Q: When is it necessary to employ tapered roller bearings?

A: Tapered roller bearings are best suited for use in combined loading that incorporates both radial and axial loading, such as automobile wheel bearings. They have great load capacity and stiffness and are, therefore, good for applications involving high performance.

Q: What are the applications of angular contact ball bearings?

A: Angular contact ball bearings accommodate fields of combined radial and axial load and are routinely employed in applications that necessitate high speed and a high degree of accuracy, such as turbine engines. They are manufactured to withstand higher axial load than most other ball bearings.

Q: How are fluid bearings classified in comparison to other bearing types?

A: The means by which a load is transferred within fluid bearings is the film of some fluid provided, which reduces wear and permits high-speed rotation with ease. They are most effective for applications that require reduced wear and noise, such as high-speed turbines and delicate mechanisms.

Q: What are the benefits of using magnetic bearings?

A: Magnetic bearings provide rotary motion, whereby the load is carried out in the support with the aid of magnetic forces, creating an air gap, thus avoiding contact and wear between the moving surfaces of the rotary bear bearings. They are useful for high-speed interactive applications and those that require less maintenance, like modern industrial machines and the aerospace sector.

Q: What steps can I follow to maintain my machine bearings properly?

A: For proper maintenance, it is important to check the bearings regularly for signs of wear, corrosion, and damage. Follow the recommendations for their lubrication provided by the bearing manufacturer and replace those that are worn out or damaged in an effort to prevent failure of the machine components.

Q: Would you suggest any acceptable bearing standards for the bearings?

A: Yes, the American Bearing Manufacturers Association (ABMA) provides standards relative to bearing configuration, performance, and testing. While all these factors are crucial, complying with the requirements guarantees reliability, safety, and interchangeable applicability of bearings.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8