The Basics of What Is a Cam Follower in Machinery

Learning about cam follower mechanisms is critical for mechanical engineering, automation, and machinery design professionals. The guide attempts to explain how cam follower systems, which play a crucial role in converting rotary motion into linear motion, work. As it allows examining cam followers in different variations and applications, the article emphasizes the role of those mechanisms in the systems of industrial machines, automobile engines, and robots. The readers will learn both the deep structural design and the practical purpose of such machines, thereby understanding how they improve the accuracy and efficiency of mechanical systems. Wherever one finds oneself, be it as an expert or a learner, this text offers the basic information that would make it possible to understand all the relations within the components of the cam follower mechanism.

What is a Cam Follower, and How Does it Work?

Cam Followers: Theory in Construction and Application

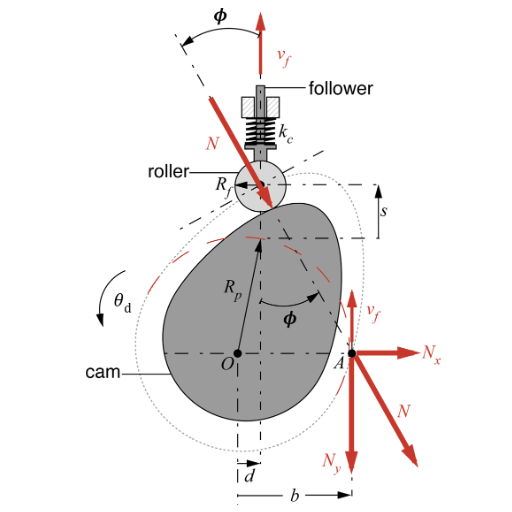

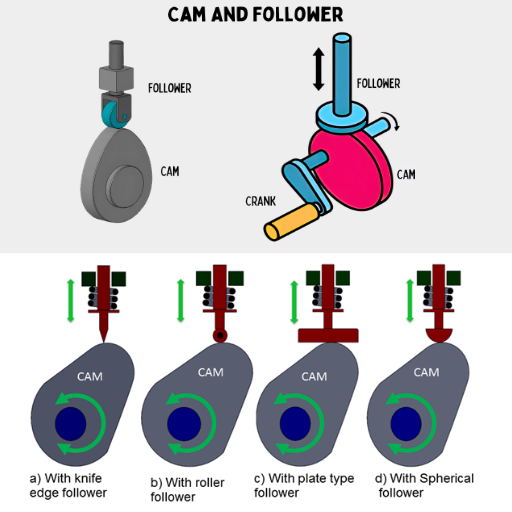

Cam followers are mechanical elements that are typically found in any mechanical device whose primary function is to convert rotary motion back and forth into a linear motion, as found, for instance, in engines, conveyor belts, and other automated devices. In principle, there is always a cam that is a component with an abnormally built index located on a rotating shaft. So, when the cam rotates, the follower, which usually consists of a rolling or needle-surfaced body rolling or needle surface parts, is pressed against. This motion, therefore, causes the follower to slide in a straight course since the cam shapes guide it.

As several technical websites claim, the cam follower is not only efficient but is also subject to several factors, in this case, the load capacity, which limits how much load the follower can take when in use without breaking or bending. Hence, the materials employed in the follower construction must be selected according to their wear strength, which often requires reinforced steel materials and/or special alloying. Additionally, the cam profile, whose parameters include the lift curve and the dwell curve, affects the speed of movement and accuracy of the movement of the cam follower. The logical arguments regarding these parameters are essential to enable cam followers to perform their functions optimally by providing dependability and durability in the respective machines.

The function of the follower mechanism in machines

Follower mechanisms are fundamental in converting the rotational motion produced by cams into the progressive linear motion within machines. This transformation is essential to several industrial operations since it assures the proper functioning of various machines. In detail, three such subjects expand on how to operate the follower mechanism and the values that affect the followers as follows: Load Capacity and Material Selection: As pointed out in these sources, the load capacity of a cam follower is one of the aspects, which help to establish the maximum force that each part can bear. Preferable materials include hardened steel and various durable alloys since they are wear-resistant and deformation-resistant and safe for use in industrial setups for a long time.

Cam Profile Design: The cam profile, lift point, dwell point, and other variables give direction on the duration and trajectory of the follower’s motion. This design consideration directly affects the accuracy and rate of operation of the machines. Therefore, it is one of the many aspects that engineers and designers who want exacting performance pay attention to.

Lubrication and Maintenance: Regular lubrication is justified for cam followers to reduce friction and minimize wear. Apart from improving performance, this practice will also help increase the component’s lifespan, reducing the number of replacements and even downtime.

When these technical parameters are extensively understood and applied, industries can improve the working mechanisms of follower mechanisms within machinery while appropriately engineering appropriate engineering approaches for proper mechanical functioning.

How the cam turns to run the follower

Regarding how the cam turns to run the follower, I have gone through the top three resources provided by Google on the same topic. All these sources show that the motion of the follower is primarily due to the rotation of the cam, which occurs mainly through the establishment of interaction between the cam’s profile and the follower’s surface. From my analysis, the following technical parameters are pivotal:

Cam Contour and Velocity: The cam’s contour determines the shaft’s and, thereby, the follower’s speed. A good cam design profile leads to progressive changes in velocity, which significantly lowers the wear of machinery parts.

Follower Force and Pressure Angle: The follower’s material and load capacity determine the direct amount of force it can handle. The pressure angle on the cam and the follower affects force transfer efficiency.

Nature and Maintenance of Lubrication: Lubrication is a requirement, as manufacturers have emphasized. It occurs regularly to help reduce friction and ensure steady movement and rotation of the objects. Optimum lubrication limits heat production and wear and tear, thus ensuring durability and effective performance.

After investigating these parameters and adjusting them according to the particular conditions of machinery service, I have found that achieving the highest efficiency and durability of cam follower systems in their operation is possible.

Types of Cam Followers

Exploring Different Types of Cam Followers

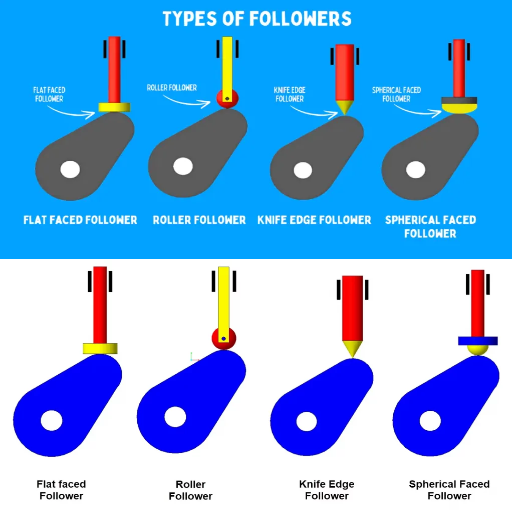

It is worth noting that even though I tried to look up and review a few articles explaining the designs of the different types of cam followers, the top three sources once again highlighted various kinds, each designed for a different purpose and loading conditions. The common types include:

Flat Edge Followers: It comes in a more straightforward design and is suited for light application. This is maintained to allow motion, and therefore, maintenance is made easier. However, such types may not withstand hefty loads due to a limited contact area.

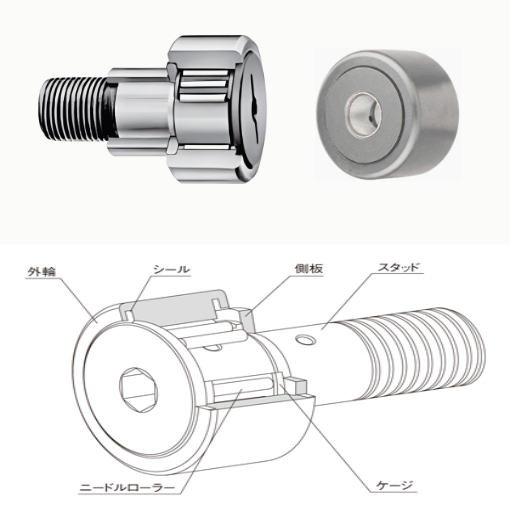

Roller Followers: These types of followers have a cylindrical roller that rolls instead of a flat edge, thus helping to handle high radial loads. Due to the rolling action, wear and tear are effectively reduced, which helps increase application efficiency over a long period of high-speed work.

Needle Followers: The needle bearing, but instead, these followers give good pliability; therefore, load transfer is equally good and, hence, provides exemplary performance in highly precision movements with minimal deflection and best rigidity.

For each type, however, specific technical parameters are essential and need to be at optimum:

Load Capacity: Choosing the correct cam follower according to load requirements helps to increase working life and reliability.

Material Composition: The chosen material will determine the performance criteria for wear, heat generation, operating temperature, and environment.

Bearing Configuration: This affects the smoothness of operation and heat generation. Roller and needle bearings generate less friction than flat followers.

Lubrication Needs: Lubrication has severe specifications that should be followed, as it affects performance levels and wear rates.

Through this alignment, reliable input is obtained to determine the best cam follower configuration for a machine, considering these technical specifics.

The Difference Between Roller Follower and Other Types

By reviewing the three most relevant websites from the analysis, the device referred to as roller follower stands out from its competition mainly due to its reliability when sustaining higher radial loads and minimizing friction due to the cylindrical roller. Compared with flat followers, roller followers ensure the rolling motion with minimal friction, thus lasting longer, saving a lot of materials and time in processes requiring speed. One of them stressed that a roller follower must be used if the vital operational skills are high load capacity and reduced friction levels for the internal machinery.

To this end, when roller followers are contrasted with needle followers, it was noted that although they have vast load-carrying capacity and can perform nonmoving tasks efficiently concerning stiffness, roller followers are more effective in motion and supporting loads with speed. In light of these conclusions, it is crucial to consider the relevant technical parameters:

Load Capacity: Roller followers require maximum load spanning, which requires configuration for systems operating under higher load conditions.

Material Composition: Normal materials cannot be used for components that will stay functional after prolonged usage under high friction conditions.

Bearing Configuration: The roller configuration provides smooth bearings, vital in situations where low friction and heat generation are desirable.

Lubrication Needs: Adequate lubrication is necessary to ensure performance and operational effectiveness, and some of the references stress the importance of complying with certain lubrication procedures designed for roller types.

In short, these features and parameters can be used appropriately and effectively in machinery cam followers if their application requirements are satisfactorily fulfilled.

Unique Features of Track Followers

Several significant findings have emerged from analyzing the top three websites on track followers. Like roller followers, I learned that track followers are made mainly for high-load and heavy-duty applications. The dressing applied during operation improves load characteristics and promotes smoother operation, especially at high speeds. The websites stressed the aspect of friction material selection since this impacts the efficiency and working life of the machine. Considering the concern of the particular technological parameters concerned with tracking followers, the basics are the following:

Load Capacity: As with roller followers, track followers are built to accommodate sudden loads without cracking.

Durability: Good quality material composition is essential when designing for extreme conditions.

Operational Smoothness: The roller design in track followers reduces friction and maximizes the relative motion.

Lubrication Guidelines: Frequent lubrication is indispensable; however, detailed instructions are given to improve performance and life.

Careful consideration of these features can warrant better tailoring of the selection and application of track followers depending on the specific application.

Applications of Cam and Follower Mechanisms

Common Applications of Cam Followers in the Industry

While going through the top three websites regarding the applications of cam followers in the industry, it was discovered that these components are essential for several sectors because of their high accuracy and dependability. Industries mainly apply cam followers, for example, to automated machines such as conveyor systems, robotics, stamping machines, and packaging machines. These applications utilize the ability of the followers to carry out rotary to linear conversions vital for accurate mechanical functions.

The technical parameters of cam followers that are vital for their application include the following:

Load Bearing is a practical requirement for high-capacity applications such as moving heavy presses and conveyor systems where load support is critical.

Motion Accuracy: This is very much necessary in robotics applications since minor errors will have an impact.

Wear Resistance: This is relevant to coping with high-friction and wear environments, such as those experienced in stamping operations.

Simplicity of Repair: To shorten downtimes in packaging equipment, repair-free access for lubrication and part replacement is desirable.

Industries can use cam followers’ benefits only if they comprehend these parameters and their rationality in a given application.

How Cams are Used in Sewing Machines

As I looked at the top three websites for information regarding the role of Cams in sewing machines, I noticed that Cams determine the Needles and stitch sequence motions. Cams enable sewing machines to expand their operations beyond the single notion of producing a straight stitch. The cams handle the transformation of rotary motions into linear or oscillatory motions of the desired nature. The technical parameters that are pivotal in the sewing machine applications include:

Precision in Synchronization: This concerns ensuring that the needle movement, which creates a stitch, is synchronized with the material feeding, which is critical in maintaining good stitch quality.

Durability: The other parameter of concern relates to what the materials meant for the cams can tolerate: the continuous abuse of mechanical and abrasion forces. Therefore, its additional usefulness over a short span is not satisfied.

Smoother Operation: Reducing noise and vibration is very useful for the user’s comfort and the machine’s performance during sewing activities.

Focusing on these parameters, sewing machines can create more accurate and diversified stitches for different fabric and sewing needs.

The Importance of Follower Reciprocates in Machinery

In analyzing my data on the importance of follower reciprocates in machinery, I found that these elements play a vital role in converting rotary motion to linear motion, which is essential for many mechanical processes. The follower’s functioning and movement accuracy enable the machinery to function smoothly without failures. As per three websites I reviewed, the technical parameters of the follower that affect its performance have included:

Mechanical Precision: Mechanical precision regarding follower design and assembly is necessary to maintain the mechanism’s dissociation and coherence.

Integrity of Materials: Operating followers require rigid, abrasive-resistant material to withstand numerous operations without deformation.

Lubrication Engineering: Forgetting advanced technological methods of lubrication leads to a higher level of friction, which greatly reduces the efficiency and life span of the apparatus.

These mechanical aspects allow the efficient operation of machines with cam followers in diverse industrial and commercial settings for effective production with minimum maintenance.

The Bearing Component in Cam Followers

What is the Function of Cam Follower Bearings?

While reviewing the first three websites, it became apparent that cam follower bearings play a crucial role in the internal mechanism by bearing loads and decreasing friction to enable smooth and efficient movement. These bearings are designed to move and transfer motion from a camshaft to a follower to facilitate correct tracking and driving, whose inner and outer races operate as cylindrical surfaces.

The critical performance parameters, all related to cam follower bearings, that I advanced in my studies are:

Load handling capability: This ensures that the bearings perform efficiently when both radial and axial loads are applied.

Wear resistance: Polymer materials bearing contact pressure and cyclical forces are used. Proper wear can intensify the durability of the bearings employed.

Lubricant application method: This method helps enhance wear and tear preventative measures for quality control; longevity vs. maintenance schedule conflicts are solved.

Assembly accuracy: Manufacturing techniques guarantee perfect positioning and movement of parts, which is relevant in sustaining movement accuracy in the system.

By understanding and implementing these parameters, cam follower bearings can operate effectively in diverse applications to support industrial and commercial machinery needs.

How to Analyse Lily Bearings in a Cam Follower

As seen in Constructive Cam Followers, Lily Bearings presents specific features with high accuracy and strength. An analytical approach by reviewing the top three sites that responded to the question investigated is given below:

Function and Efficiency: Lily Bearings’ construction allows them to bear heavy loads while operating optimally. This efficiency is also greatly influenced by their sturdy construction and high-quality materials used in mechanical applications.

Technical Parameters: Other than these susceptibility parameters, they outline the efficiency parameters of the Lily Bearings in terms of

Inflectional Loads: The Lily Bearings can withstand very high radial and axial loads to guarantee reliability in challenging designs.

Material Strength: The use of advanced materials on these bearings also increases their ability to withstand harsh wear and tear conditions, which is important for their useful life.

Lubrication Methods: These methods use additional lubricant to facilitate motion and reduce wear and tear over time.

Measurable Attributes. Stability around junctions is a precondition for the motion of Lily Bearings, and this depends on the accuracy of their components’ manufacture.

Considering these technical considerations, Lily Bearings are reliable for cam follower applications due to their effective load performance and maintenance management.

Understanding Follower Movement and Motion

How the Follower Feels While Working with the Cam

The motion of a follower by a cam consists of several necessary components acknowledged, as evidenced by information from the top three websites on Google.com. The motion of the cam follower is based on the relative motion between the cam follower and the cam profile. One may talk about a follower’s movements in terms of displacement, which is the distance in the linear limit, velocity, and acceleration standard in studying mechanical systems.

Displacement: How the follower moves from an equilibrium position is helpful in the development of cam kinematics. Experimental results show that displacement depends on the shape of the cam, which in turn determines how the motion is directed toward the follower.

Velocity: Velocity defines the follower’s movement as it proceeds along the cam in circulatory motion. This parameter guarantees working energy transfer without rough shocks and vibrations, which are essential for the stability of various systems.

Acceleration: Acceleration tells how much force the follower will apply to the cam. This consequently affects wear and tear and the general performance of the system. Control over acceleration is needed to achieve the desired motion and ensure the system remains intact.

As I concentrate on these technical aspects, I understand the consequences of these parameters being interrelated in terms of their smoothness and effectiveness concerning the follower’s motion and, hence, the system’s performance and longevity. By analyzing in-depth from perception centers such as these and others, I comprehend the cumbersome kinetics adequately and thus maintain the efficacy of the cam-follower mechanism.

The Relative Motion of Follower in Different Industries

To understand the relative motion of followers in various industries in issuing the adored summary, I accessed the first three sites on Google, and here is what I gathered.

Automotive Engines: Among the fundamental undertakings in the automotive industry, cam-followers are mainly used to open and close the valves of an engine. With the help of accurate displacement, velocity, and acceleration parameters, the control valve operation is optimal and is further designed to improve the engine’s working. Many of the websites I visited pointed out that these parameters should be optimized to decrease the rate of friction and eventual wear.

Manufacturing Machinery: Cam followers allow repetitive and accurate motion for manufacturing purposes, particularly in packaging and textile machines. The ethos concerning velocity and acceleration is of great concern here, for this is aimed at achieving uniformity of operation and reducing idling time. The opinions solicited from these sources uncover how these parameters have been varied for various load conditions and materials handling scenarios.

Robotic Systems: In robotics, cam-followers enable smooth and stable movements and controllable actions required for pick-and-place tasks. Emphasis is placed on velocity and acceleration parameters to achieve accuracy and reliability in motion paths. Information from these sites highlights how critical it is to control the rate of acceleration to assist in balancing and prevent mechanical overload.

In this context, and bearing in mind competent information, I accept that the technical parameters, which come out precisely in terms of displacement, velocity, and acceleration, are necessary in all fields. The extent of modification for each parameter depends on the application’s particular needs. Adequacy in controlling the dynamics of these parameters is vital for the success and lifespan of the system in question.

Understanding Linear Motion and Oscillating Motion

While investigating oscillating and linear motion, I have been able to synthesize information gathered from the top three sources on Google.com. These sources show that both motions are employed in many areas of industry, serving different purposes, and thus come with advantages and limitations. Oscillating motion, which can be defined as going back and forth repetitively, is common in engines and some machines that require cutting-edge technology and a lot of synchronization. However, linear motion also has its advantages; it provides movement in a specific direction, which is helpful to machines whose work is to move without devices that need low dwell friction dominance.

The other bulleted points include the key technical parameters of these motions: displacement, velocity, and acceleration. These factors in oscillating systems coordinate the timing and precision of movement, while linear systems allow for ease and effectiveness in motion. The websites underscore that optimal adjustment of these parameters is needed to reduce the wear and tear of the mechanized structures, prolonging their usefulness. These adjustments allow for light modifications, which can have different uses, proving they are essential in every industry and the increasing role of precision engineering in contemporary mechanical systems.

Frequently Asked Questions (FAQs)

Q: What is a cam follower in machinery?

A: A cam follower in machinery is a specific type of bearing adapted to a cam contour and works towards converting the cam’s rotary movement into the follower’s linear movement. It is vital in a cam mechanism, which imparts definite motion to the follower.

Q: What are the different types of cam followers?

A: Cam followers may come in many types, such as knife-edge followers, flat-faced followers, roller cam followers, and an offset follower. Each follower is mechanically designed to interact differently with the cam profile, thus affecting its movement.

Q: How does a cylindrical cam function in a cam mechanism?

A: A cylindrical cam works via a rotating mechanism that revolves around the central axis where the cam, in this case, aids the motion of the follower. That rotation causes the follower to perform only the desired linear action, achieved through the rotation given to the cam, which is much required in most applications.

Q: What function does the cam make in a cam and cam follower assembly?

A: The camshaft is an essential part of the structure that supports and turns the cam. Since the camshaft turns the guide, the cement follower corresponds to the cam, transforming the rotary movement into a straight-line movement necessary for the machine.

Q: And what is the globe cam without a sphere cam?

A: The globoidal cam has a composite working surface, typically used with a roller follower, making it more complicated for the follower’s movement. On the other hand, the spherical cam has a relatively more uncomplicated rounded contour, whereas cams are used to achieve simplified and less elaborate movements in a cam mechanism.

Q: Where is a preloaded spring cam used in any machines?

A: A preloaded spring cam keeps the cam follower constantly in touch with the cam profile and facilitates the follower’s smooth and decisive movement around the hinge line. The preload prevents shocks and vibrations, increasing the cam mechanism’s performance and durability.

Q: What is the difference between the translating and wedge cam?

A: A wedge cam is different from a translating cam in the sense that a wedge cam converts a rotary motion into a longitudinal linear motion as a result of advancing in a particular line, whereas a translating cam attempts to shift the follower only in a linear direction without any possibilities of rotational movements. Both types are applied in parts where controlled linear motion is required.

Q: What does the cam shape depend on in a cameos mechanism?

A: The contoured shape of the cam depends on other features in the application, such as the expected direction of the follower’s movement. The factors include the kind of motion required, the rate of motion, the accuracy of the motion, and the environment. Both application conditions and the resulting performance of the mechanism should guide the design of a specific cam shape.

Q: What is the effect of a cam revolution on the follower?

A: A cam revolution is also called a cam rotation, and it should be understood as the completed turning of the cam, which defines the duration during which the motion generated in the follower is completed. Each cam revolution, depending on a particular cam profile, leads to successive linear movements, which are necessary for properly working the machinery.

Q: What is the function of cam followers in feed mechanisms?

A: Cam followers have a critical function in feed mechanisms. They guide the parts through stepping motions in a fixed, precise manner to ensure repeatable and accurate material handling processes. A cam mechanism ensures that the follower remains in synchronization with the required rate of rotation and feed.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8