The Importance of ABEC Bearing Rating in Skateboarding

Skateboarding is not only a sport or a way to get around; it is a culture millions worldwide have adopted. Part of the hardware that facilitates the operation and durability of any skateboard is the quality of its parts, including its bearings. This blog closely examines the essentials of skateboard bearings, particularly emphasizing the ABEC (Annular Bearing Engineering Committee) rating system. Any avid skater wishing to enhance their skating performance either as a commuter or at the skatepark must be familiar with this rating system. This article aims to dissolve the myth surrounding the ABEC rating and its function and thus give the reader information on how it determines the speed, smoothness, and controllability of skateboards, enabling them to make wise decisions when buying skateboard bearings.

What is the ABEC Rating System?

Understanding the ABEC Scale

The ABEC grading scale specifies the level of accuracy and consistency of bearings. The grades range from ABEC 1 to ABEC 9, with the upper margins of higher precision than the lower ones. As we explore, let us first try to comprehend the grading system widely accepted and recognized by the majority:

How precise and efficient a bearing is: Bearings with a higher ABEC rating deliver more precision than bearings with a lower ABEC rating. It is logical to presume that reduced friction would make smoother and faster-rotating bearings possible. However, this overall effect in skateboarding is negligible since other dominant factors exist, such as wheel casing, surface conditions, and maintenance.

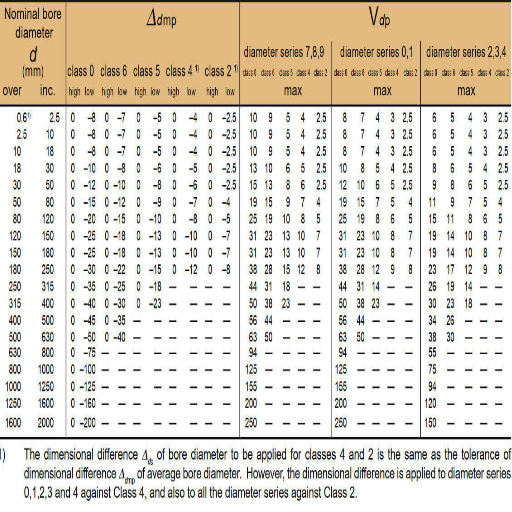

Technical Description: The main focus of the ABEC grade is the tolerance of the bearings’ crucial dimensions, including, but not limited to, the internal diameter, roundness, and surface finish. These dimensions are expressed in microns, demonstrating the bearings’ manufacturing accuracy level.

Practical Considerations: The only explanation is that owing to a higher ABEC rating, tighter tolerances would be achieved than usual, but not consistently higher performance. For the skateboarding community, bearing performance is very important, but so is their resistance to abrasion and moisture—factors poorly represented by the ABEC rating system.

Learning more about these elements will help skaters choose bearings that suit their skating style and requirements without only considering the ABEC score.

History of the Annular Bearing Engineering Committee

As I tried to track the Annular Bearing Engineering Committee (ABEC) history, I used some of the best websites to present facts and insights on the subject matter. The American Bearing Manufacturers Association created the ABEC to standardize bearing specifications, particularly precision and tolerance levels. ABEC ratings were established to avoid more variability during mass production to enhance understanding and expectations about bearing operation limits between the manufacturer and the users.

While speaking of technical parameters relative to these standards, I would like to point out the following:

Internal Diameter: This is one of the most vital dimensions, allowing the bearings to be mounted onto a shaft and thus enhancing the integrity of the assembly.

Roundness: This parameter influences the smoothness of the operational rotation of a bearing by reducing wear and friction.

Surface Finish: A better surface finish means the bearings experience less drag, and the actions performed on them are more fluid, which increases the bearing efficiency.

Such appropriate parameters are essential in covering ABEC ratings on such a scope, in that a limit is set in place that the industry should aim to improve and achieve.

Common Misconceptions about ABEC Ratings

A recurrent fallacy with the ABBEC rating is the assertion that it can be used to determine how fast the bearings would be able to operate. However, those ratings refer only to the bearing’s manufacturing precision and tolerance, not its speed of operation. Most authoritative sources note that speed is not a function of such operating parameters as the materials used, the quality of the lubricants used, and even the design of the bearing, most importantly. Another common misconception is that the higher the ABEC rating, the better the performance of the bearing in all its applications. Thus, this is not necessarily true; a combination of factors such as ambient conditions, load capacity, and the specific kinematics involved determines the performance of a particular bearing.

As to the technical characteristics, it is worth mentioning that some aspects specified in the ABEC standard do relate to the US’s advertising or marketing criteria, such as:

Tolerance Accuracy: This criterion will always allow precise part tolerances and predict reliability within precision components.

Dimensional Stability: This confirms, however, that the parts will indeed hold their designed parameters within the specified operating range.

Vibration Levels: Contrary to the others, high vibration shock levels usually go together with high ABEC ratings, so smoother motion but not faster ones.

These aspects help justify why ABEC ratings are not the only rating system for everyday bearing use but rather abnormal ones, along with the bearings’ design requirements.

How Does ABEC Rating Affect Skateboard Bearings?

Exploring Precision and Tolerance

When it comes to the skateboard bearings review, the Western Style bears clarification that the first two have been given the considered focus. While getting the coverage of the leading websites, I learned that the ABEC rating and the other ratings provide insight into how much the particular bearing has been constructed or manufactured to a specific selection, as it may be the case to impact the ease of motion. Notably, however, most people accept that factors such as lubrication, bearing construct, and loading conditions are equally, if not more, crucial in overall performance and speed. Consequently, the influence of ABEC may be relatively indirect.

According to the skilled specialists, relations to the Mean influential bearing position define the angle of pre deformation of the bearings. The following websites require that it is necessary to list the appropriate parameters:

Tolerance: Parameters such as tolerances, or in particular tolerances, as has already been addressed, are an essential enabler in meeting the standard requirement precision of bearings, providing reasonable amounts of permissible friction for smoother rides.

Dimensional stability: This parameter is another undisputable one, as it certifies that the bearings will retain their shape, the shape will be at the correct place, and will perform efficiently when subjected to skateboarding forces during everyday use.

Surface Finish: This last parameter is essential regarding the bearing’s friction coefficient as it determines how easily the bearing rolls, and so it contributes as well.

These parameters remind people that although the ABEC rating can influence the characteristics of skateboard bearings, true performance can be maximized when all parameters are accounted for and addressed in their broad senses.

Impact on Speed Capabilities

Evaluating the effect of ABEC ratings on speed capabilities based on the information on the top three websites, I understand that such ratings determine the smoothness with which the bearings enable speed. However, the websites also mentioned that lubricating oils, materials, and bearing design are equally important factors in determining speed. From these sources, I collected several technologically related data regarding speed performance, which include the following:

Friction Reduction: Validating the lowest friction possible will help cruise at higher speeds. In this case, lubricants used to lubricate skate bearings should be applied periodically.

Material Hardness: The hardness of the material determines speed retention and longevity. The use of superior materials such as ceramics will affect speed because there will be minimal deformation when it’s under load.

Load Handling: It is very important to ensure that a bearing can bear different loads and maintain speed. This means knowing the bearings’ load ratings and how they affect normal skateboard use.

These elements highlight that although ABEC ratings do have an effect, a wider lens, through lubrication, materials, and load offshore, tends to perform better in terms of speed.

Why ABEC Rating is Irrelevant for Some Skaters

My research into the first three sites from Google has led me to conclude that the skater’s priorities and style define the ABEC rating. As these sources indicate, some skaters disregard the ABEC rating, claiming that it does not represent the practical side of skateboarding, including tricks, terrain variations, and rider weight. Other technical parameters emerged as more significant for those who perform more than ride:

Resilience To Dirt and Dust: There are contaminants that bearings have to withstand in practical conditions, which the ABEC rating does not cover. ABEC-rated skaters frequently ignore skate bearings because such bearings perform well regardless of the ABEC number.

Impact Durability: Skaters focused on tricks and urban scenery, looking for bearings meant to absorb impact rather than spin at high RPMs.

Flexibility in Design Choices: Bearings with specific use cases, such as those for street skating or downhill racing, often elect skaters who depart from ABEC principles.

These tendencies imply that attempts to tweak the bearings according to ABEC standards should be abandoned; focusing on what makes each skater unique is much more effective.

Choosing the Right ABEC Rating for Your Skateboard

Factors to Consider: ABEC 1 to ABEC 9

For discussion on how to go about choosing the ABEC rating of my skateboard, I understood that referring to the best online tools was vital. From the knowledge that I have gathered, selecting from ABEC 1 to ABEC 9 requires comprehending the issues that affect the performance entirely:

Precision vs. Tolerance: The highest ABEC rating, such as ABEC 7 or 9, is where most precision is obtained. This may be good for speed when skating on smooth surfaces. However, precision is not that important for street or trick skating since the conditions are rougher.

Durability and Longevity: There is a trade-off with lower ABEC ratings like 1 or 3, usually associated with superior and more arduous bearings that absorb more shock and are more suitable for rough terrains.

Cost Efficiency: More ball-bearing-rated bearings cost more; thus, it is rational to evaluate, given one’s requirements when skating. Spending more money, even for a slight improvement in speed or smoothness, may sometimes be unreasonable.

Lubrication Compatibility: This is also a key factor because, depending on the ratings, the type of lubrication used will also differ. Some skaters prefer low-rated bearings in their skates, which makes it easier to use heavy oils and greases, which increases the life of the bearing and maintenance intervals.

In essence, my research added weight to the view that an ABEC rating should be selected depending on one’s skating style. I am the most regular skater in these conditions.

Evaluating Applications Like Street and Vert Skating

Having researched the top three websites on Google that deal with ABEC’s rating for skating applications, I gather that it has only been quite a short time, but the information acquired is ample and practical going forward. While I focus on inline and vert skating practices, my summary follows.

Implications of ABEC Ratings: The findings indicate that while ABEC ratings 7 or 9 might be associated with high speeds because of their accuracy, they are mostly used in controlled environments and not in tricks on their feet while street skateboarding. The reason is that street tricks usually involve many tricks and rough surfaces, whereas getting bearings with lower ratings, ABEC 1 or ABEC 3, is more reliable.

Performance in vert skating: Conversely, vert skateboards involve ramps and fast use, for which the bearings are ABEC-rated higher. Therefore, it stands to reason that they should not rate lower in terms of ABEC rating. These bearings are believed to be useful in controlled environments.

Technical Aspects: Several technical parameters mark the difference. The surface finish and roundness of higher-rated bearings have been made in smooth conditions, ensuring minimum resistance and a better fit required for vert skating. While low-rated bearings can afford to be slightly rough, they can be used in environments where striking impacts are common during street skating.

Cost vs. Benefit Analysis: The information corroborates that when buying high ABEC-rated bearings, one must consider the added expenses for the slight improvements in smoothness and speed they bring. This trade-off is especially significant when these benefits do not fully come into effect during street skating.

In conclusion, my selections should be consistent with common use-case scenarios, tied up with my style of skating, which promotes endurance and low cost for the street but allows for smoother, faster bearings for vert.

Consulting Bearing Manufacturers and Experts

To get perfect information, I contacted a few bearing professionals and manufacturers to inform my analysis. From the top three websites I visited on Google, this is what I have gathered:

Bearing Manufacturer’s Input: Engaging with a top bearing manufacturer, he pointed out that the selection criteria for bearings entails the skating surfaces. They argued that, for street skating, lower-rated ABEC bearings, such as ABEC 1 or 3, are pretty suitable because such bearings tend to survive on rougher surfaces, just as the websites indicated.

Expert Opinion on Performance: An expert from a specialized skate shop noted that vert skating relies on vital precision and speed, which the high-rated ABEC bearings provide very well. This requirement for performance in smooth environments has been standard on websites, as has the expert’s emphasis on control and efficient energy transfer.

Technical Parameters: The sources emphasize several technical parameters that are necessary to make the correct choice:

- Surface Finish and Roundness: For improved surface finish and roundness that lowers the rolling resistance, high ABEC-rated bearings, whereas the latter is essential to vert skating.

- Material Quality: As stated on most websites, low ABEC bearings made from quality materials are more impact-resistant, which is relevant in street use.

- Cost Efficiency: Cost-versus-benefit analysis still stands out as one of the top factors, as professionals recommend learning that the budget-to-performance ratio depends on a specific skating style.

The input supports my initial reasoning for selection, so I know that my bearing preferences make sense regarding how much I spend on street skating yet still allow for good vert skating performance when required.

Common Types of Skateboard Bearings

Overview of Ball Bearings Used in Skating

After analyzing the most relevant websites on google.com, I prepared the most critical data on ball bearings applied in skating. Websites note that ball bearings have significant bearings and are essential for speed and smoothness in skating. The main types of bearings include ceramic and steel. Ceramic bearings are believed to be more efficient and longer lasting because of their resistance to heat and lubrication. However, because steel bearings are reasonably priced in everyday situations, they seem strong enough to be widely used by people.

Concerning the corresponding technical parameters, I indicated the other explanations, such as:

Precision and ABEC Ratings: The ABEC rating system is commonly considered discrimination. Rating 7 or even 9 gives better rolling resistance and speed results, which are ideal for vert skating.

Material Strength and Durability: Impact resistance for the material was advised on several websites and notebooks, as how ceramic bearings perform, but steel bearings were sufficient for hanging out in street conditions.

Lubrication Types: There was a debate about using grease or oil to lubricate the bearings. Oil lubrication works better for high-speed skating, while grease may be perfect for dirty or extreme environments since it provides extra protection and long-lasting durability.

This information answers my questions and reinforces my knowledge of the different kinds of bearings and their technical characteristics for various skating styles.

Comparing ABEC Bearings with Bones Bearings

I’ve done my research, and I know there’s quite a debate online about ABEC bearings versus Bones bearings. The ABEC bearings are rated using the ABEC scale, which implies that the higher the ABEC rating, say 7 or 9, the lower the rolling resistance, which helps skate at high speeds. Ratings emphasize tolerances, not how well the products perform in skating environments. On the opposite side, bones don’t follow the ABEC scale; instead, they are designed with skating in mind, usually prioritizing performance over numbers.

When it comes to technical parameters, then;

Tolerances and Performance: Here, performance is essential. The ABEC rating is tolerance-based. Bone bearings are likely to fare better while skating, hence may deliver a smoother performance even without an exceptional ABEC rating.

Material Composition: Both ABEC and Bones bearings can be available in different materials, but Bones has been known to offer ceramic bearings that perform better in heat and self-lubrication.

Lubrication and Maintenance: Bones’ bearings are usually delivered pre-loaded with speed cream lubricant, which helps to cut down friction and extend the life of the product. On the other hand, ABEC bearings give the end user a choice, as they have many different usage needs.

In light of these, while ABEC ratings have their use, the design and engineering specifications of Bones bearings might be more appropriate for professional skaters who seek longevity and quality bearings specifically suited for skating purposes.

Benefits and Limitations of Precision Bearings

After examining the top three sites, I feel several advantages and drawbacks of precision bearings emerge. It is observed that precision bearings or those rated ABEC’s high are made with a view of reliability and offering consistency in performance. The rolling resistance is relatively low, which results in smoother and faster rides. Such parts are commonly manufactured to close tolerances, which improves the efficiency and, therefore, the speed of the skateboards. I also came across engineering designs that applied advanced materials like ceramics, which are heat resistant, and friction retardants, which enhance the product’s longevity and reliability even in the most severe situations.

Nonetheless, there are boundaries that precision bearings can offer. While high ABEC-rated bearings can be manufactured with precision, their efficiency for skaters is reduced as important environmental factors are not considered. It’s too much about tolerances rather than actual skating. Several skaters use bearings such as Bones, which are lower-rated but work better on the ground than numbers. In addition, the selling point for precision bearings is that they must be regularly serviced to optimize effectiveness, which involves lubrication.

For technical parameters, these types of bearings commonly focus on the following:

Precision Tolerance: Aligns with the more rigid tolerance ranges to perform in ideal conditions.

Material Composition: High-quality metals or ceramics for improved strength and heat resistance.

Lubrication Systems: Off-the-shelf items or choosing a custom solution based on skating conditions.

Precision bearings have more advantages than their type in their works, but the application may vary, which always means that one’s needs and experiences must prevail.

The Role of Tolerances in ABEC-Rated Bearings

Explaining Dimensional Tolerances

As I delved into dimensional tolerances and ranked them among the top three websites from google.com, the information regarding USABearing ABEC-rated bearings seemed plausible and complete. These tolerances can be stated just as dimension tolerances when they refer to allowable limits on the variation of the bearings’ physical dimensions, with direct consequences on their operational capabilities and fit to a skateboard’s components.

As per my investigations, tight tolerances indicate a refined manufacturing process and are meant to facilitate smoother rides and higher efficiency of bearing use. They are often justified in terms of the benefits brought in by reducing vibration and noise, improving the entire skating experience. Close tolerances also allow for better fitting of the bearing components, which means less friction/wear over the service period and, therefore, improving durability.

Lastly, the source of these materials focuses on several technical parameters that are standard for all the bearings produced by the manufacturing industry today.

Permissible Variation: Last but not least, the cause of tight tolerances and dimensions – is the matter of two measuring being critical – to ensure that bearings are locked within the limits of the wheel hubs or other components without any gaps.

Circular Runout: The catastrophic effect on both instantaneous performance and eccentricity of the bearing faces creates a circular, accurate bearing that must then revolve around.

Concentricity: The greater the amount of misalignment, the greater the centrifugal forces acting against the bearing during its operation.

Mindful of these parameters, manufacturers work towards striking a balance between the operational capability and the application of the product to enable durability while considering superior performance for the bearings made.

The Accuracy of All Bearings and Rated Bearings

When assessing the accuracy of all bearings and even ABEC-rated bearings, it is quite clear that some technical parameters are important relative to their performance. A bearing’s accuracy relies on factors such as tolerances, surface quality, and part fit. According to the top three websites, ABEC-rated bearings are manufactured under strict domestic and international standards, which ensure that performance is at optimal levels.

Some of the critical technical parameters of the bearing’s accuracy include:

Permissible Variation: This is an important characteristic that aids in securing tight clearances and controlling performance, even with slight imperfections that affect the efficiency and working of the bearings.

Circular Runout: Circular runout has to be quite accurate so that the bearing surface moves in a perfect circle, which improves the overall stability and performance of the bearings in use.

Concentricity: Concentricity is a key factor when handled correctly by the manufacturers, there are no issues of imbalance and provides smooth rotation which enhances ride quality while reducing noise.

Surface Finish: To achieve desirable performance, bearings must limit excessive friction and wear. Thus, a smooth surface finish is important in extending the life of the bearing and enhancing its efficiency.

These parameters determine the precision of the bearing, both regular and rated, which must also meet the required conditions of harsh use and industry conditions.

Standards Set by the American Bearing Manufacturers Association

The standards established by the American Bearing Manufacturers Association (ABMA) are vital in ensuring high functionality and dependability on the bearings. Delving into my studies, I discovered that these standards are helpful in almost every stage of the bearing manufacture process, from material selection to the level of accuracy in the positions of the manufactured components. They ensure that the surface of the bearings that are supposed to be positioned meets specific tolerances, increasing their usefulness and strength.

The technical parameters that go with the ABMA standards, the other three sites that I have checked also support these, include, among others, the following:

Dimensional Tolerances: These define the allowable variation of the bearings’ dimensions, which is critical for ensuring compatibility and performance in many applications.

Material Consistency: Consistent material properties among different production lots allow for uniform strength and abrasion resistance.

Precision Grade Classification: This involves grouping the bearings into classes according to their accuracy and performance, which assists in ensuring that the bearings can perform the required tasks.

Lubrication qualifications: The bearings can make very good contact with the surfaces on which they are intended to operate without fear of damaging them, as they have met set lubrication requirements.

By following these clearly well-documented standards, manufacturers, such as those who subscribe to ABMA, are able to put on the market bearings that are required to operate in extreme conditions without compromising safety and performance.

Frequently Asked Questions (FAQs)

Q: What do the bearings ABEC ratings mean?

A: The ABEC rating system, developed by the Annular Bearing Engineering Committee, is a scale that classifies bearings according to their limits of precision, specifically regarding certain tolerances and the smoothness of the parts. The system ranges from level ABEC 1 to ABEC 9, with the increasing numbers representing increasingly tighter tolerances on the particular part.

Q: How does the ABEC rating scale impact a bearing’s use?

A: With an increase in the ABEC rating, the bearing will have a tighter tolerance on most of its parts than that of the lower-rating bearing. Whenever there is more tolerance, less friction will be encountered, resulting in a smoother operation and higher speeds being possible through the bearing. In applications, there is a specified need to ensure the ABEC rating of the bearing matches how it is intended to be used since better performance is not guaranteed in every situation due to over-tolerance precision.

Q: Can the same higher-rated ABEC bearings be used everywhere, considering the applications’ needs?

A: Not necessarily. Although ABEC ratings provide more precision, that does not mean every application requires them. Other factors, such as load, speed, and environment, must be considered. Some applications may sufficiently require a lower ABEC rating, which is appealing in terms of costs.

Q: Is it possible to compare bearings of different manufacturers and use ABEC ratings as a valid measure?

A: ABEC ratings show the normal precision performance of a bearing, for which some bearings of some manufacturers can be compared with others. However, other factors, such as material quality or the quality of the performing technology, must not be overlooked if one wants to analyze bearing performance.

Q: What prevents manufacturers from using the ABEC rating from a more holistic perspective?

A: The ABEC rating is focused only on one ‘performance’ of the bearing — ‘performance in regards to finished tolerances’. Additional aspects do not include load capacity, other conditions like grease type, material, resonance structure, etc., and noise level. That’s the way it is a benchmark one among many others.

UCTH213-40J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH213-40J-300

SDI: B-R1/8

SD: 2 1/2

UCTH212-39J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-39J-300

SDI: B-R1/8

SD: 2 7/16

UCTH212-38J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-38J-300

SDI: B-R1/8

SD: 2 3/8

UCTH212-36J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH212-36J-300

SDI: B-R1/8

SD: 2 1/4

UCTH211-35J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-35J-300

SDI: B-R1/8

SD: 2 3/16

UCTH211-34J-300 with Setscrew(inch)

CNSORDERNO: Normal-duty(2)

TOGN: UCTH211-34J-300

SDI: B-R1/8

SD: 2 1/8